Patents

Literature

293 results about "Yaw-rate sensor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A yaw-rate sensor is a gyroscopic device that measures a vehicle’s angular velocity around its vertical axis. The angle between the vehicle's heading and vehicle actual movement direction is called slip angle, which is related to the yaw rate.

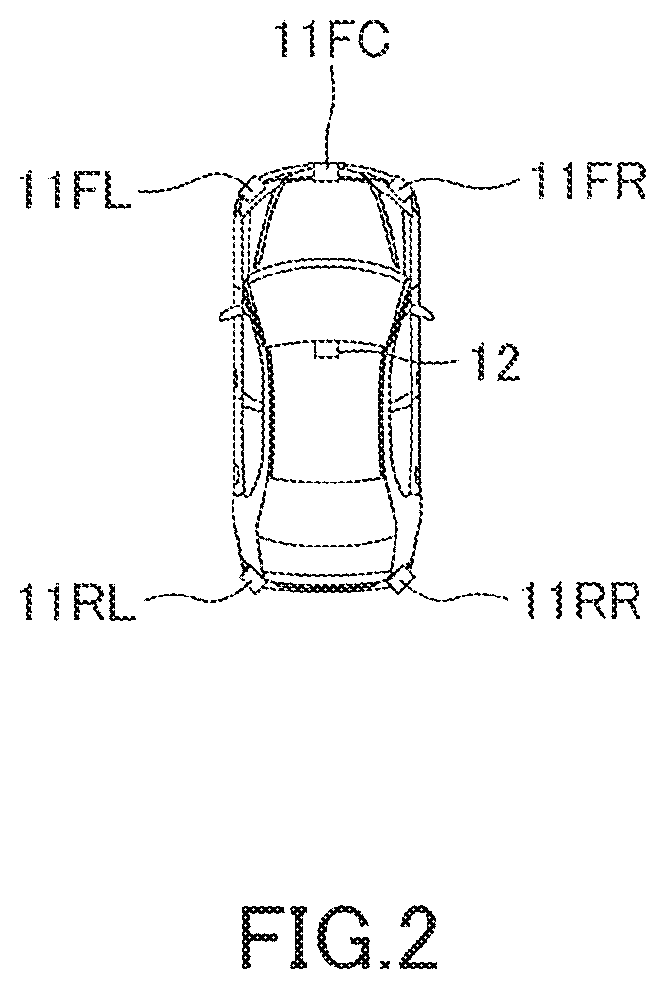

Vehicle yaw rate correction

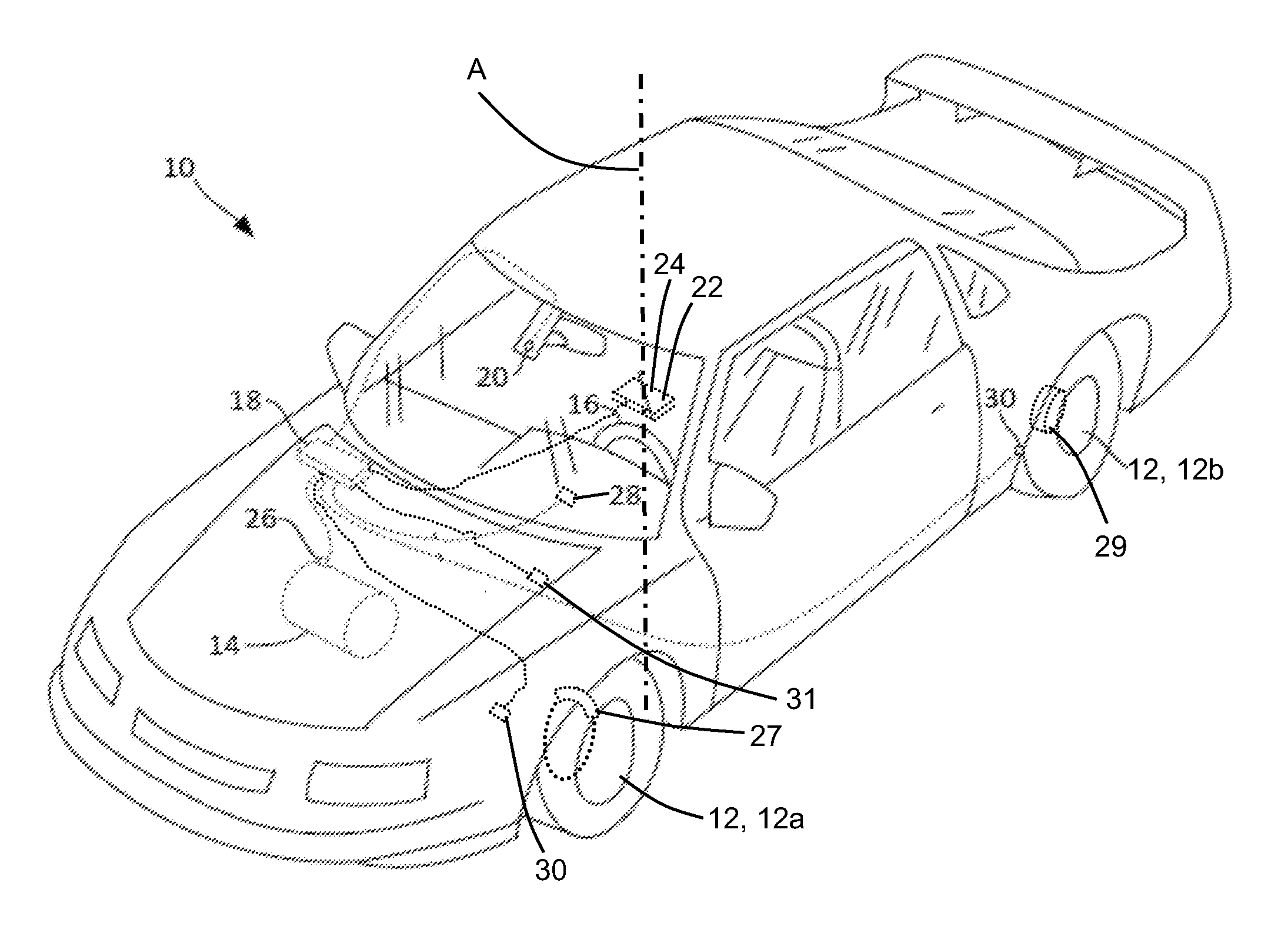

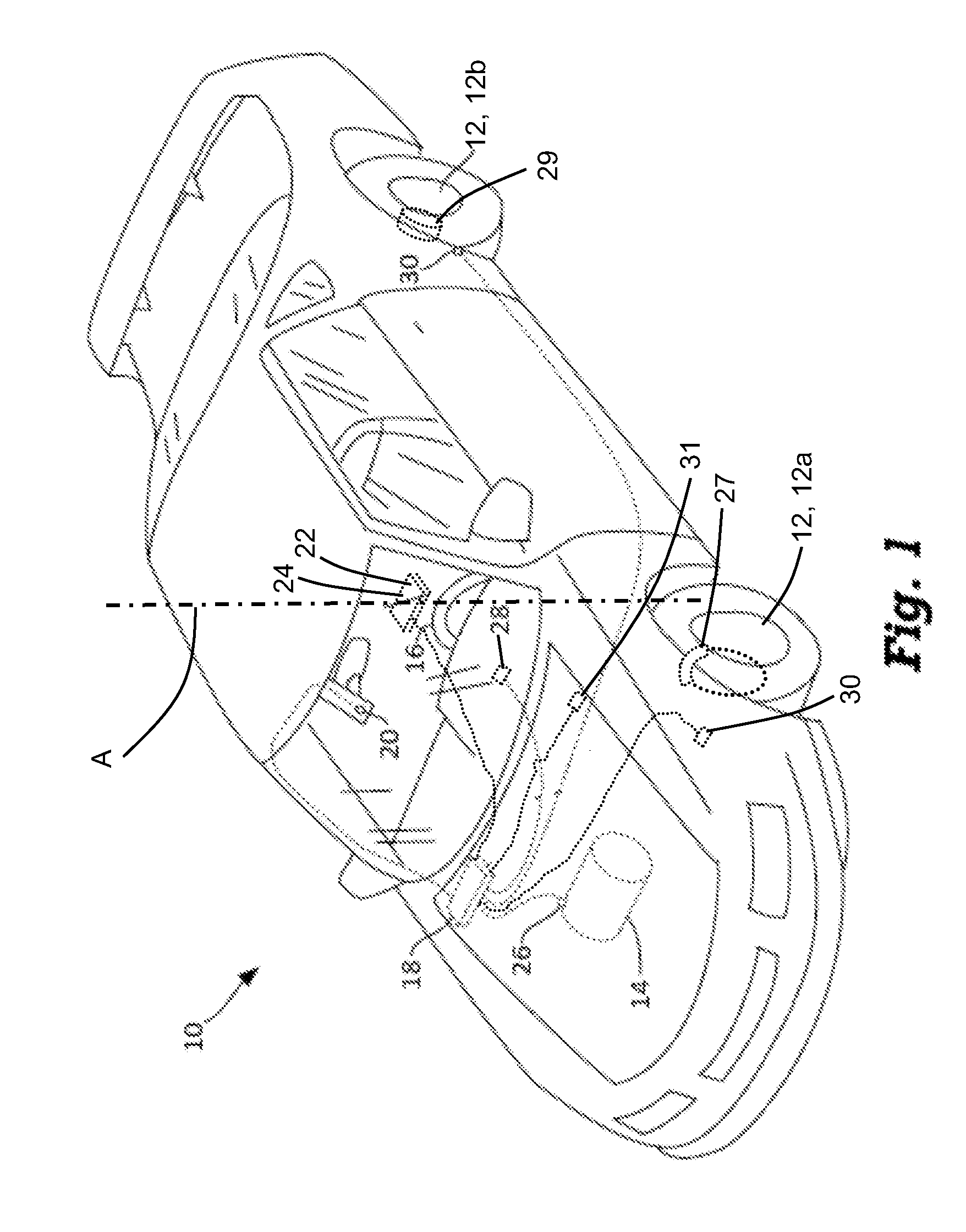

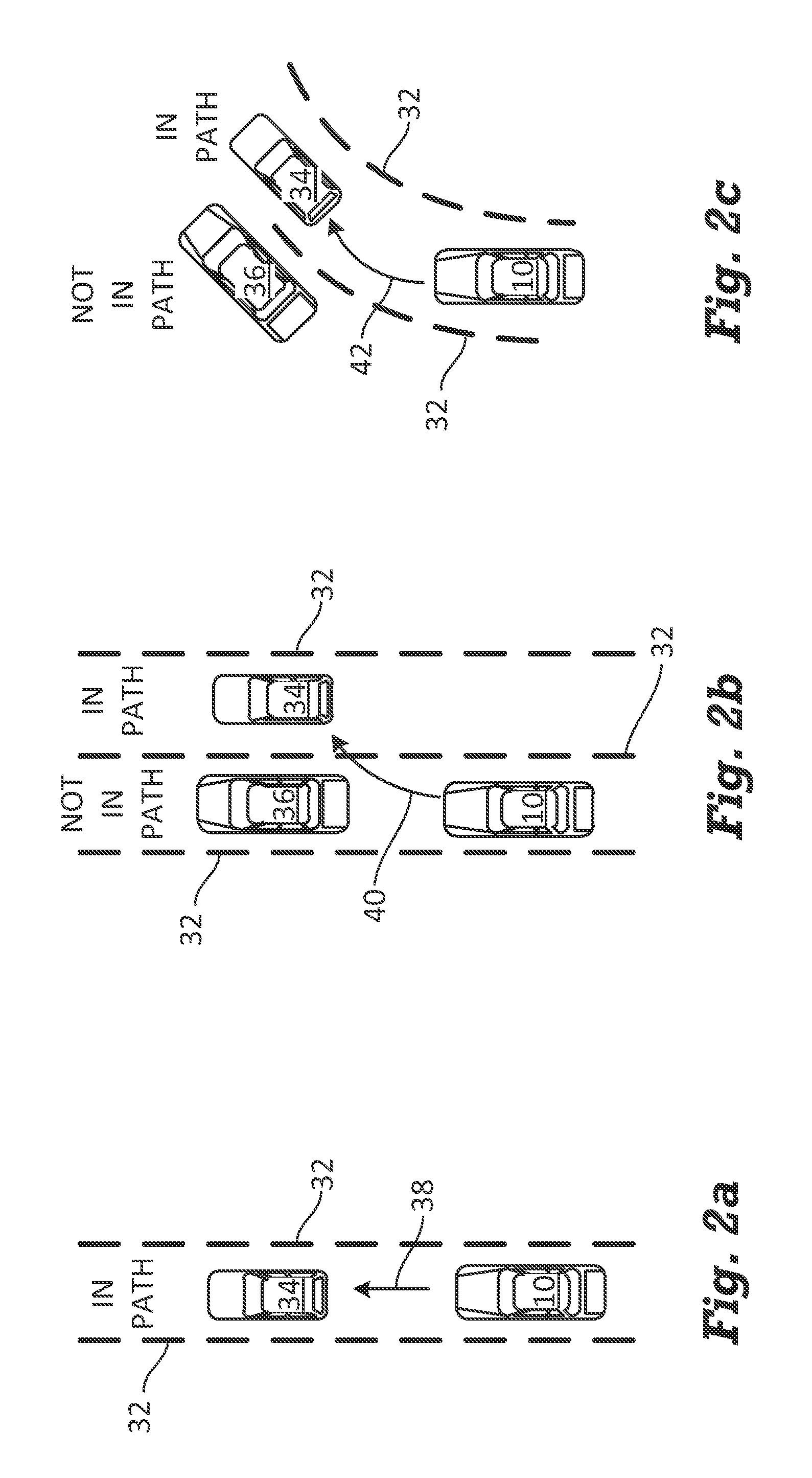

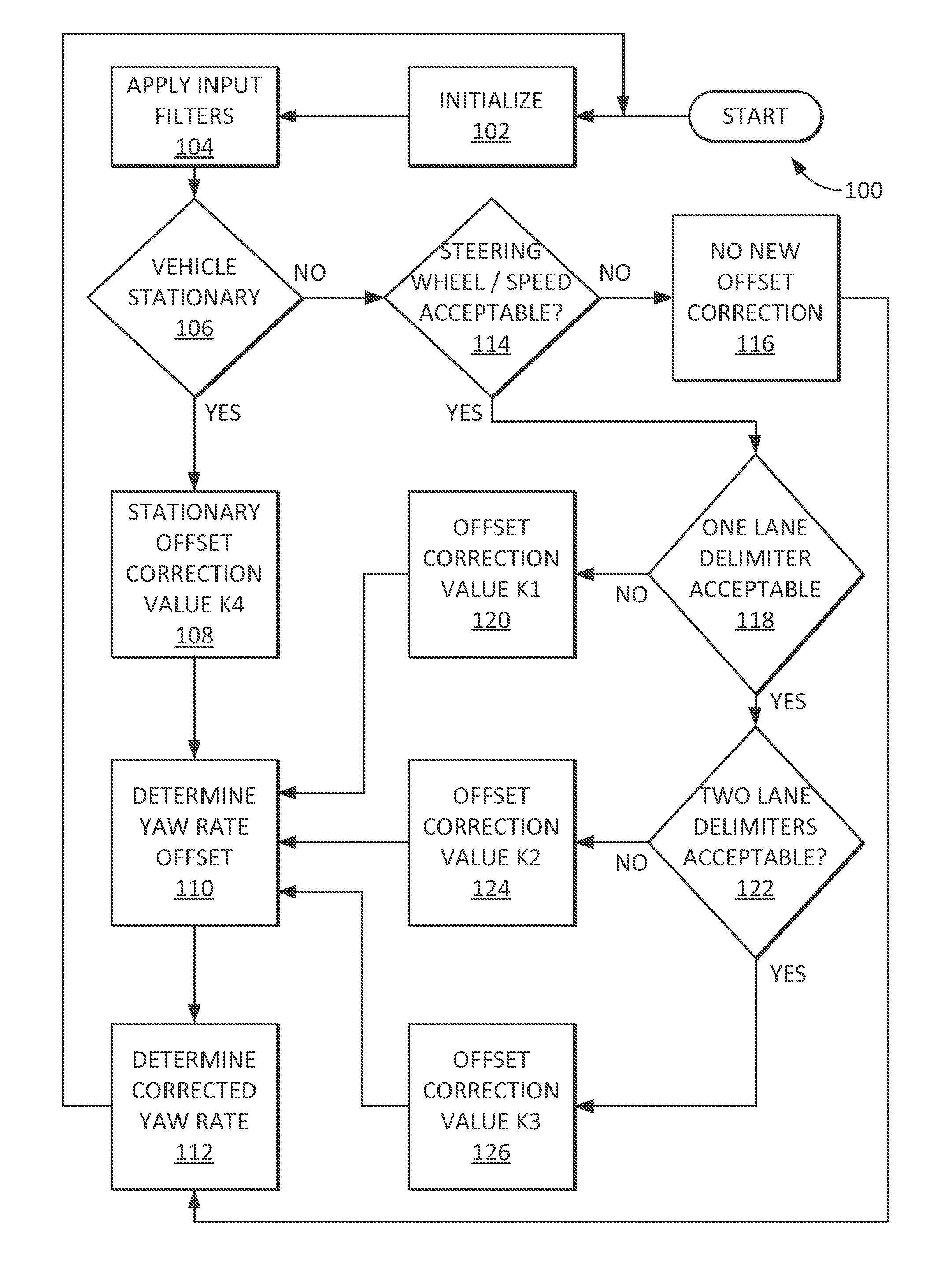

A control system or method for a vehicle references a camera and sensors to determine when an offset of a yaw rate sensor may be updated. The sensors may include a longitudinal accelerometer, a transmission sensor, a vehicle speed sensor, and a steering angle sensor. The offset of the yaw rate sensor may be updated when the vehicle is determined to be stationary by referencing at least a derivative of an acceleration from the longitudinal accelerometer. The offset of the yaw rate sensor may be updated when the vehicle is determined to be moving straight by referencing at least image data captured by the camera. Lane delimiters may be detected in the captured image data and evaluated to determine a level of confidence in the straight movement. When the offset of the yaw rate sensor is to be updated, a ratio of new offset to old offset may be used.

Owner:MAGNA ELECTRONICS

Vehicle yaw rate correction

A control system or method for a vehicle references a camera and sensors to determine when an offset of a yaw rate sensor may be updated. The sensors may include a longitudinal accelerometer, a transmission sensor, a vehicle speed sensor, and a steering angle sensor. The offset of the yaw rate sensor may be updated when the vehicle is determined to be stationary by referencing at least a derivative of an acceleration from the longitudinal accelerometer. The offset of the yaw rate sensor may be updated when the vehicle is determined to be moving straight by referencing at least image data captured by the camera. Lane delimiters may be detected in the captured image data and evaluated to determine a level of confidence in the straight movement. When the offset of the yaw rate sensor is to be updated, a ratio of new offset to old offset may be used.

Owner:MAGNA ELECTRONICS INC

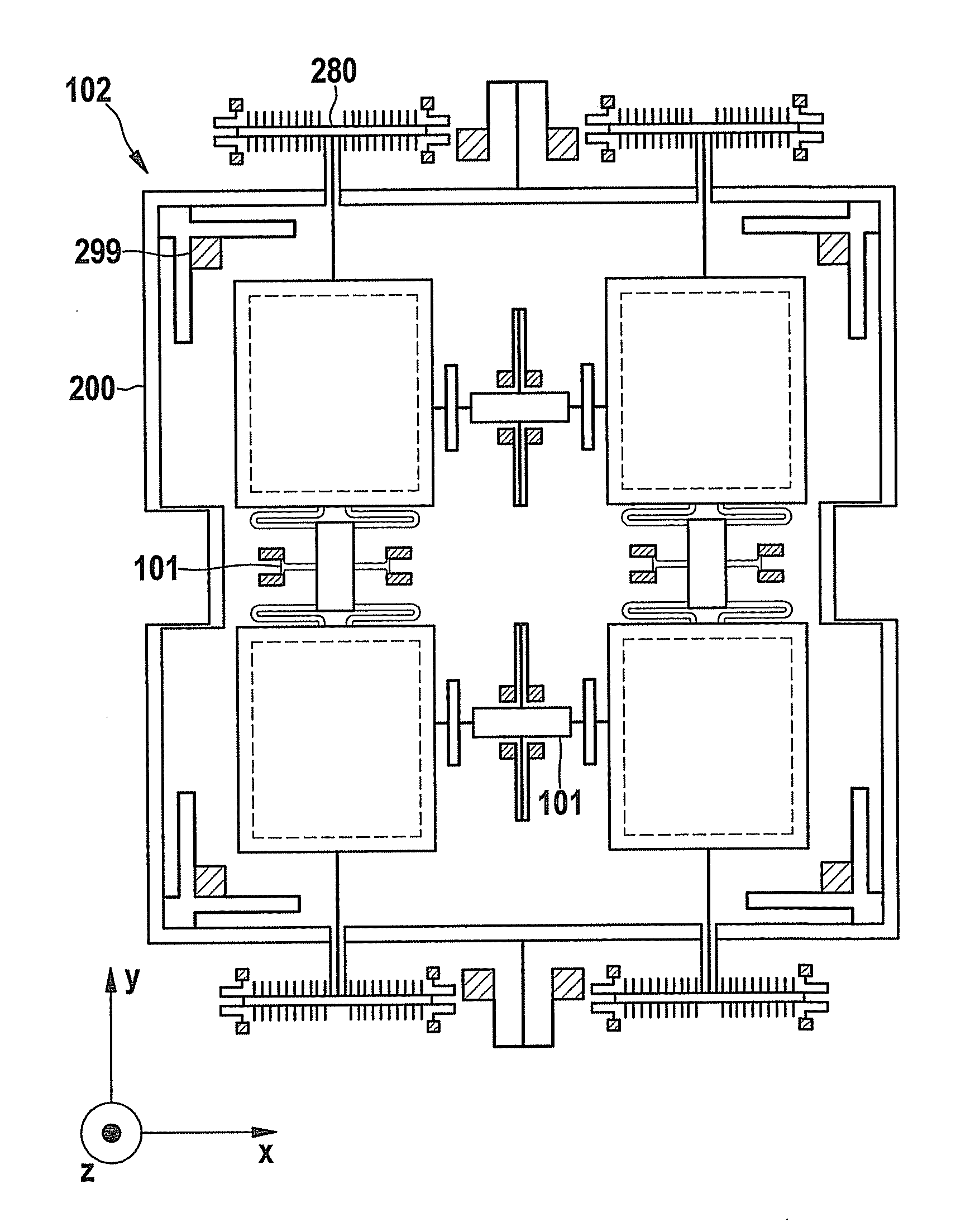

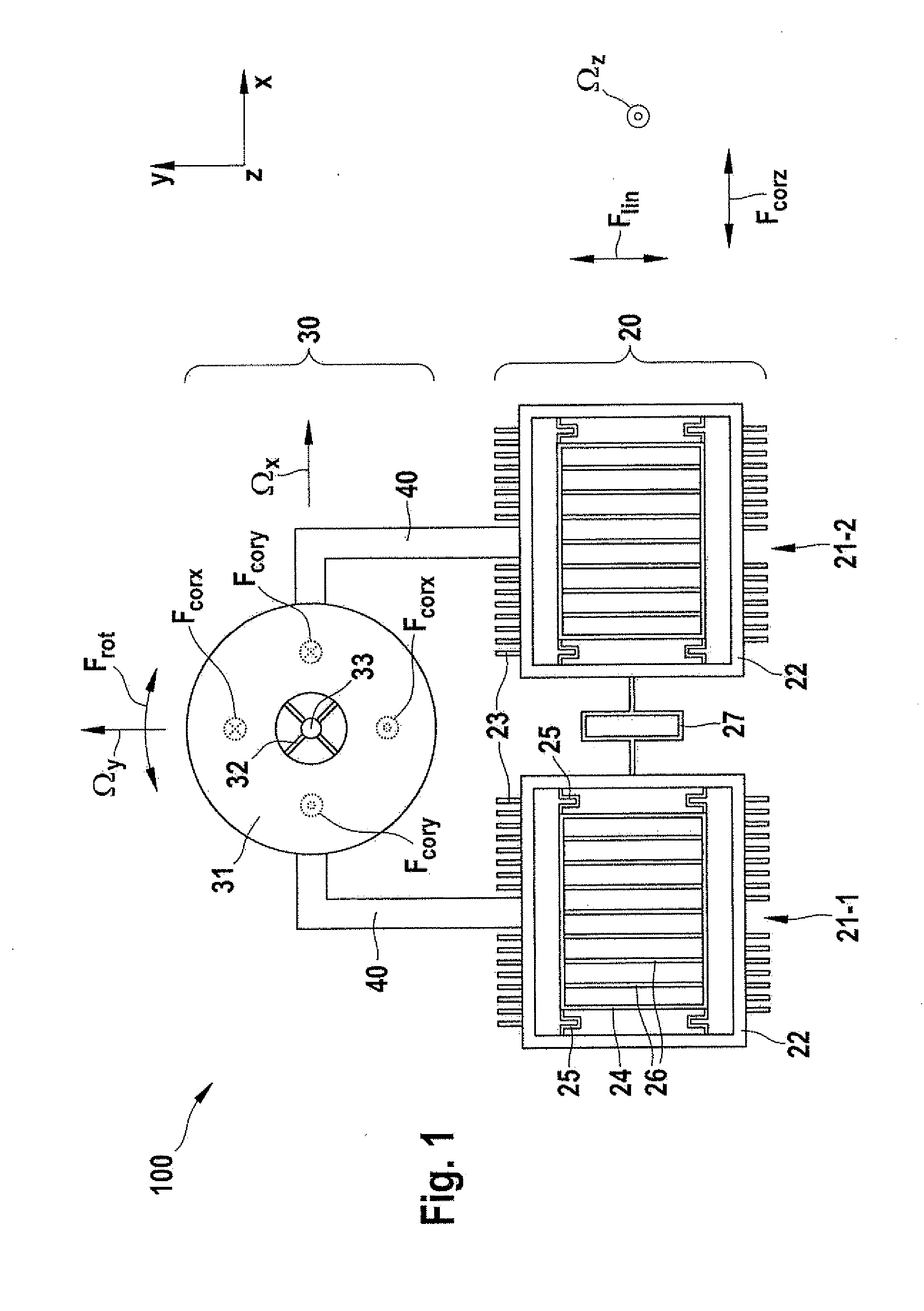

Yaw-rate sensor

ActiveUS20120060604A1Reduces space and power requirementEasy to make costAcceleration measurement using interia forcesLeaf springsEngineeringCoriolis force

A yaw-rate sensor having a substrate and a plurality of movable substructures that are mounted over a surface of the substrate, the movable substructures being coupled to a shared, in particular, central spring element, means being provided for exciting the movable substructures into a coupled oscillation in a plane that extends parallel to the surface of the substrate, the movable substructures having Coriolis elements, means being provided for detecting deflections of the Coriolis elements induced by a Coriolis force, a first Coriolis element being provided for detecting a yaw rate about a first axis, a second Coriolis element being provided for detecting a yaw rate about a second axis, the second axis being oriented perpendicularly to the first axis.

Owner:ROBERT BOSCH GMBH

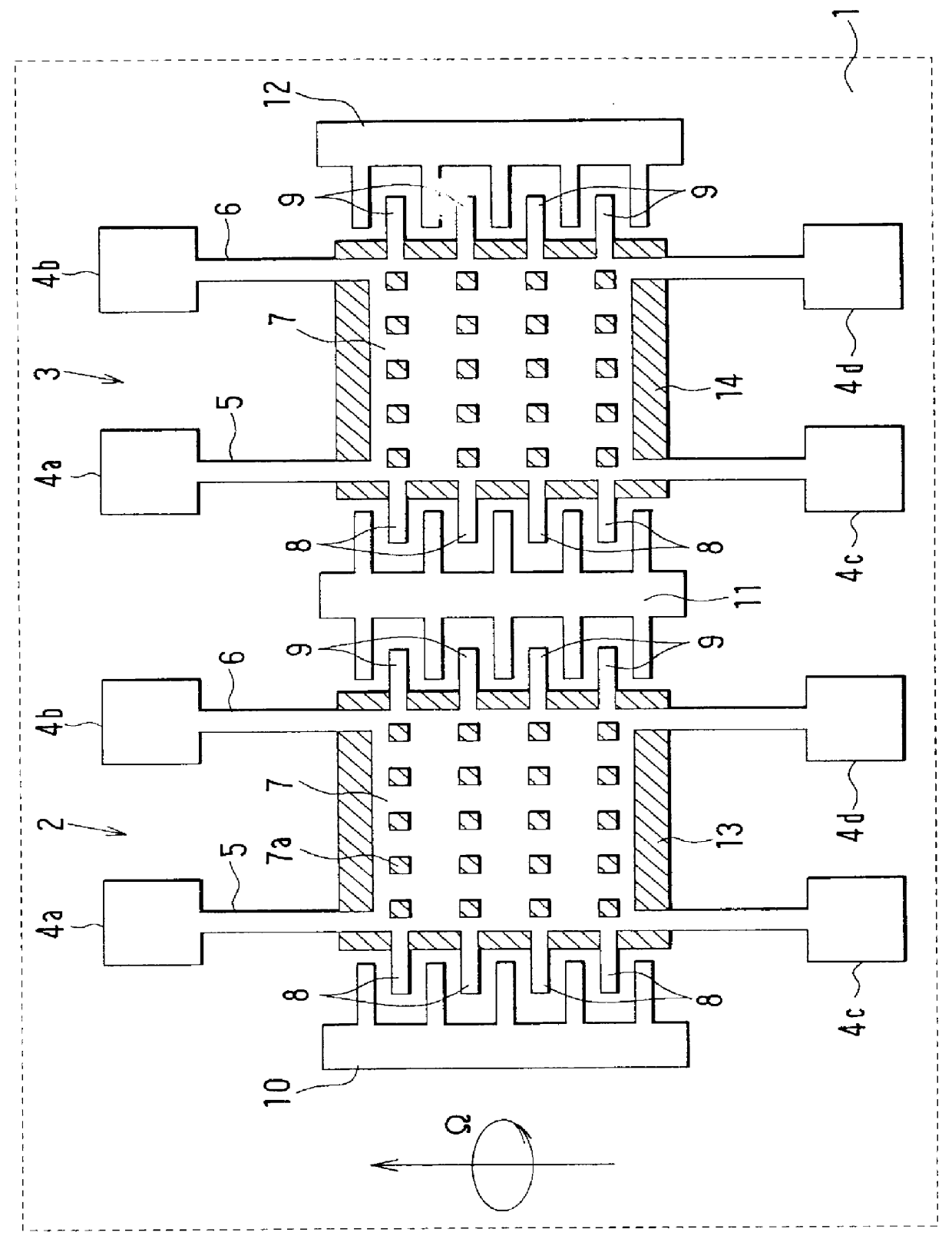

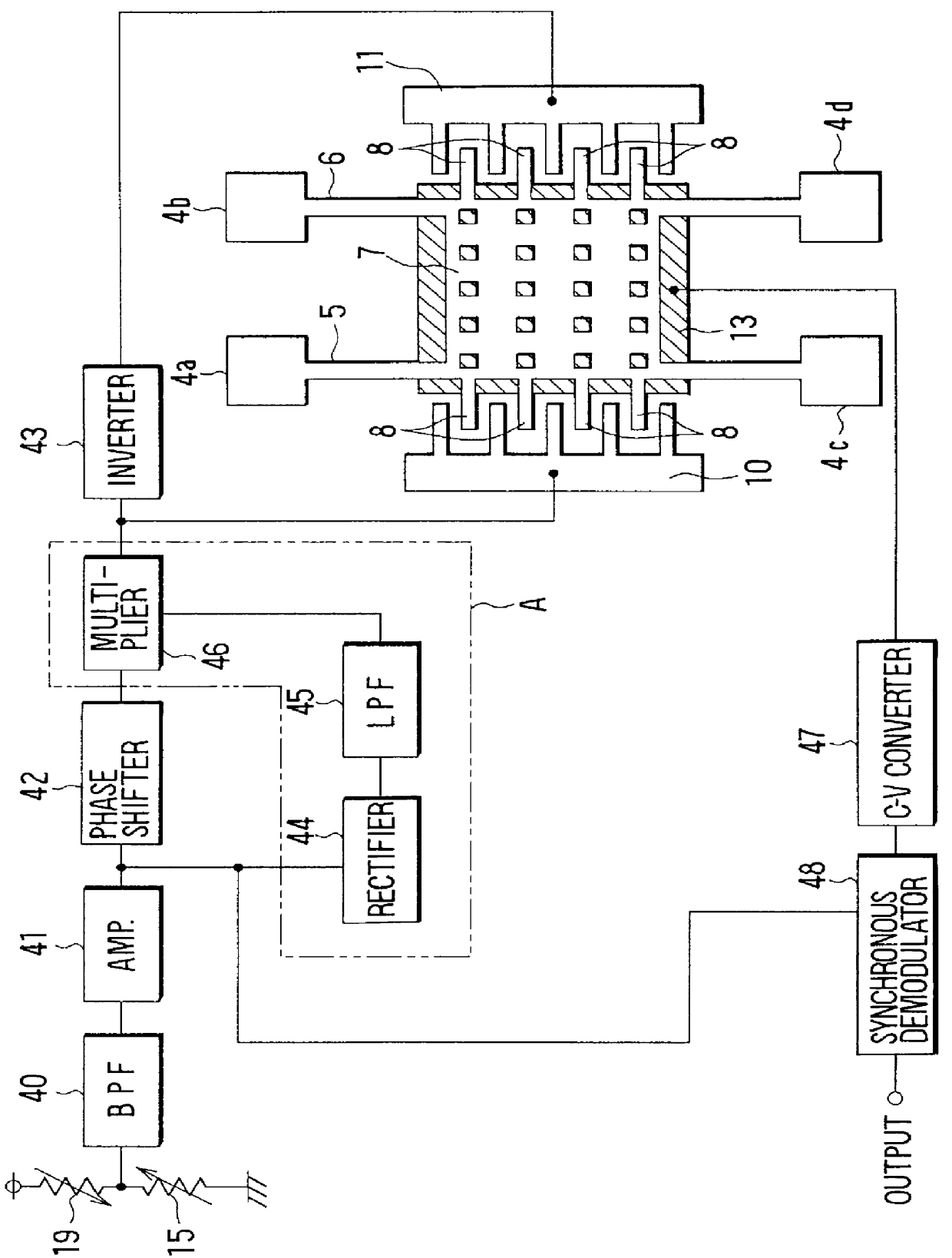

Semiconductor type yaw rate sensor

InactiveUS6028332AEasy to carryAccurate monitoringAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsSemiconductor materialsEngineering

A semiconductor type yaw rate sensor has a substrate, a beam structure formed from a semiconductor material and having at least one anchor portion disposed on the substrate, a weighted portion located above the substrate a predetermined gap therefrom, and a beam portion which extends from the anchor portion and supports the weighted portion. A movable electrode is formed onto the weighted portion, and a fixed electrode is formed on the substrate in such a manner that the fixed electrode faces the movable electrode. When a drive voltage is applied between the movable electrode and the fixed electrode, the beam structure is forcibly caused to vibrate in a direction that is horizontal relative to a substrate surface plane. In this yaw rate sensor, a strain gauge to monitor forced vibration of the beam structure is formed in the beam portion. As a result, the forced vibration of the beam structure can be monitored with a simple structure.

Owner:DENSO CORP

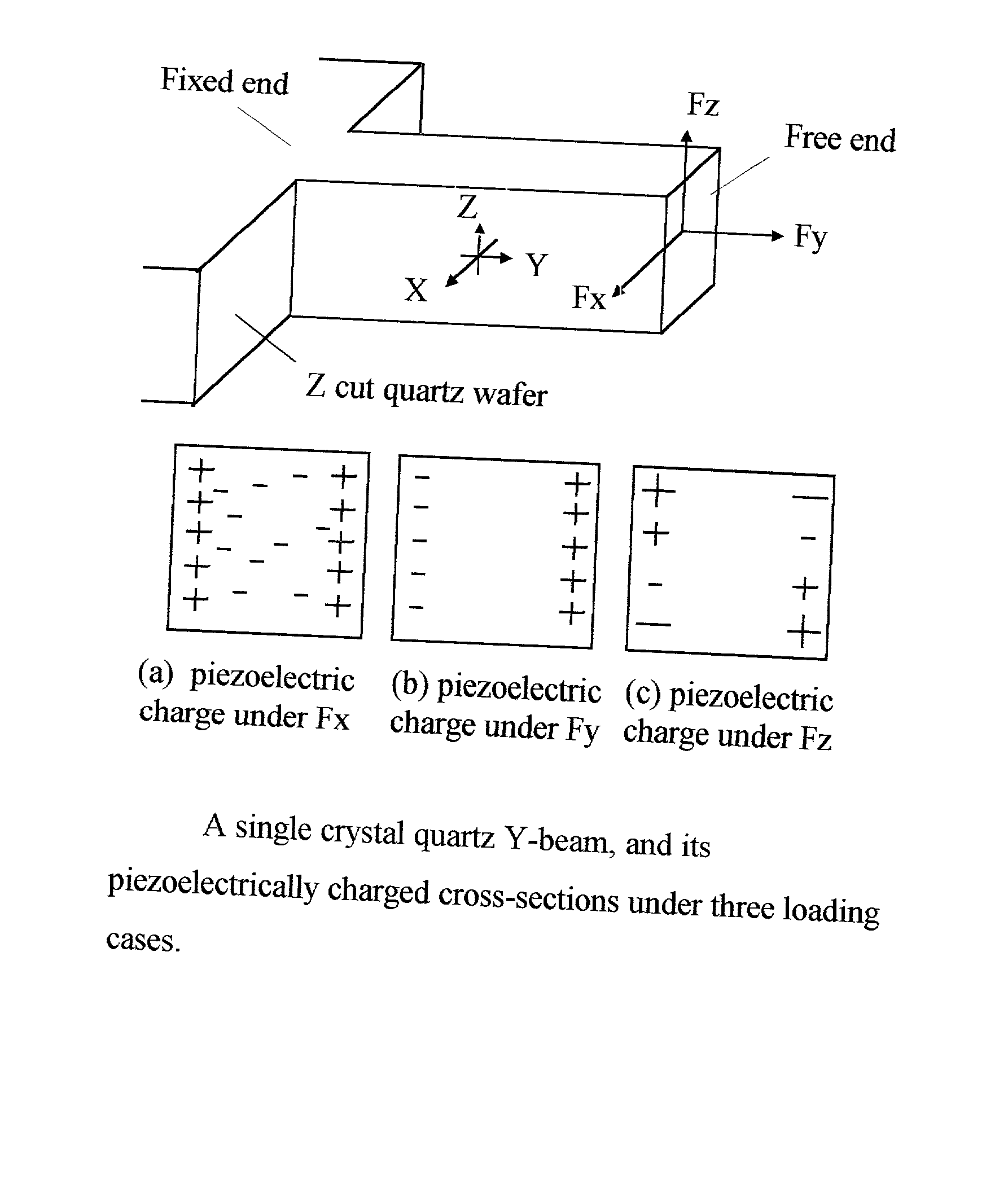

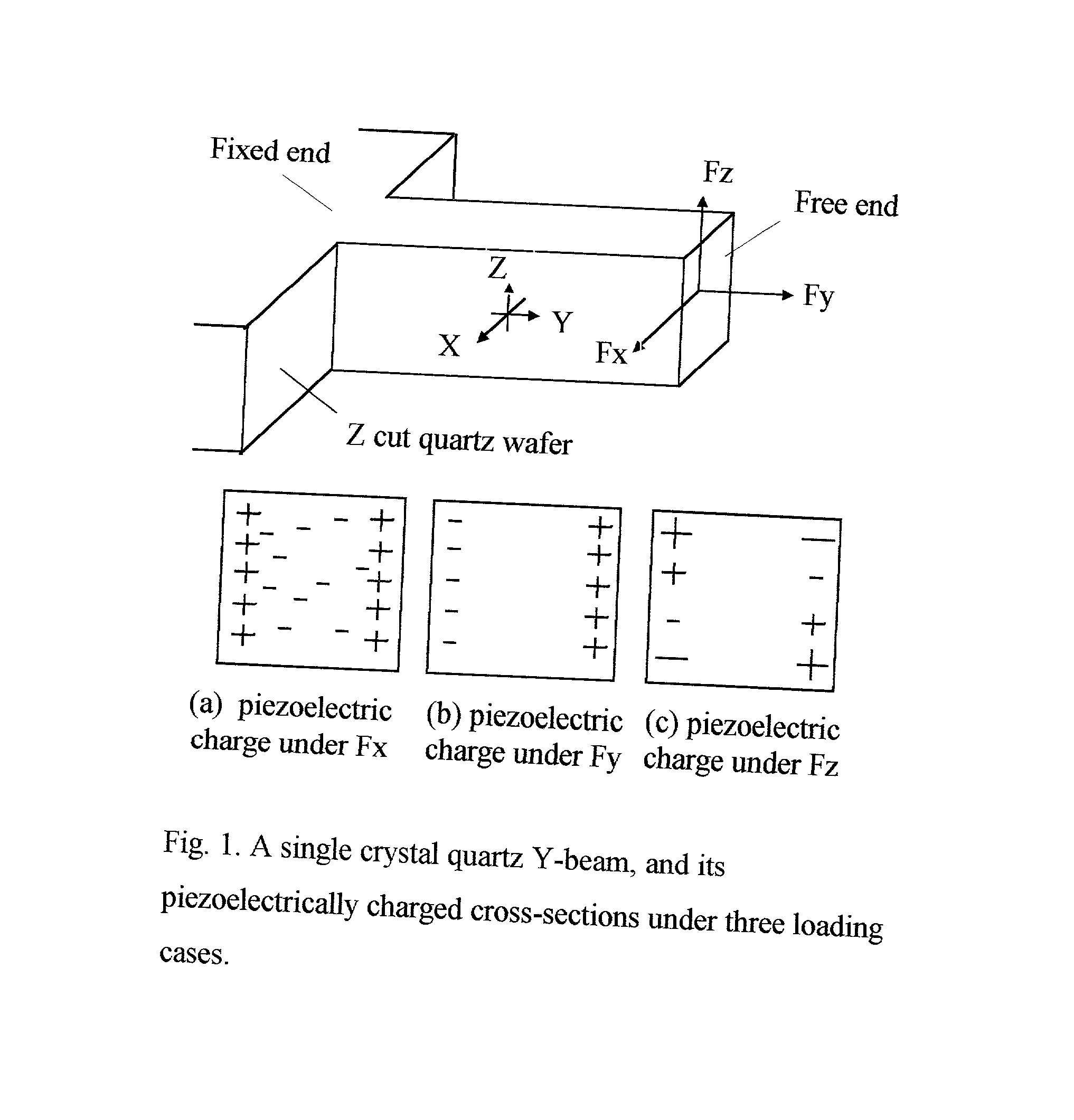

Micro yaw rate sensors

InactiveUS20020066317A1Electric signal transmission systemsAcceleration measurement using interia forcesEngineeringMicromachinings

Yaw rate sensors are provided, the use of which permits quantitative measurement of yaw rate. The yaw rate sensor comprises at least a base, a first suspension and a second suspension with a proof mass supported between the two suspensions, which together form a resonator. The first suspension has a pair of thin-wire driving electrodes double side patterned on the surfaces. When a driving voltage is applied to the driving electrodes, it imposes an electric field to piezoelectrically induce a driving resonance. When the sensor is rotated around its sensing axis, the resonator will be forced to generate a sensing resonance out of the driving resonance plane to compensate the change in the linear momentum which must be conserved. The piezoelectric charge signal generated by the sensing resonance on the sensing electrodes which are double side patterned on the surfaces of the second suspension is used to detect the yaw rate. Specifically, the amplitude of the sensing resonance is in proportion to the yaw rate. The structure of the yaw rate sensors of this invention is suitable for mass production by lithographic micromachining techniques at low cost.

