Motor type active stable rod control system

An active stabilizer bar and control system technology, applied in interconnection systems, elastic suspensions, vehicle components, etc., can solve problems such as the inability to select the working mode, the inability to adjust the anti-roll moment value in real time, and poor body roll effects , to achieve the effect of simple structure, ensuring ride comfort and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

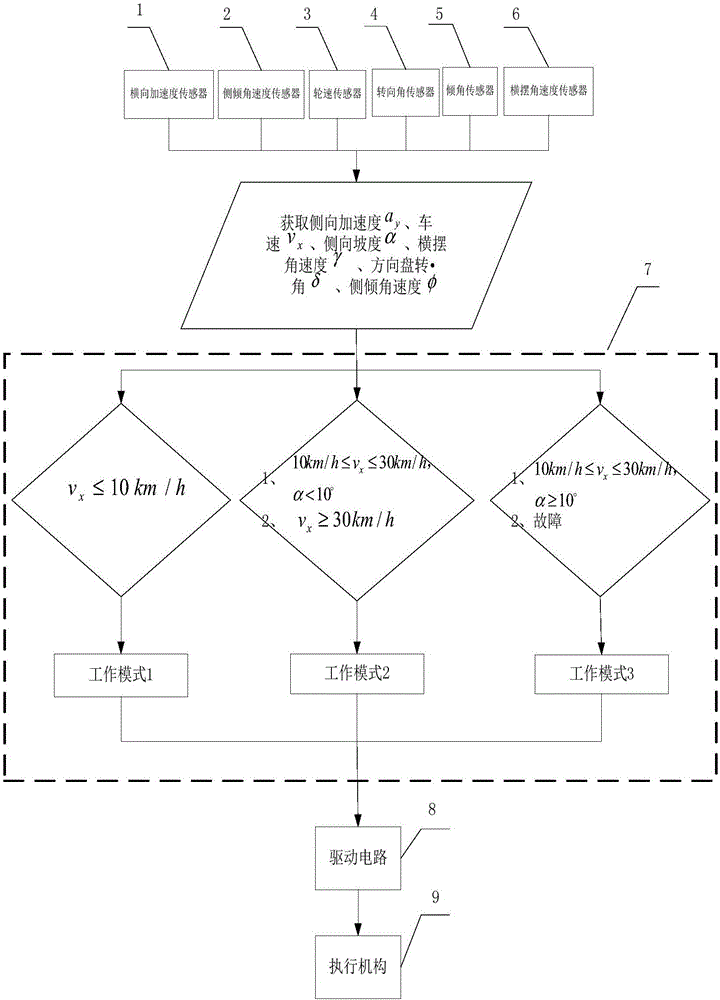

[0020] Such as figure 1 As shown, the motor-type active stabilizer bar control system of the present invention includes a lateral acceleration sensor 1, a roll angular velocity sensor 2, a wheel speed sensor 3, a steering angle sensor 4, an inclination sensor 5, a yaw angular velocity sensor 6, and an ECU control unit 7. Drive circuit 8 and actuator 9;

[0021] The ECU control unit 7 is electrically connected to the actuator 9 through the drive circuit 8, and the lateral acceleration sensor 1, the roll sensor 2, the wheel speed sensor 3, the steering angle sensor 4, the inclination sensor 5 and the yaw rate sensor 6 are respectively It is electrically connected with the ECU control unit 7.

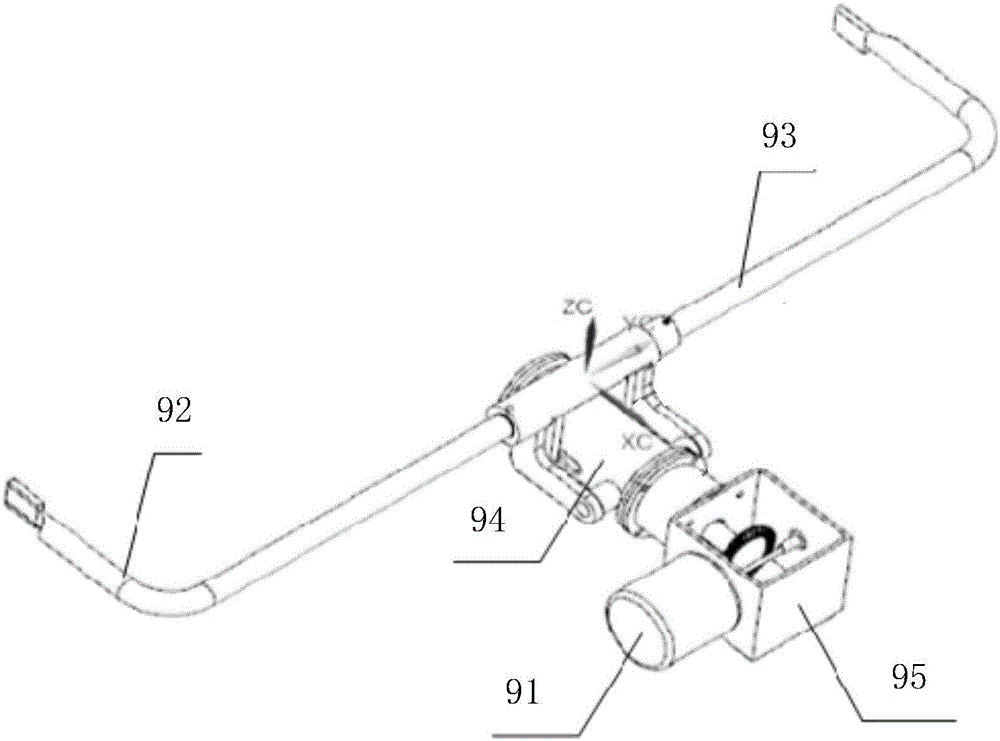

[0022] Such as figure 2 As shown, the executive mechanism 9 includes a motor actuator 91, a left stabilizer bar 92, a right stabilizer bar 93, a transmission mechanism 94, and a reduction mechanism 95. The input end of the transmission mechanism 94 is connected to the output end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com