Digital net making machine for plain net and digital net making method for plain net

A flat screen and digital technology, applied in the field of printing equipment, can solve problems such as slow production speed, hidden safety hazards, nozzle blockage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

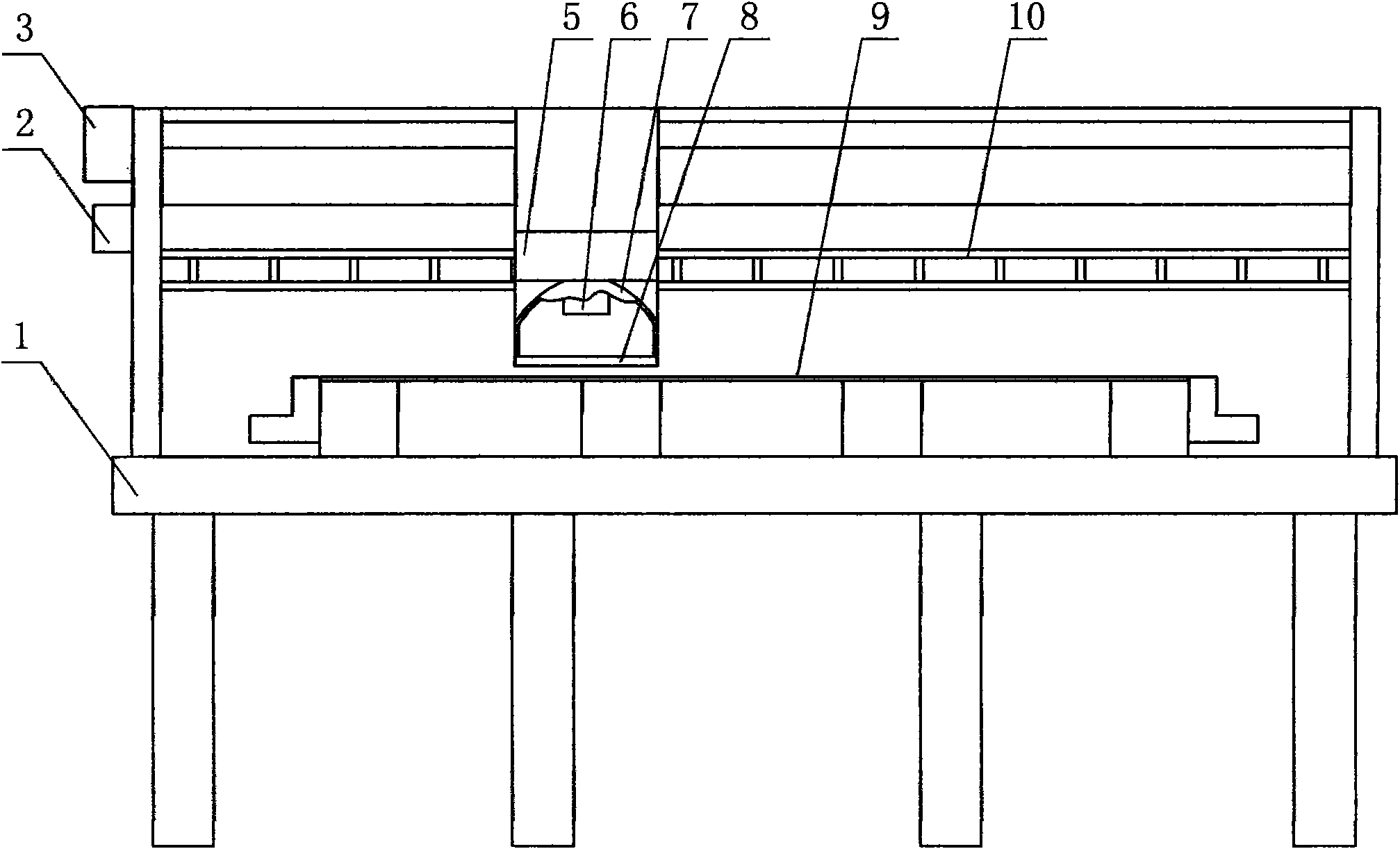

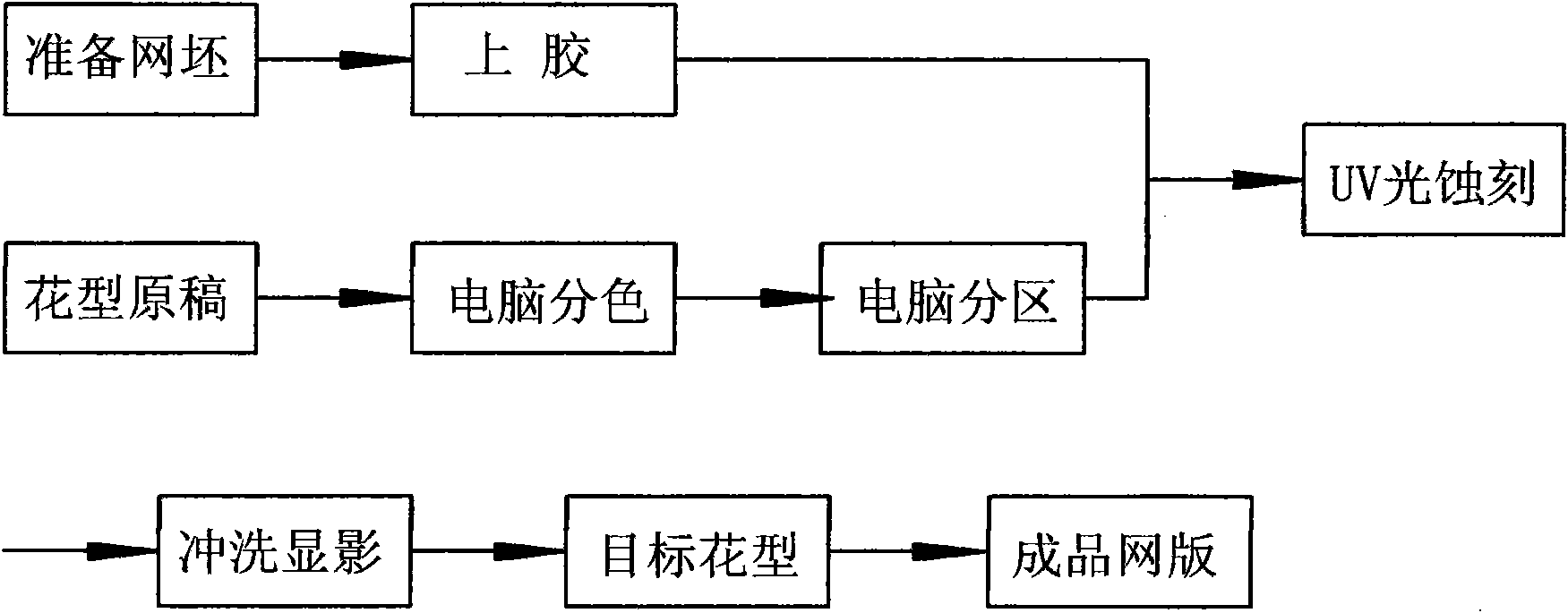

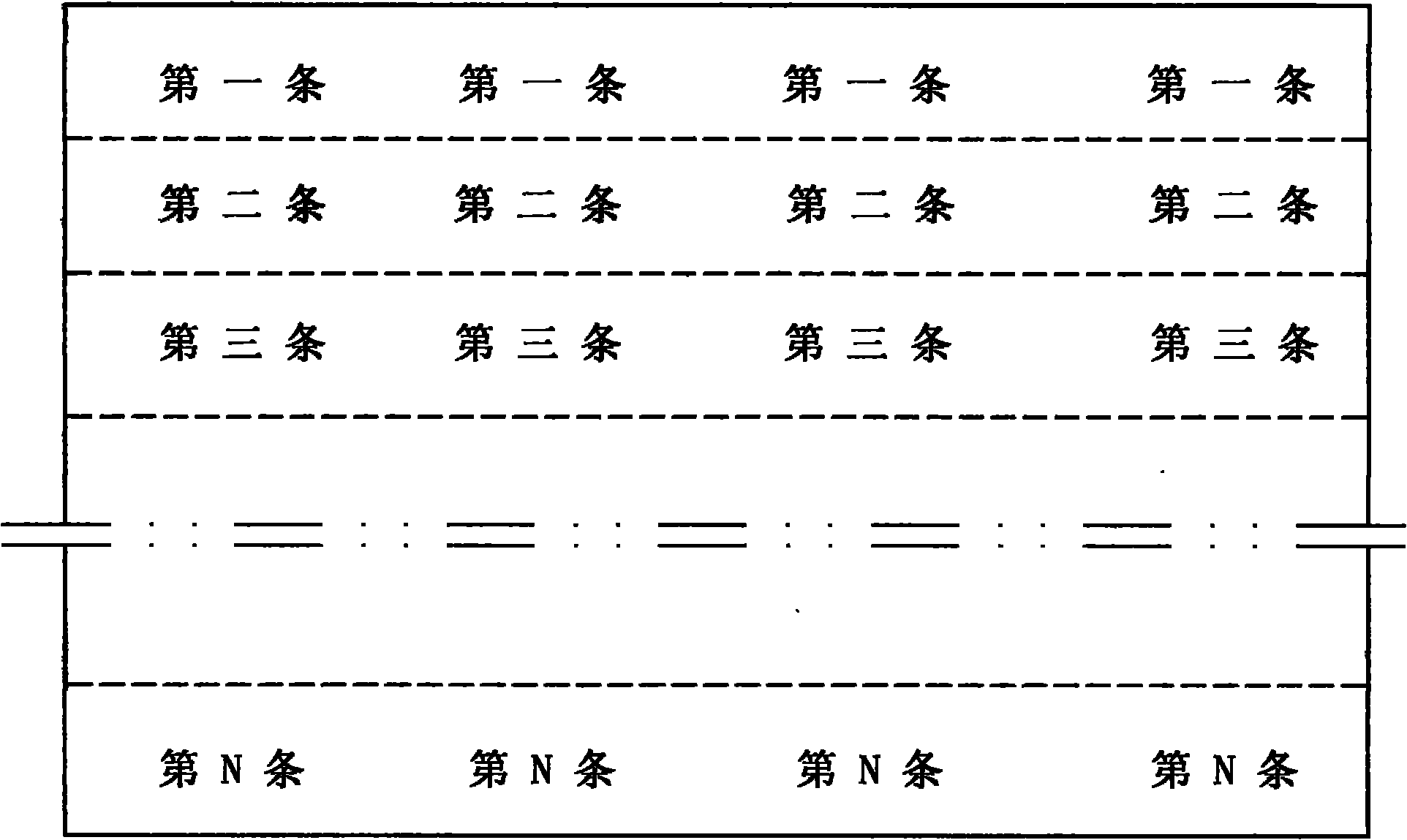

[0027] Such as figure 1 As shown, the flat screen digital screen making machine includes a frame 1, on which a workbench for fixing the flat screen 9 is provided; both sides of the workbench are provided with Y-direction guide rails, the Y-direction guide rails A walking frame 10 driven by the first power device 2 is installed on the walking frame 10; an X-direction guide rail is provided on the walking frame 10, and a UV photoetching head driven by the second power device 3 is installed on the X-direction guide rail; The UV photoetching head includes a mounting base 5, and the mounting base 5 is provided with a liquid crystal display screen 8 for scrolling and displaying bar-shaped color separation images. The width of the bar-shaped color separation image is consistent with the effective display of the liquid crystal display screen 8. The width is equal, the liquid crystal display screen 8 and the flat screen 9 are installed in parallel, and the scroll direction of the strip-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com