Owner:LIN GANG

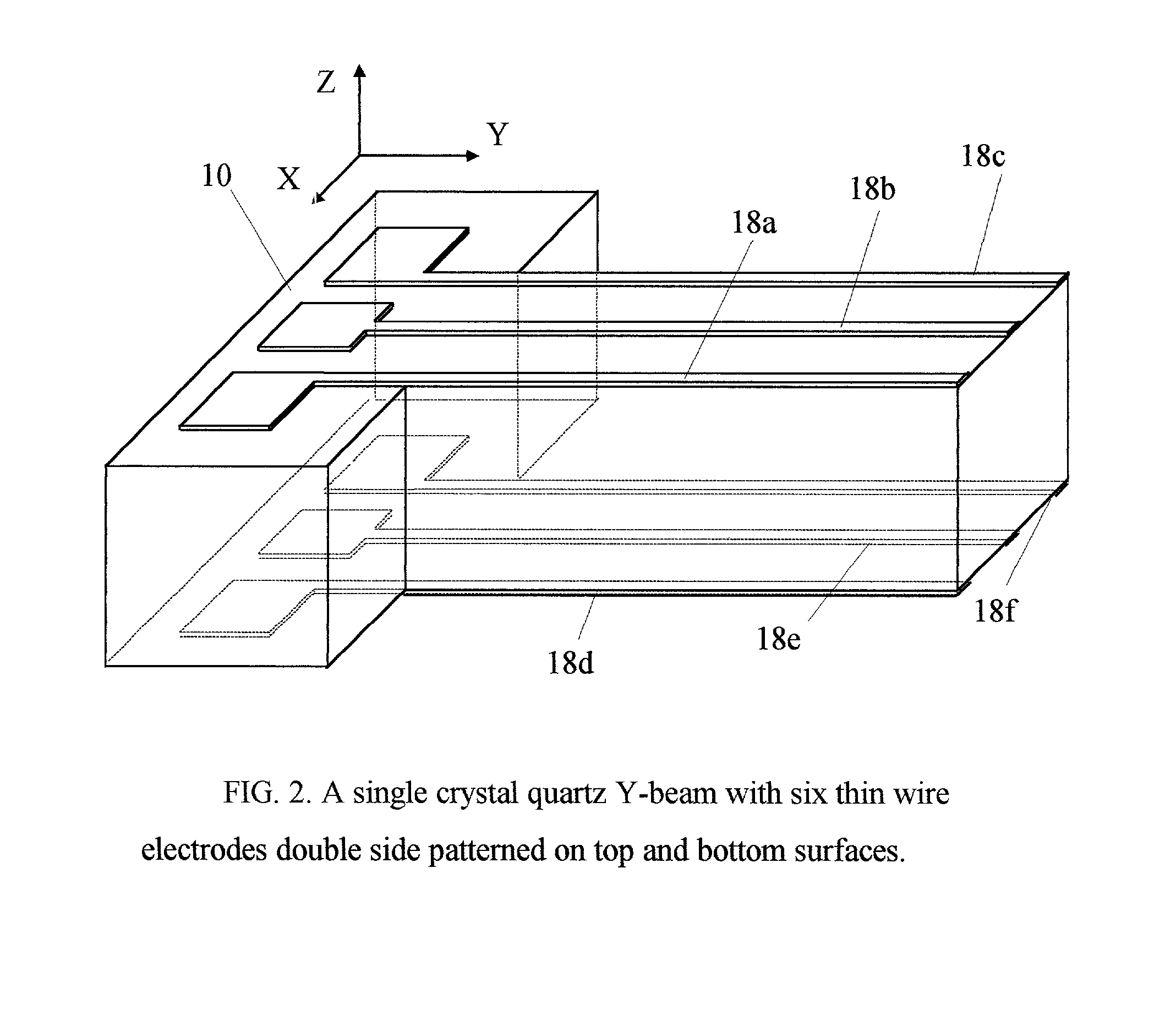

Trailer tongue length estimation using a trailer yaw rate sensor

A control system for estimating the tongue length of a trailer being towed by a vehicle in connection with a front wheel steering with or without coordinated rear wheel steering associated with the vehicle. The control system employs an algorithm that calculates an estimated trailer yaw rate based on a corrected tongue length, a front wheel steering angle, a rear wheel steering angle, vehicle speed and a vehicle yaw rate. The estimated trailer yaw rate is compared to a measured trailer yaw rate to generate a yaw rate error that is converted to a tongue length error. The tongue length error is compared to the estimated tongue length to become a corrected estimated tongue length for a next computation period. After a few seconds of processing, the corrected estimated tongue length will be the actual tongue length of the trailer.

Owner:GM GLOBAL TECH OPERATIONS LLC

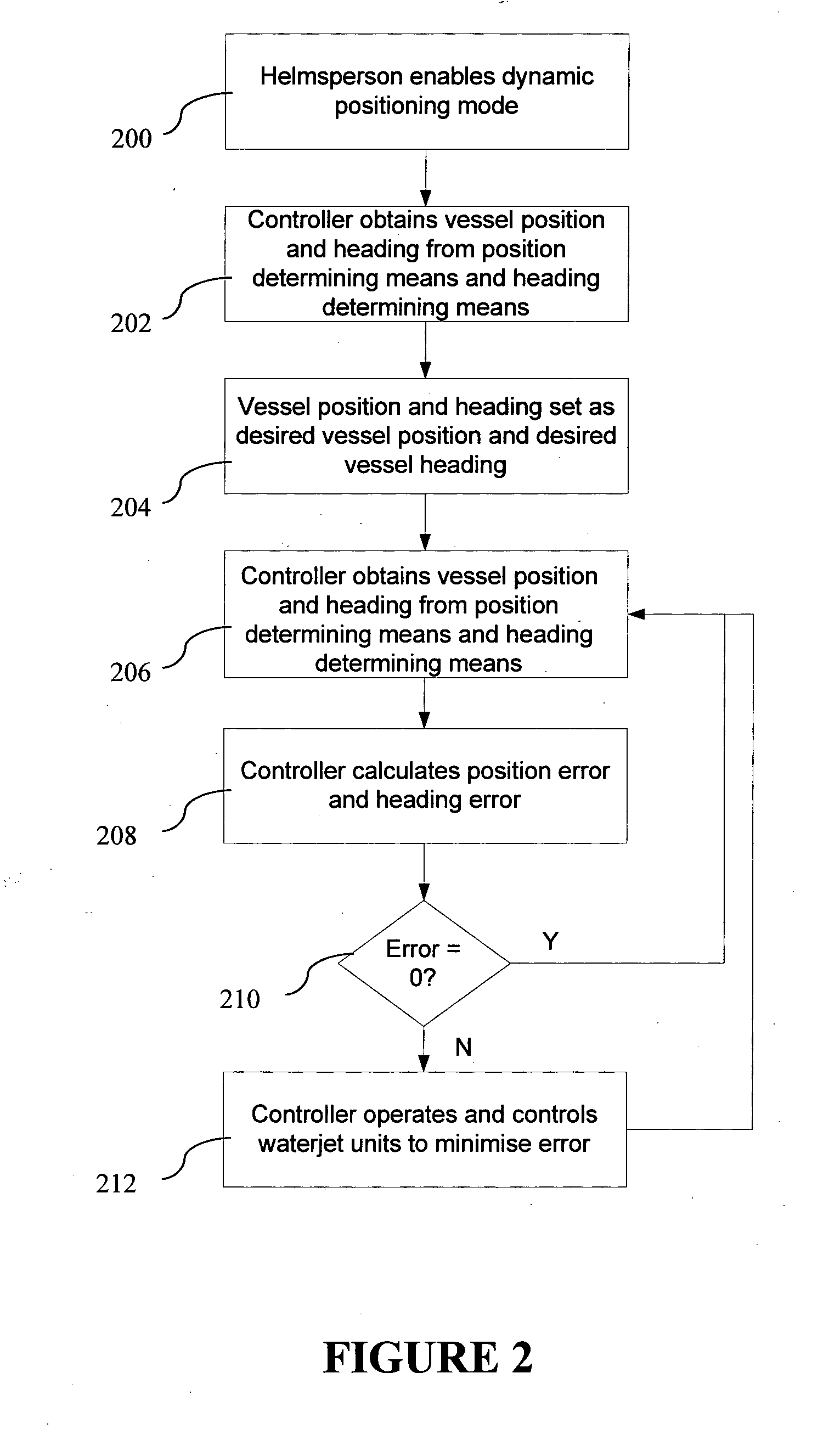

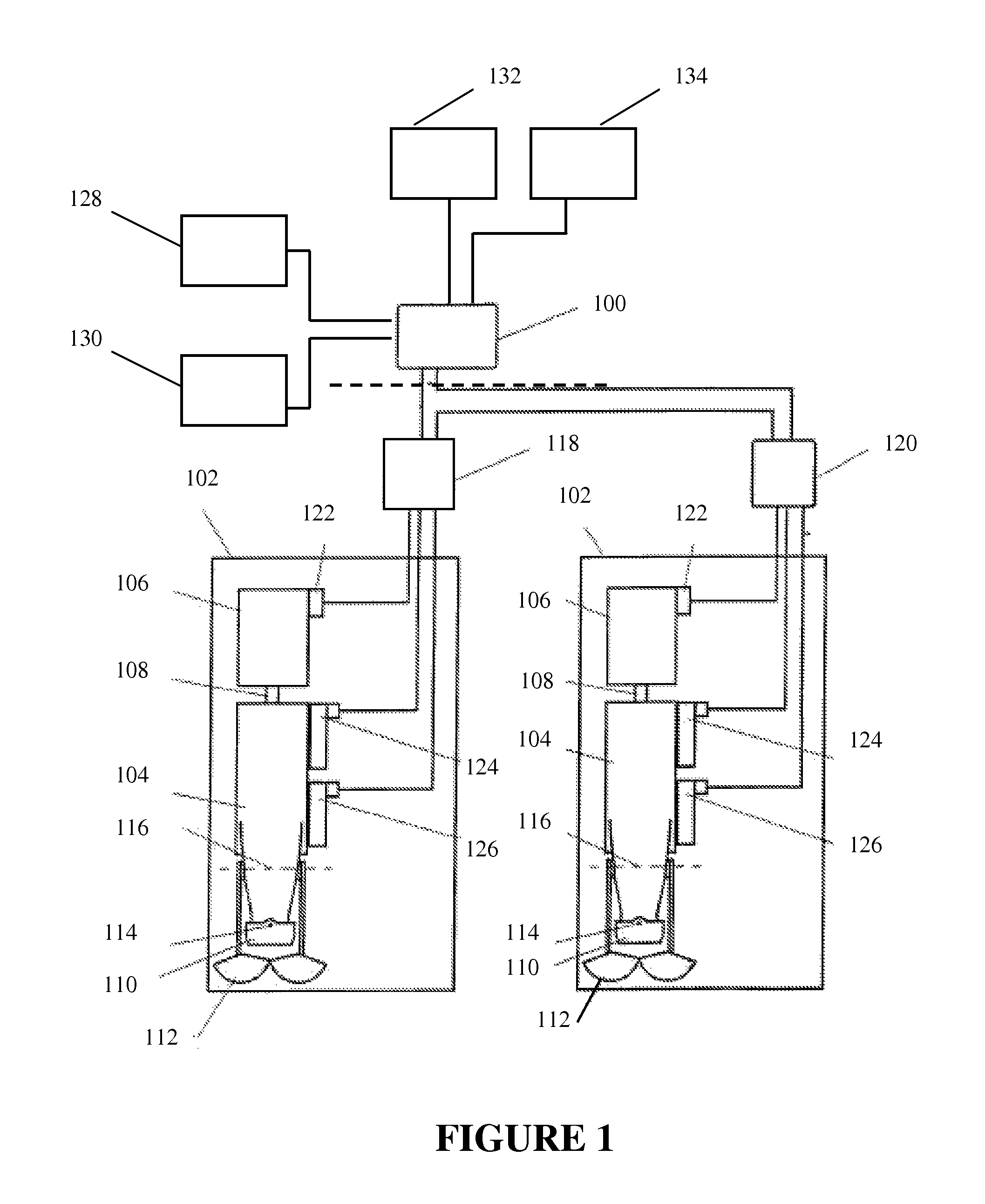

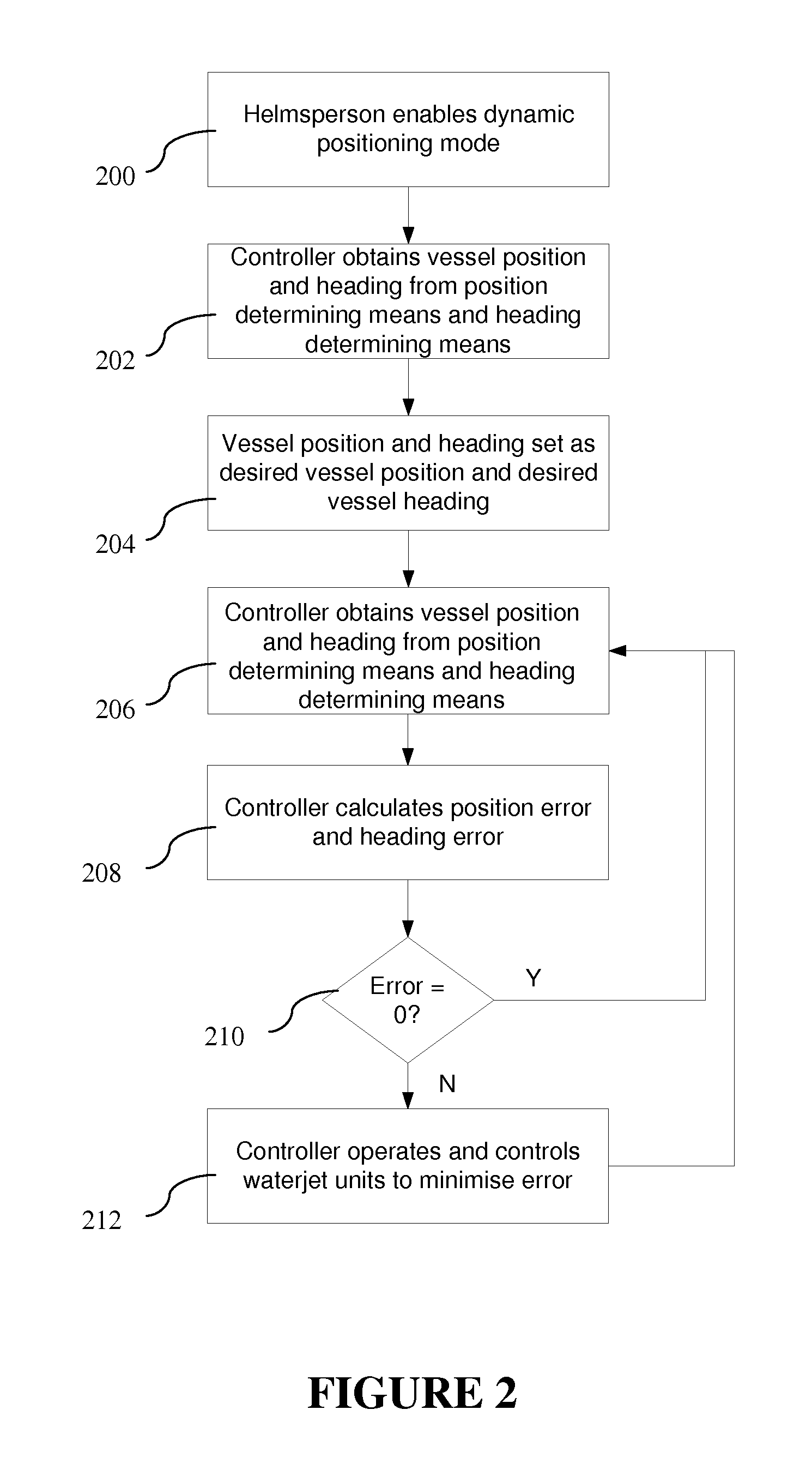

Relating to Control of Marine Vessels

ActiveUS20100023192A1Minimize errorMinimize positionAuxillariesDigital data processing detailsAccelerometerMarine engineering

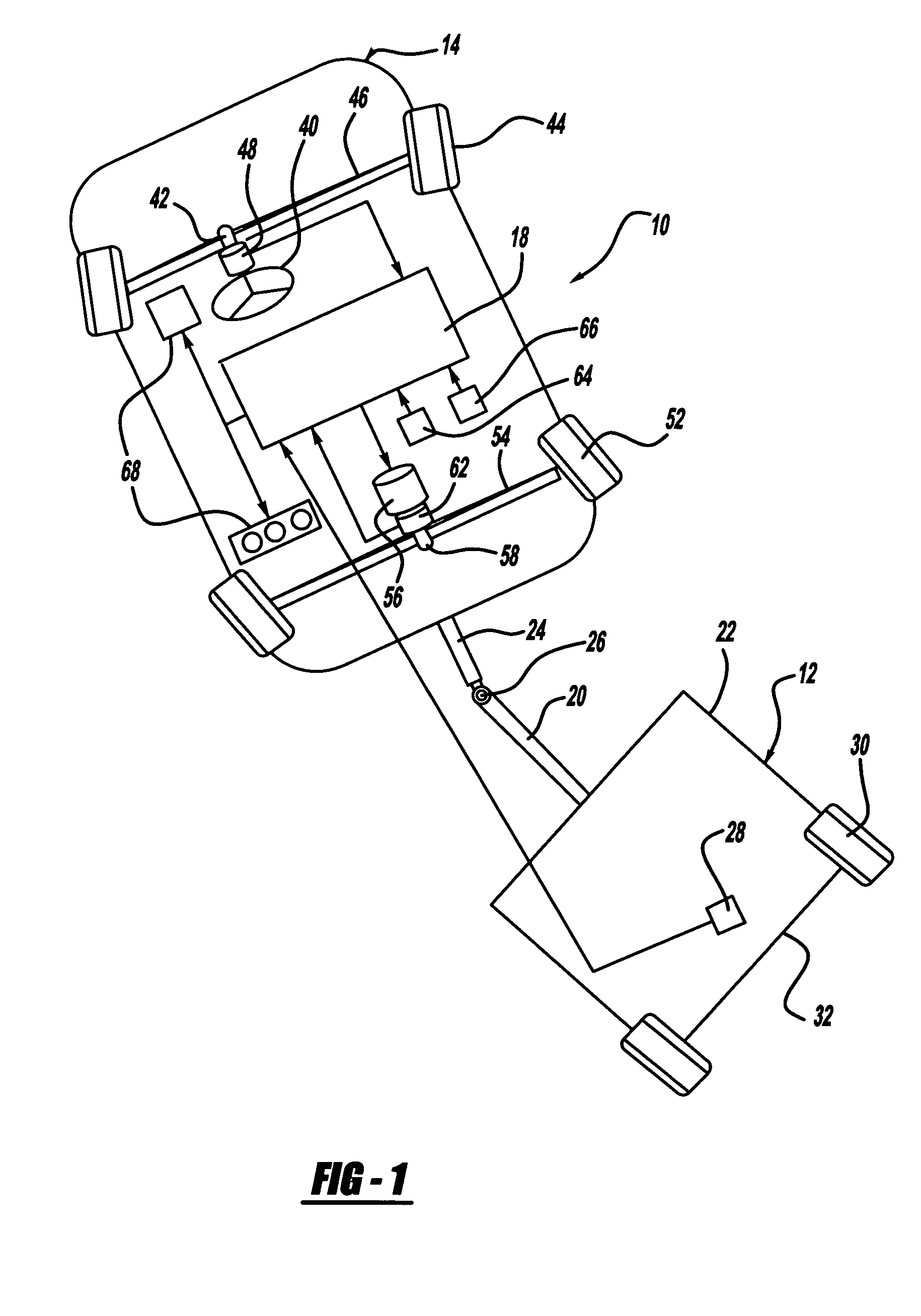

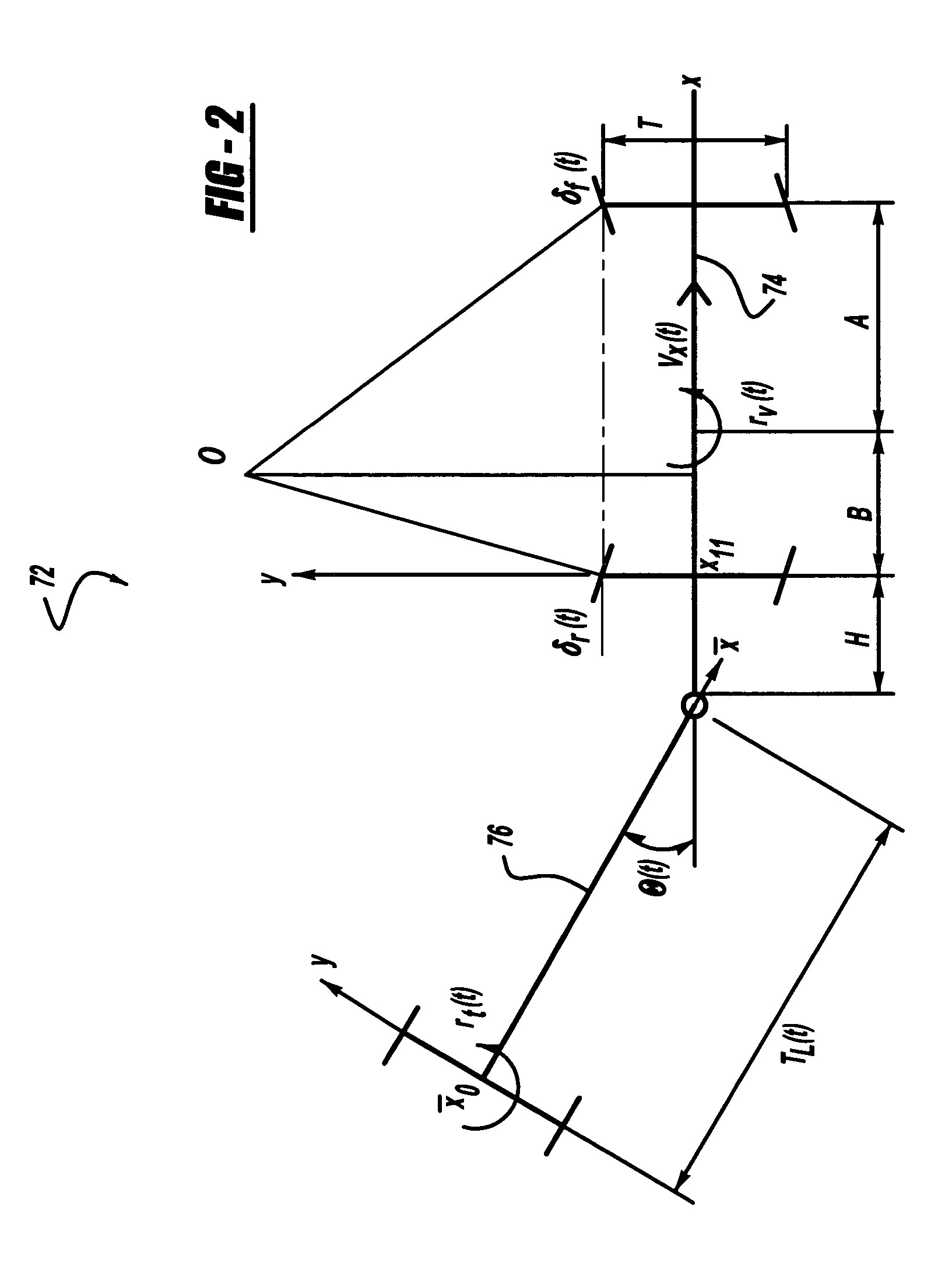

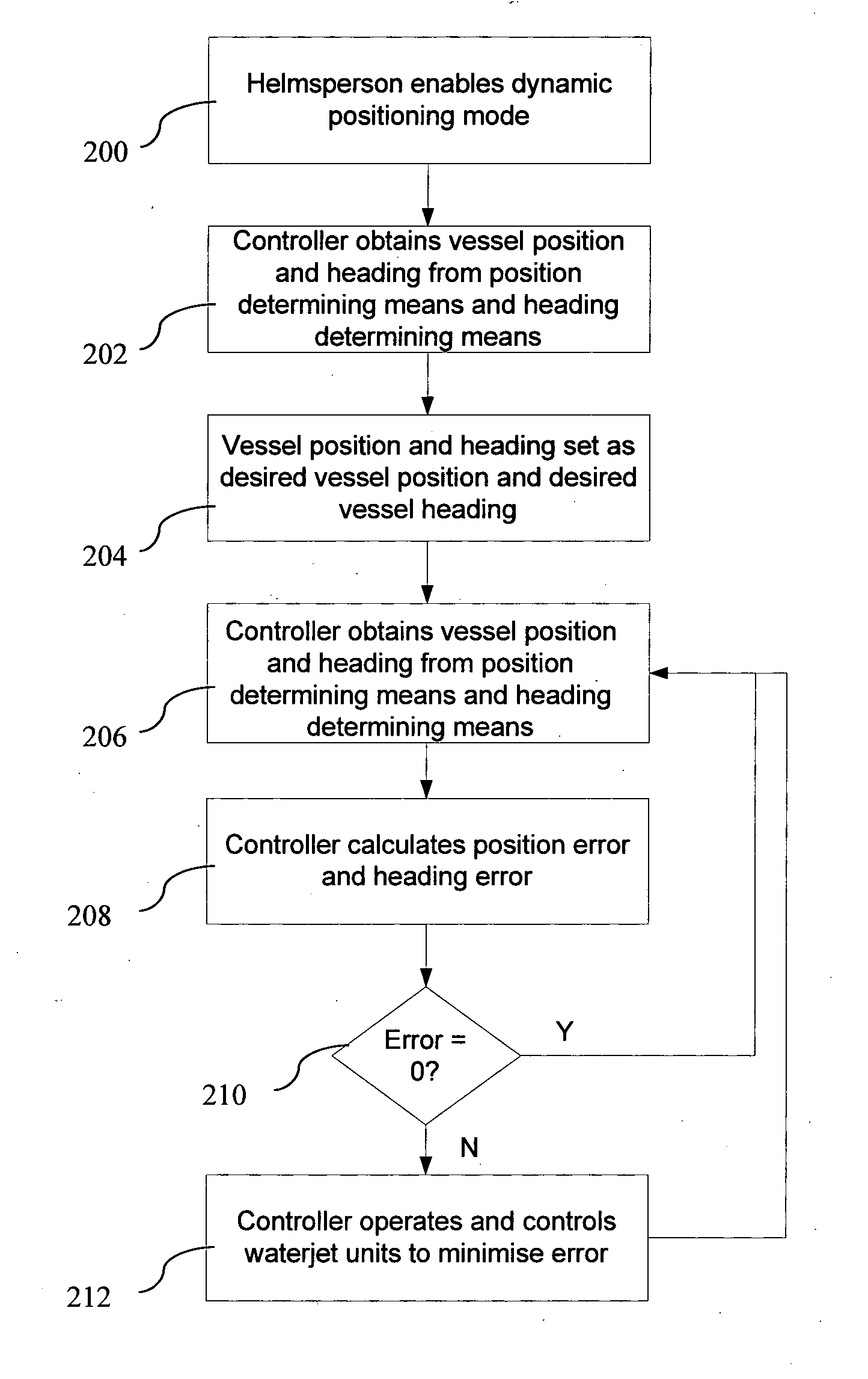

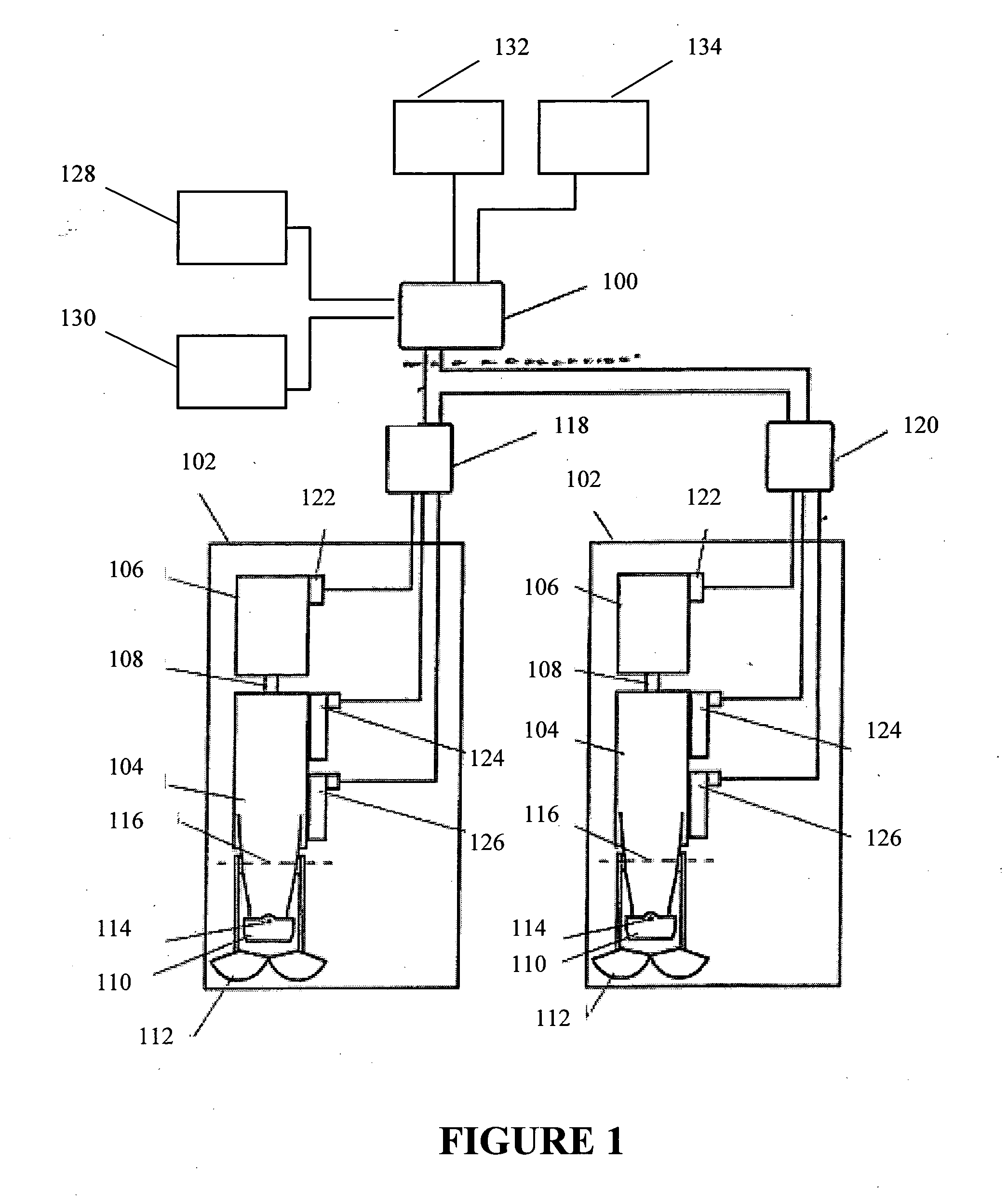

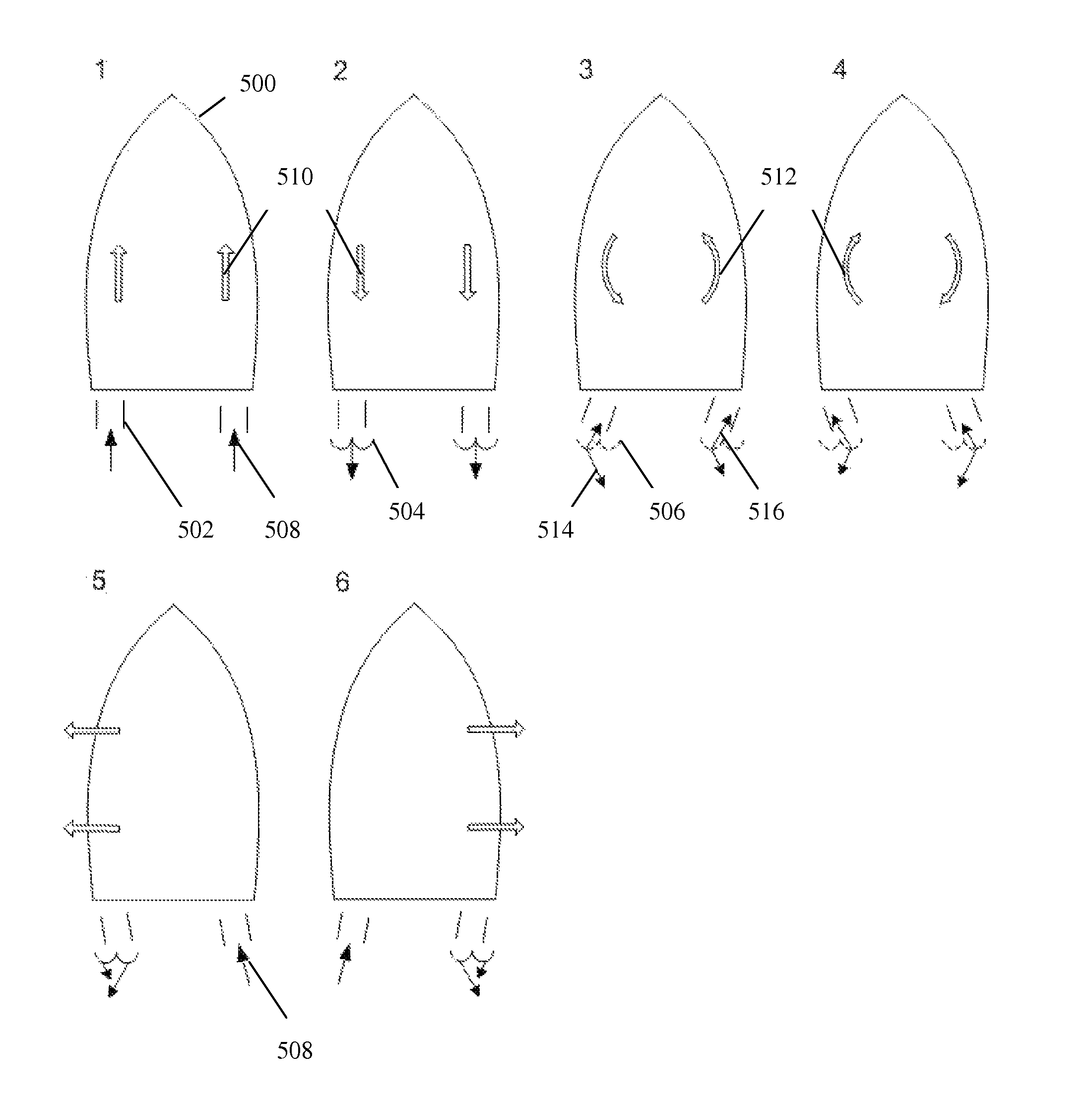

A dynamic control system for a marine vessel having two or more waterjet units as the primary propulsion system of the vessel, for maintaining vessel position or velocity when in a dynamic control mode, comprises a position or velocity indicator to indicate vessel position or velocity or deviations in vessel position or velocity; such as a satellite-based positioning system indicator, or accelerometers as a relative position indicator, a heading indicator to indicate vessel heading from position heading or yaw rate or deviations in vessel heading or yaw rate, such as a compass as an absolute heading indicator or a yaw rate sensor as a relative heading indicator, and a controller to control the operation of the waterjet units to substantially maintain the vessel position or velocity, and vessel heading or yaw rate when the dynamic control mode is enabled.

