Short-process producing and processing technology and equipment for cold rolling ultrahigh strength steel

A technology of ultra-high-strength steel and processing technology, applied in metal processing equipment, metal rolling, manufacturing tools, etc., can solve the problems of continuous annealing process, such as high energy consumption, inability to fit rolling deformation, and reduce production efficiency, so as to reduce energy consumption Consumption, shorten the production process, improve the effect of performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

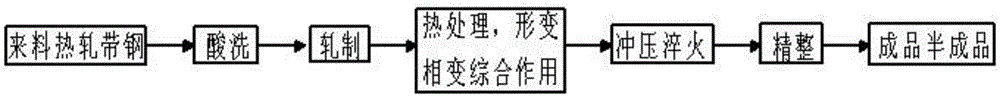

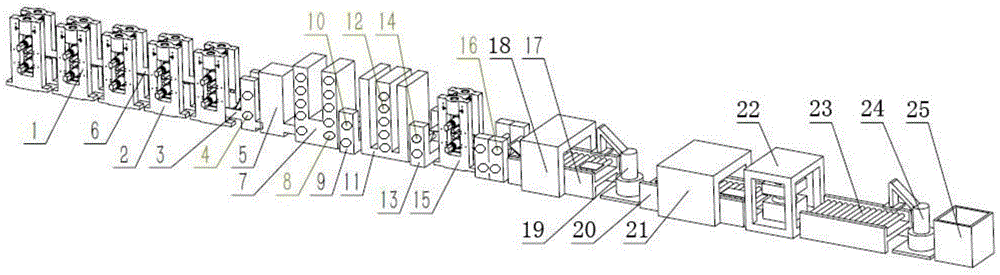

[0024] A short-process production and processing process of cold-rolled ultra-high-strength steel, which mainly includes: hot-rolled strip steel with incoming materials, pickling, rolling, heat treatment, stamping and quenching, finishing, and finished and semi-finished products. The specific steps are as follows:

[0025] (1) After the incoming hot-rolled steel strip is processed by pre-rolling processes such as pickling, cold rolling is carried out, and the cold rolling is fully continuous cold rolling or reversible cold rolling;

[0026] (2) After rolling to the required size, heat treatment and comprehensive treatment of deformation and phase transformation are carried out. The heat treatment in this step includes three stages, which are respectively preheating section, heating section, and soaking section; Heating to 150°C; the heating section continues to heat the strip steel to a temperature above 700°C; the soaking section keeps the strip steel at the temperature of the...

Embodiment 2

[0038] A short-process production and processing technology of cold-rolled ultra-high-strength steel, the specific steps are as follows:

[0039] (1) After the incoming hot-rolled steel strip is processed by pre-rolling processes such as pickling, cold rolling is carried out, and the cold rolling is fully continuous cold rolling or reversible cold rolling;

[0040] (2) After rolling to the required size, heat treatment and comprehensive treatment of deformation and phase transformation are carried out. The heat treatment in this step includes three stages, which are respectively preheating section, heating section, and soaking section; Heating to 200°C; the heating section continues to heat the strip steel to a temperature above 950°C; the soaking section keeps the strip steel at the temperature of the heating section and keeps it warm for 5 minutes; Control the tension of strip steel at 5.0kg / mm 2 , so that the strip steel can further improve the microstructure and comprehen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com