Owner:CWF HAMILTON

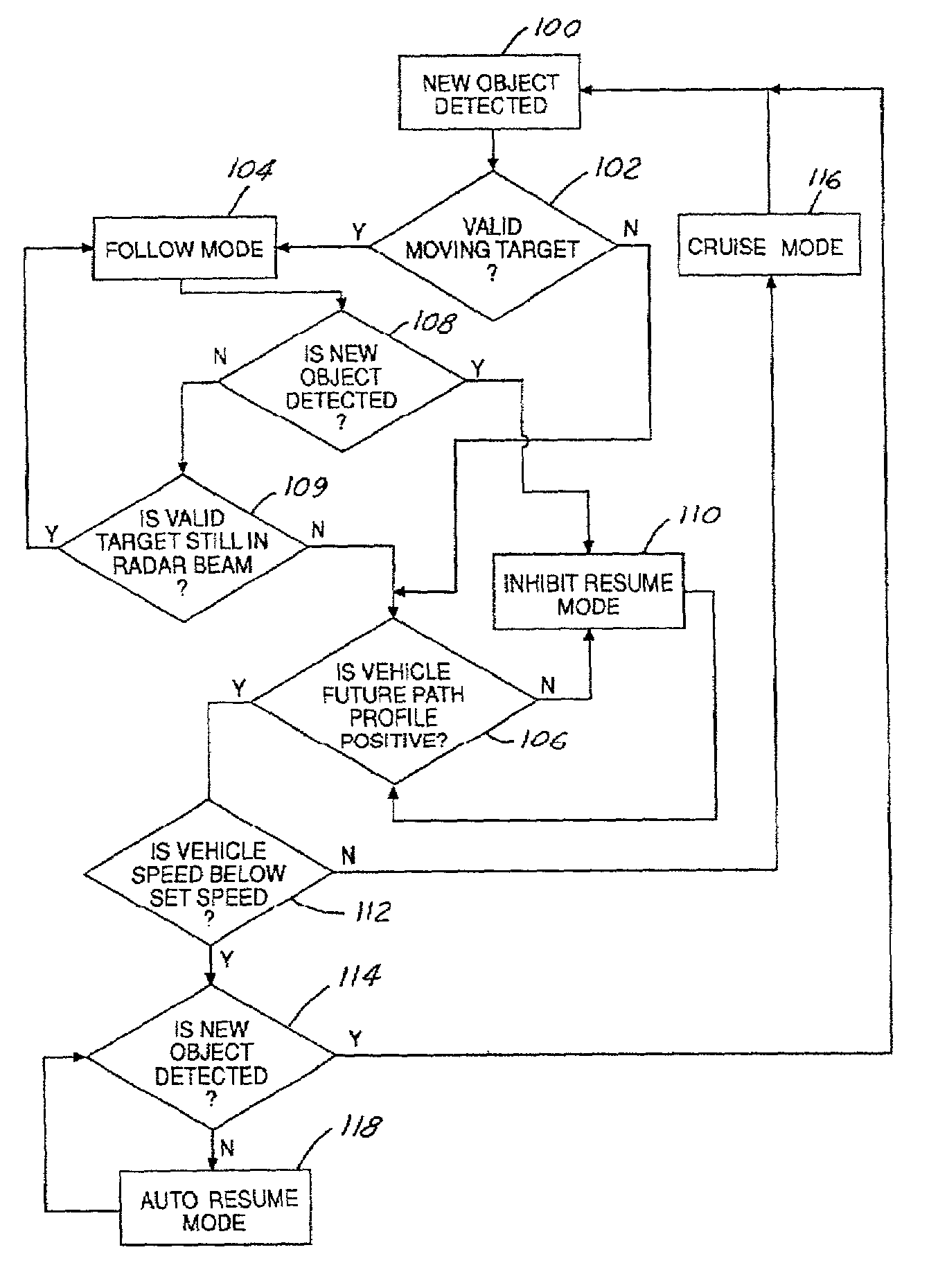

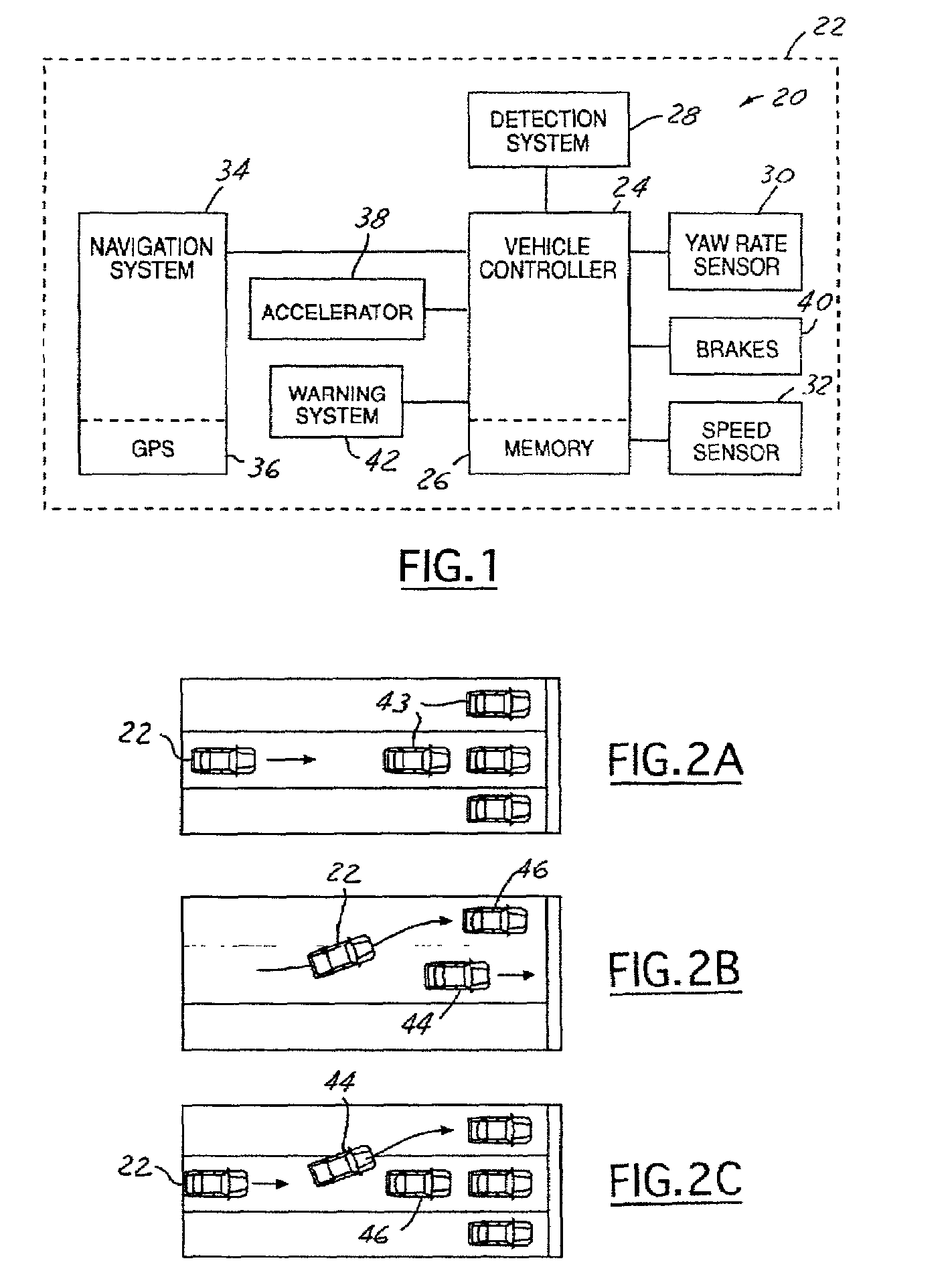

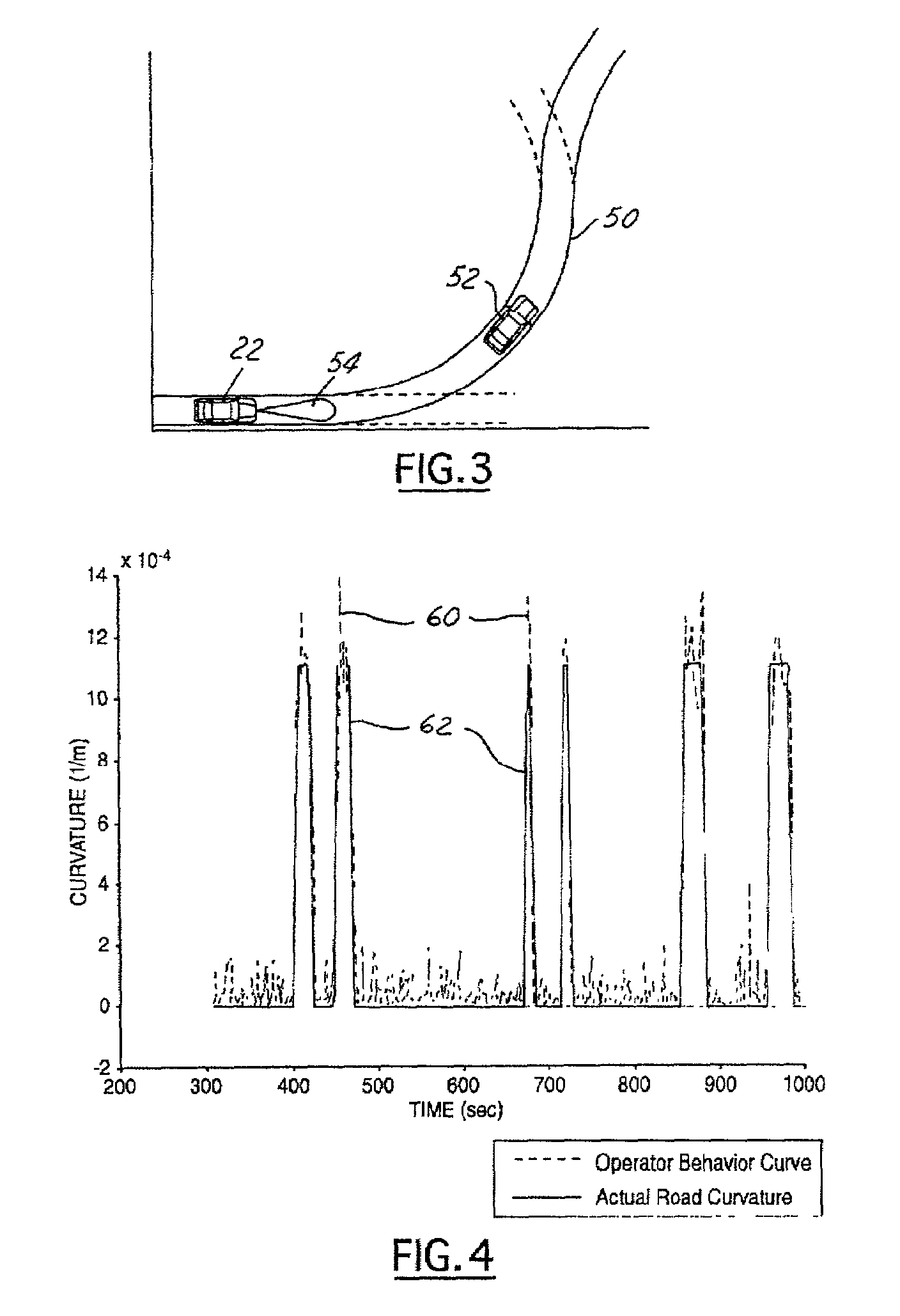

Object detection in adaptive cruise control

InactiveUS6968266B2Prevents false accelerationInstruments for road network navigationVehicle fittingsMobile vehicleRadar systems

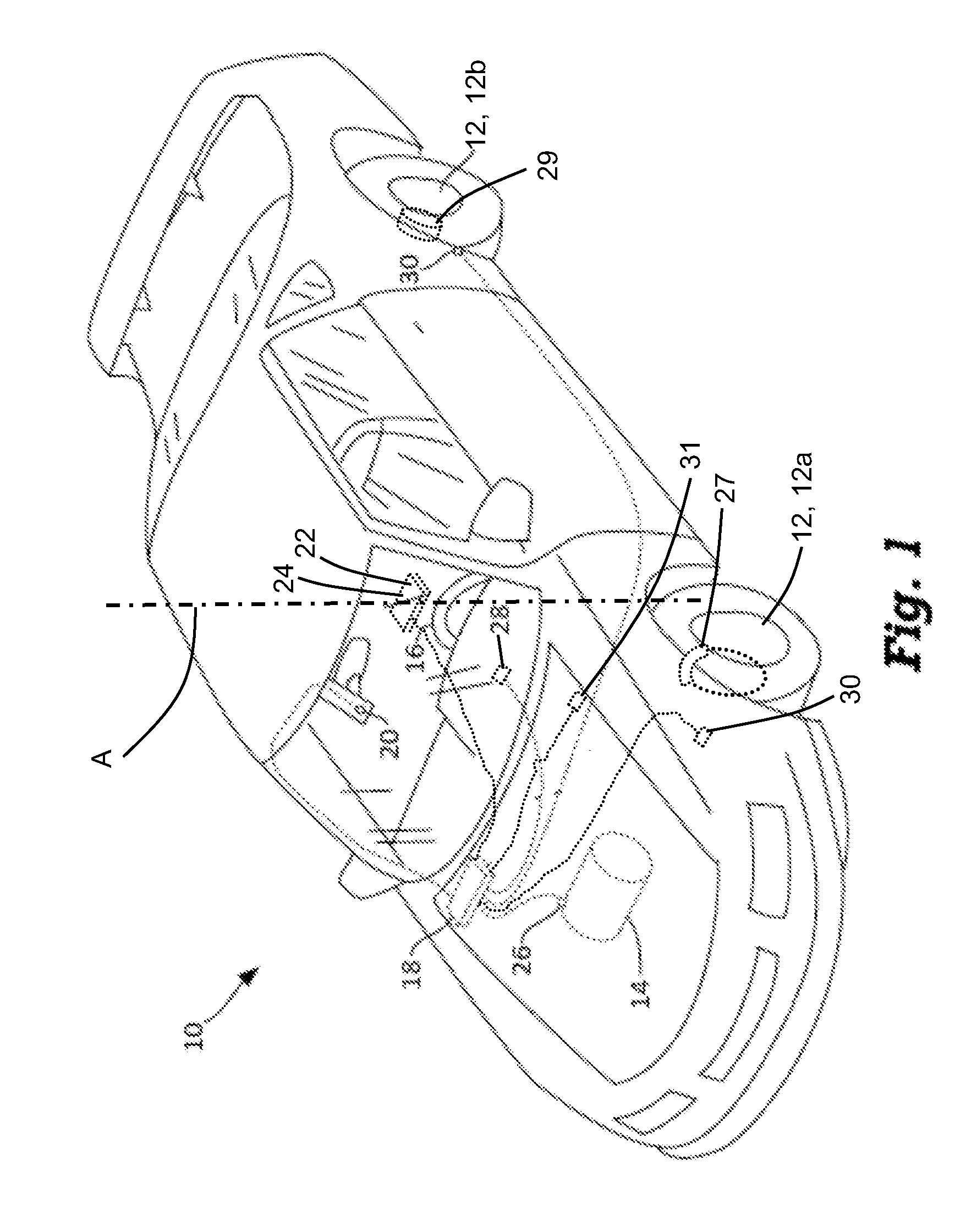

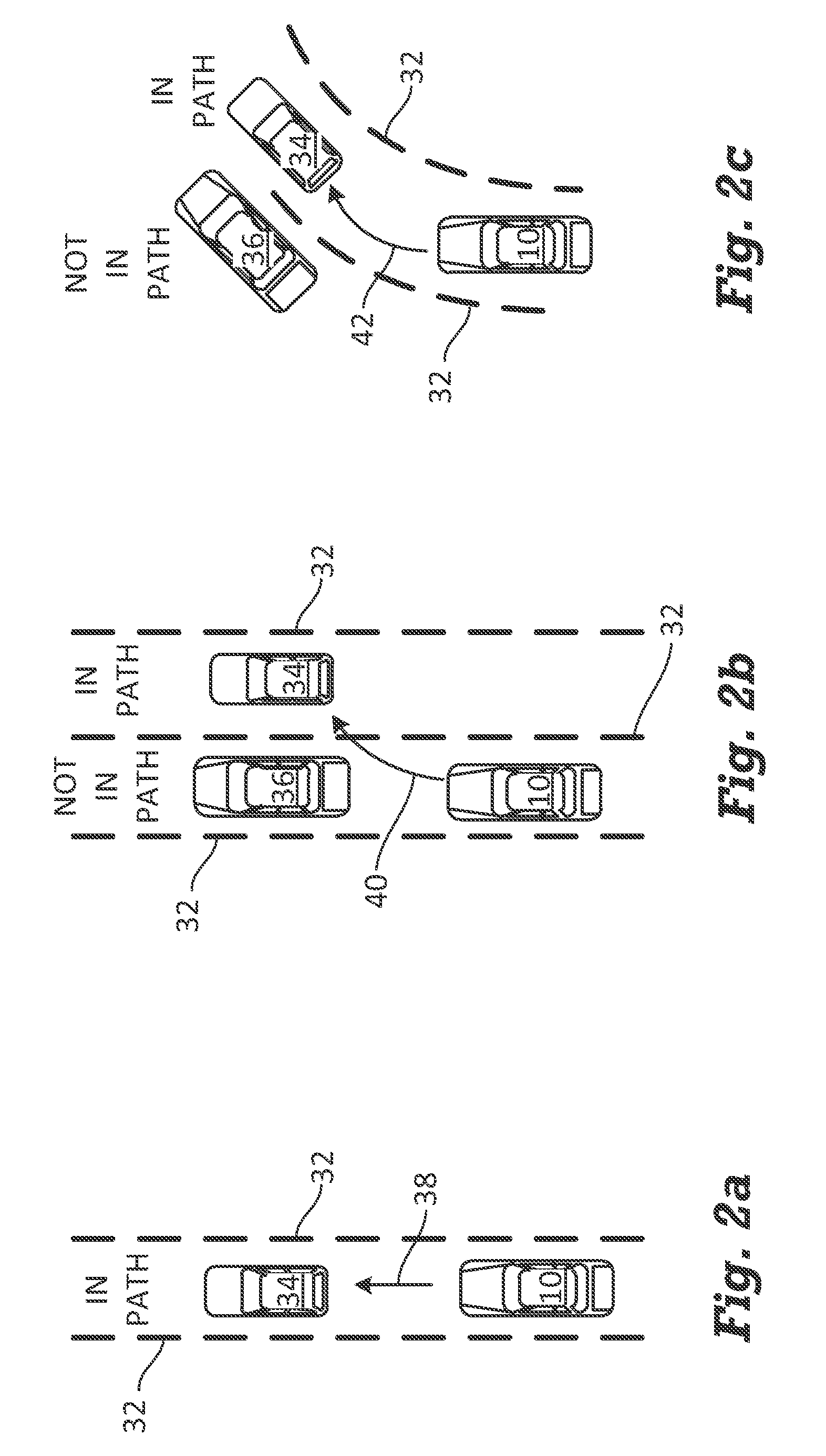

A control system 20 for an automotive vehicle 22, such as an adaptive cruise control (ACC) system, is provided including a controller 24. The controller 24 is electrically coupled to a radar system and a navigation system. The detection system 28 detects an object and generates an object profile. The navigation system 34 generates a navigation signal. The controller 24 in response to the object profile and the navigation signal, generates a predicted future path profile and inhibits resume speed of the vehicle 22 in response to the predicted future path profile. An additional feature of the invention is that the controller 24 may also be electrically coupled to a yaw rate sensor 30. The yaw rate sensor 30 senses the yaw rate of the vehicle 22 and generates a yaw rate signal. The controller 24 in response to the yaw rate signal inhibits resume speed of the vehicle 22.

Owner:FORD GLOBAL TECH LLC

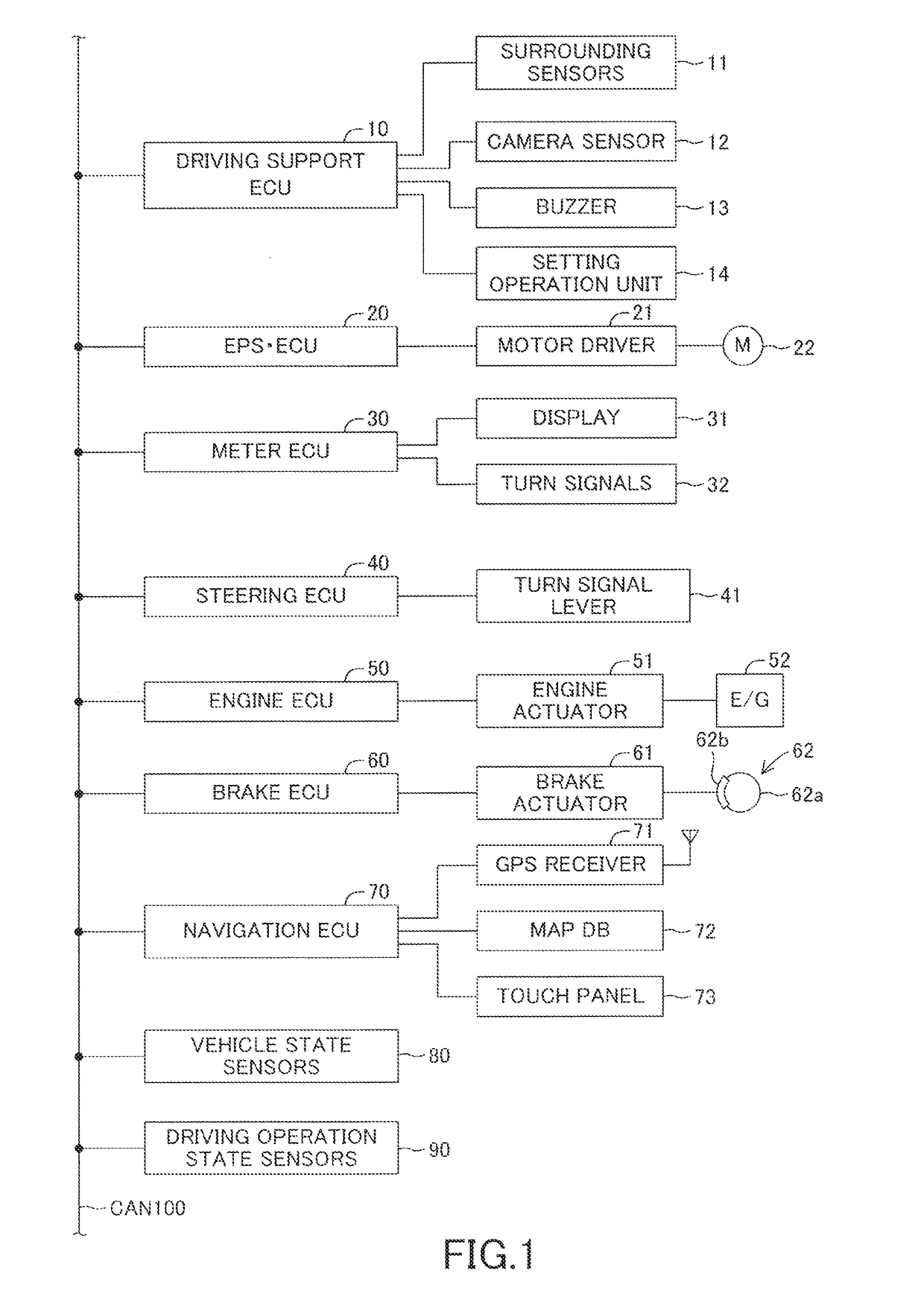

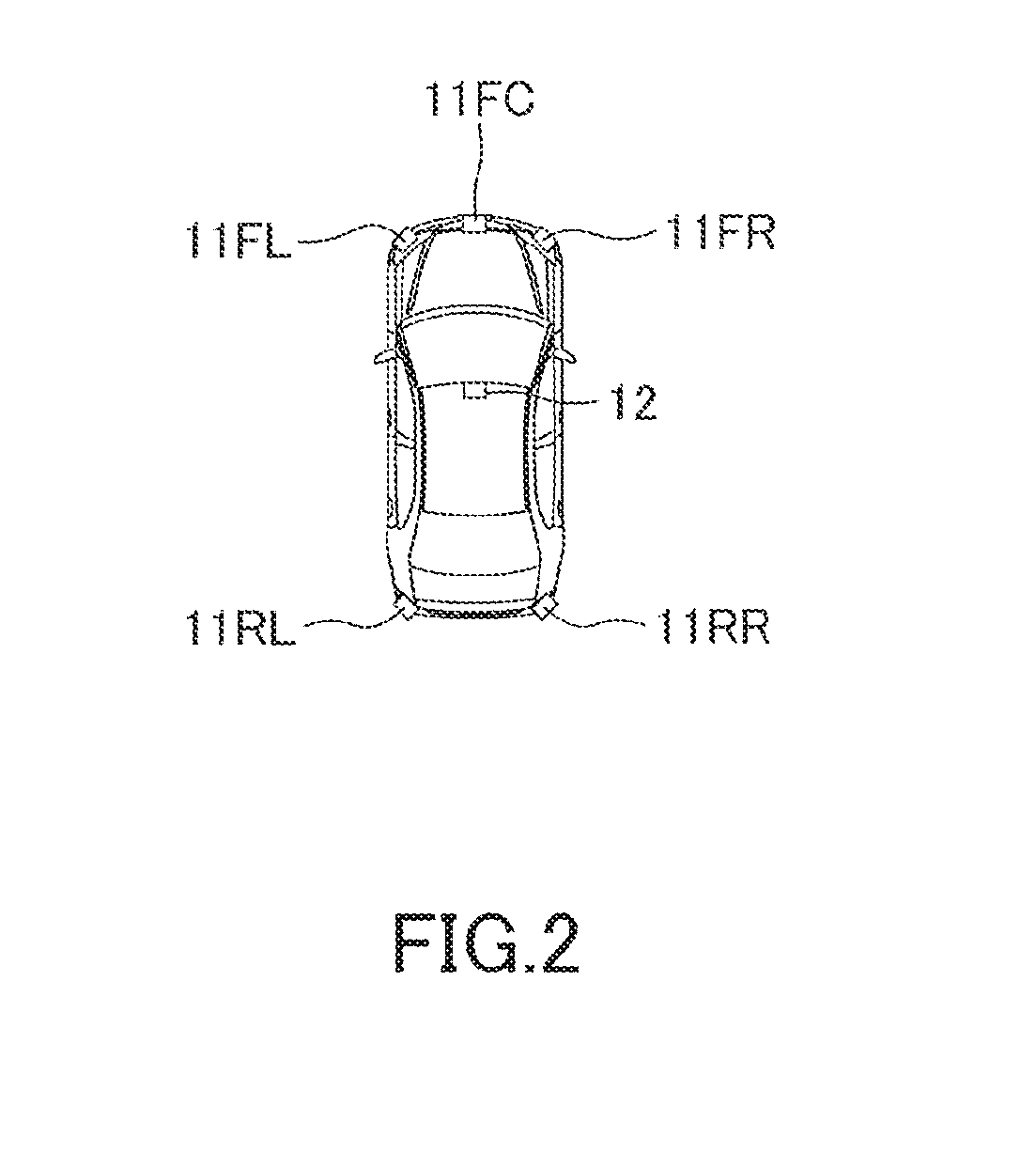

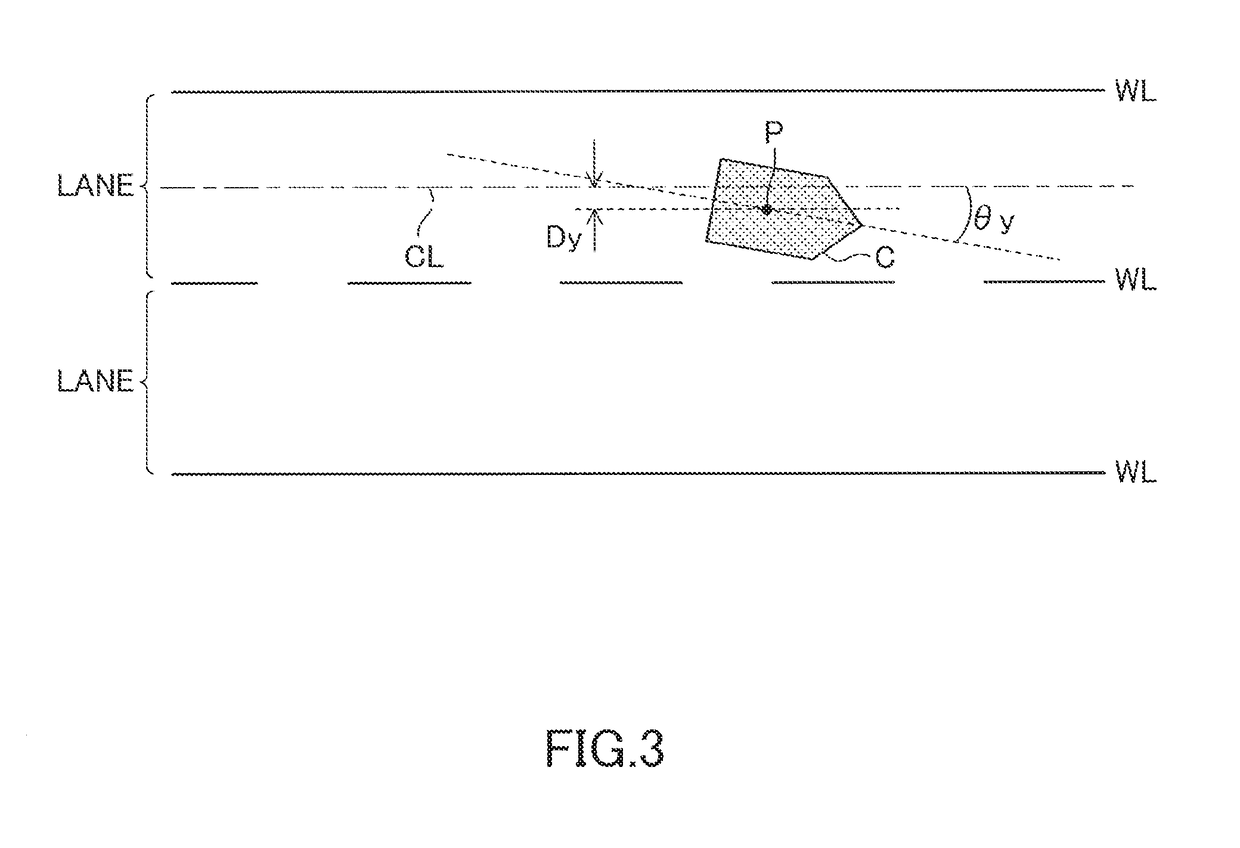

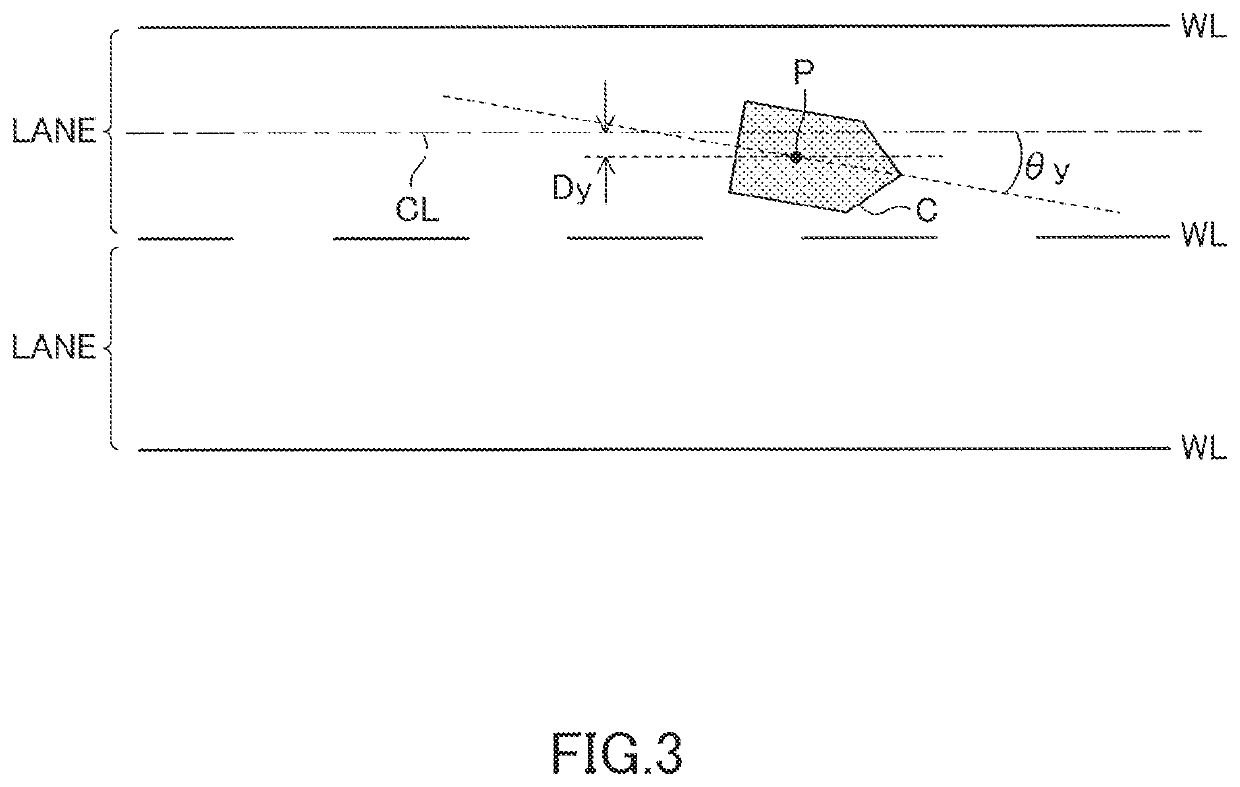

Lane change assist device

A yaw angle return controller is configured to end first yaw angle return control at a predetermined time when a value which is calculated by adding yaw angle detected by a lane recognition device at a predetermined time and an estimated yaw angle change amount is the same as yaw angle at lane change start time under a state where the first yaw angle return control is being executed. The predetermined time comes after the first start time and before the first finish time. The estimated yaw angle change amount is calculated by multiplying the yaw rate detected by a yaw rate sensor at the predetermined time by a predetermined time period for foreseeing.

Owner:TOYOTA JIDOSHA KK

Lane change assist device

A yaw angle return controller is configured to end first yaw angle return control at a predetermined time when a value which is calculated by adding yaw angle detected by a lane recognition device at a predetermined time and an estimated yaw angle change amount is the same as yaw angle at lane change start time under a state where the first yaw angle return control is being executed. The predetermined time comes after the first start time and before the first finish time. The estimated yaw angle change amount is calculated by multiplying the yaw rate detected by a yaw rate sensor at the predetermined time by a predetermined time period for foreseeing.

Owner:TOYOTA JIDOSHA KK

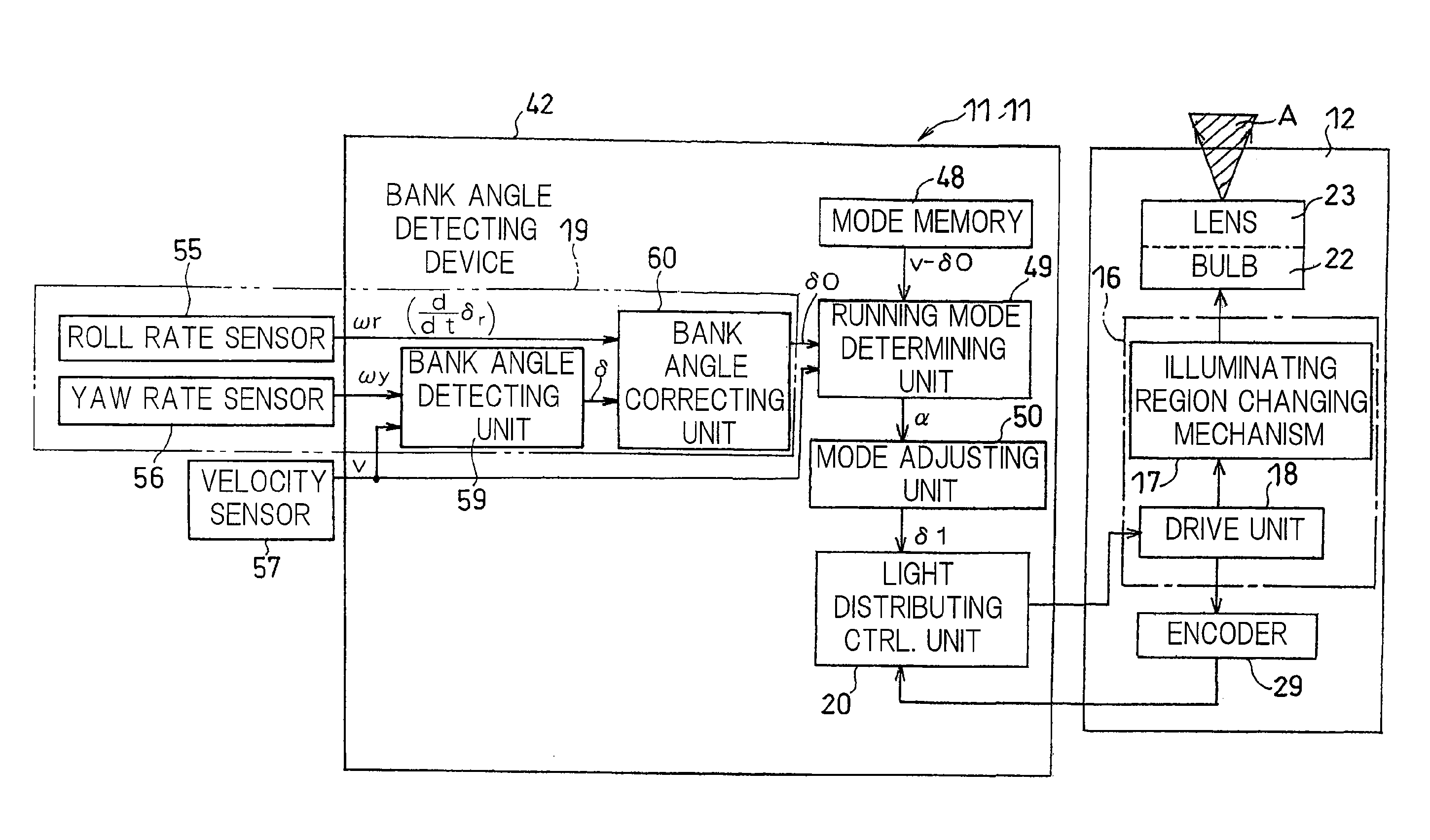

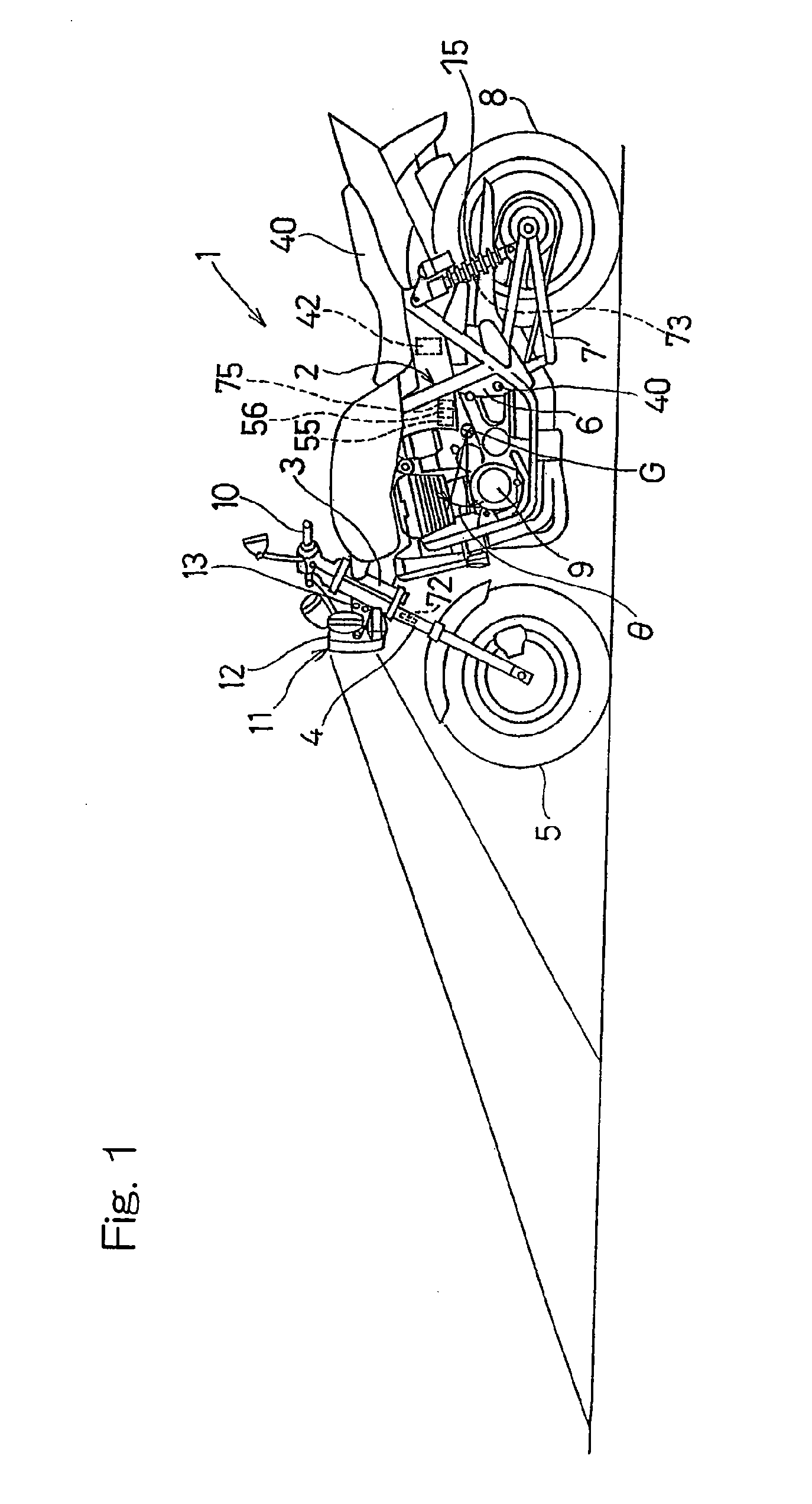

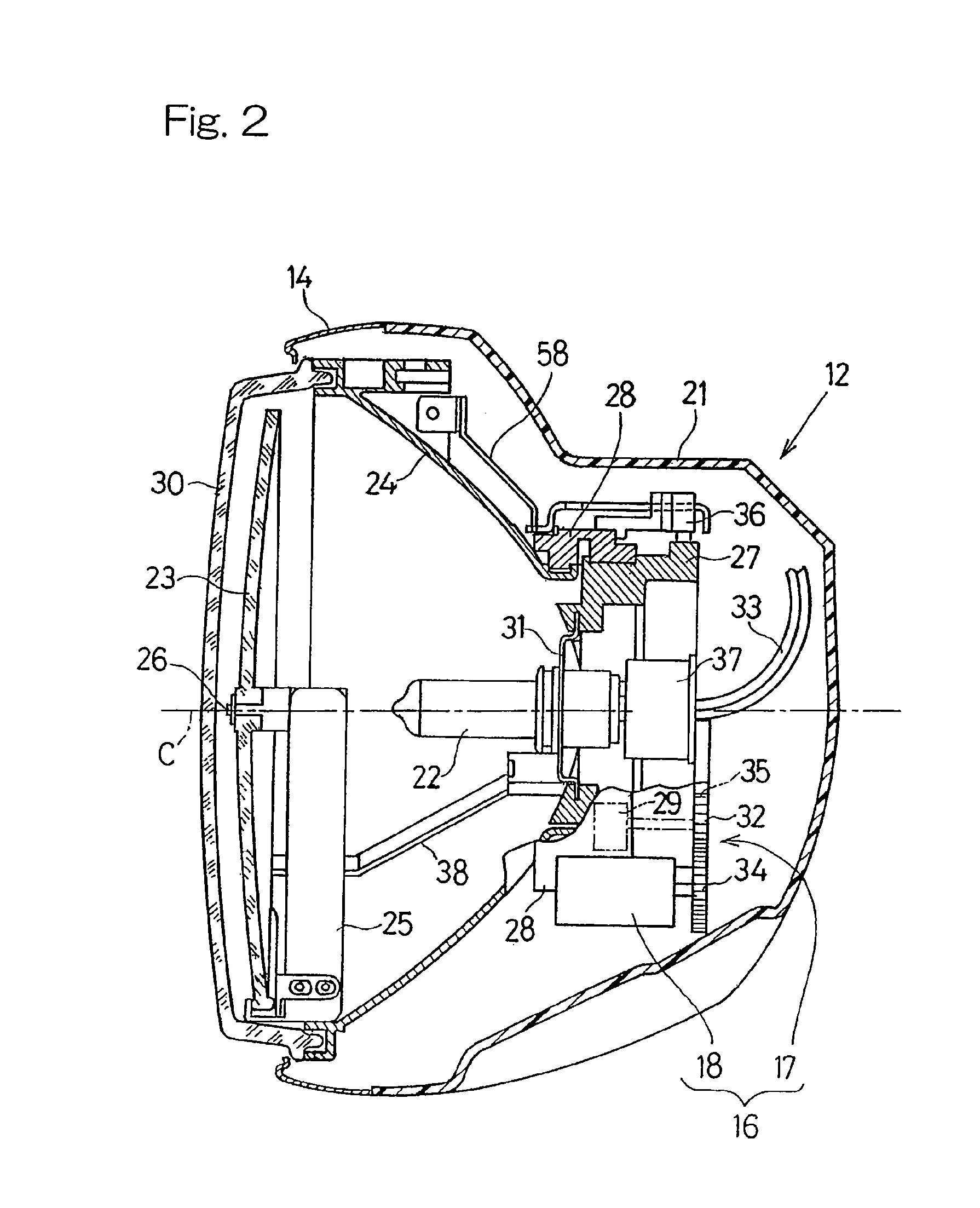

Bank angle detecting device and headlight device for motorcycle

ActiveUS20100168958A1Accurate detectionMinimize changesPoint-like light sourceLighting support devicesAngular velocityRoll rate

A bank angle detecting device includes a roll rate sensor for detecting a angular velocity ωr about a longitudinal axis of the motorcycle; a yaw rate sensor for detecting a angular velocity ωy about an vertical axis of the motorcycle; a bank angle detecting unit for detecting the motorcycle bank angle δ for calibration use based on the yaw rate ωy and a traveling velocity v; and a bank angle correcting unit for correcting the basic motorcycle bank angle δr, determined from an output ωr of the yaw rate sensor, so as to approach the motorcycle bank angle δ that is detected by the bank angle detecting unit, to thereby determine the estimated bank angle δ0.

Owner:KAWASAKI MOTORS LTD

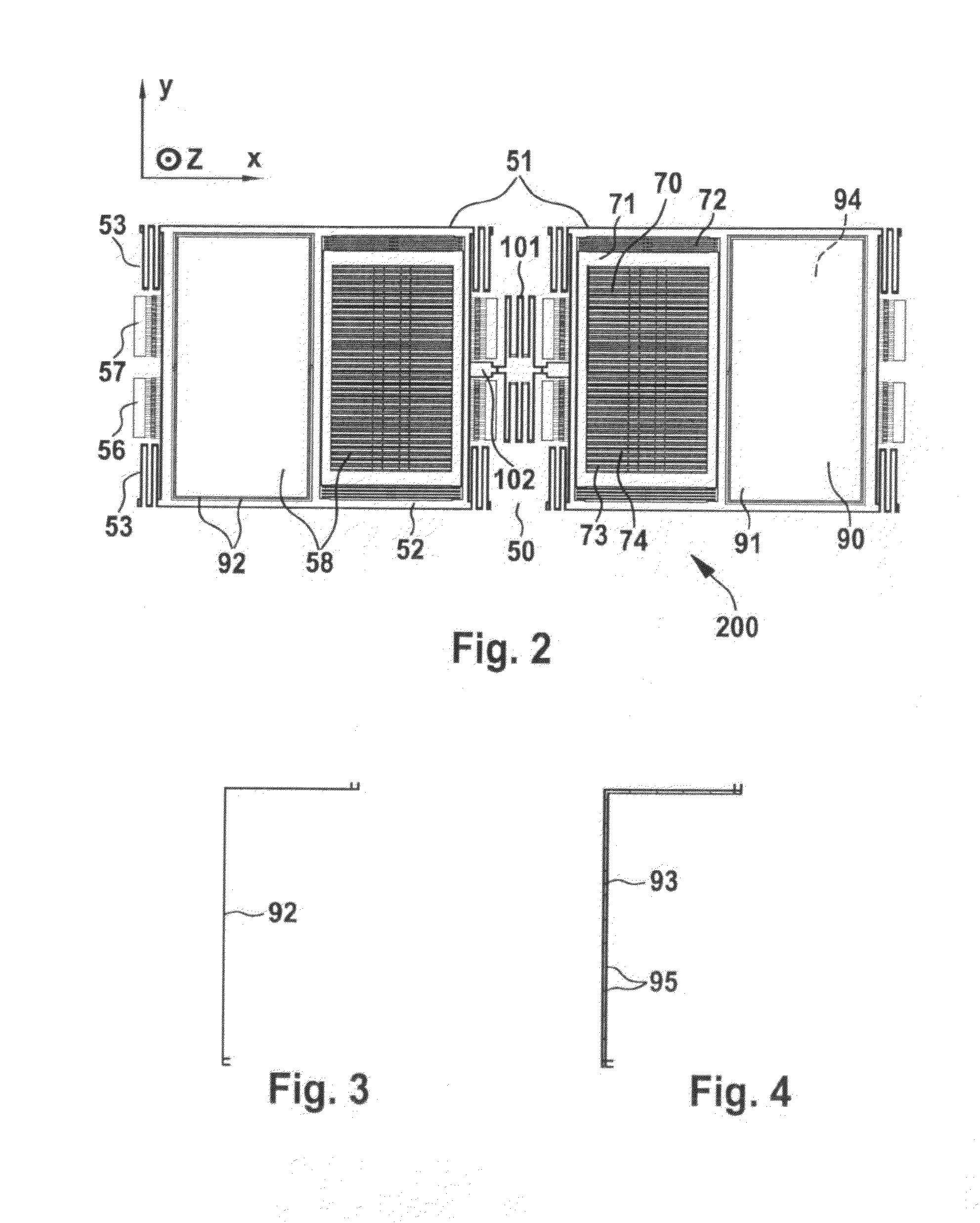

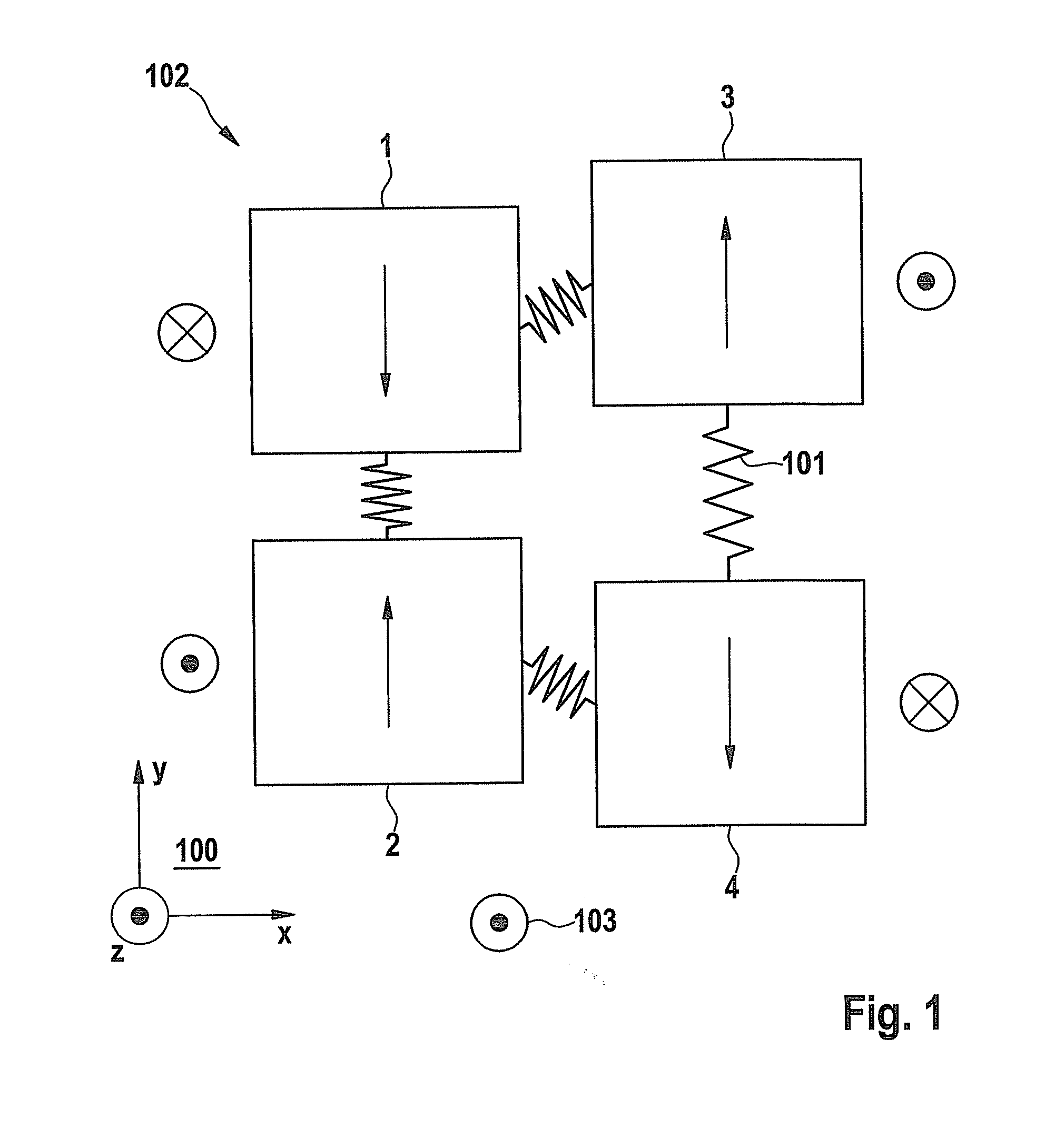

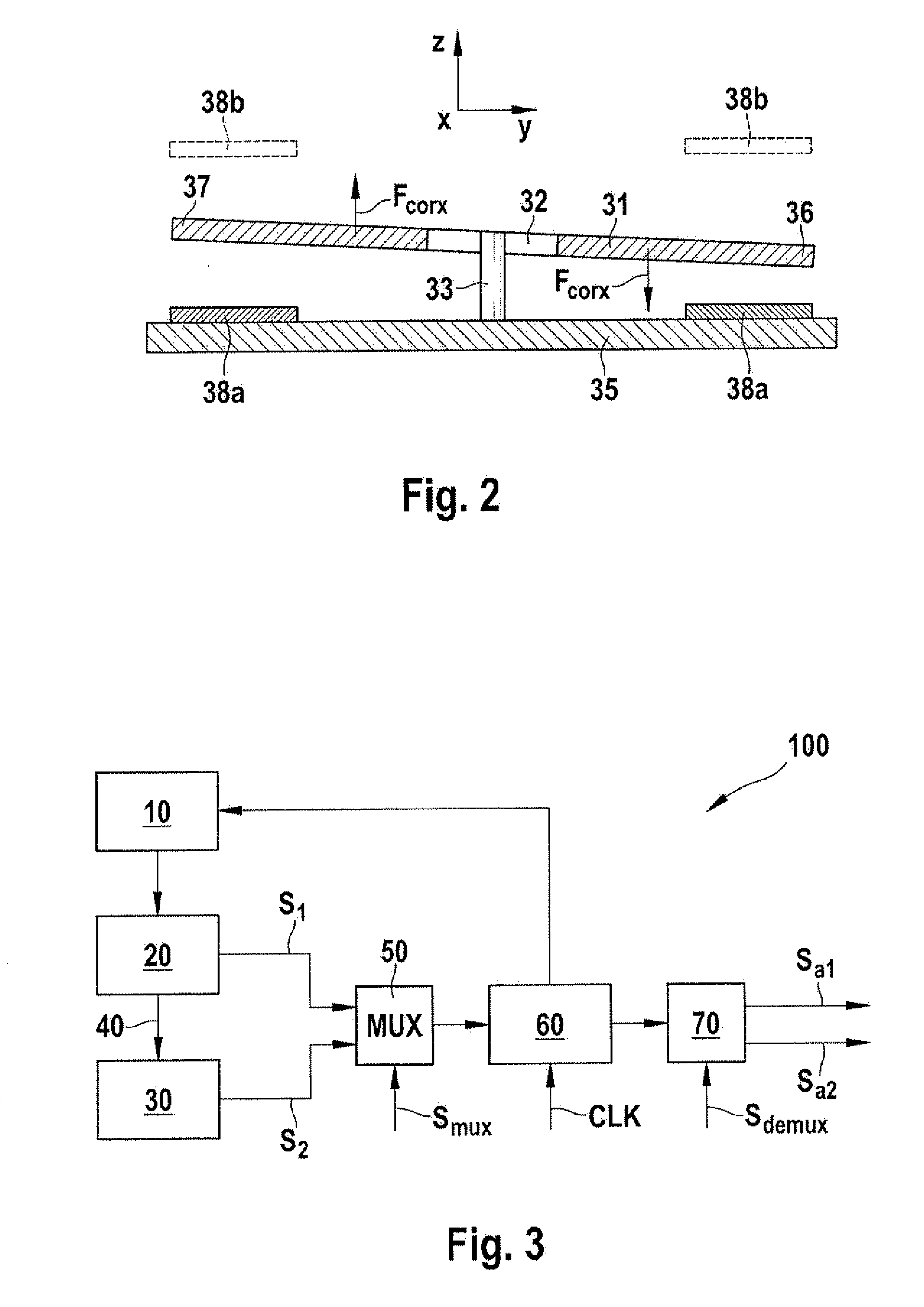

Yaw-rate sensor and method for operating a yaw-rate sensor

ActiveUS20120125099A1Insensitive to interferenceAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsClassical mechanicsYaw-rate sensor

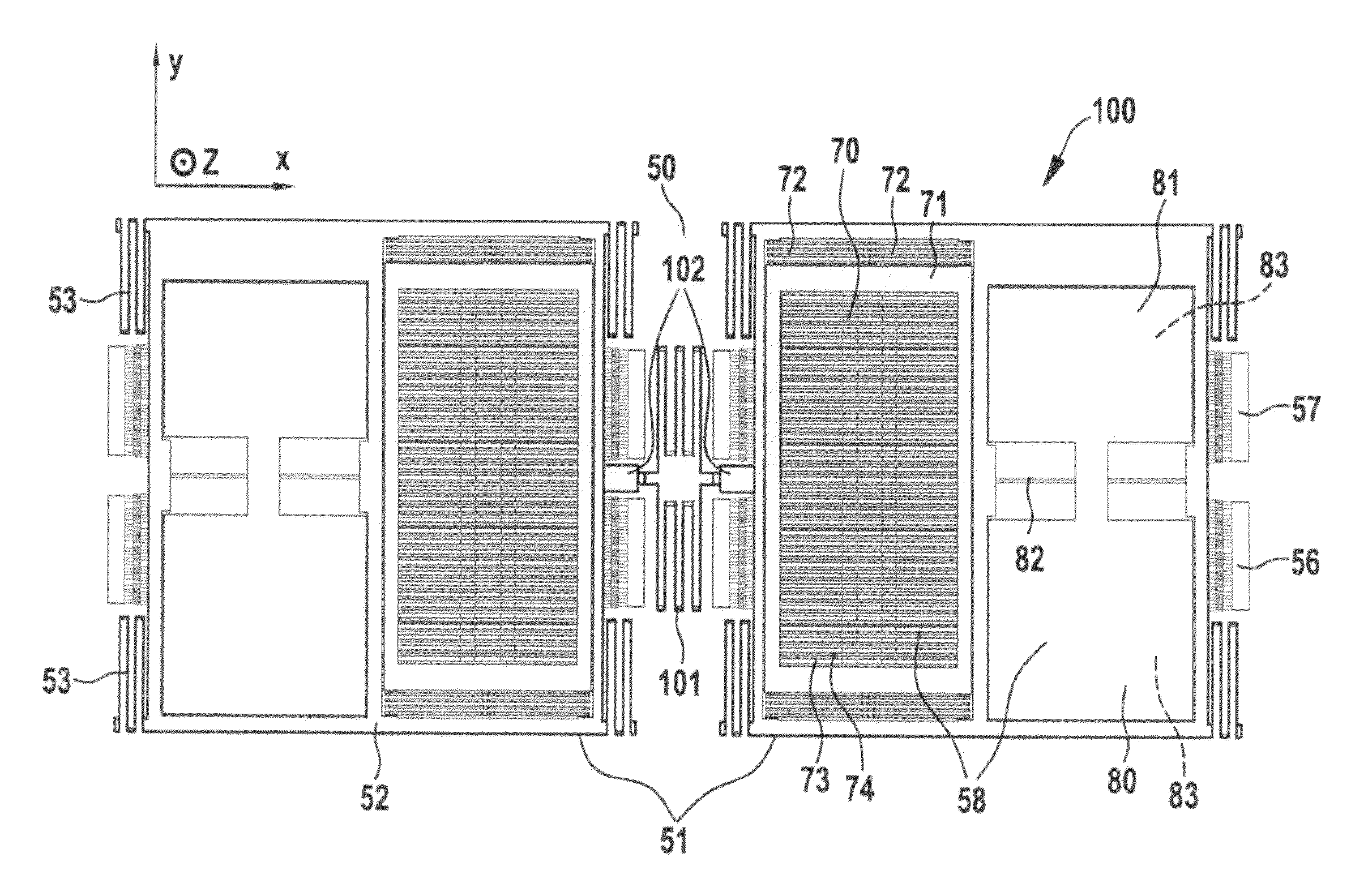

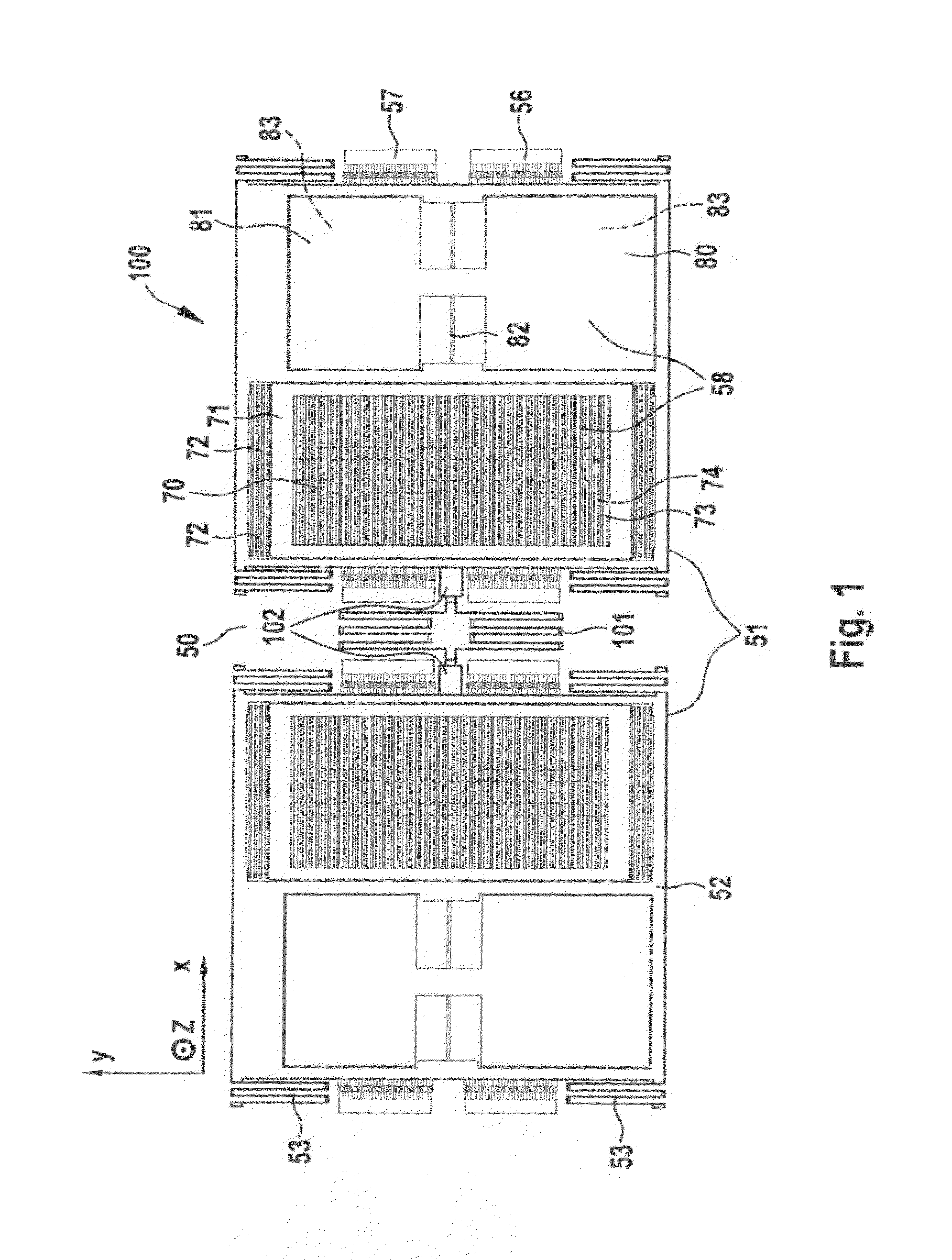

A yaw-rate sensor includes: a substrate having a main extension plane for detecting a yaw rate about a first axis extending parallel to the main extension plane; a first Coriolis element; a second Coriolis element; a third Coriolis element; and a fourth Coriolis element. The first Coriolis element and the fourth Coriolis element are drivable in the same direction parallel to a second axis extending parallel to the main extension plane and perpendicularly to the first axis. The first Coriolis element and the second Coriolis element are drivable in opposite directions parallel to the second axis. The first Coriolis element and the third Coriolis element are drivable in opposite directions parallel to the second axis.

Owner:ROBERT BOSCH GMBH

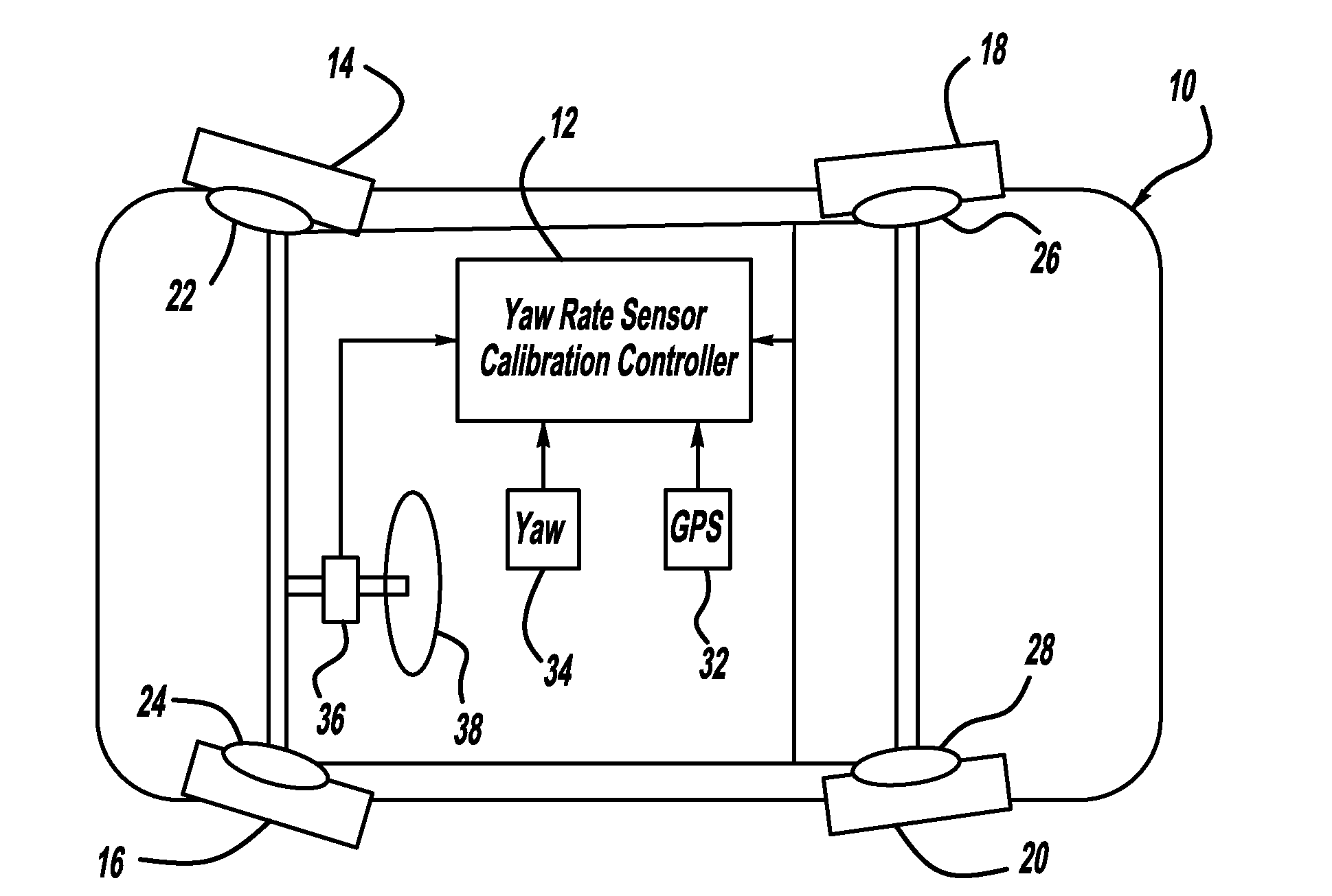

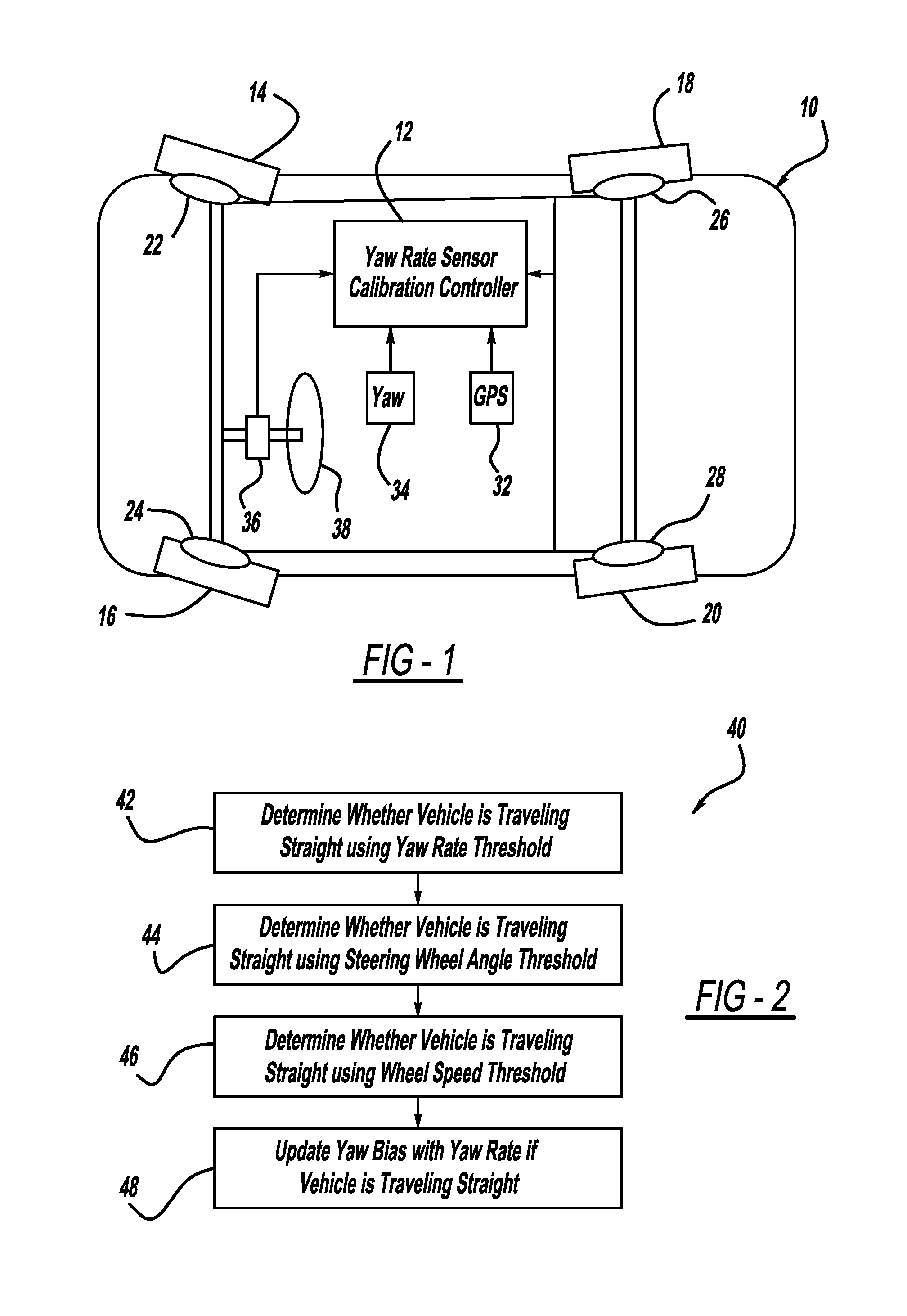

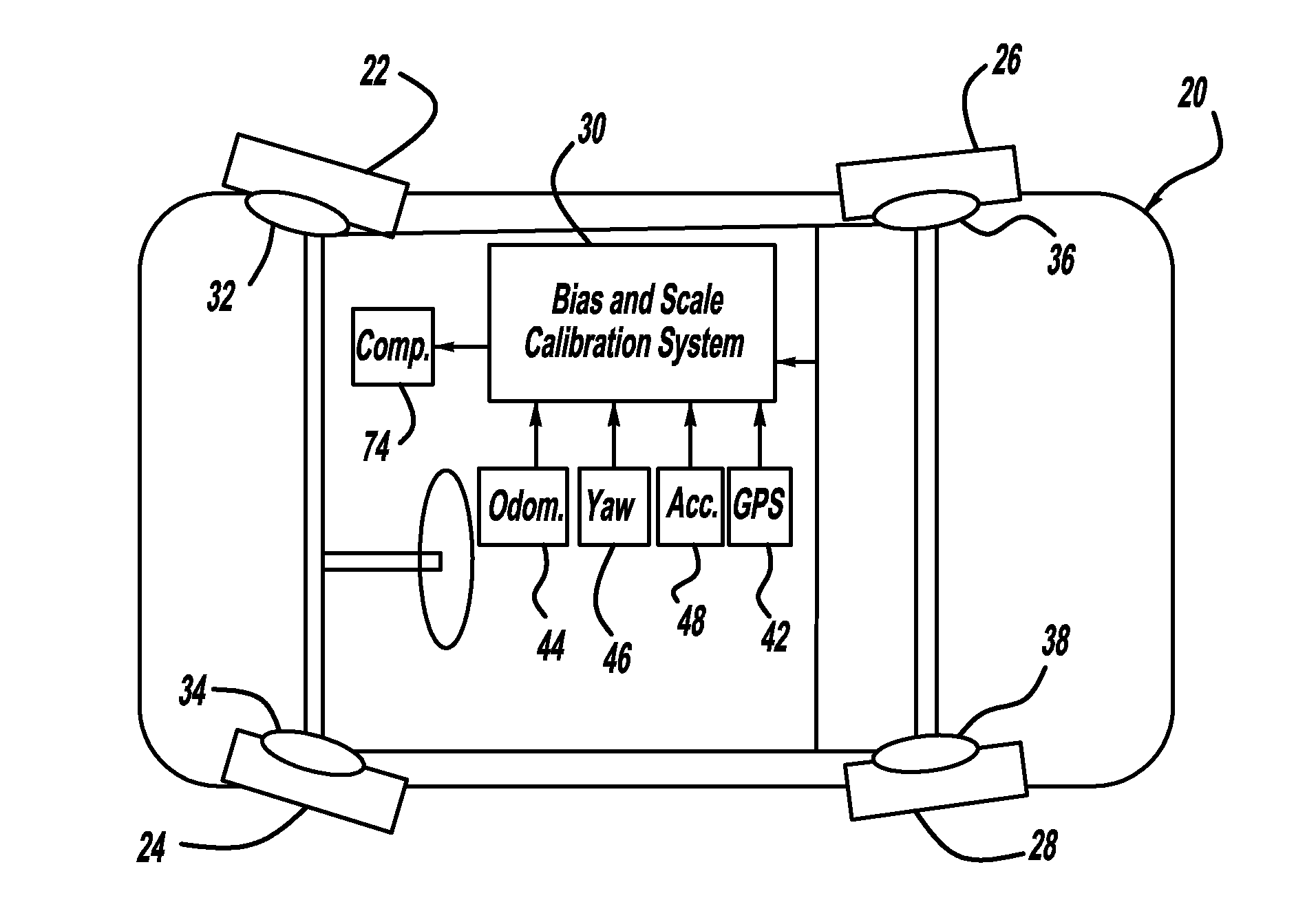

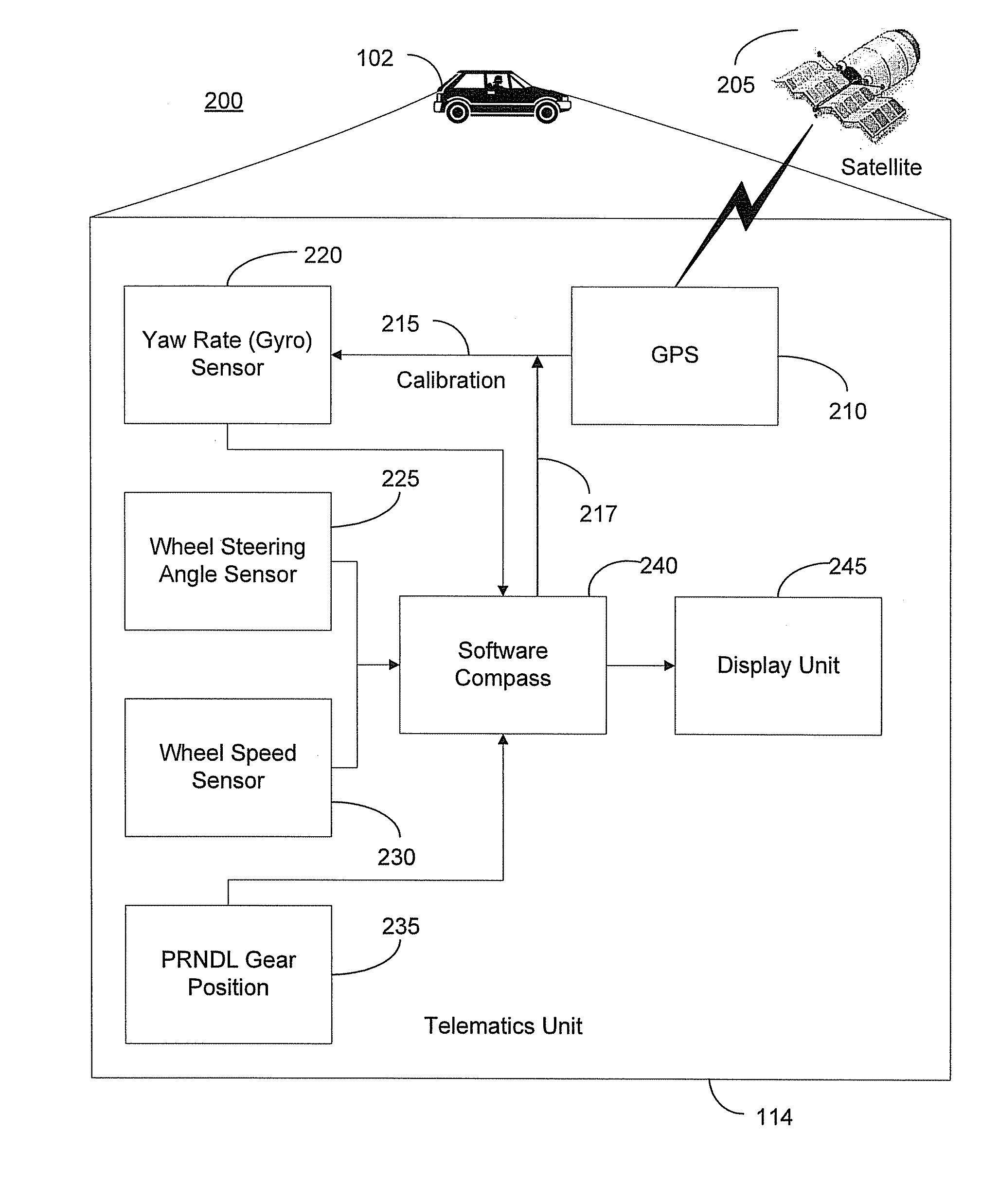

In-vehicle sensor-based calibration algorithm for yaw rate sensor calibration

A system and method for calibrating a vehicle heading sensor, such as a yaw-rate sensor, when GPS signals are not available using a bias update model that employs a bias gain factor. In order for the bias update model to be accurate, the vehicle should be traveling relatively straight. One embodiment of the present invention uses three thresholds to determine if the vehicle is traveling straight. These thresholds include a yaw-rate threshold, a steering wheel angle threshold and a wheel speed threshold. If all three of the thresholds indicate that the vehicle is traveling straight, then the update bias model can be used to calibrate the yaw-rate sensor.

Owner:GM GLOBAL TECH OPERATIONS LLC

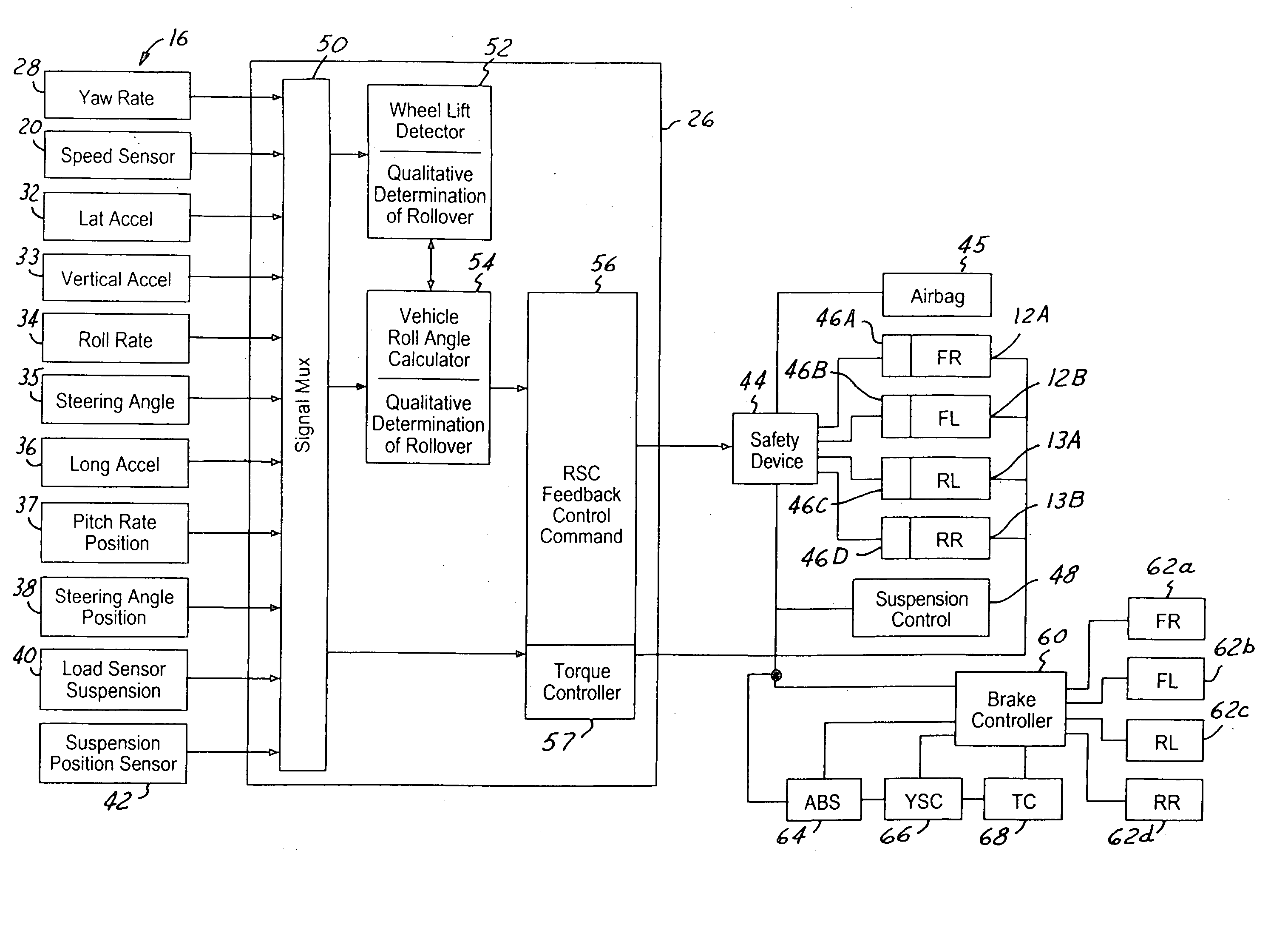

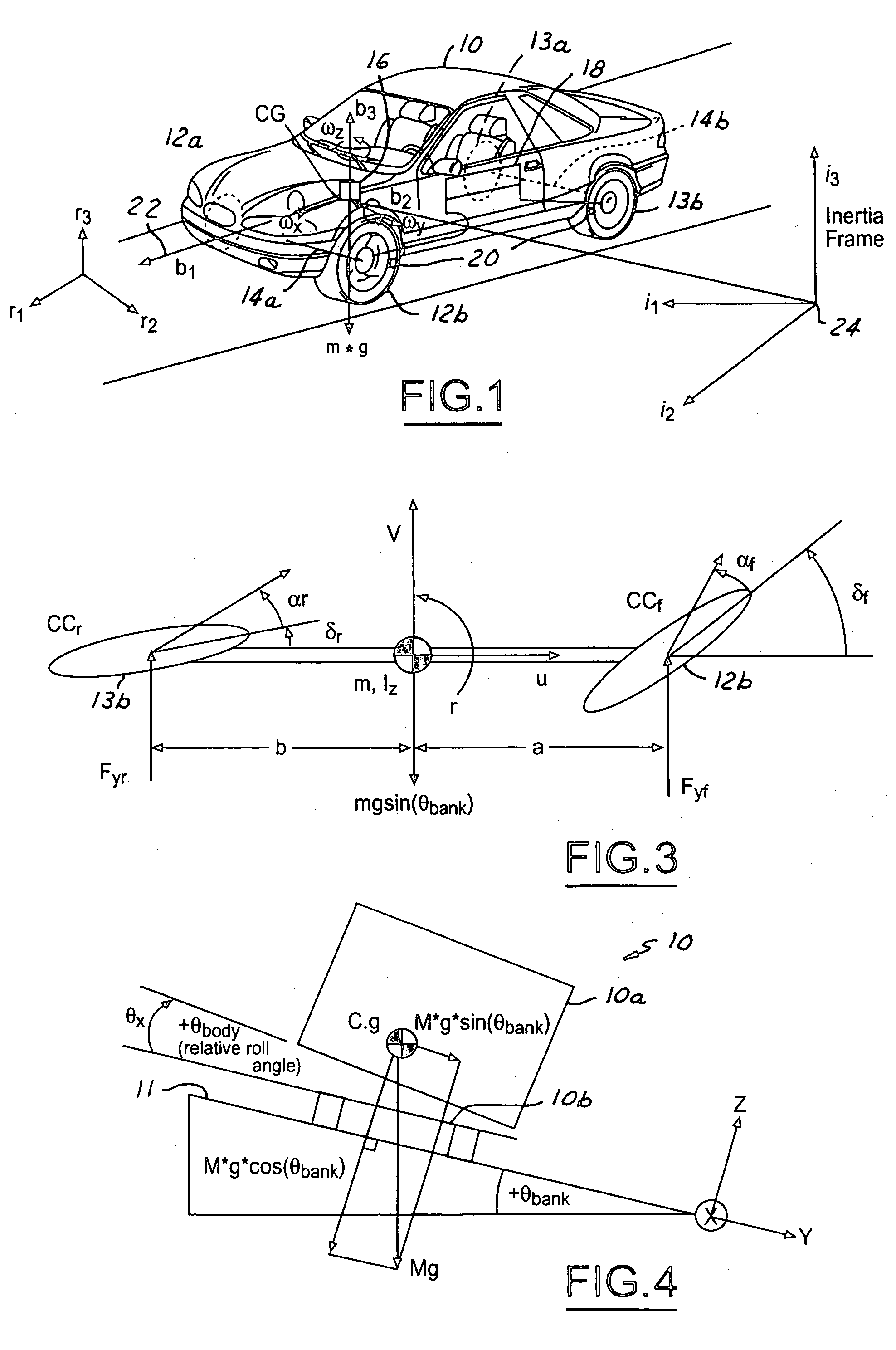

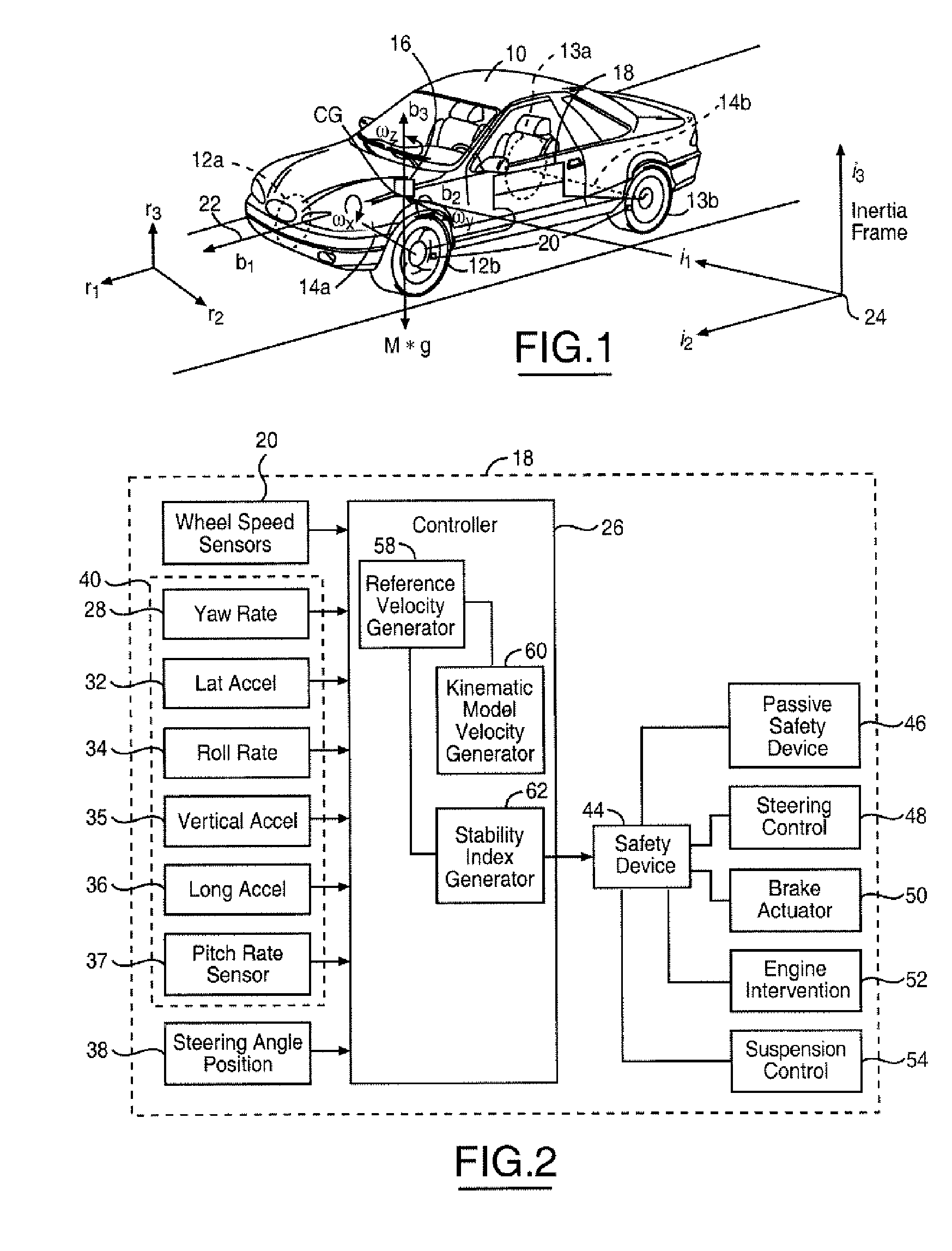

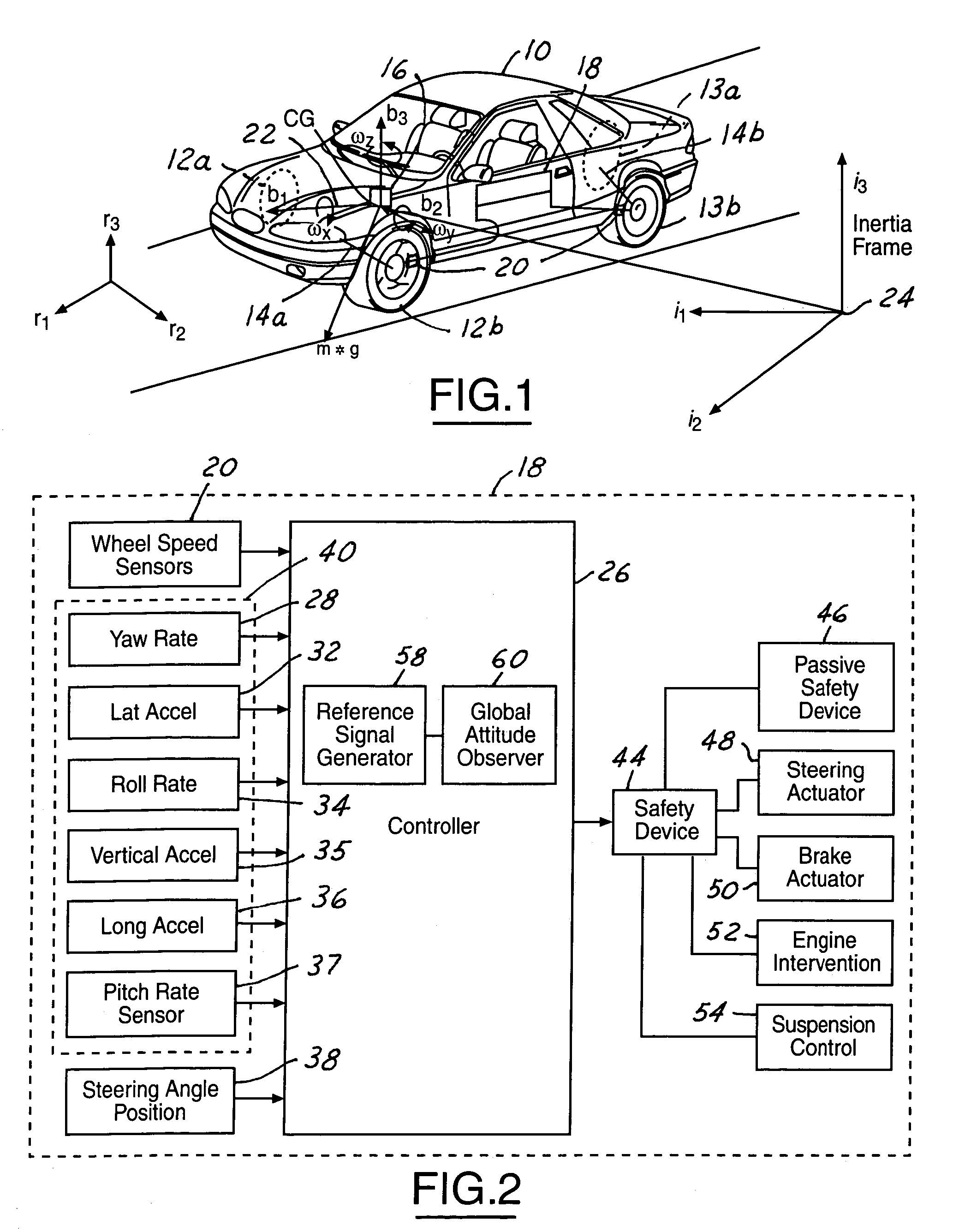

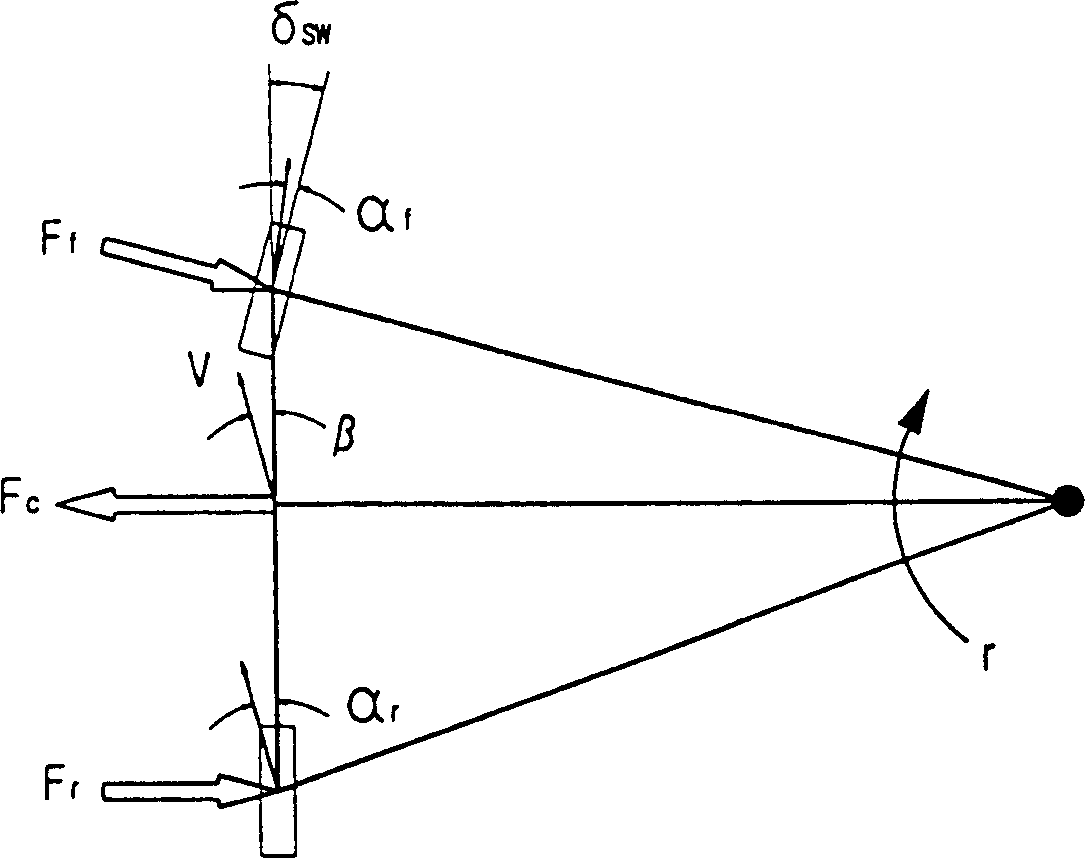

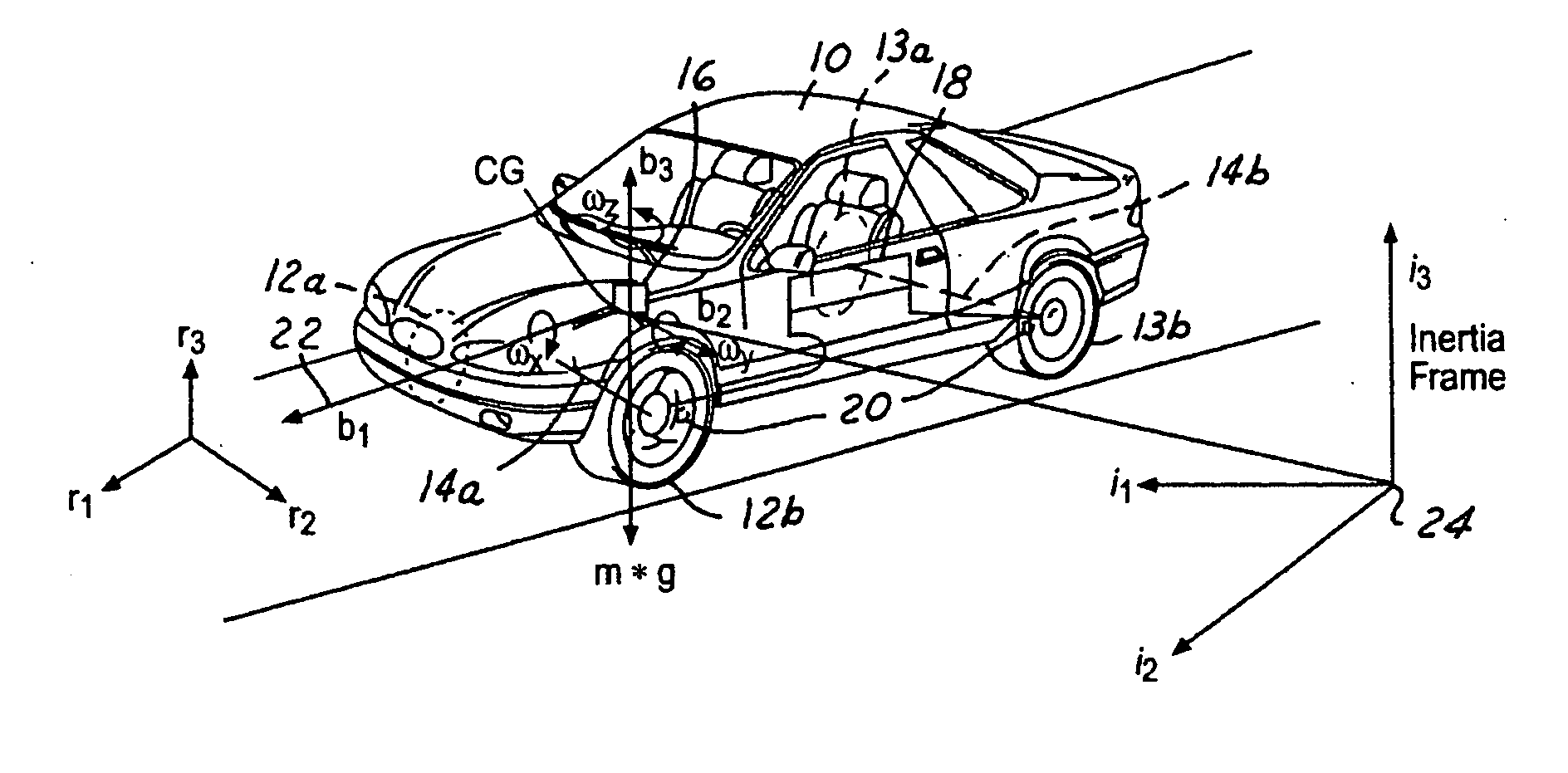

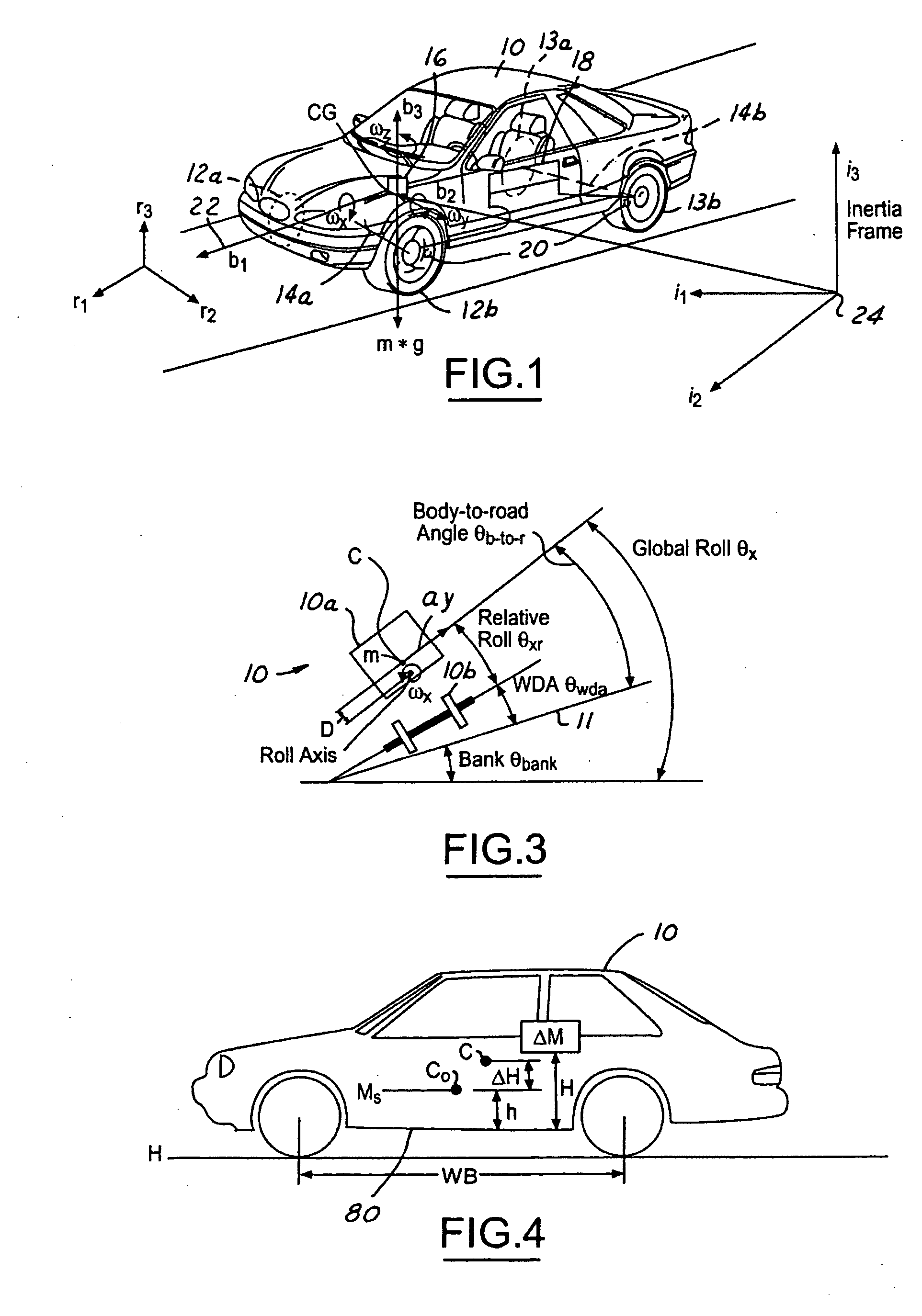

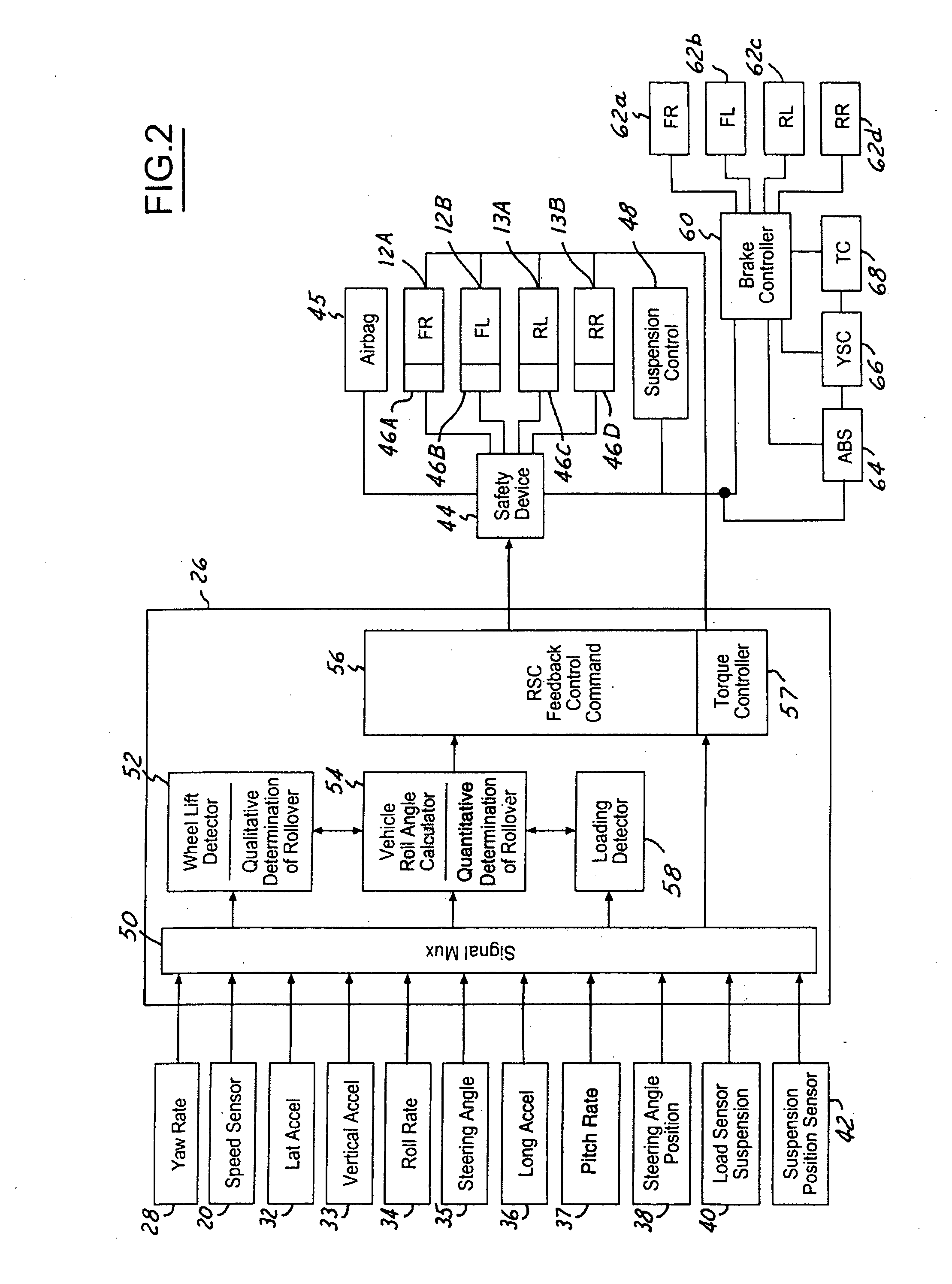

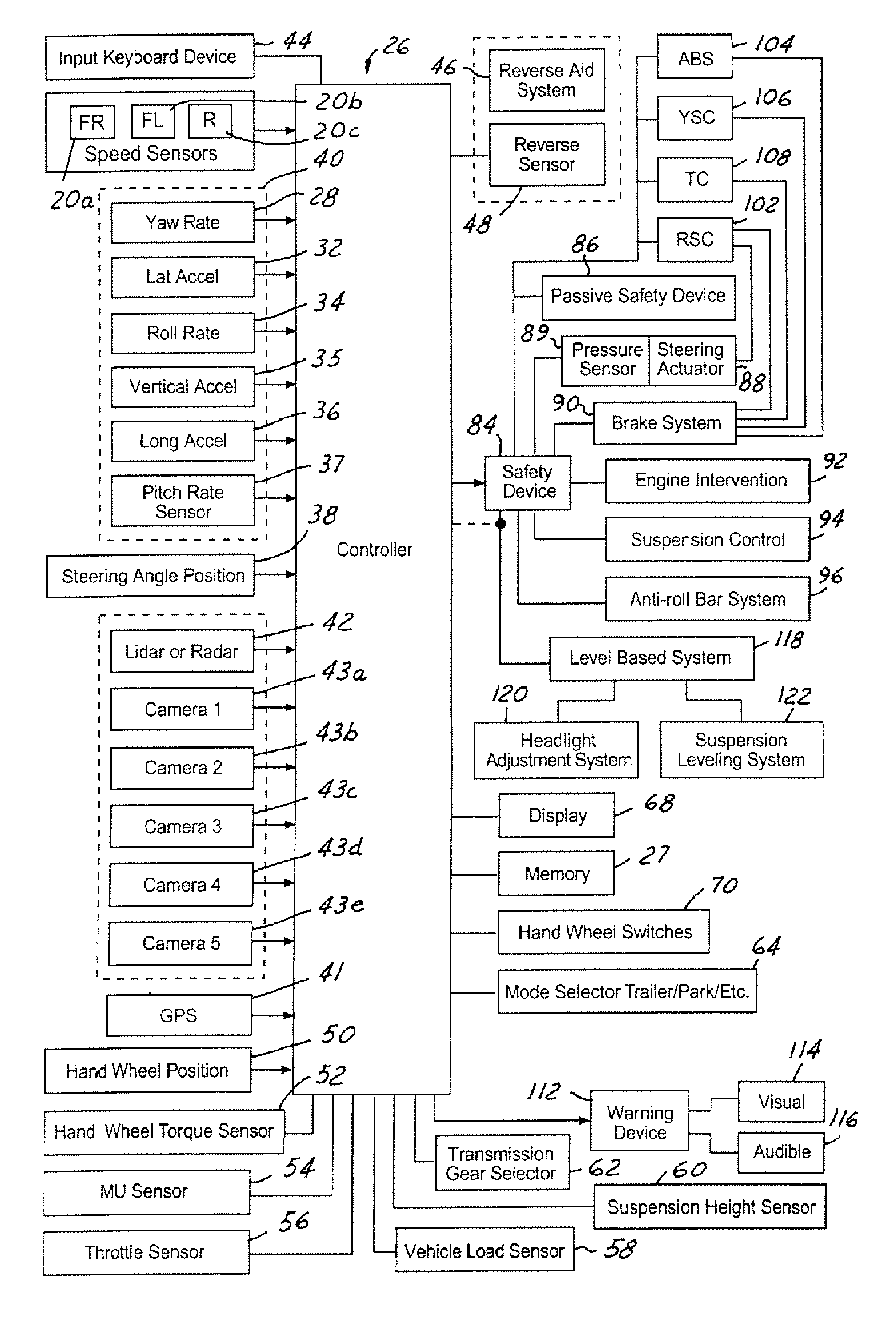

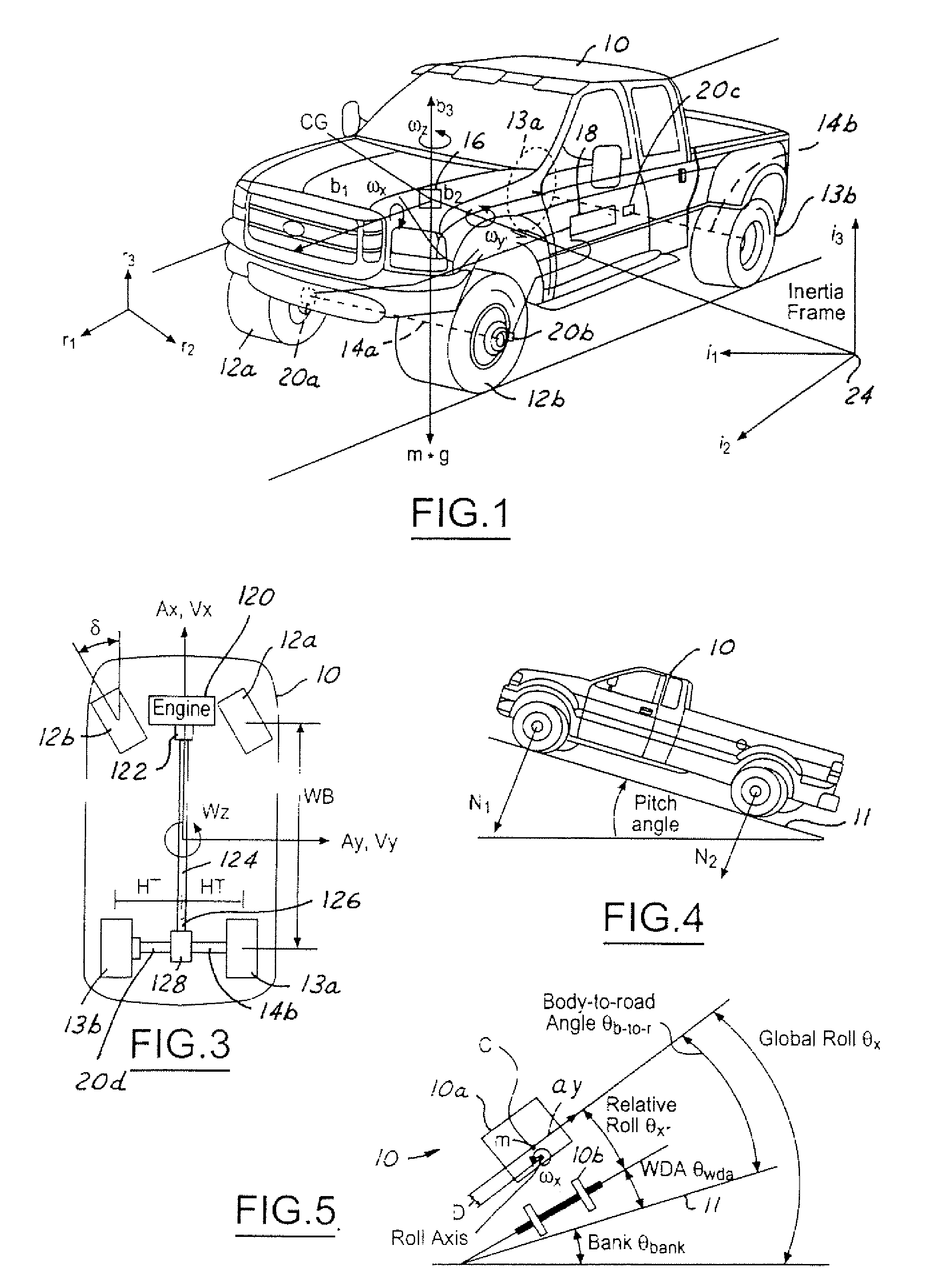

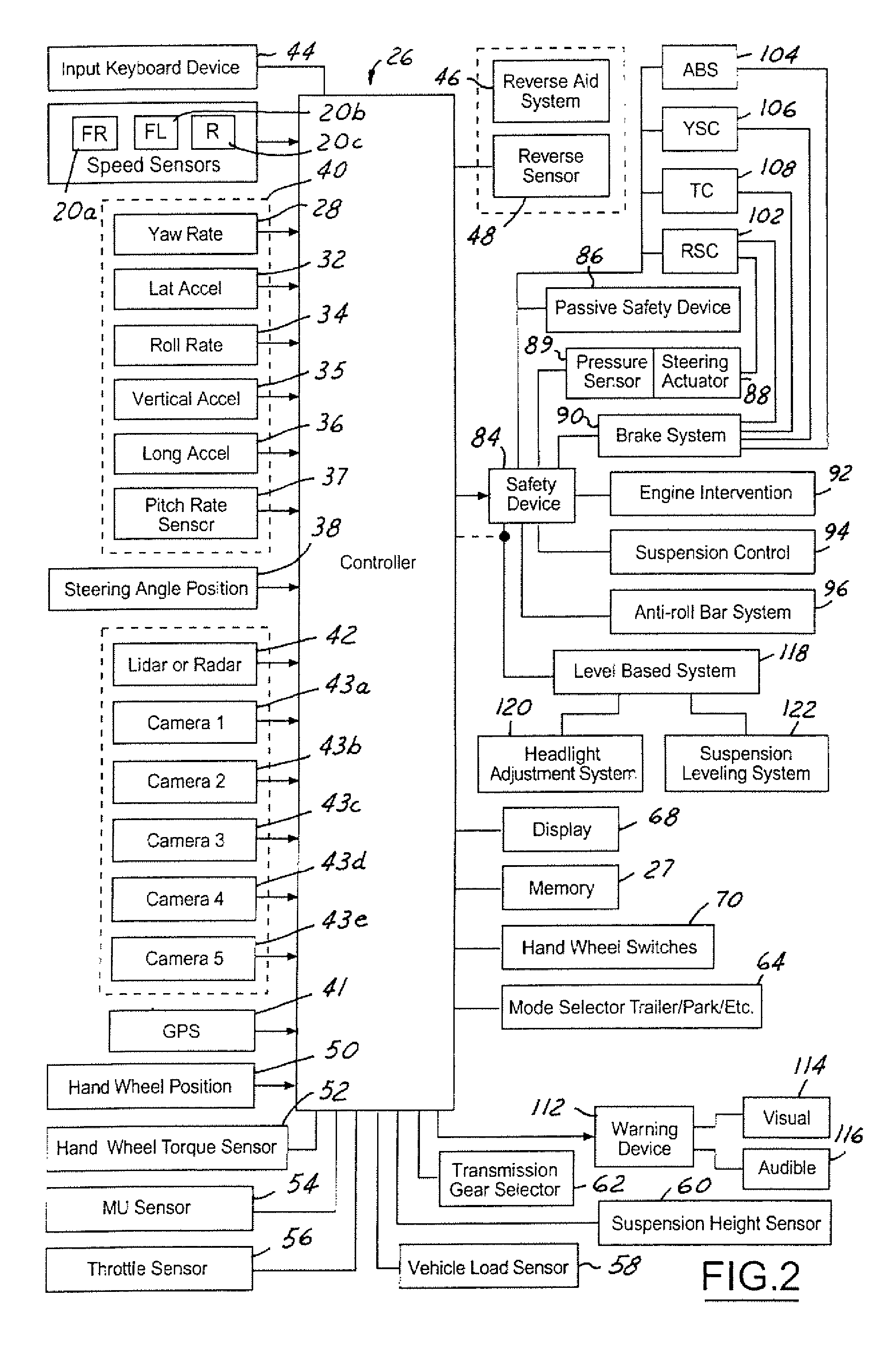

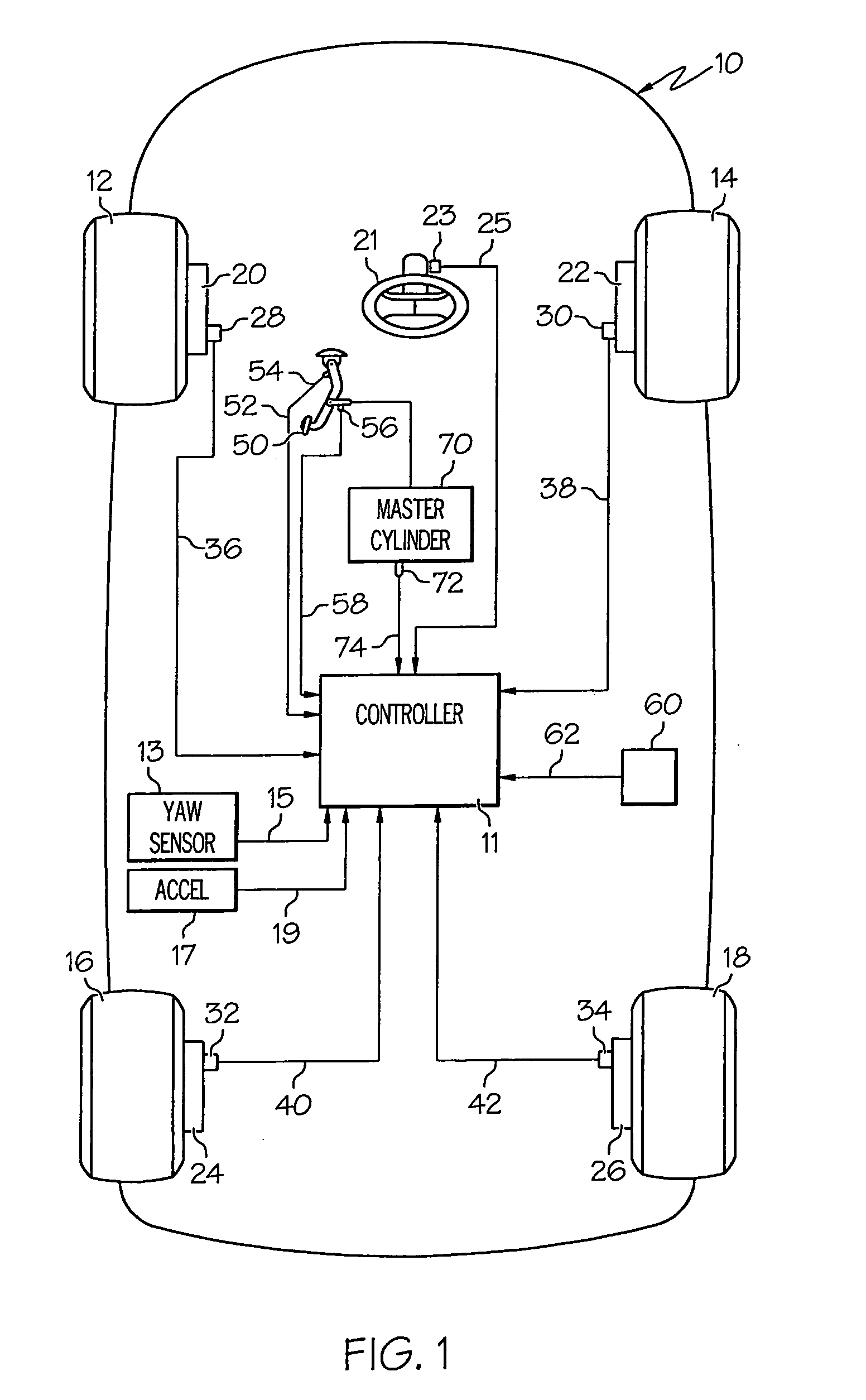

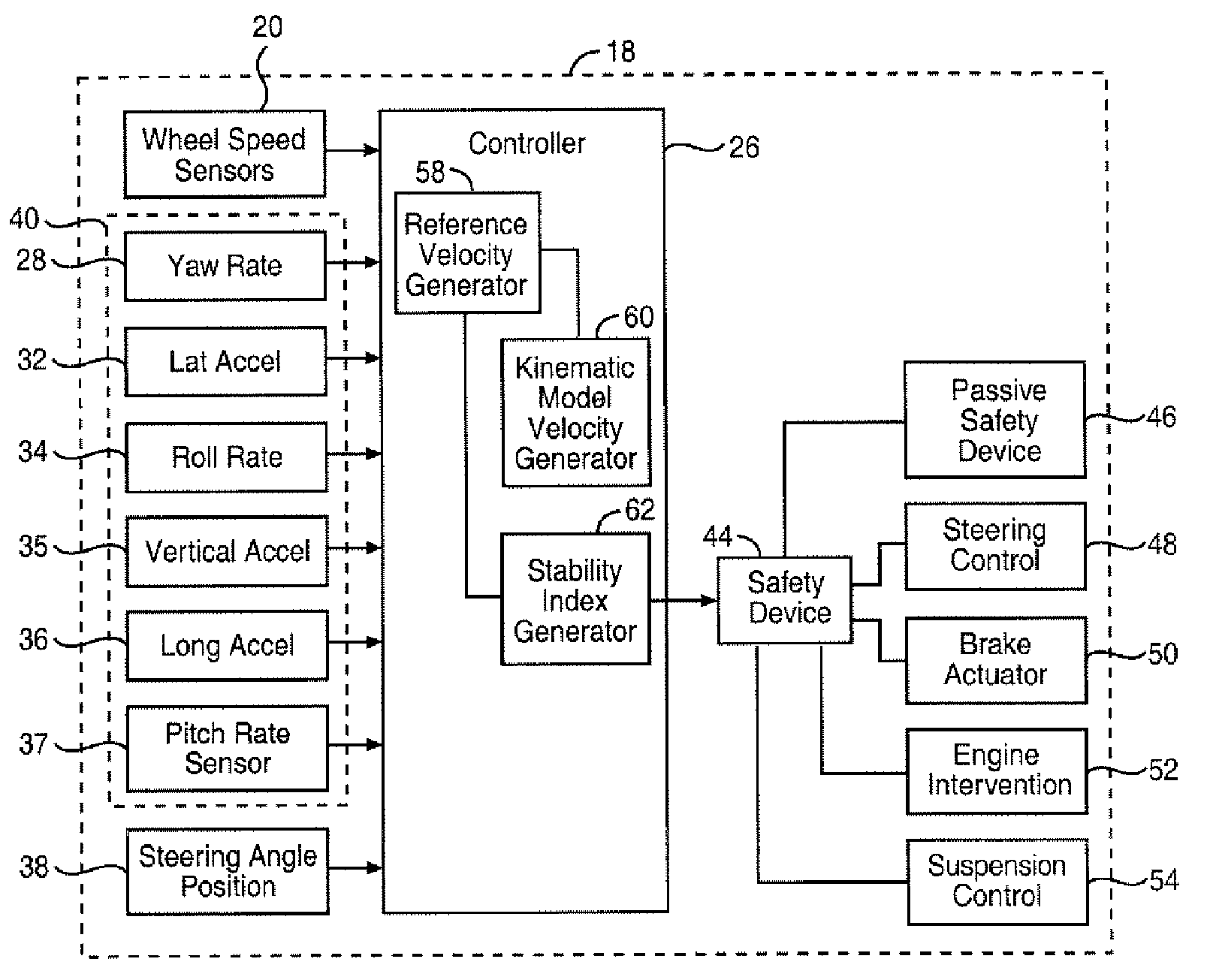

System and method for determining desired yaw rate and lateral velocity for use in a vehicle dynamic control system

ActiveUS20050273240A1Sure easyVehicle body stabilisationAnalogue computers for trafficVehicle dynamicsControl system

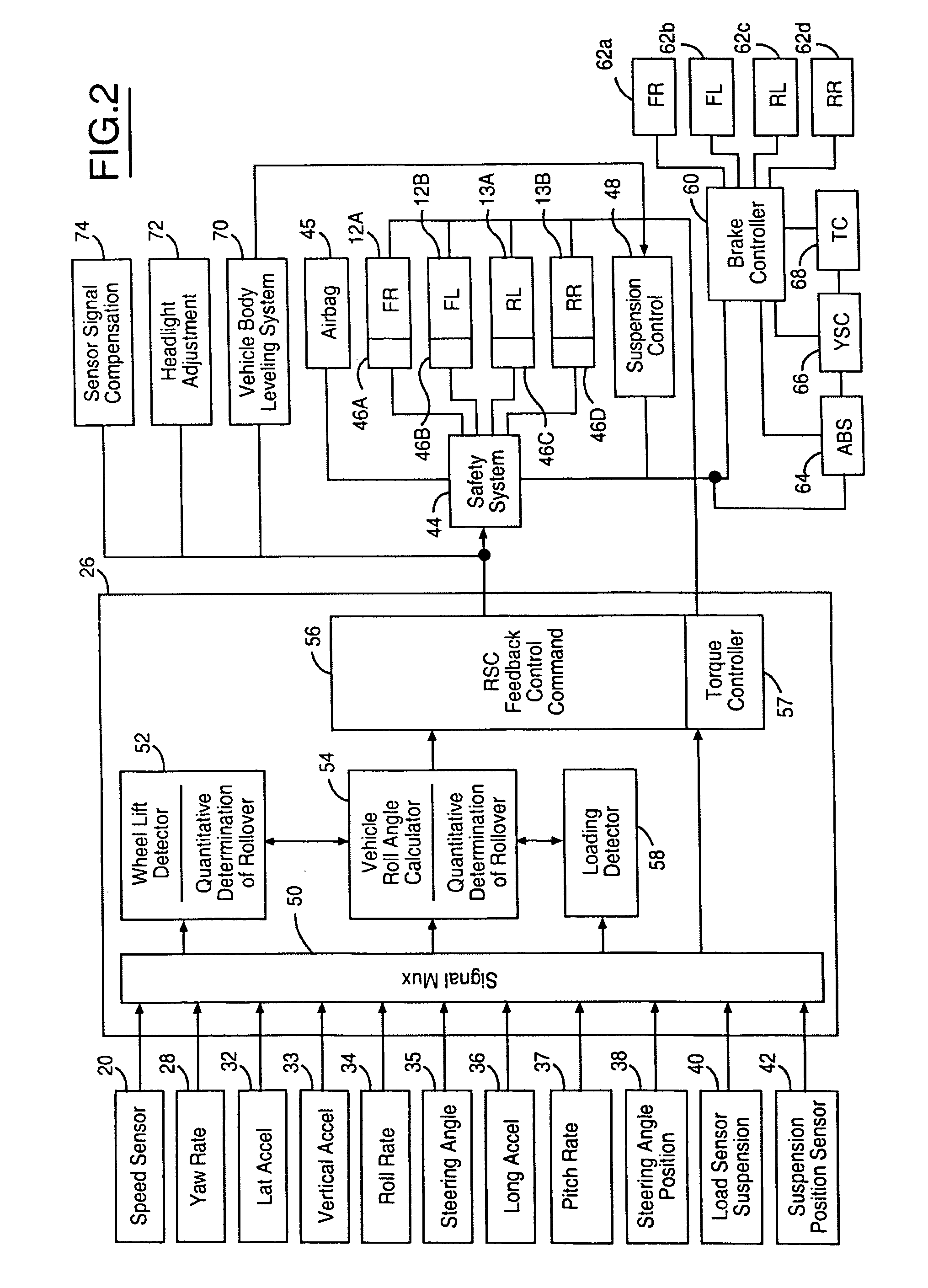

A control system (18) and method for an automotive vehicle (10) includes a lateral acceleration sensor (32) generating a lateral acceleration signal, a yaw rate sensor (28) generating a yaw rate signal and a safety system. A safety system (44) and the sensors are coupled to a controller (26). The controller (26) determines a front lateral tire force and a rear lateral tire force from the vehicle yaw rate signal and the vehicle lateral acceleration signal, determines a calculated lateral velocity from the front lateral tire force, the rear lateral tire force and a bank angle, determines a calculated yaw rate from the front lateral tire force and the rear lateral tire force, the controller controlling a safety system in response to the calculated lateral velocity and the calculated yaw rate.

Owner:FORD GLOBAL TECH LLC

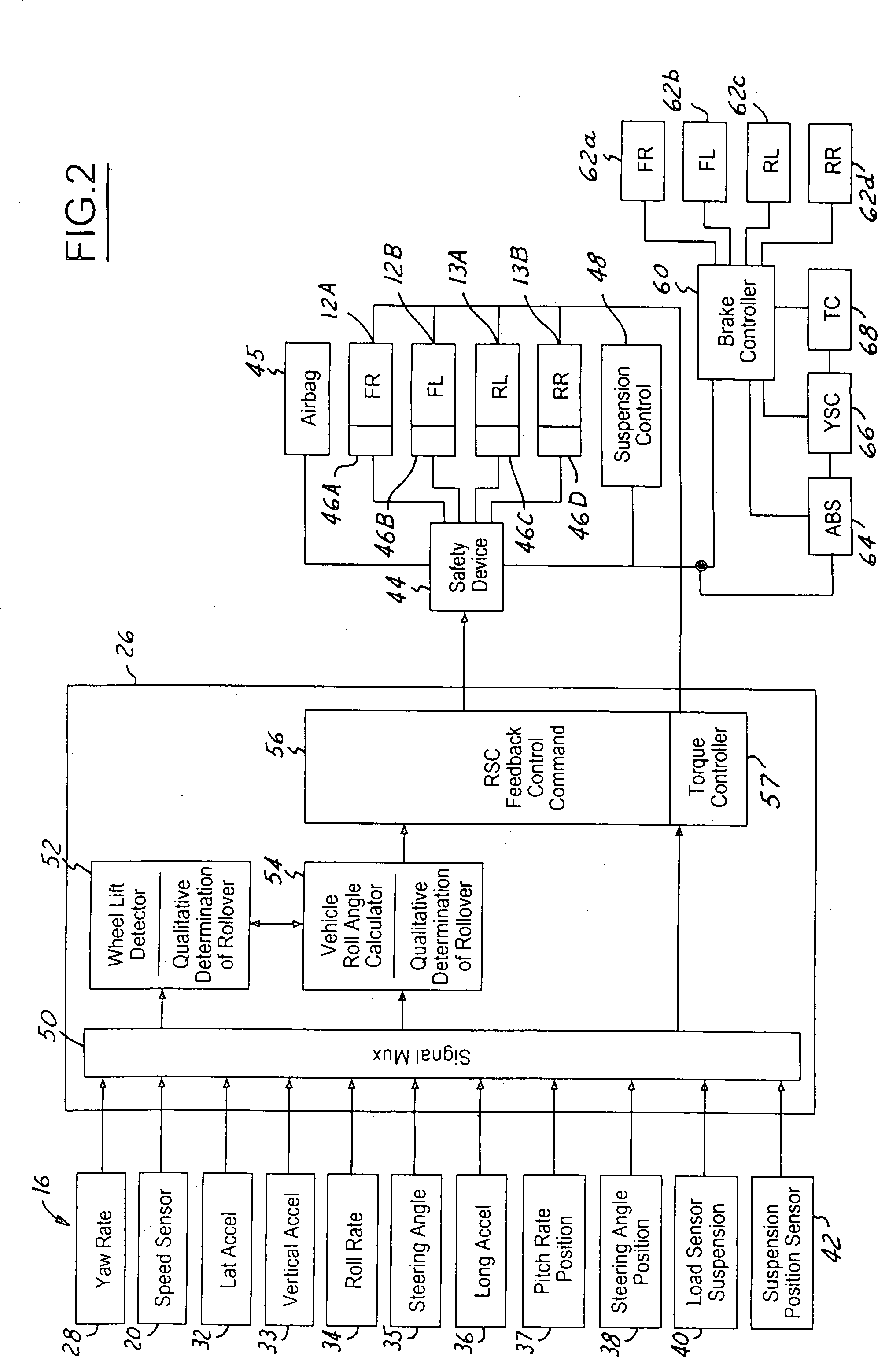

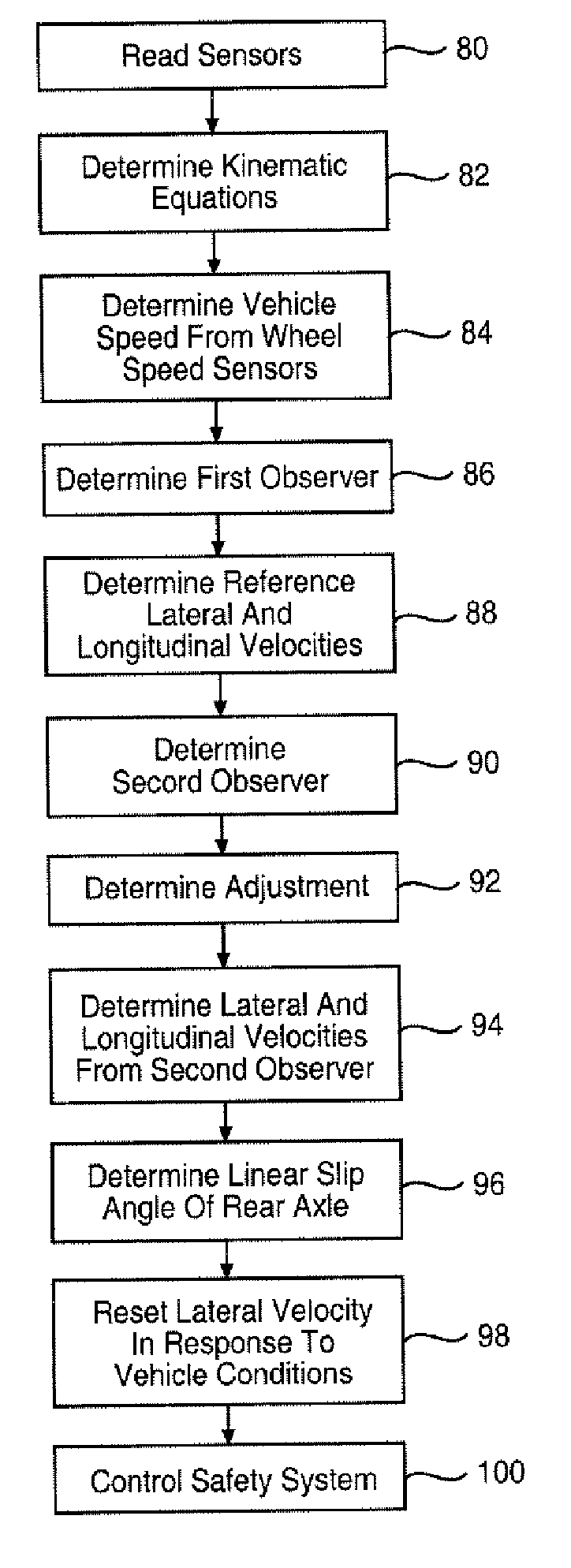

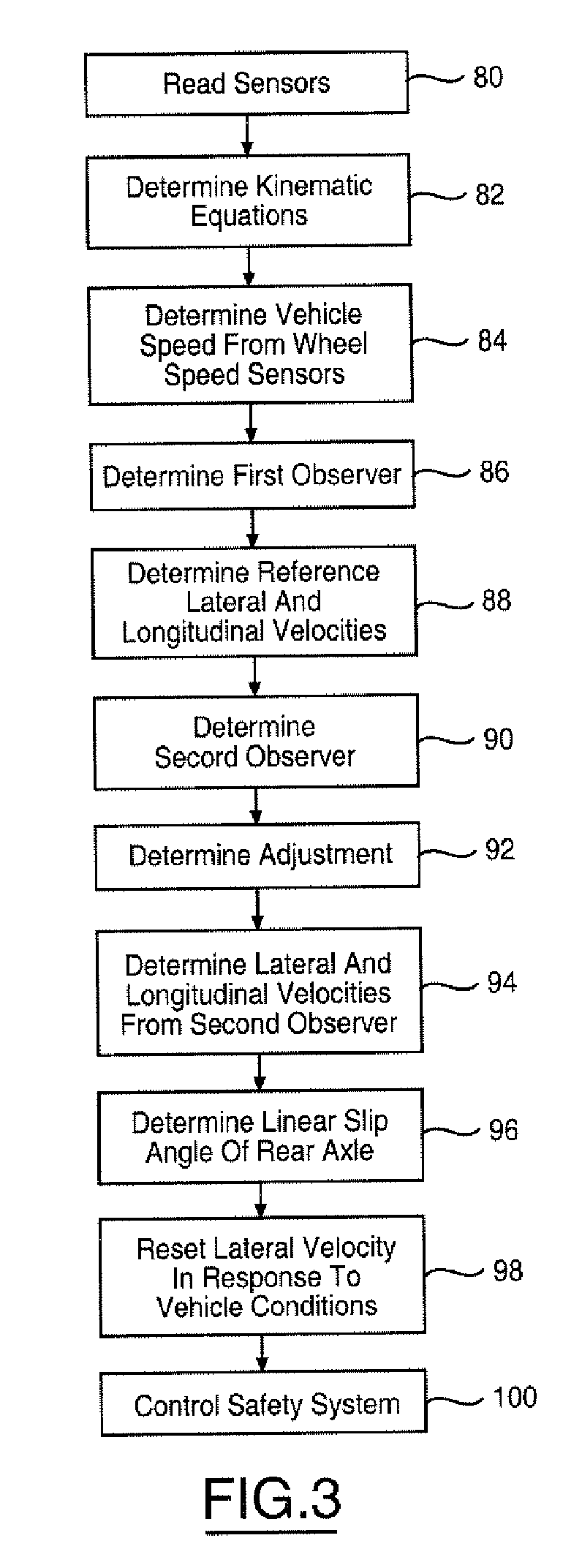

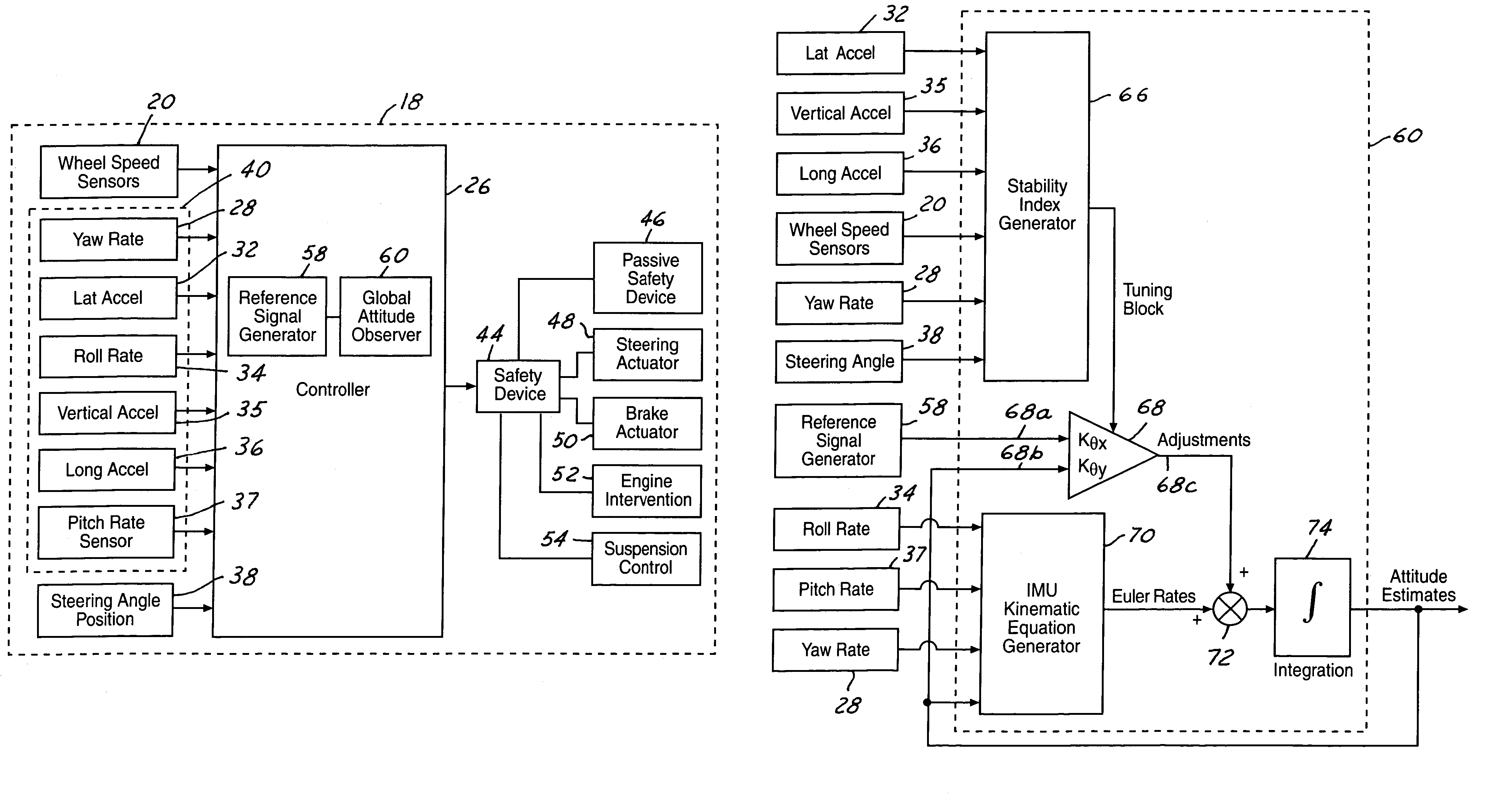

Lateral and longitudinal velocity determination for an automotive vehicle

InactiveUS20070005212A1Low costAccurate estimateAnalogue computers for trafficPedestrian/occupant safety arrangementStability indexWheel speed sensor

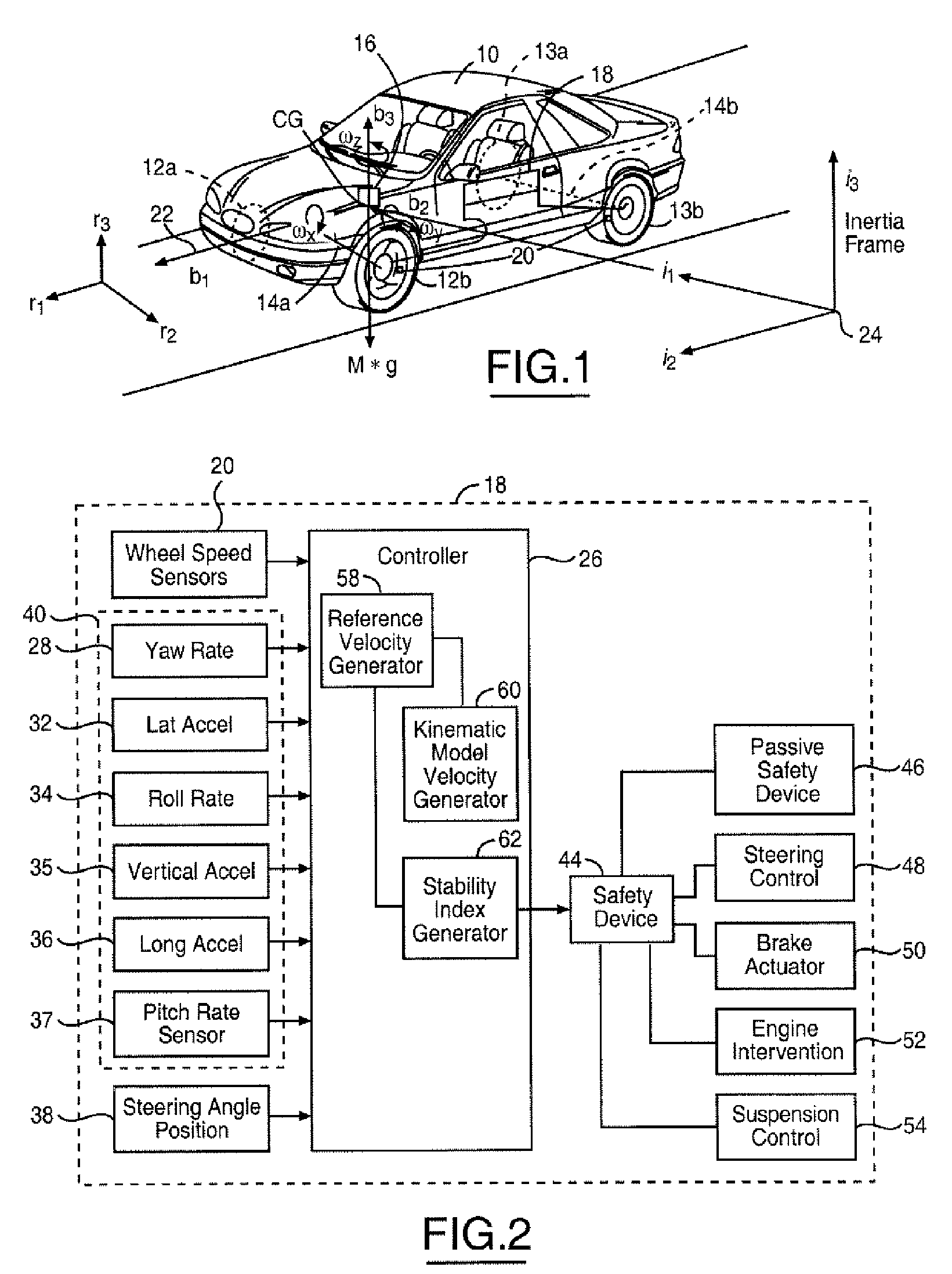

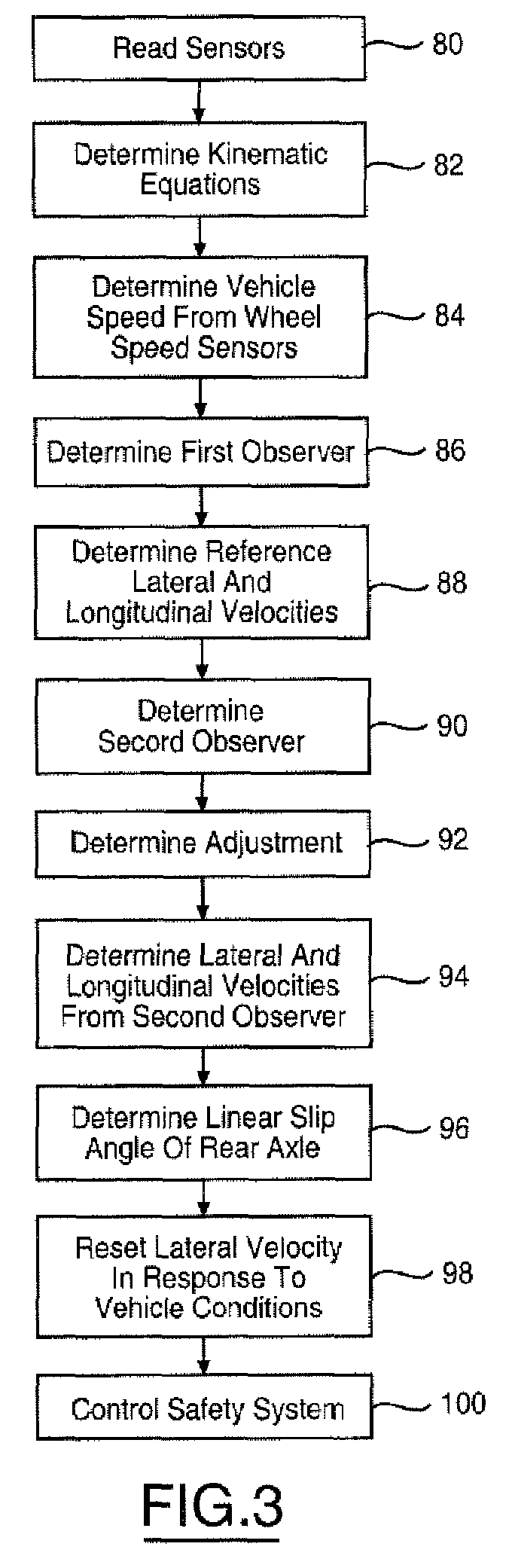

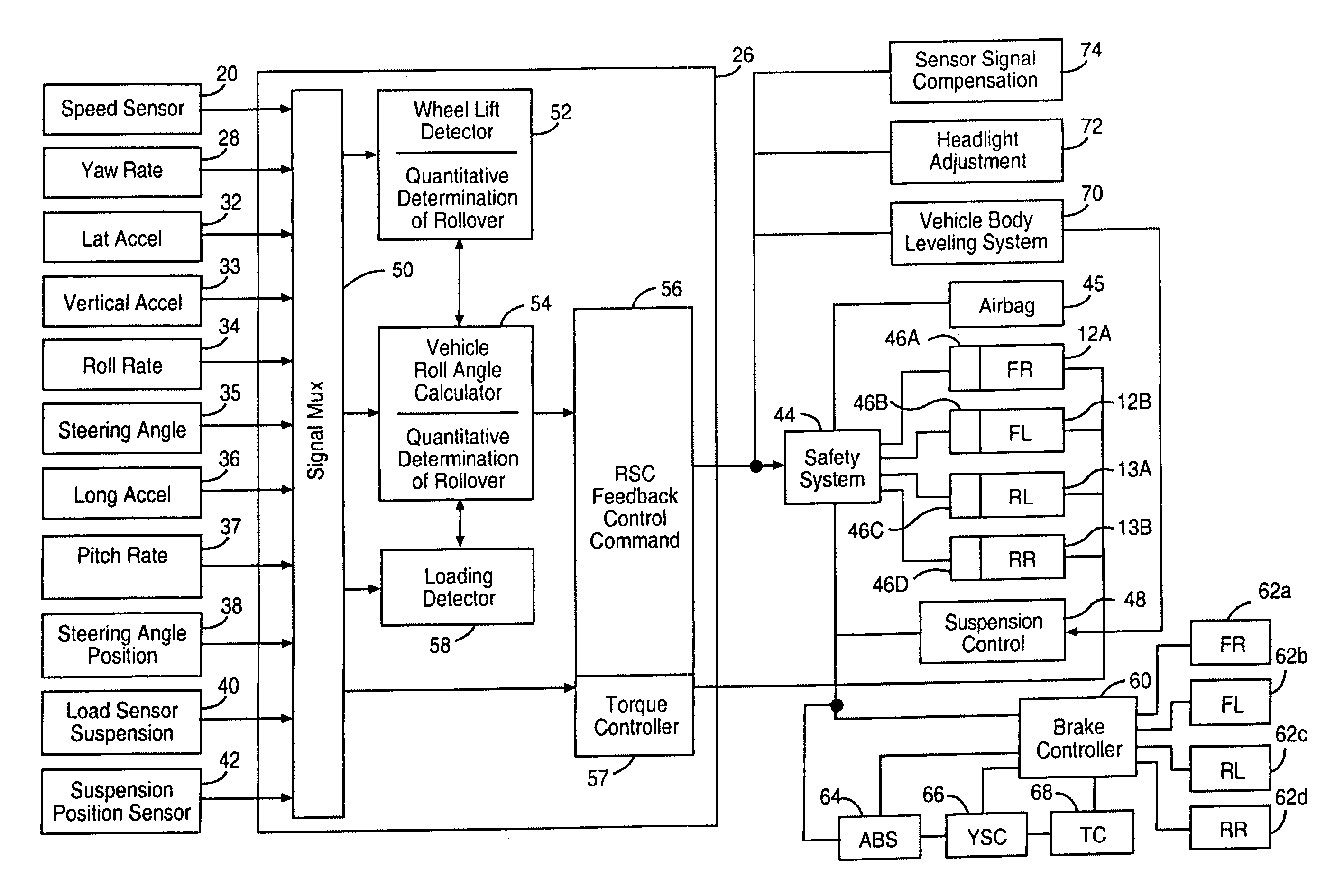

A system (18) for controlling a safety system (44) of an automotive vehicle (10) includes a longitudinal acceleration sensor (36), a vehicle speed sensor (20), a lateral acceleration sensor (32), a yaw rate sensor, and a controller (26). The controller (26) determines a stability index and provides a first observer that determines a reference longitudinal velocity in response to the longitudinal acceleration signal, the yaw rate signal, a pitch attitude and vehicle speed from wheel speed sensors. The controller (26) determines a reference lateral velocity in response to the lateral acceleration signal, the yaw rate signal, a roll attitude, a pitch attitude and vehicle speed from the wheel speed sensors. The controller provides a second observer that determines a second longitudinal velocity in response to the longitudinal acceleration signal, the yaw rate signal, a lateral velocity, the pitch attitude and a first adjustment based on the longitudinal reference velocity. The controller determines a second lateral velocity in response to the lateral acceleration signal, the yaw rate signal, a roll attitude, a pitch attitude and a second adjustment based on the lateral reference velocity. The controller determines an output lateral velocity and an output longitudinal velocity in response to the first observer, second observer and the stability index. The controller controls the safety system in response to the output lateral velocity and the output longitudinal velocity.

Owner:FORD GLOBAL TECH LLC

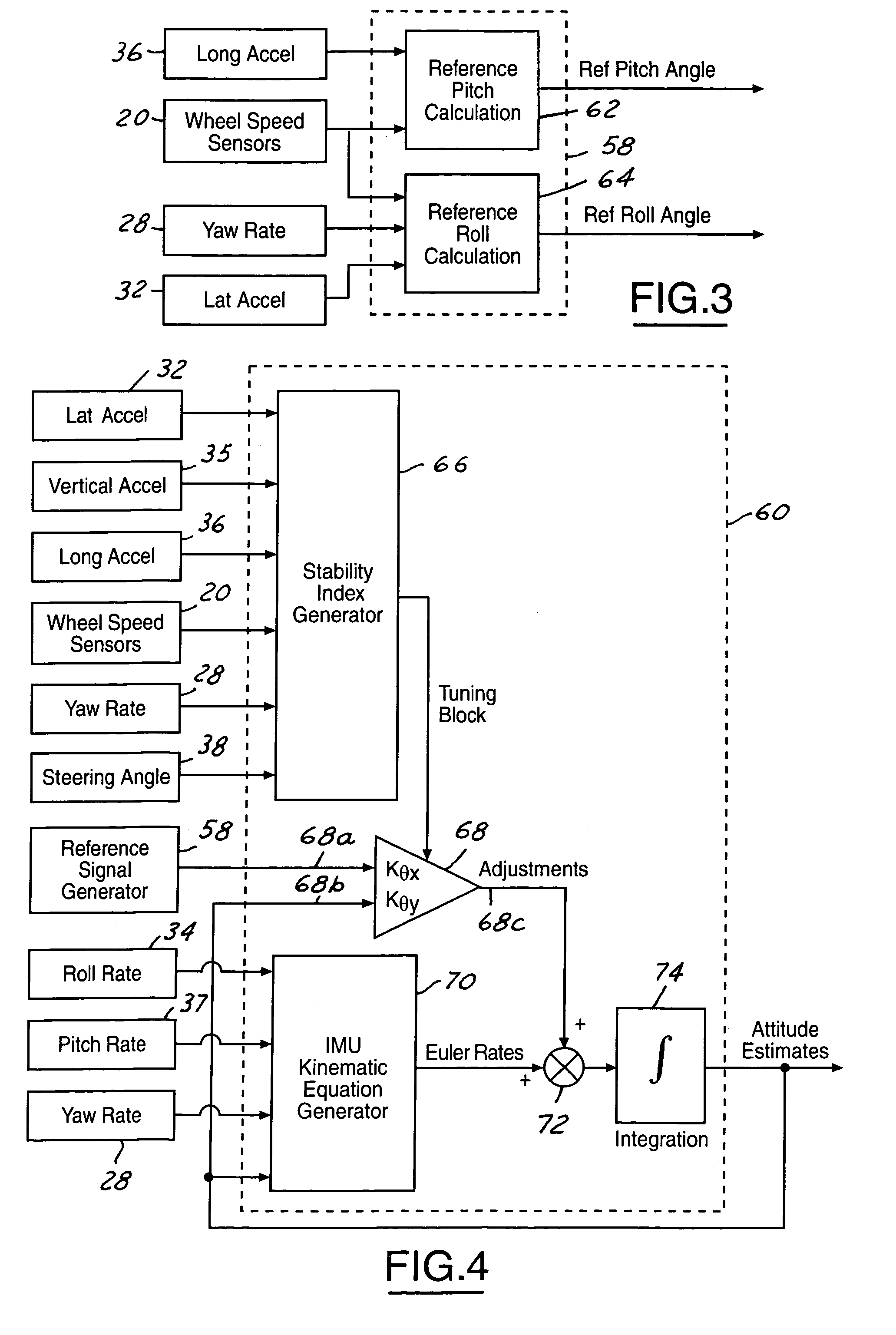

Attitude sensing system for an automotive vehicle relative to the road

InactiveUS7222007B2Accurate estimateImprove performanceDigital data processing detailsAnimal undercarriagesMobile vehicleMotorized vehicle

A system (18) for controlling a safety system (44) of an automotive vehicle (10) includes a longitudinal acceleration sensor (36), a vehicle speed sensor (20), a lateral acceleration sensor (32), a yaw rate sensor, and a controller (26). The controller (26) determines a reference pitch in response to the longitudinal acceleration signal and the vehicle speed signal and a reference roll angle in response to the yaw rate signal, the wheel speed signal and the lateral acceleration signal. The controller (26) determines a roll stability index and a pitch stability index. The controller (26) determines an adjusted pitch angle in response to the reference pitch angle and the pitch stability index and an adjusted roll angle in response to the reference roll angle and the roll stability index. The controller (26) controls the safety system (44) in response to the adjusted roll angle and the adjusted pitch angle.

Owner:FORD GLOBAL TECH LLC

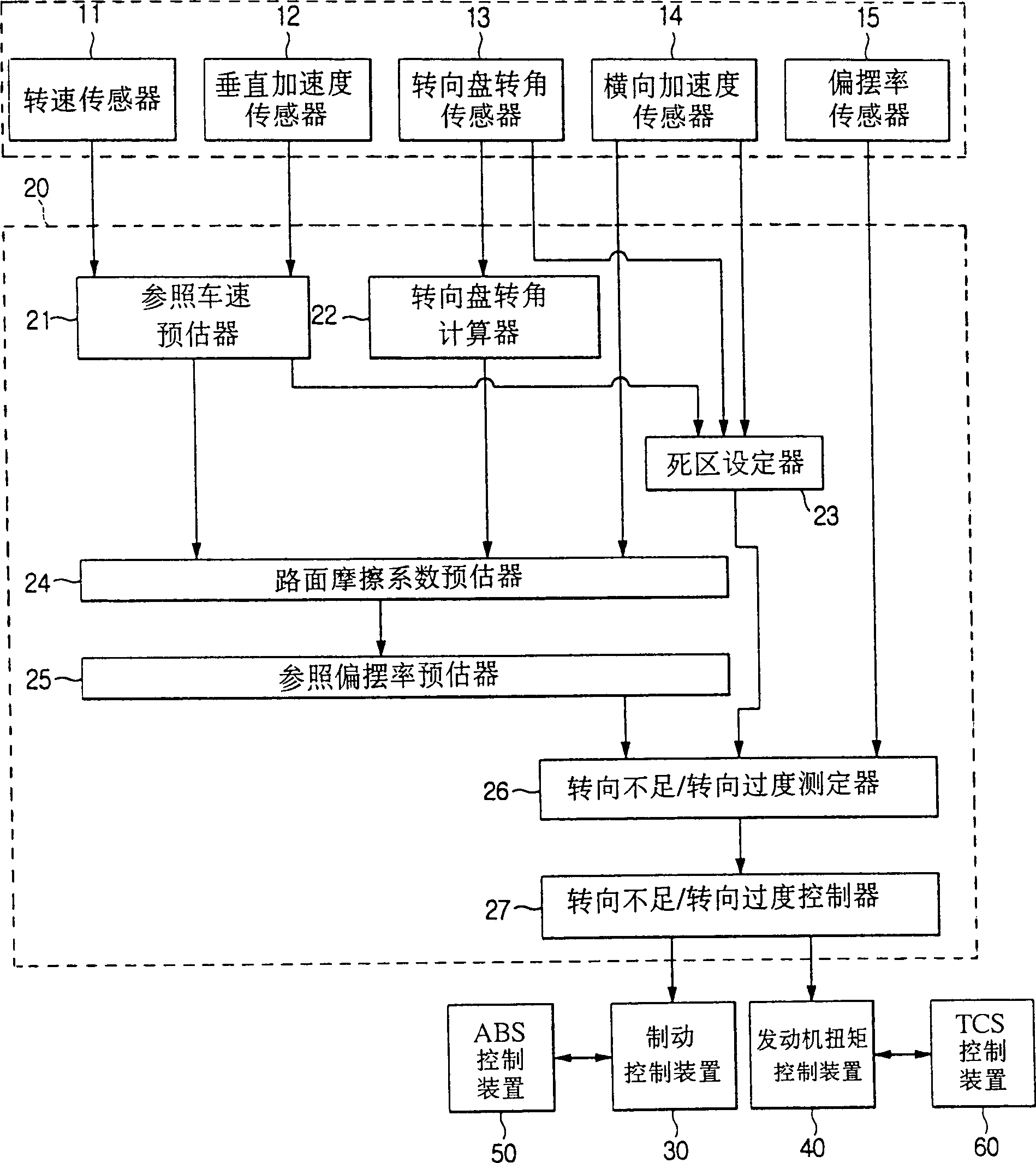

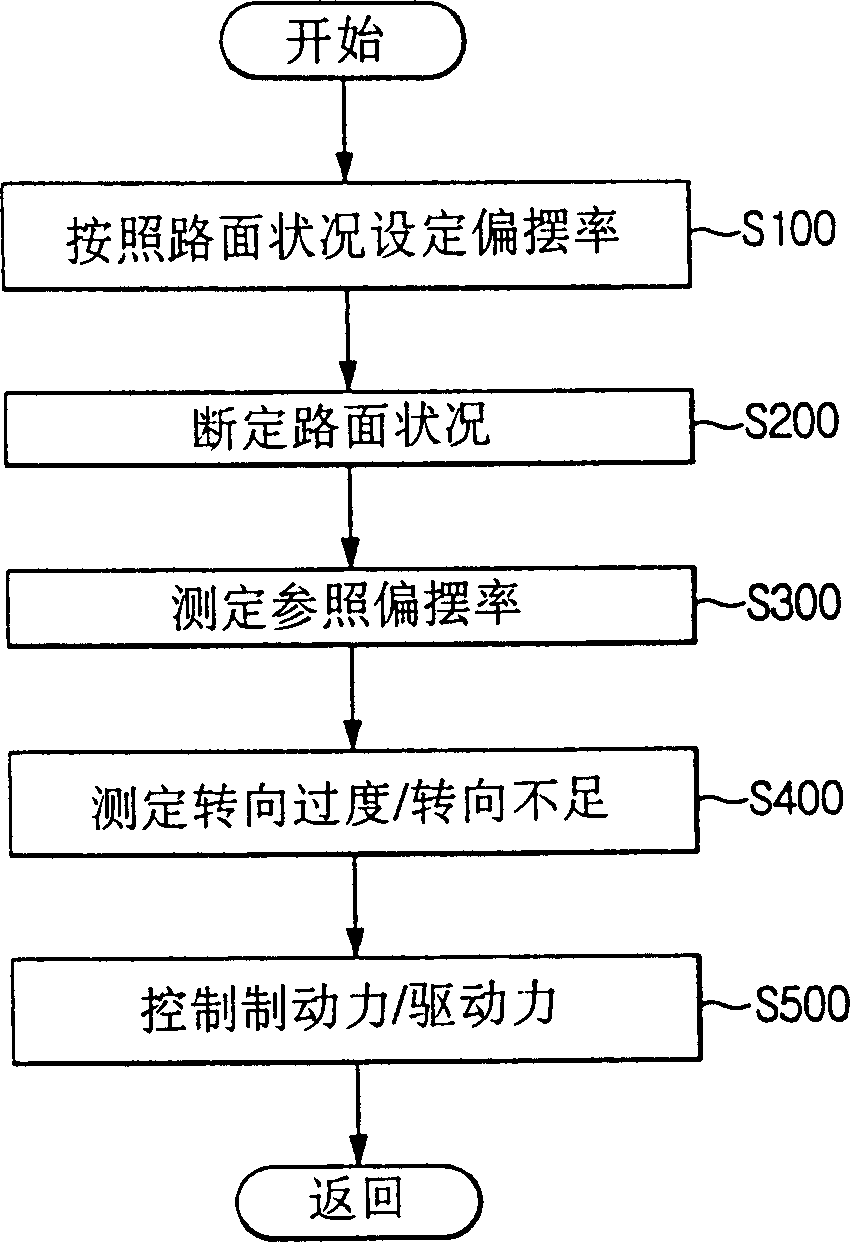

Control method for vehicle running stability

InactiveCN1439556AAchieve stabilityVehicle fittingsBrake control systemsSteering wheelUndersteer and oversteer

Disclosed herein is a method of controlling traveling stability of a vehicle. In the present invention, a driver's desired yaw rate is estimated using a steering wheel angle and a reference speed of the vehicle while turning. The condition of a road surface where the vehicle is traveling on is judged by comparing lateral acceleration of the vehicle, estimated using the estimated yaw rate and a reference vehicle speed, with lateral acceleration actually measured by a lateral acceleration sensor. A driver's desired reference yaw rate is determined according to the judged road surface condition. It is determined whether a vehicle is understeered or oversteered by comparing the determined reference yaw rate with an actual yaw rate measured by a yaw rate sensor. According to the determined result, braking force and driving force of the vehicle are controlled, thus obtaining excellent vehicle stability.

Owner:HL MANDO CORP +1

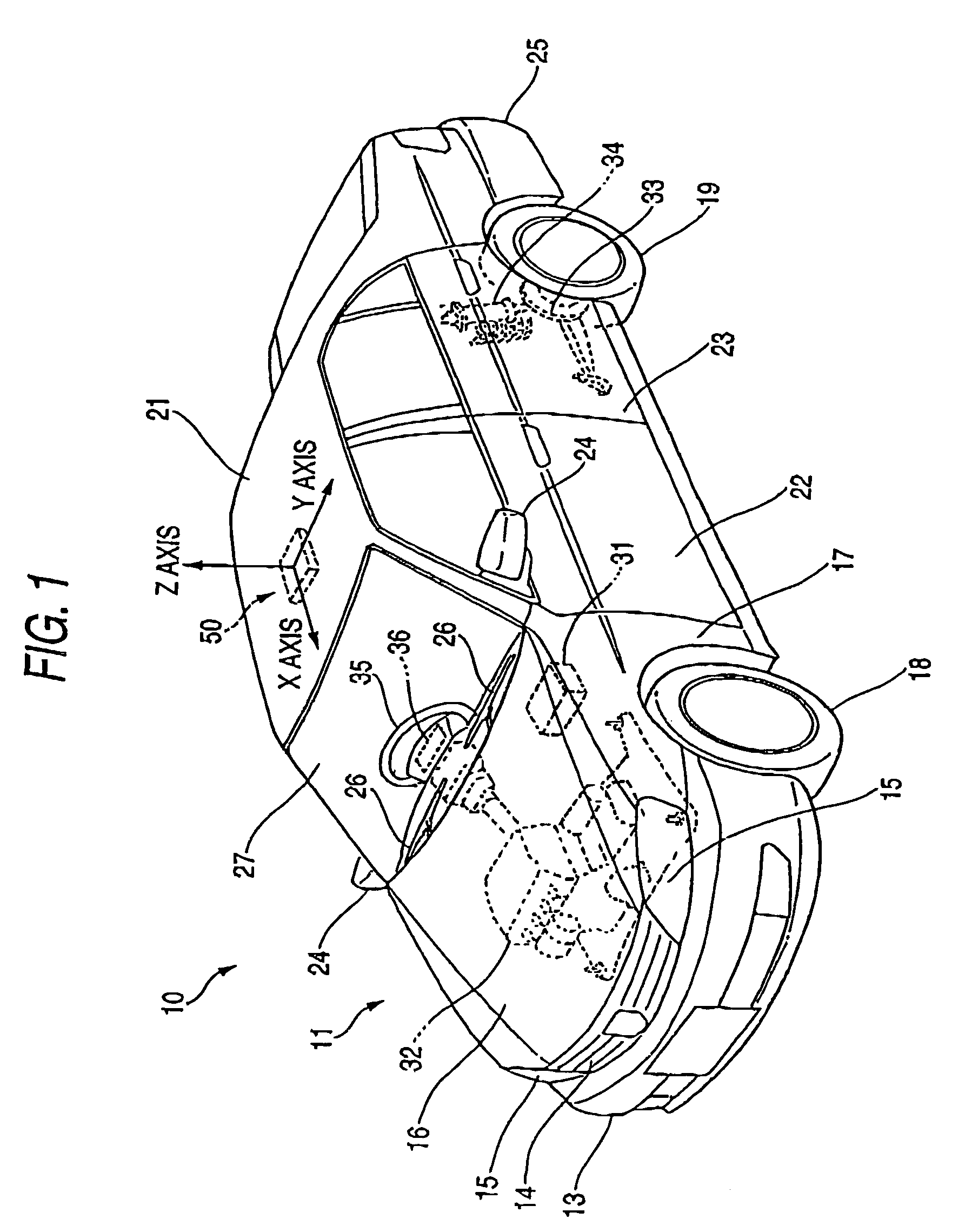

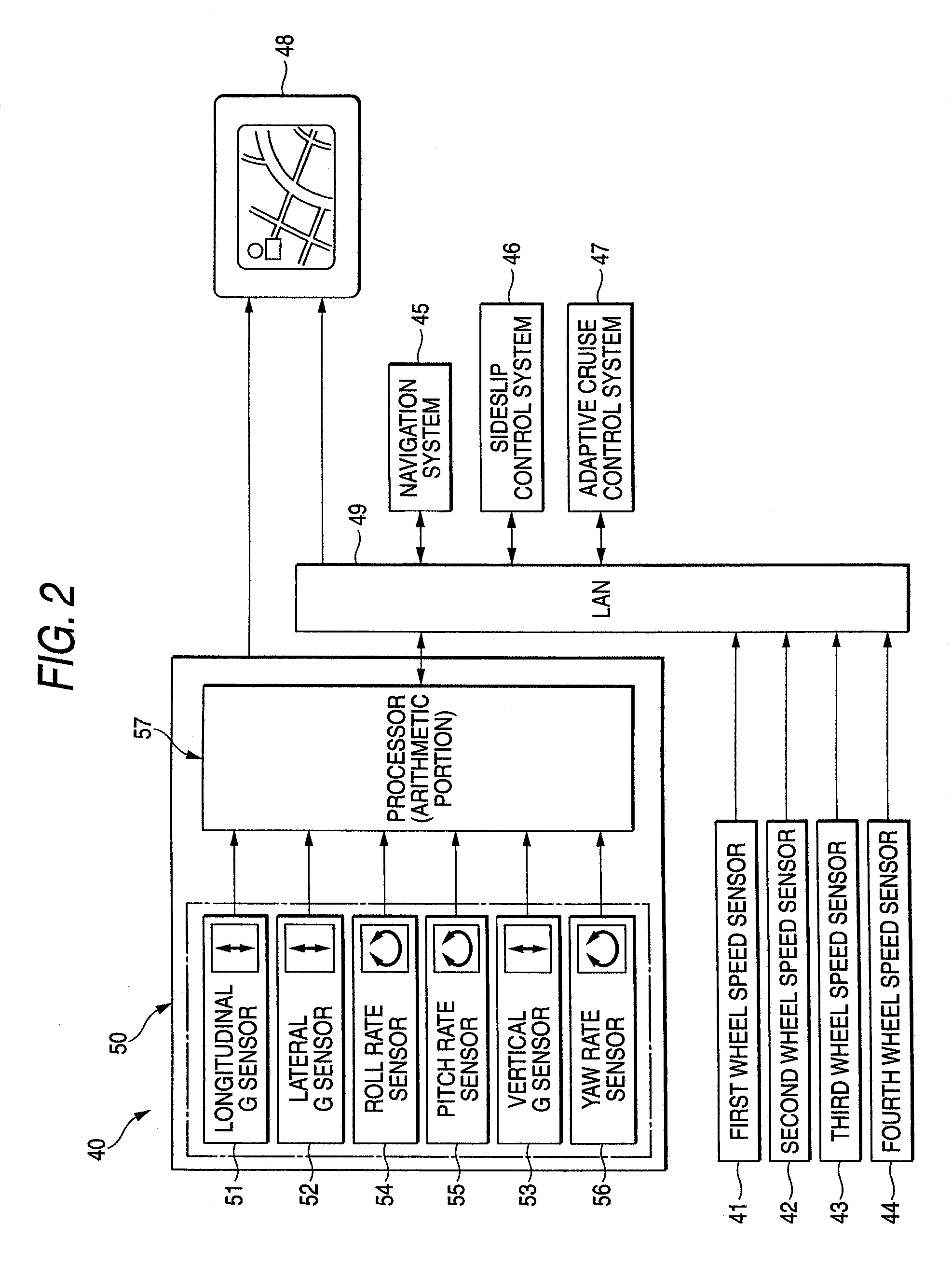

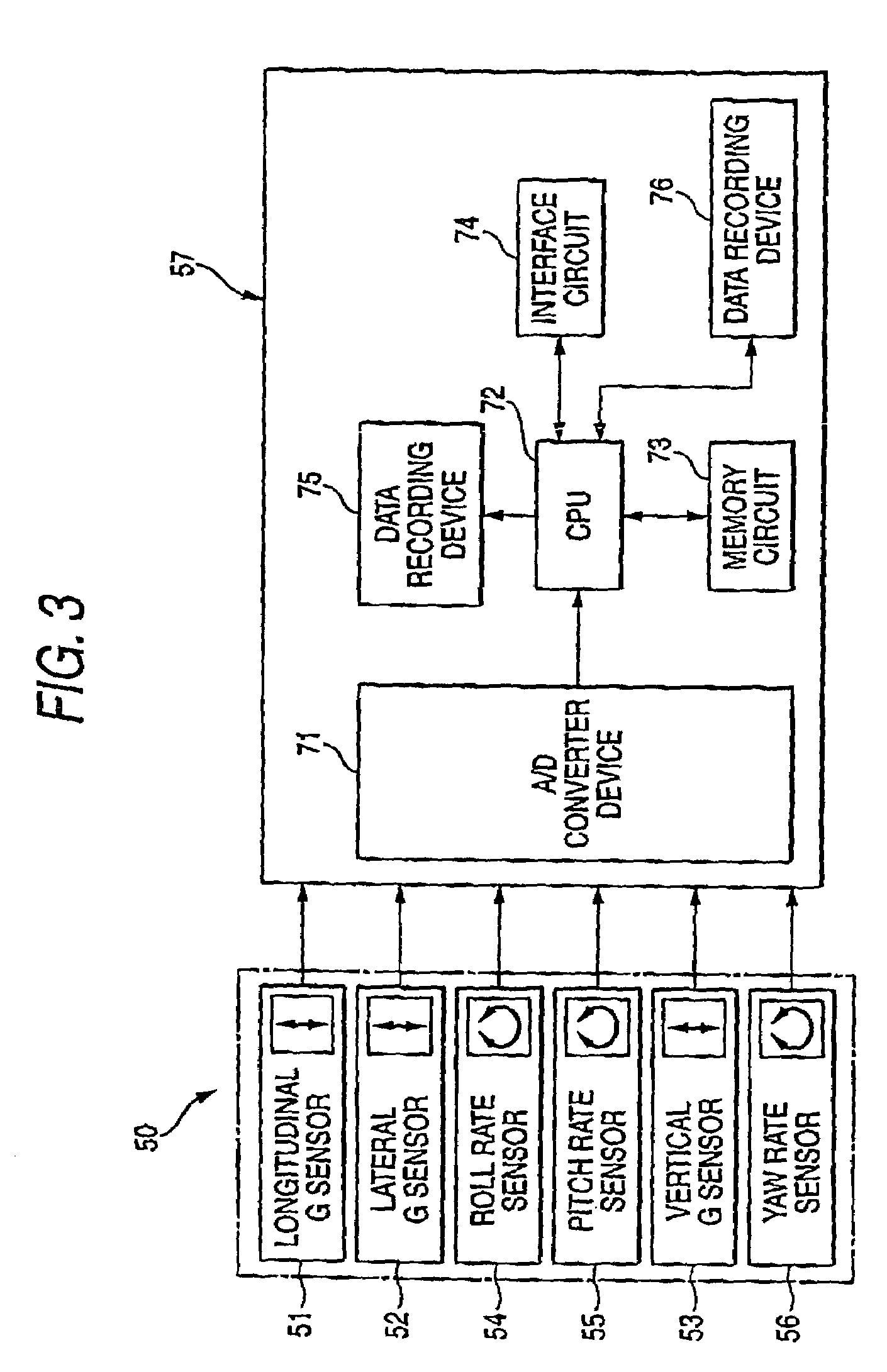

Acceleration/angular velocity sensor unit

InactiveUS7325454B2High bulk densityReduce the packing densityAcceleration measurement using interia forcesBrake control systemsRoll rateAngular velocity

A longitudinal G sensor 51 and a roll rate sensor 54 are mounted onto a back surface 61b of a substrate 61 in parallel with an X-axis and a lateral G sensor 52 and a pitch rate sensor 55 are mounted thereon in parallel with a Y-axis, the longitudinal G sensor 51 and the lateral G sensor 52 are positioned thereon in close vicinity to each other, and the roll rate sensor 54 and the pitch rate sensor 55 are positioned thereon in close vicinity to each other, while a vertical G sensor 53 and a yaw rate sensor 56 are mounted onto a surface 61a of the substrate 61 in orthogonal to a Z-axis and also the vertical G sensor 53 and the yaw rate sensor 56 are mounted thereon in close vicinity to each other.

Owner:HONDA MOTOR CO LTD

System and method for dynamically determining vehicle loading and vertical loading distance for use in a vehicle dynamic control system

InactiveUS20060085112A1Accurately determineDigital data processing detailsPedestrian/occupant safety arrangementVehicle dynamicsControl system

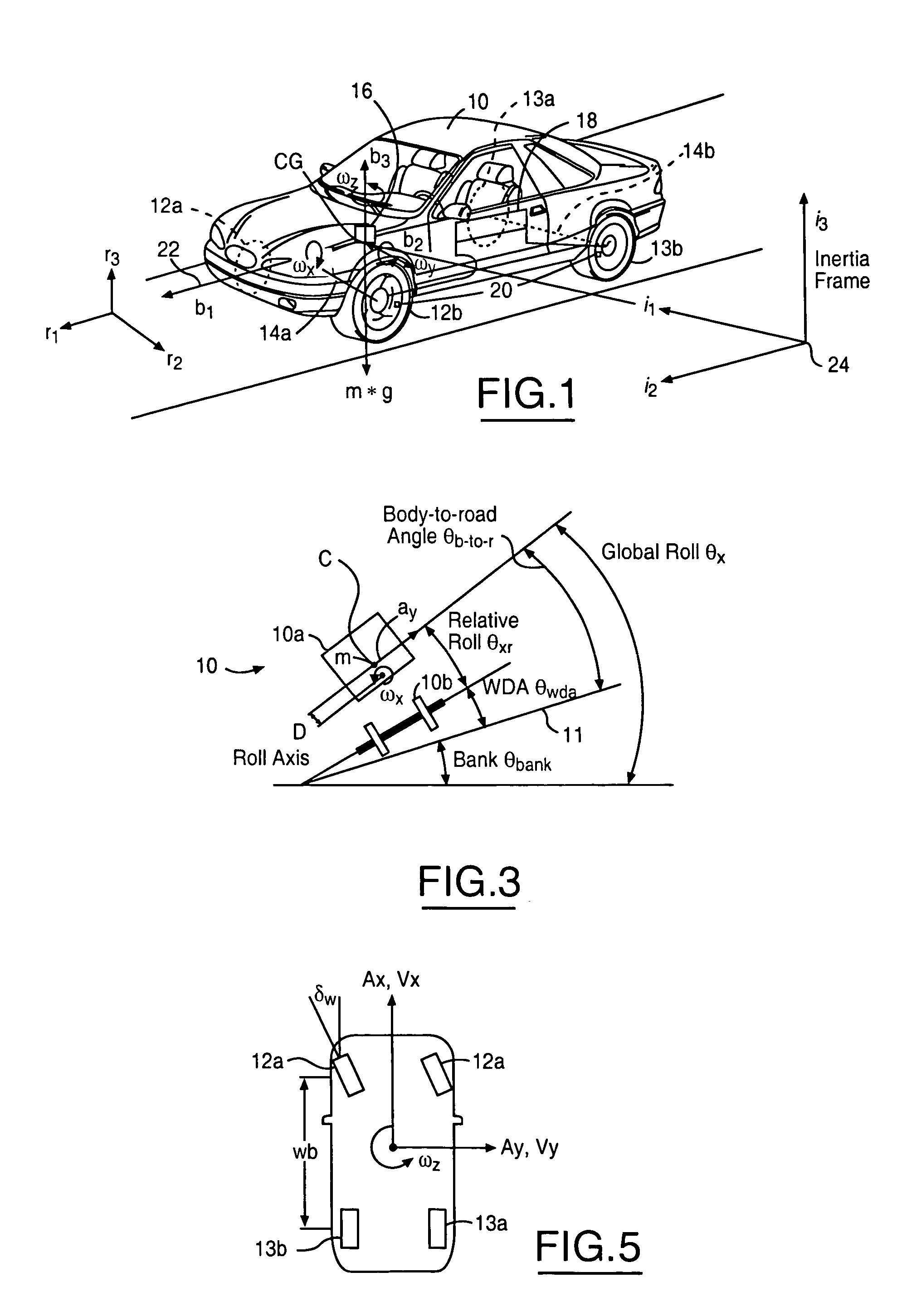

A control system (18) and method for an automotive vehicle (10) includes a roll rate sensor (34) generating a roll rate signal, a lateral acceleration sensor (32) generating a lateral acceleration signal, a longitudinal acceleration sensor (36) generating a longitudinal acceleration signal, and a yaw rate sensor (28) generating a yaw rate signal. A safety system (44) and the sensors are coupled to a controller. The controller (26) determines an added mass and the height of the added mass or a roll gradient, a roll acceleration coefficient and / or a roll rate parameter that take into account the added mass and height from the roll rate, the lateral acceleration, the longitudinal acceleration, and the yaw rate and controlling the safety system in response thereto.

Owner:FORD GLOBAL TECH LLC

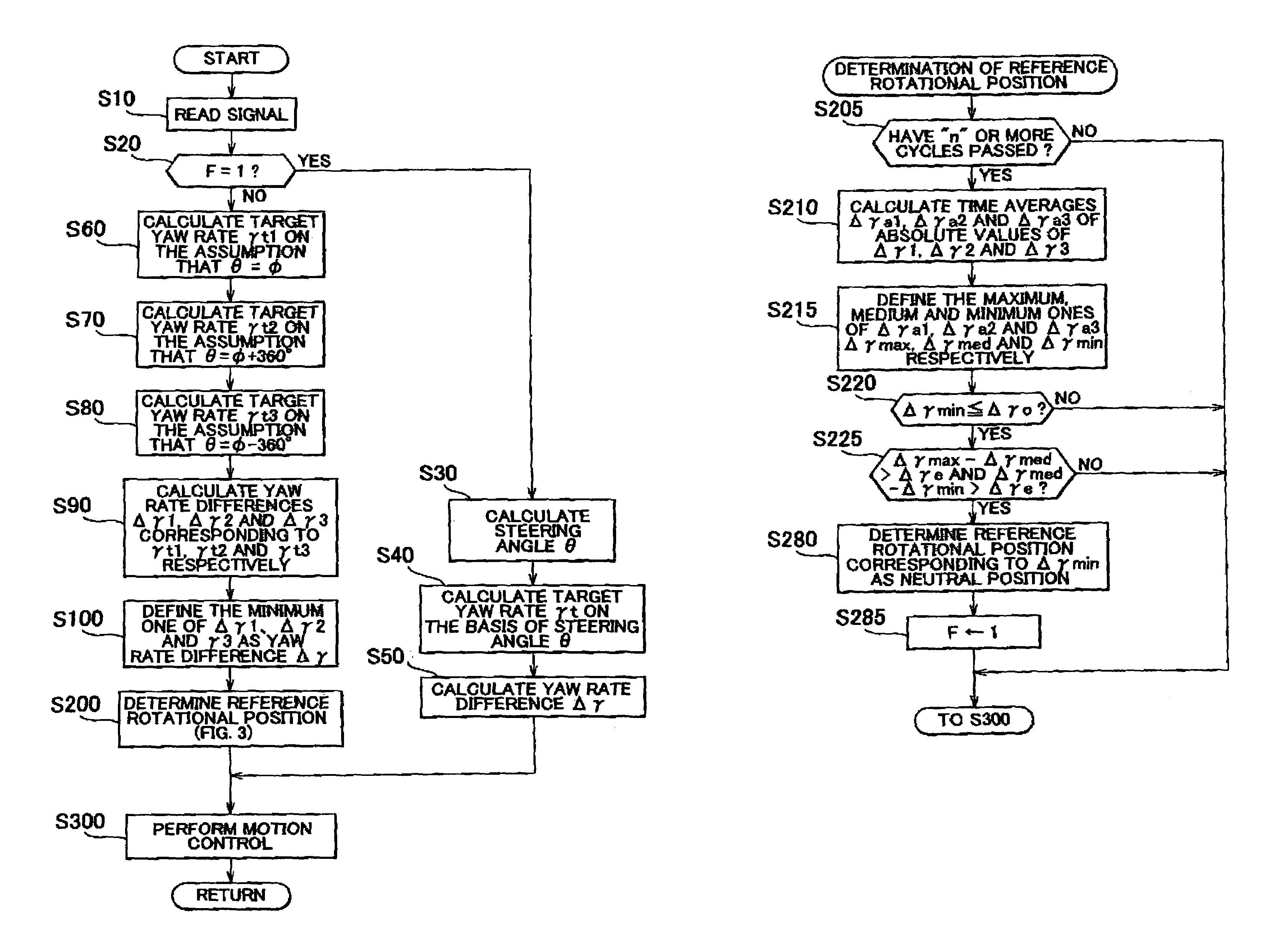

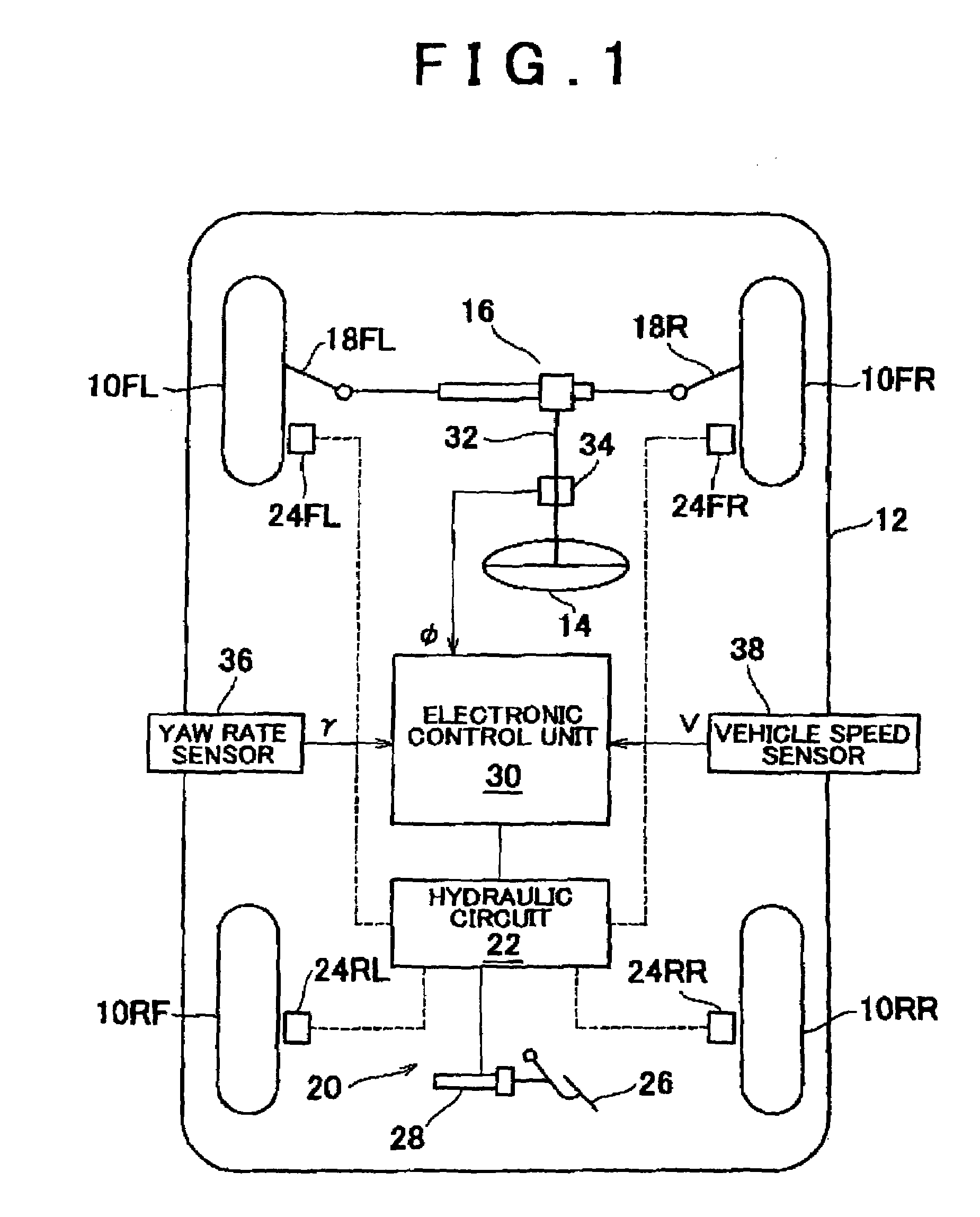

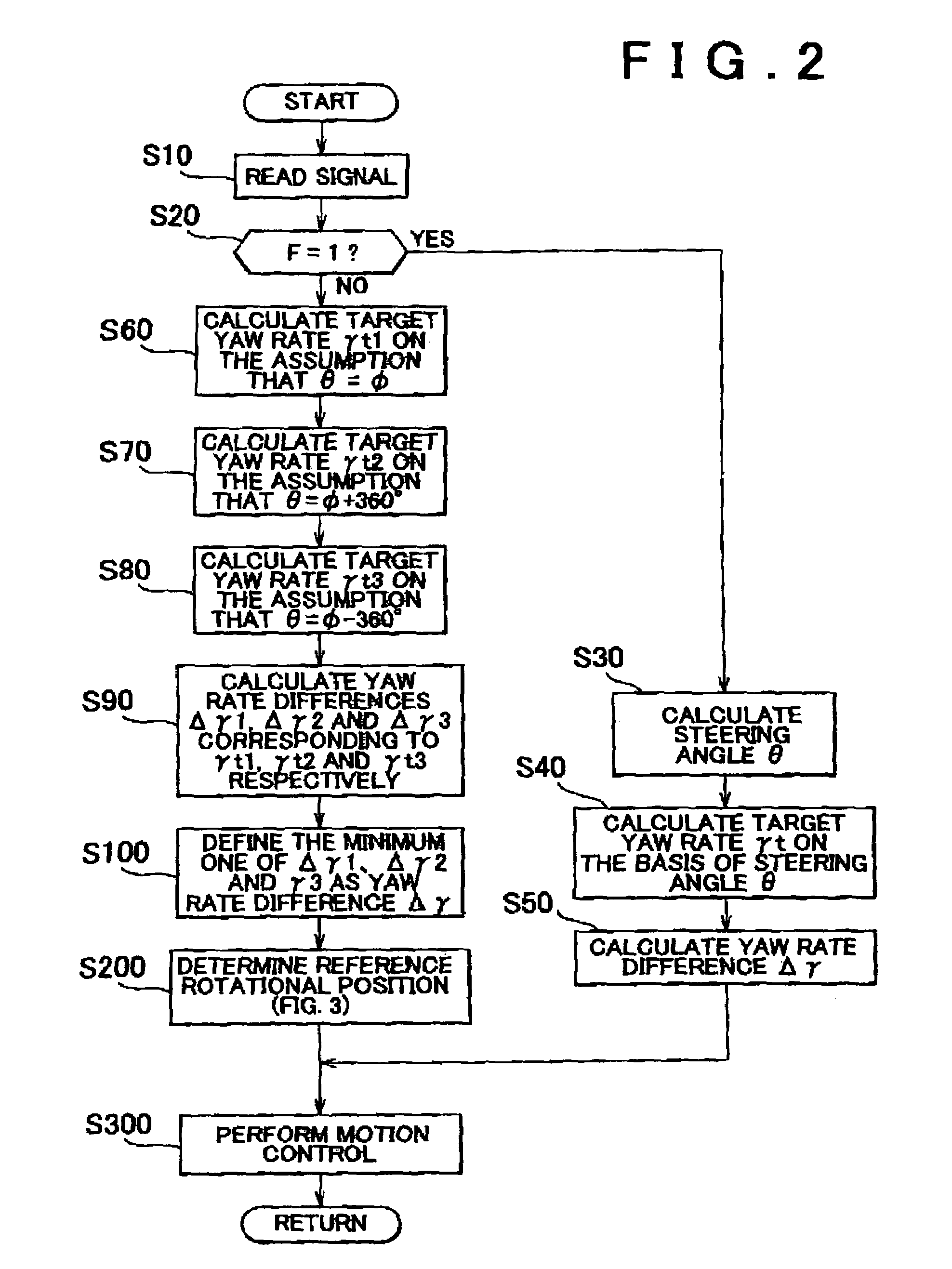

Vehicular motion control apparatus and vehicular motion control method

ActiveUS7058493B2Accurate detectionSteering initiationsDigital data processing detailsSteering angleEngineering

A vehicular motion control apparatus uses a steering angle detected by a steering angle sensor capable of detecting an absolute rotational angle. This control apparatus has a yaw rate sensor. If a reference rotational position of the steering angle sensor has not been determined, the control apparatus calculates a plurality of target yaw rates on the basis of a plurality of steering angles estimated from a steering angle detected by the steering angle sensor, and controls motion of a vehicle on the basis of the minimum one of differences between the target yaw rates and an actual yaw rate. The control apparatus determines a reference rotational position of the steering angle sensor on the basis of a steering angle corresponding to the minimum one of the differences, and then calculates a steering angle for motion control on the basis of the detected steering angle and the determined reference rotational position.

Owner:TOYOTA JIDOSHA KK

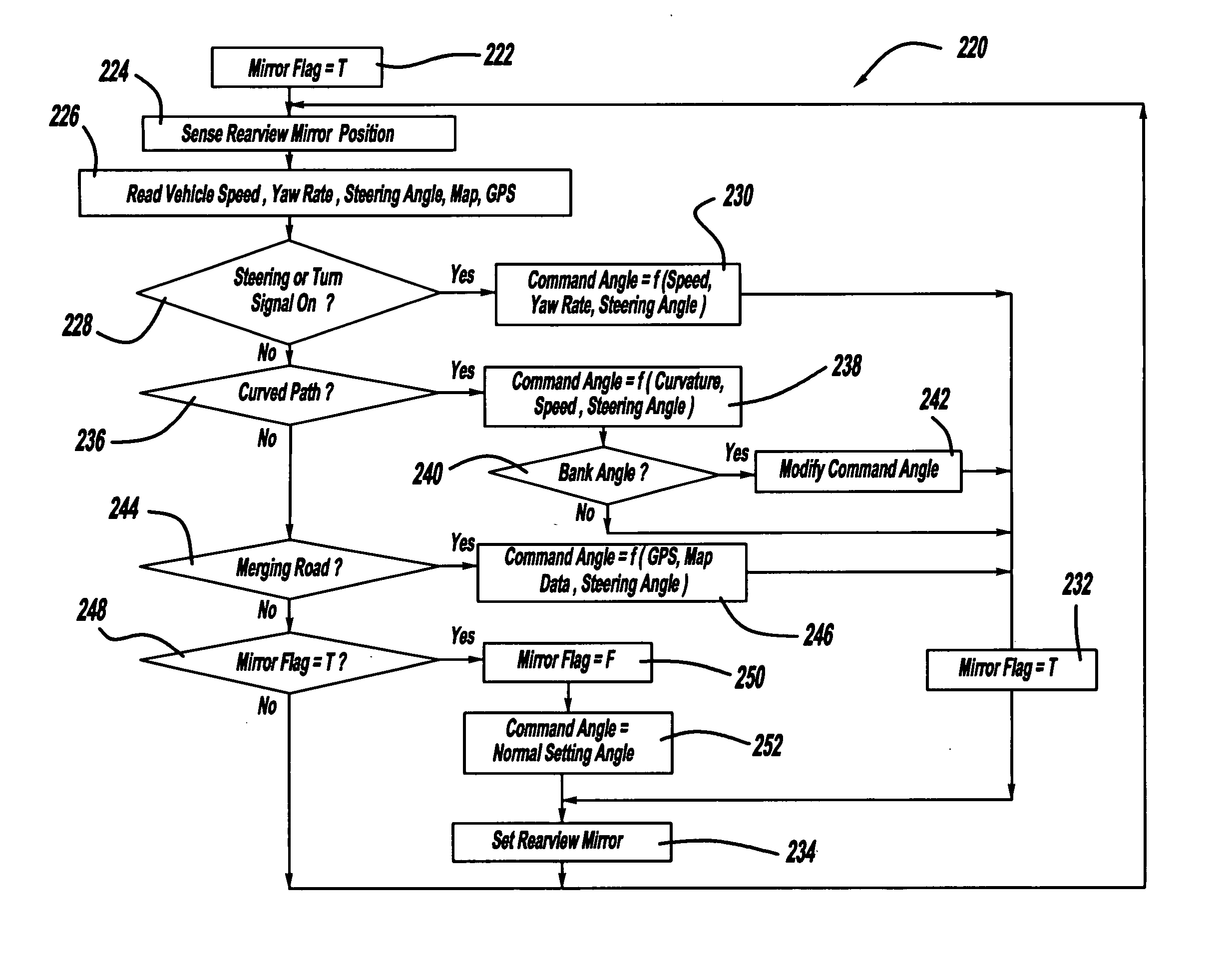

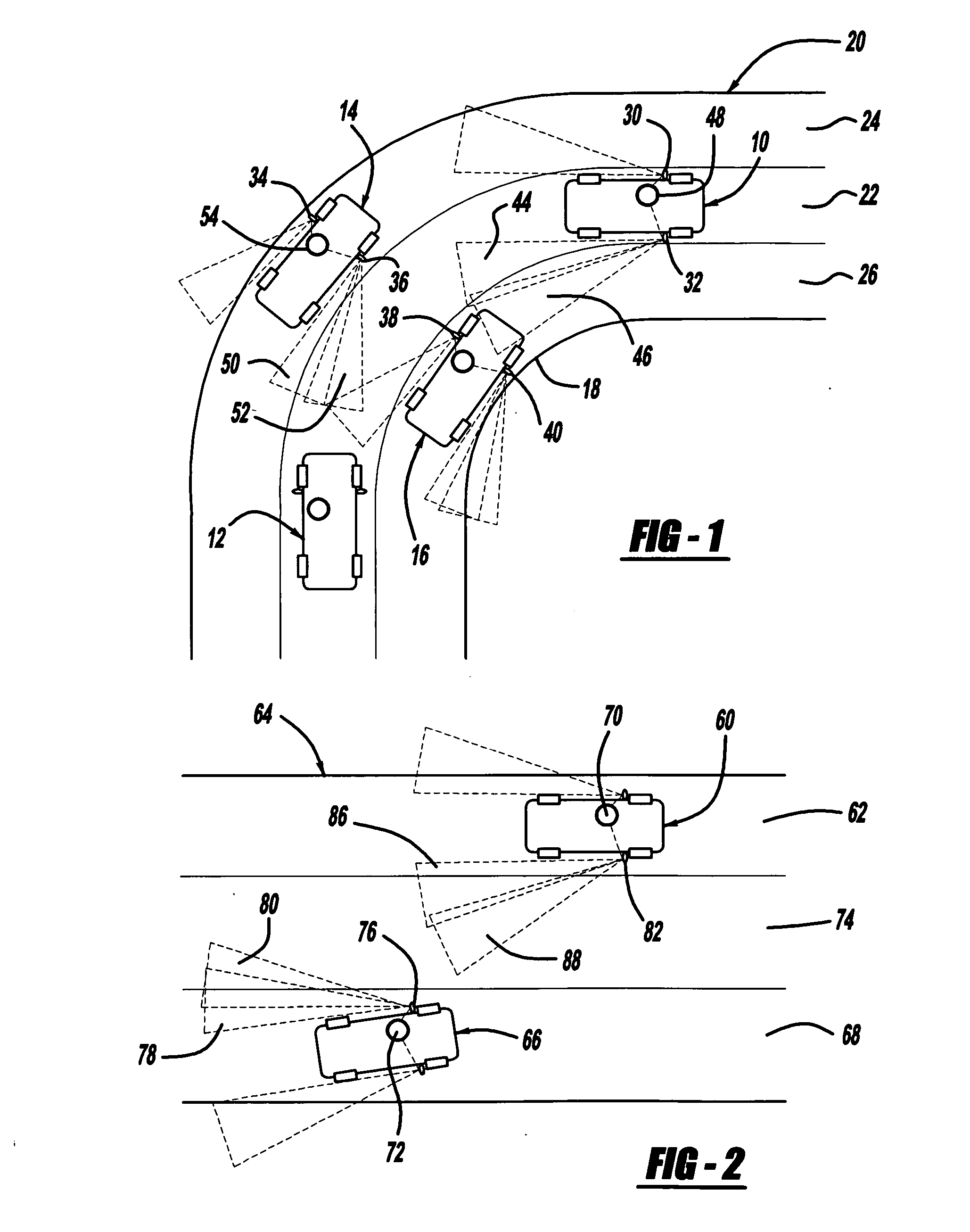

Automatic control of automotive rearview mirror

A side rearview mirror control system for a vehicle that automatically changes a rear viewing angle of a side rearview mirror. The control system receives various vehicle inputs to determine if and when a vehicle operator will turn the vehicle, make a lane change, merge into a lane of traffic, etc. The system pivots the mirror to eliminate a potential blind spot during these conditions. In one embodiment, the rear view mirror control system receives input signals from a vehicle hand-wheel angle sensor, a vehicle yaw rate sensor, a vehicle speed sensor, a turn signal indicator, a global positioning system (GPS) receiver and map information to determine whether the vehicle is turning or will be turning.

Owner:GM GLOBAL TECH OPERATIONS LLC

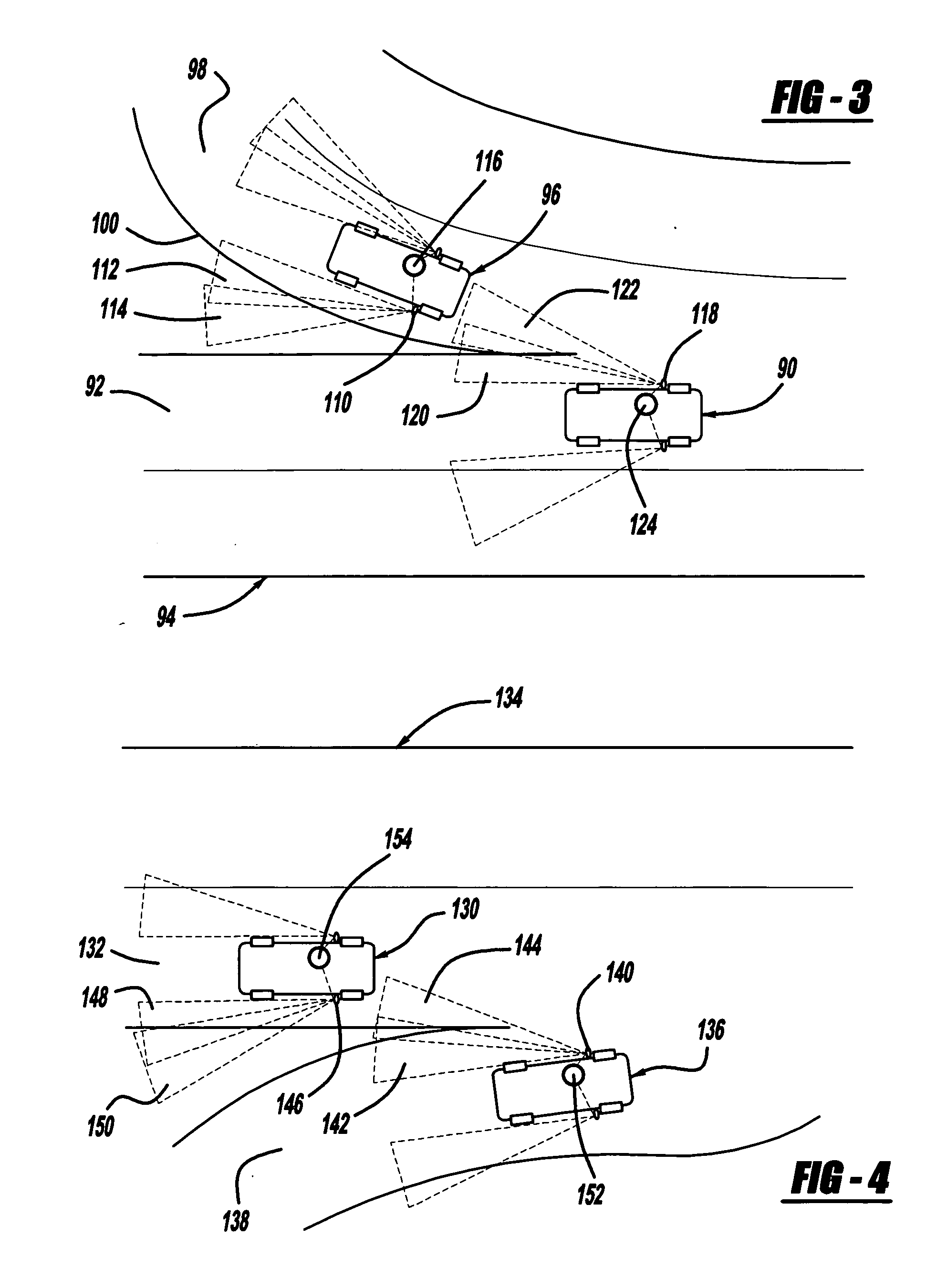

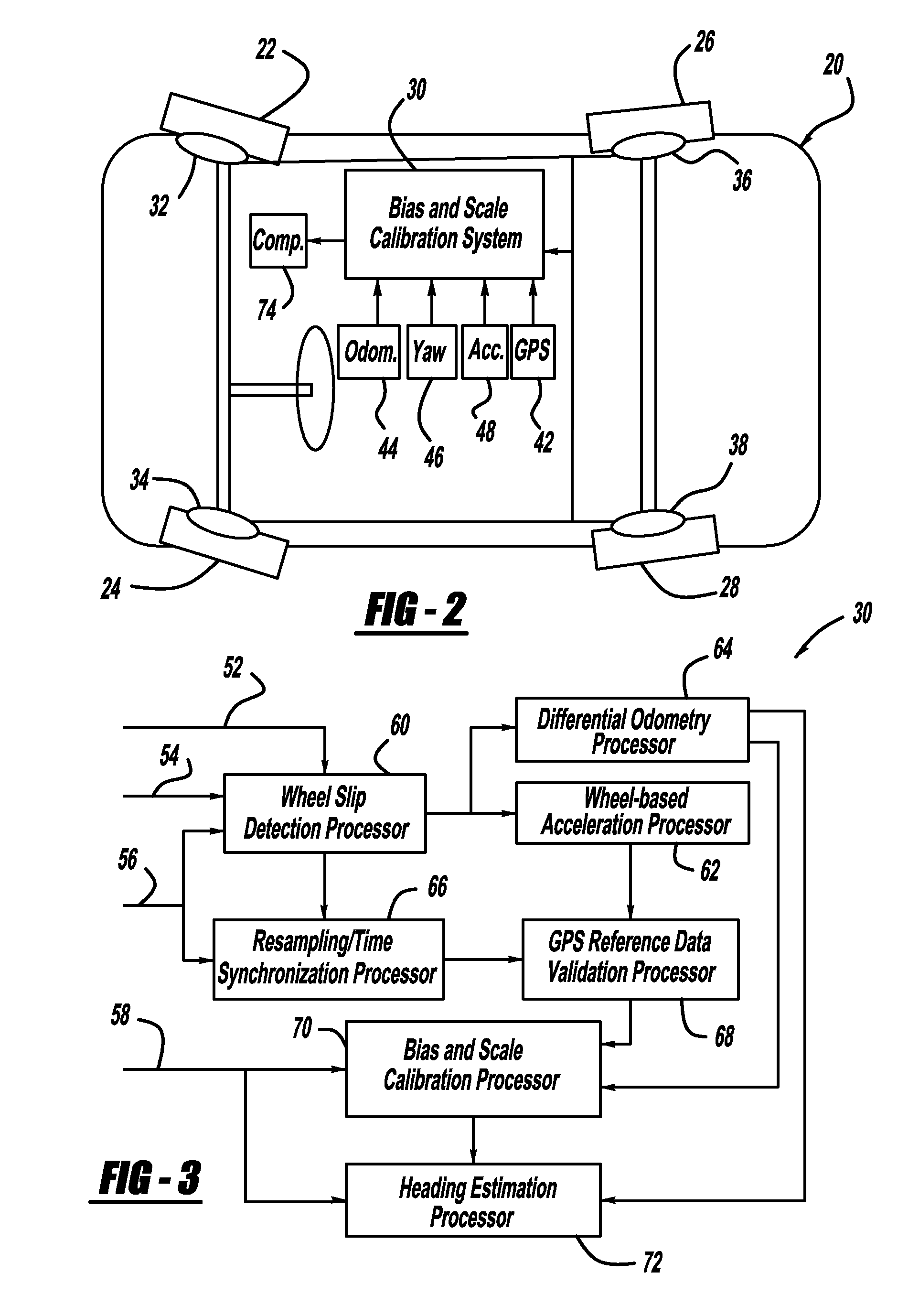

GPS-based in-vehicle sensor calibration algorithm

ActiveUS20090005985A1Digital data processing detailsNavigation by speed/acceleration measurementsOdometryData validation

A system and method for calibrating the bias and scale factors of a heading rate sensor, such as a yaw-rate sensor, using GPS signals. The system receives wheel speed or rotation signals, a vehicle odometer reading, GPS signals and yaw-rate signals. The system includes a wheel-slip detection processor that determines whether there is wheel-slip based on the wheel speed signals and the GPS signals. The system also includes a wheel-based acceleration processor that estimates vehicle acceleration. The system also includes a differential odometry processor that determines vehicle heading based on wheel speed. The system also includes a GPS reference data validation processor that determines whether the GPS signals are valid using the estimated vehicle acceleration and wheel speeds. The valid GPS signals are then used to calibrate the yaw-rate sensor signals, which can be used for vehicle heading purposes.

Owner:GM GLOBAL TECH OPERATIONS LLC

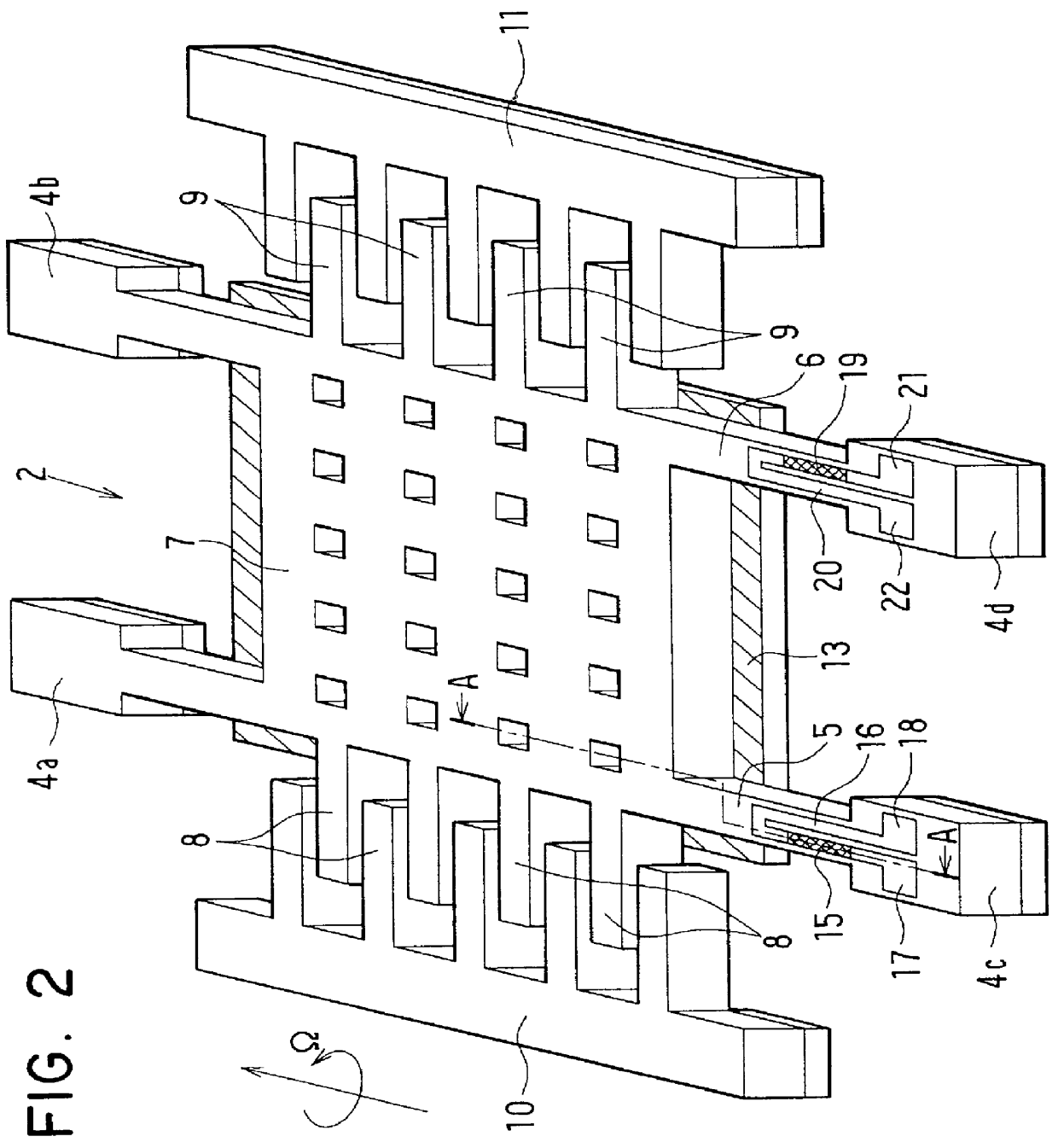

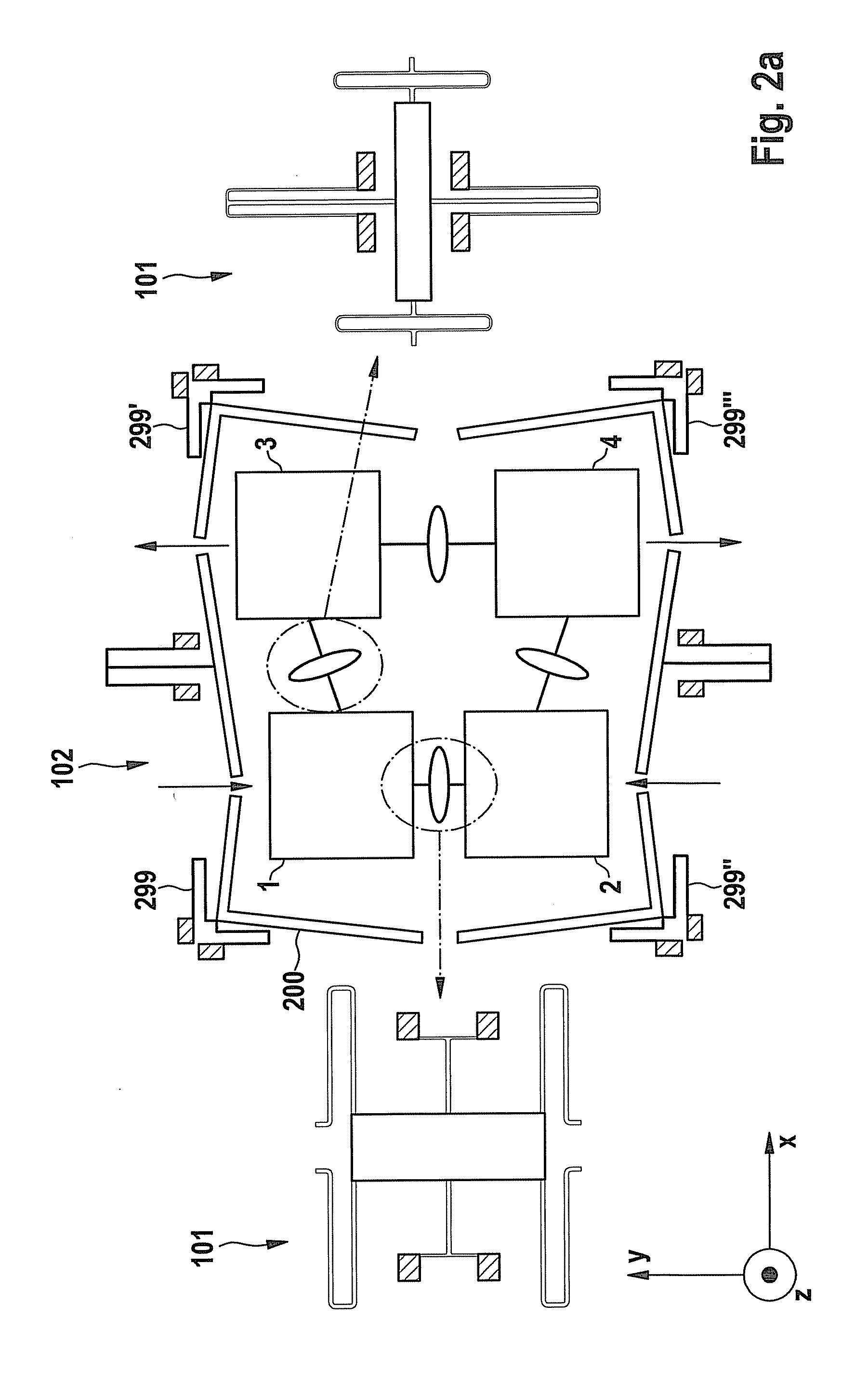

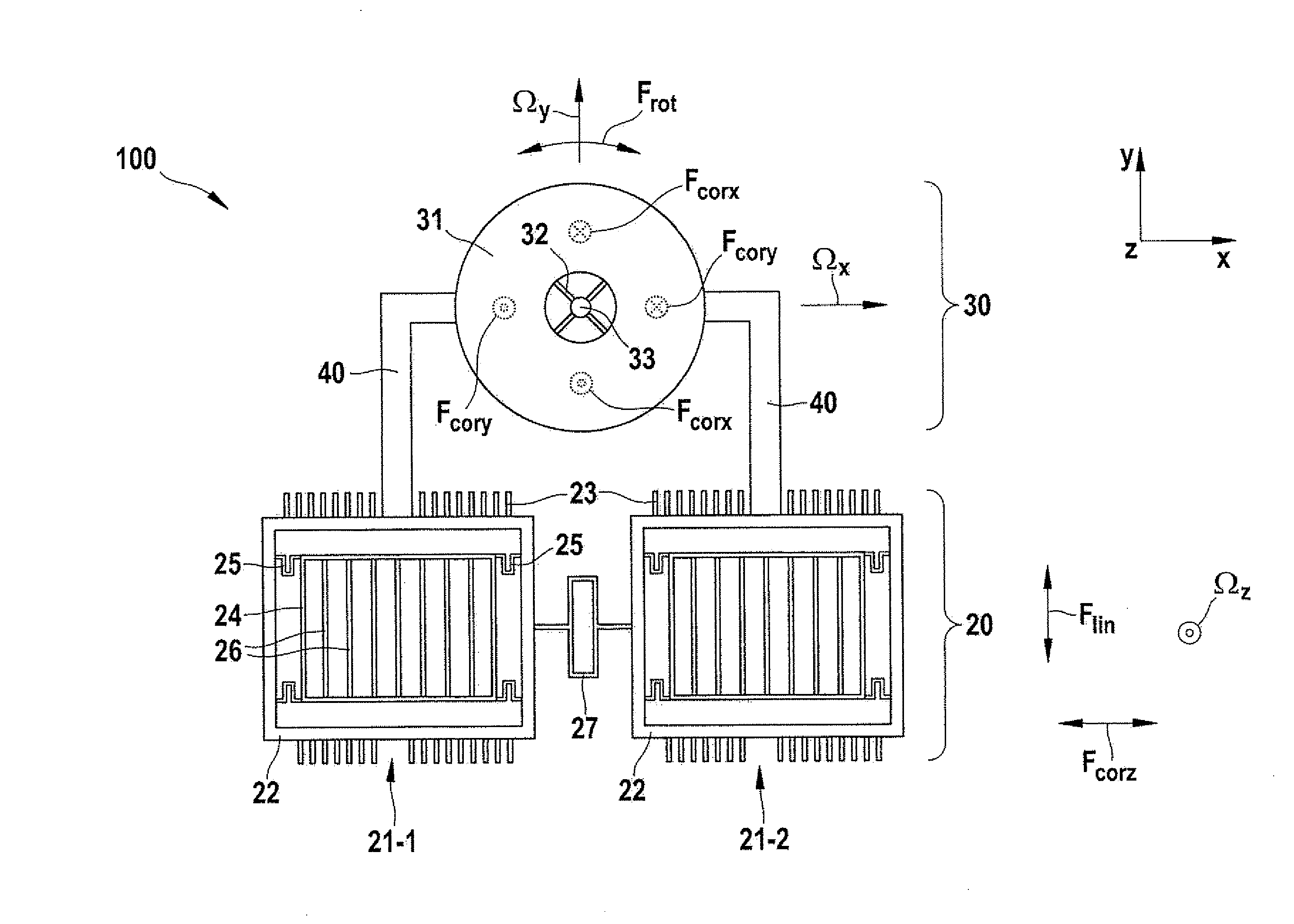

Micromechanical yaw-rate sensor

ActiveUS20110023600A1Improve mechanical propertiesCost-effective manufacturingAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsRotational axisCoupling

A micromechanical yaw-rate sensor comprising a first yaw-rate sensor element, which outputs a first sensor signal, which contains information about a rotation around a first rotational axis, a second yaw-rate sensor element, which outputs a second sensor signal, which contains information about a rotation around a second rotational axis, which is perpendicular to the first rotational axis, a drive, which drives the first yaw-rate sensor element, and a coupling link, which mechanically couples the first yaw-rate sensor element and the second yaw-rate sensor element to one another, so that driving of the first yaw-rate sensor element also causes driving of the second yaw-rate sensor element.

Owner:ROBERT BOSCH GMBH

Method and apparatus for determining a reference vehicle velocity and a rear wheel speed in a vehicle having three speed sensors

InactiveUS20050288842A1Improve accuracyAccurately determineHand manipulated computer devicesAnalogue computers for trafficControl theoryYaw-rate sensor

The method for controlling a safety system (102-108) of a vehicle (10) determines a reference velocity from a first front wheel sensor (20A) and a second front wheel speed signal from a second front wheel sensor (20B). An axle speed sensor (20C) may be used to determine an axle speed signal. A first rear speed signal and a second rear speed signal are determined from the reference velocity, a slip effect and a yaw signal. The yaw signal may be determined from a yaw rate sensor (28). Safety system (102-108) may be controlled in response to the first rear wheel speed signal and the second rear wheel speed signal.

Owner:FORD GLOBAL TECH LLC

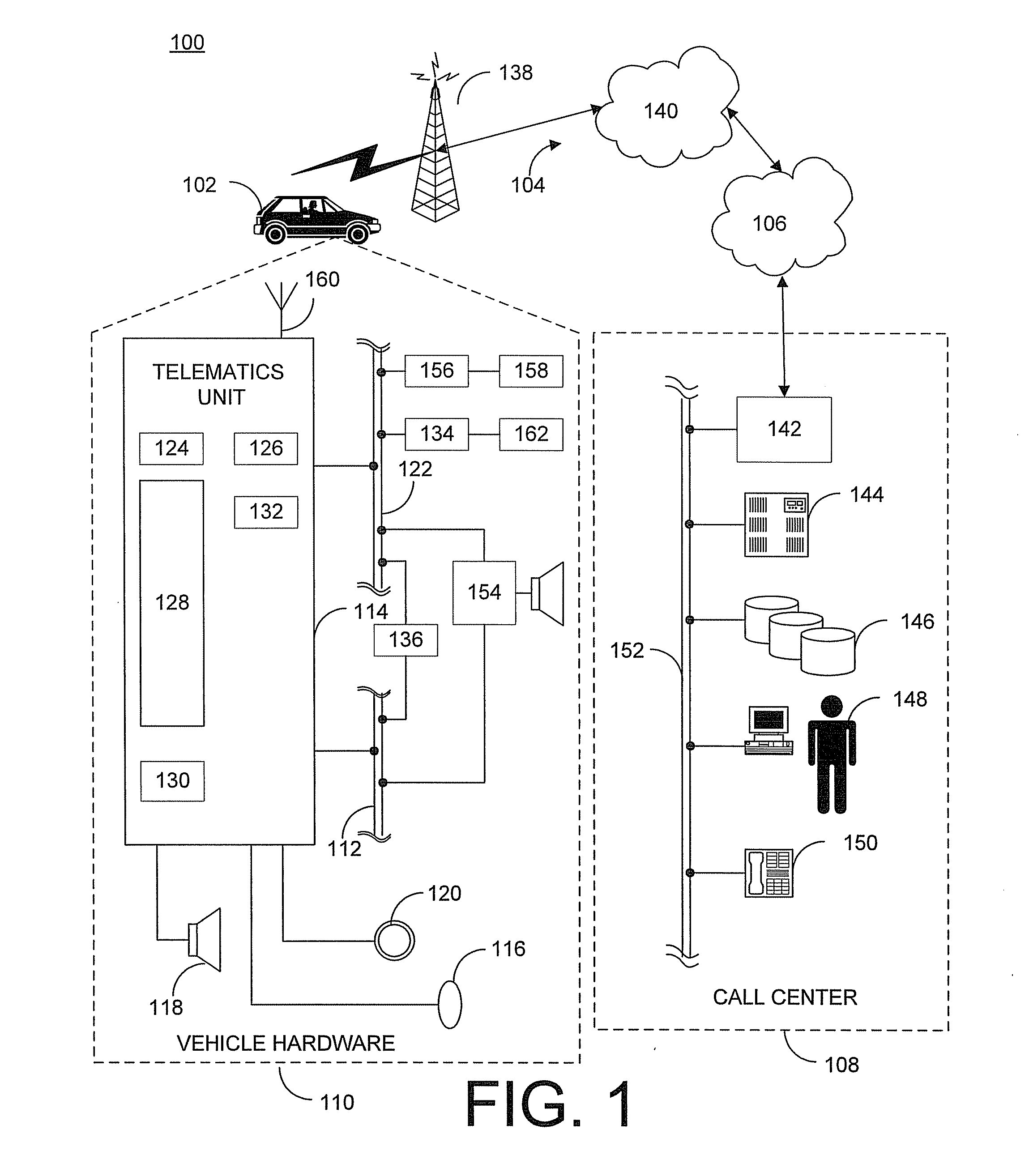

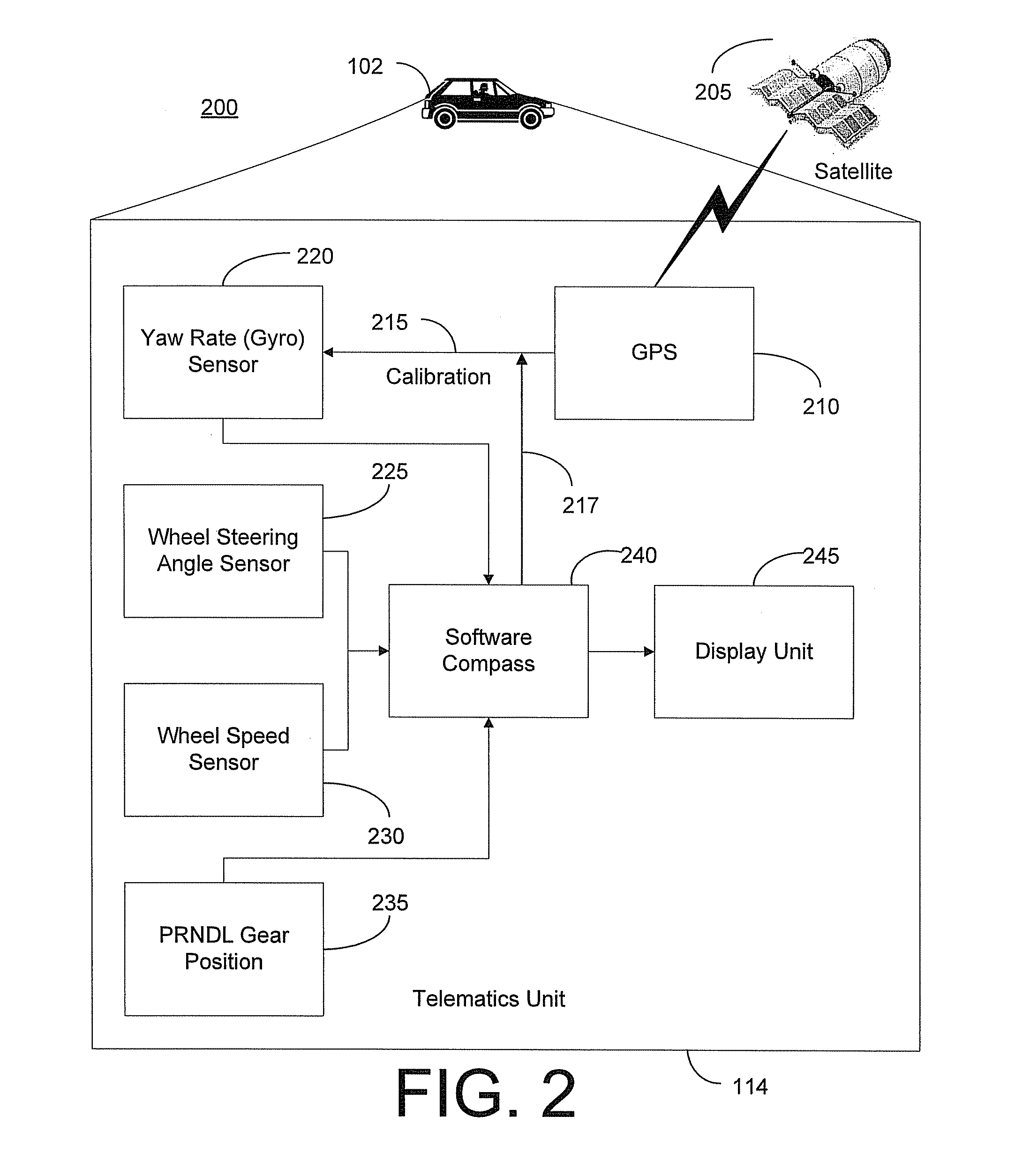

Vehicle Compass Using Telematics Unit and Vehicle Sensor Information

InactiveUS20090088974A1Accurate determinationAccurate locationInstruments for road network navigationNavigational calculation instrumentsSteering angleWheel speed sensor

A software compass used during a GPS outage calculates vehicle heading and presents it upon request. The software compass gathers information from a yaw rate sensor, wheel steering angle sensor, wheel speed sensor, and PRNDL gear position sensor to calculate vehicle heading using a weighting algorithm. Because the yaw rate sensor data is a central factor in calculating vehicle heading, the quality of calibration of the yaw rate sensor is of importance. The disclosed calibration algorithm calculates the yaw rate bias and scale factors to calibrate the yaw rate sensor.

Owner:GENERA MOTORS LLC

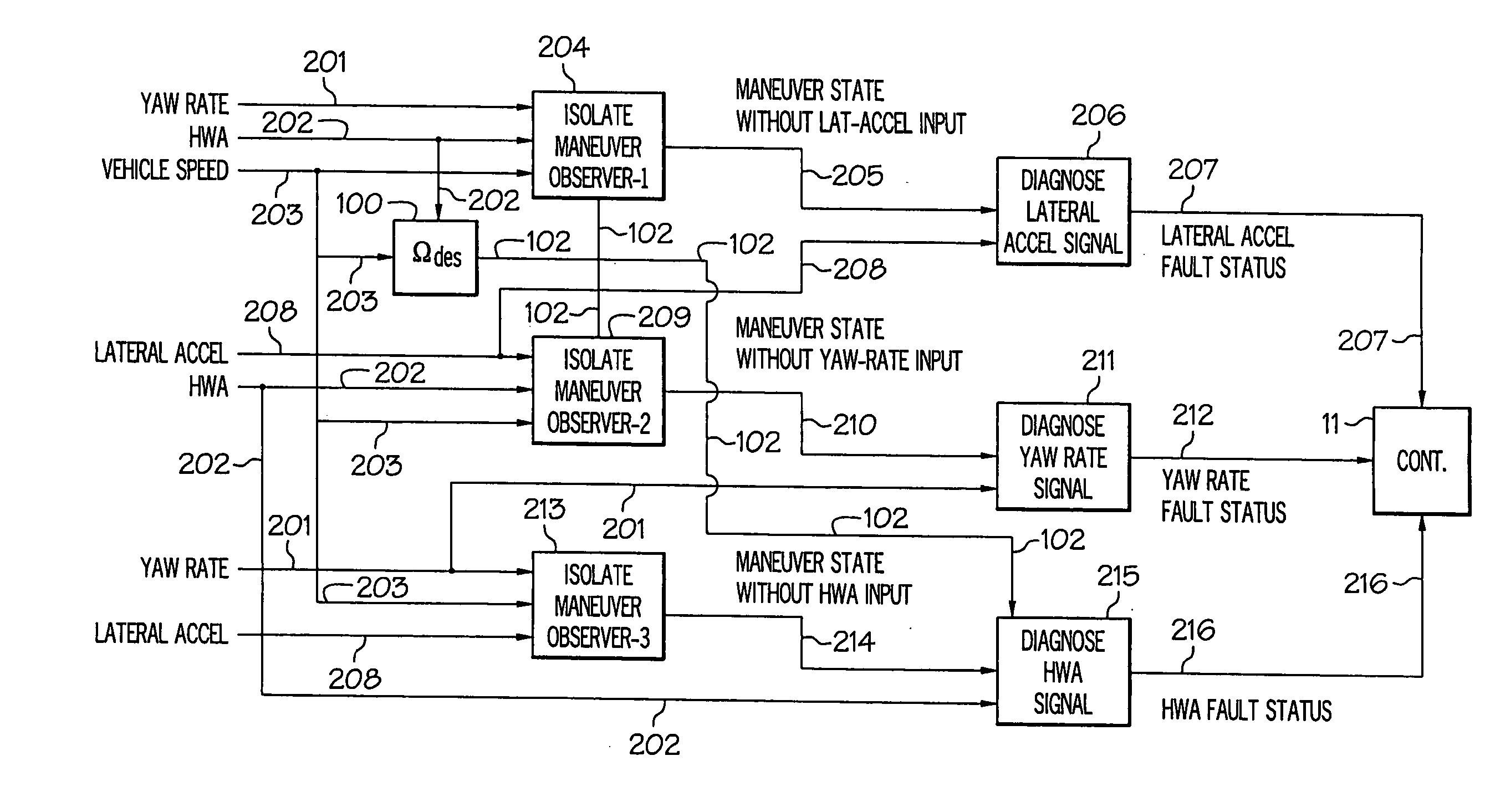

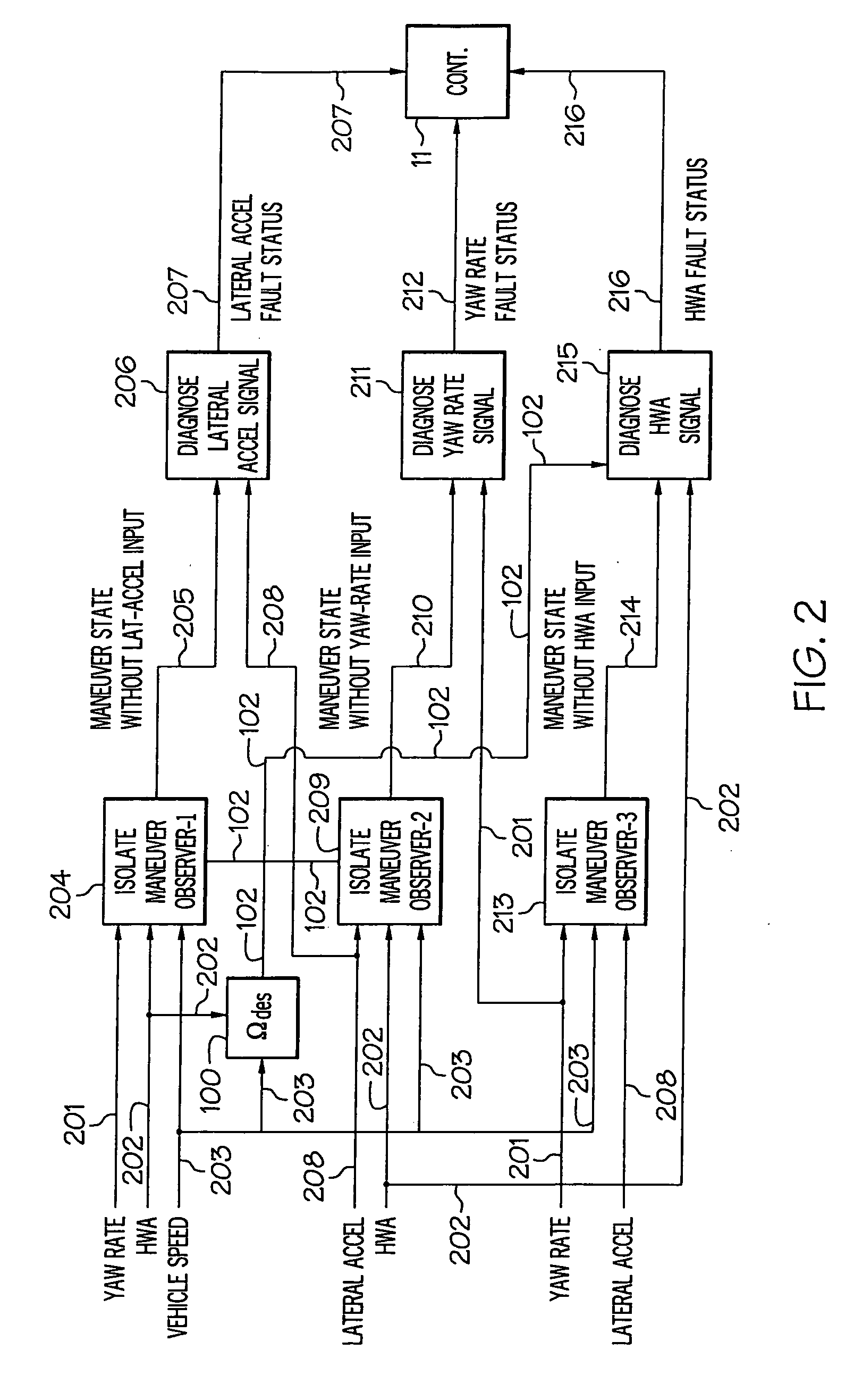

Adaptive maneuver based diagnostics for vehicle dynamics

InactiveUS20070260383A1Expand coverageVehicle testingAnalogue computers for trafficVehicle dynamicsControl system

A vehicle stability control system diagnostic strategy, wherein the diagnostic strategy may be adaptively applied based upon the identified maneuver states of the vehicle. The diagnostic architecture contains three vehicle state observers (i.e., models) each based on inputs from only two of the three sensors (yaw rate, lateral acceleration and hand wheel angle). More particularly, the first observer does not consider lateral acceleration input. The second observer does not consider yaw rate sensor input and the third does not consider hand wheel angle (HWA) sensor input in determining the vehicle state. However, estimated vehicle speed input is used by all the observers. For example, the first observer detects a maneuver state based on yaw rate and HWA and vehicle speed inputs. Then it diagnoses the lateral acceleration sensor failure based on the observer output. The diagnostics are based on vehicle dynamics correlations that hold in steady state linear range conditions. Similarly, the other two observers detect maneuver state and diagnose the respective signals. Advantageous variants include the use of a proactive sensor diagnostics strategy that provides increased coverage during steady state linear range maneuvers while simultaneously detecting faults within the required fault response time.

Owner:BWI CO LTD SA

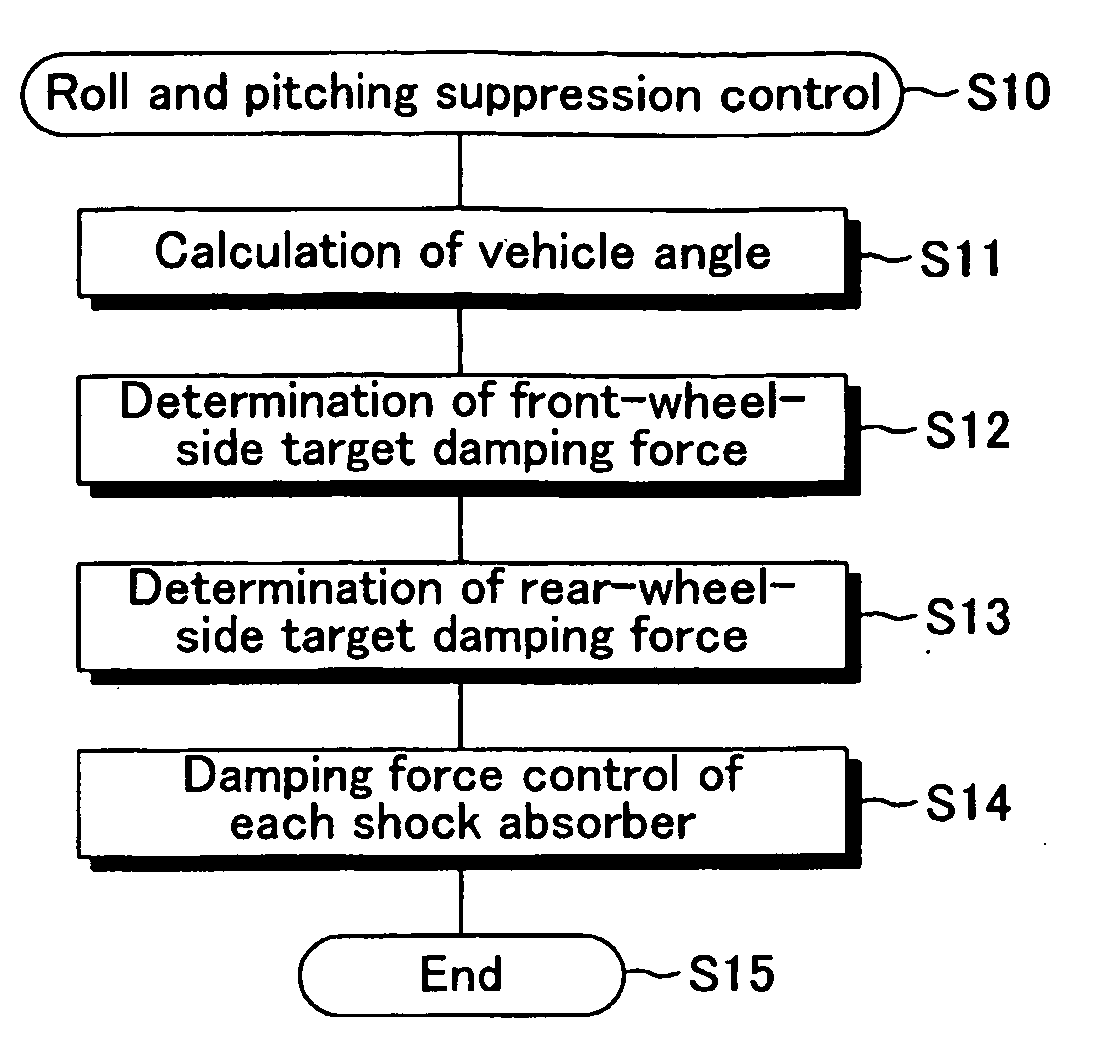

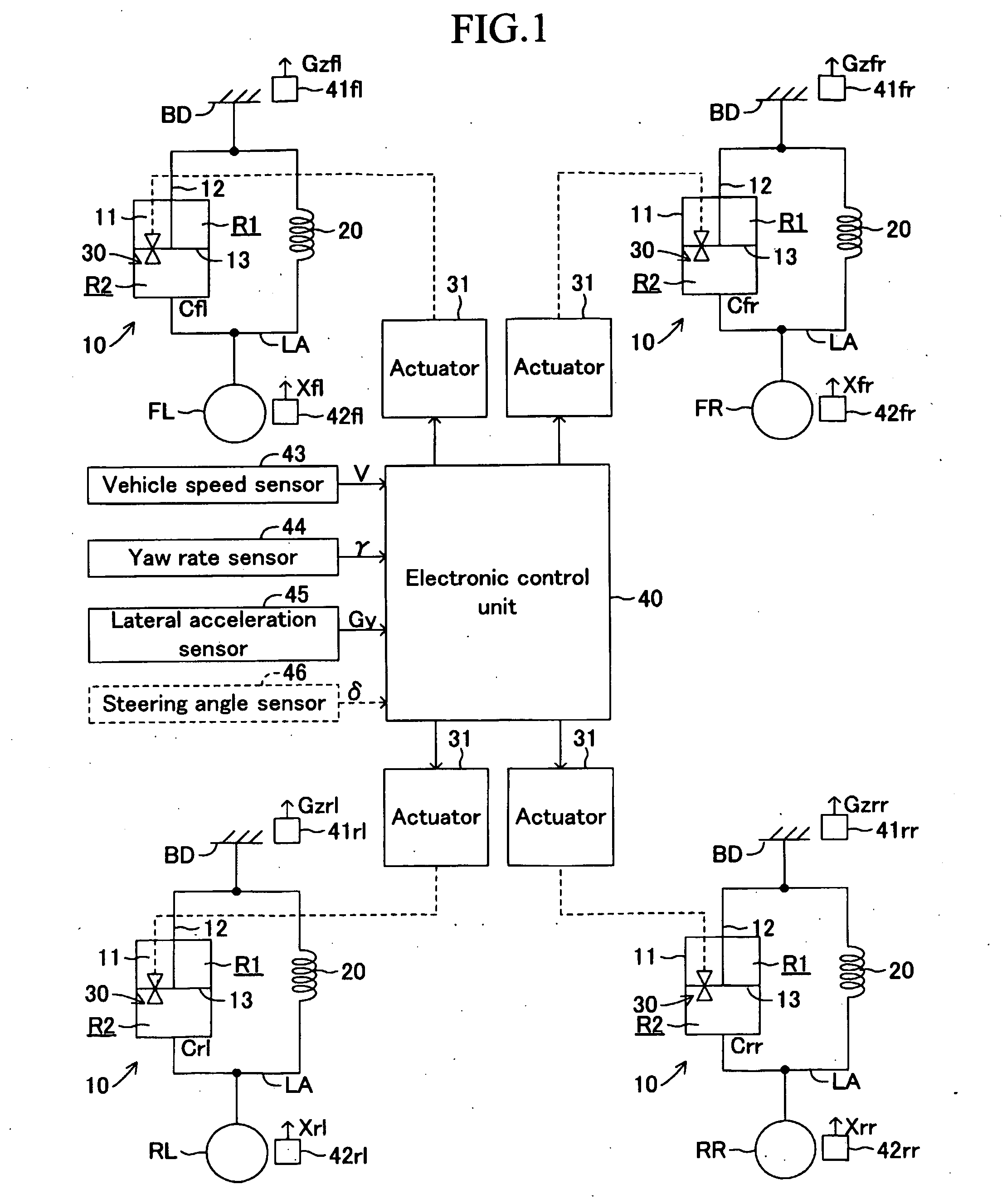

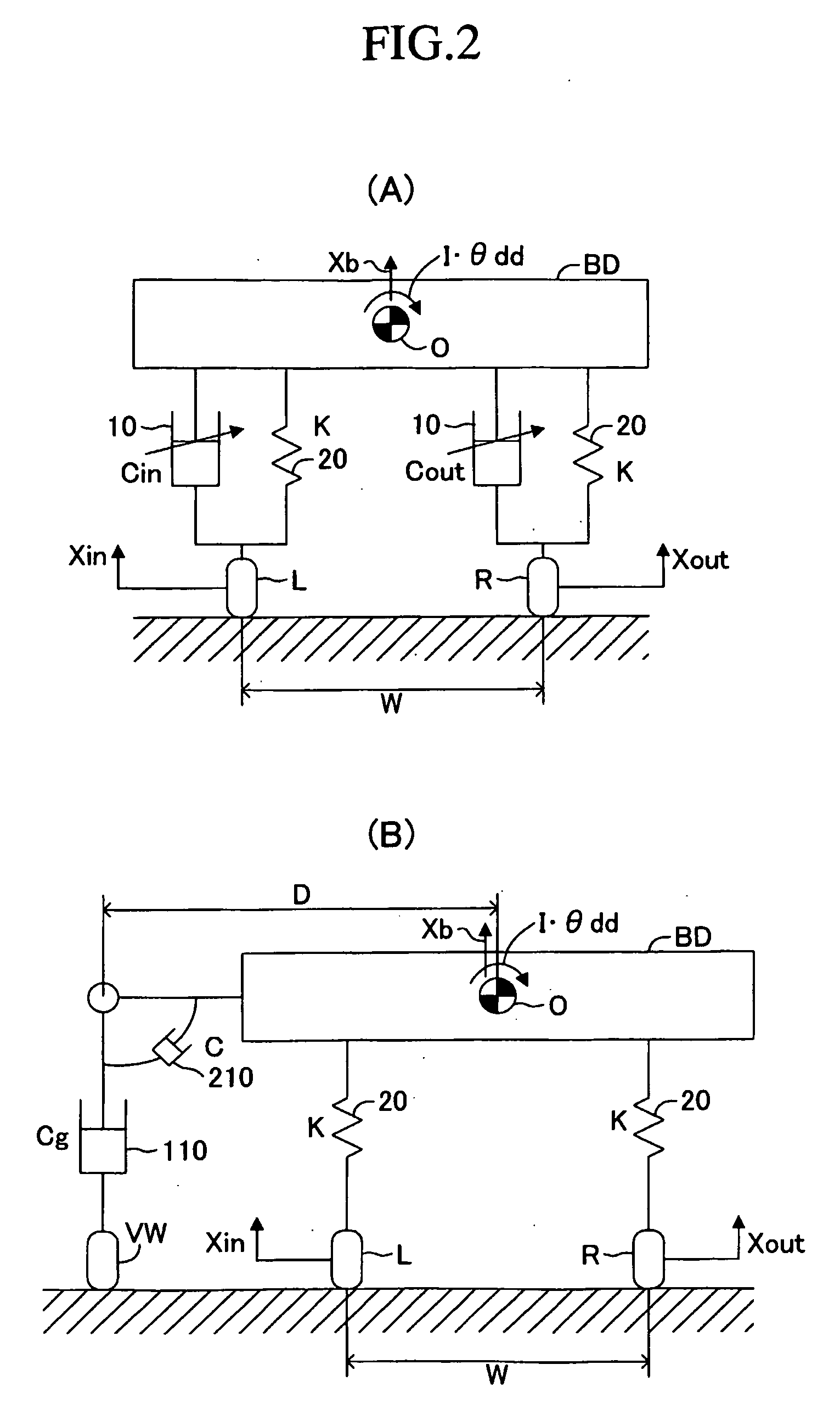

Vehicle damping force control apparatus

A damping force control apparatus has shock absorbers 10 each being capable of changing damping force. An electronic control unit 40 calculates estimated roll angle and estimated pitch angle of a vehicle body BD in accordance with sprung accelerations detected by sprung acceleration sensors 41 fl to 41rr, calculates a target pitch angle from the estimated roll angle, and determines target damping force required for front-wheel-side shock absorbers 10 such that the estimated pitch angle coincides with the target pitch angle. The electronic control unit40 calculates rear-wheel-side jack-up force exerted on the rear-wheel-side vehicle body in accordance with vehicle speed detected by a vehicle speed sensor 43, yaw rate detected by a yaw rate sensor 44 and lateral acceleration detected by a lateral acceleration sensor 45, and determines the force in the direction for overcoming the calculated jack-up force as target damping force of rear-wheel-side shock absorbers 10. The electronic control unit 40 controls the operation of each actuator 31 in accordance with the rear-wheel-side and front-wheel-side target damping forces.

Owner:TOYOTA JIDOSHA KK

Dynamic control system for a marine vessel

ActiveUS8145371B2Minimize errorMinimize positionSpeed controllerElectric devicesAccelerometerMarine engineering

A dynamic control system for a marine vessel having two or more waterjet units as the primary propulsion system of the vessel, for maintaining vessel position or velocity when in a dynamic control mode, comprises a position or velocity indicator to indicate vessel position or velocity or deviations in vessel position or velocity; such as a satellite-based positioning system indicator, or accelerometers as a relative position indicator, a heading indicator to indicate vessel heading from position heading or yaw rate or deviations in vessel heading or yaw rate, such as a compass as an absolute heading indicator or a yaw rate sensor as a relative heading indicator, and a controller to control the operation of the waterjet units to substantially maintain the vessel position or velocity, and vessel heading or yaw rate when the dynamic control mode is enabled.

Owner:CWF HAMILTON

Lateral and longitudinal velocity determination for an automotive vehicle

InactiveUS7451033B2Accurate estimateImprove vehicle performanceAnalogue computers for trafficPedestrian/occupant safety arrangementMobile vehicleStability index

A system (18) for controlling a safety system (44) of a vehicle (10) is disclosed herein. The system includes a longitudinal acceleration sensor (36), a vehicle or wheel speed sensor(s) (20), a lateral acceleration sensor (32), a yaw rate sensor (28), and a controller (26). The controller determines a stability index and provides a first observer that determines a reference longitudinal velocity in response to the sensors. The controller determines a reference lateral velocity in response to the sensors. The controller provides a second observer that determines a second longitudinal velocity in response to the sensors and a first adjustment based on the reference longitudinal velocity. The controller determines a second lateral velocity in response to the sensors and a second adjustment based on the reference lateral velocity. The controller determines an output lateral velocity and an output longitudinal velocity in response to the first and second observers and the stability index and accordingly controls the safety system.

Owner:FORD GLOBAL TECH LLC

System for dynamically determining vehicle rear/trunk loading for use in a vehicle control system

InactiveUS20060129291A1Accurate judgmentAccurately determineAnalogue computers for trafficPedestrian/occupant safety arrangementControl systemMotorized vehicle

A control system (18) and method for an automotive vehicle (10) includes a pitch rate sensor (37) generating a pitch rate signal, a longitudinal acceleration sensor (36) generating a longitudinal acceleration signal, and a yaw rate sensor (28) generating a yaw rate signal. A safety system (44) and the sensors are coupled to a controller. From the sensors, the controller (26) determines an added mass and a position of the added mass, a pitch gradient and / or a pitch acceleration coefficient that takes into account the added mass and position. The controller controls a vehicle system in response to the added mass and the position of the added mass, the pitch gradient and / or pitch acceleration coefficient variables.

Owner:FORD GLOBAL TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com