Novel film applicator

A film coating machine and a new type of technology, applied in the direction of coating, the device for coating liquid on the surface, etc., can solve the problems of poor quality of the coating film and small use range, and achieve enhanced stability, expand the field of use, and improve the coating film. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

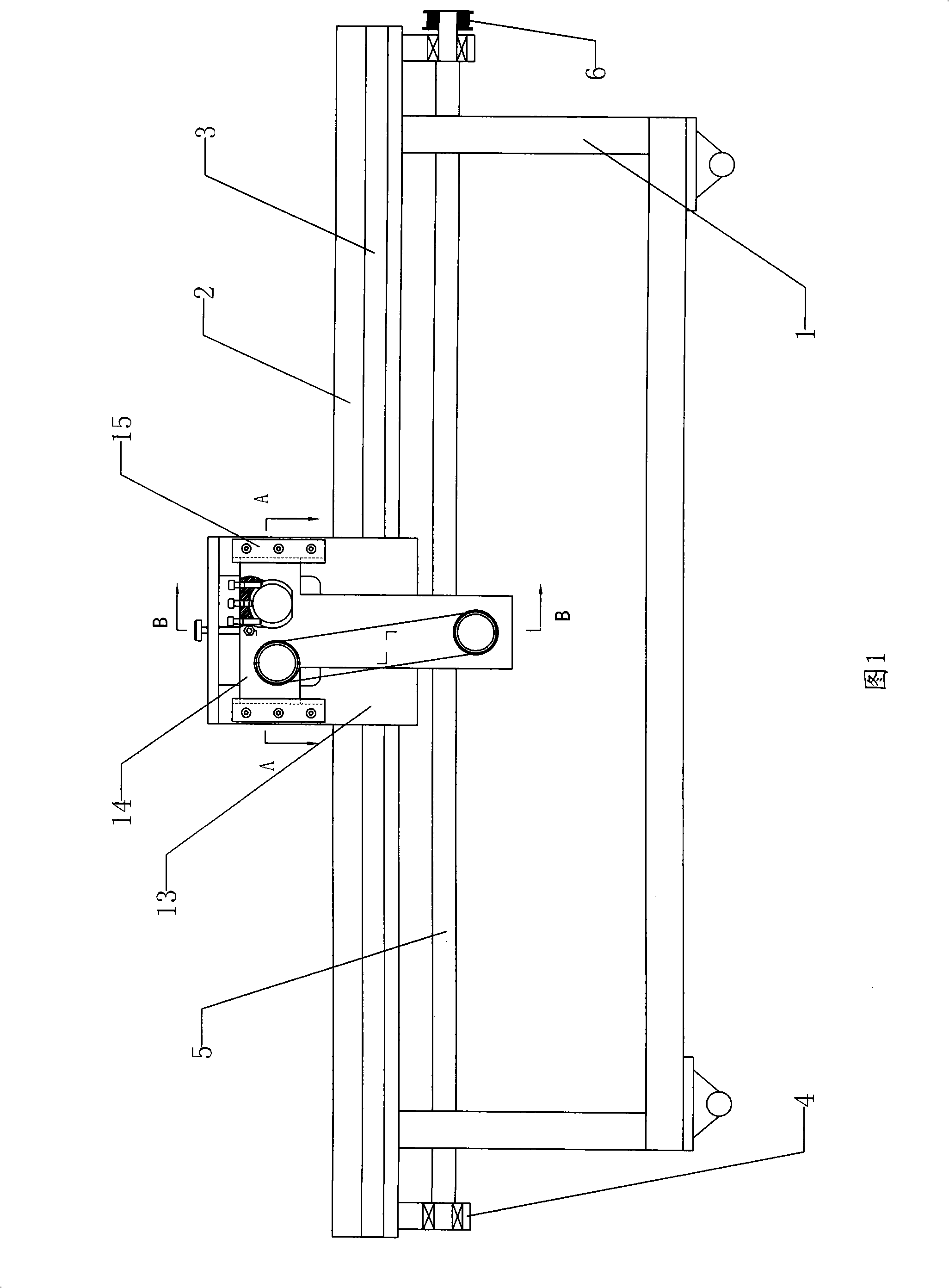

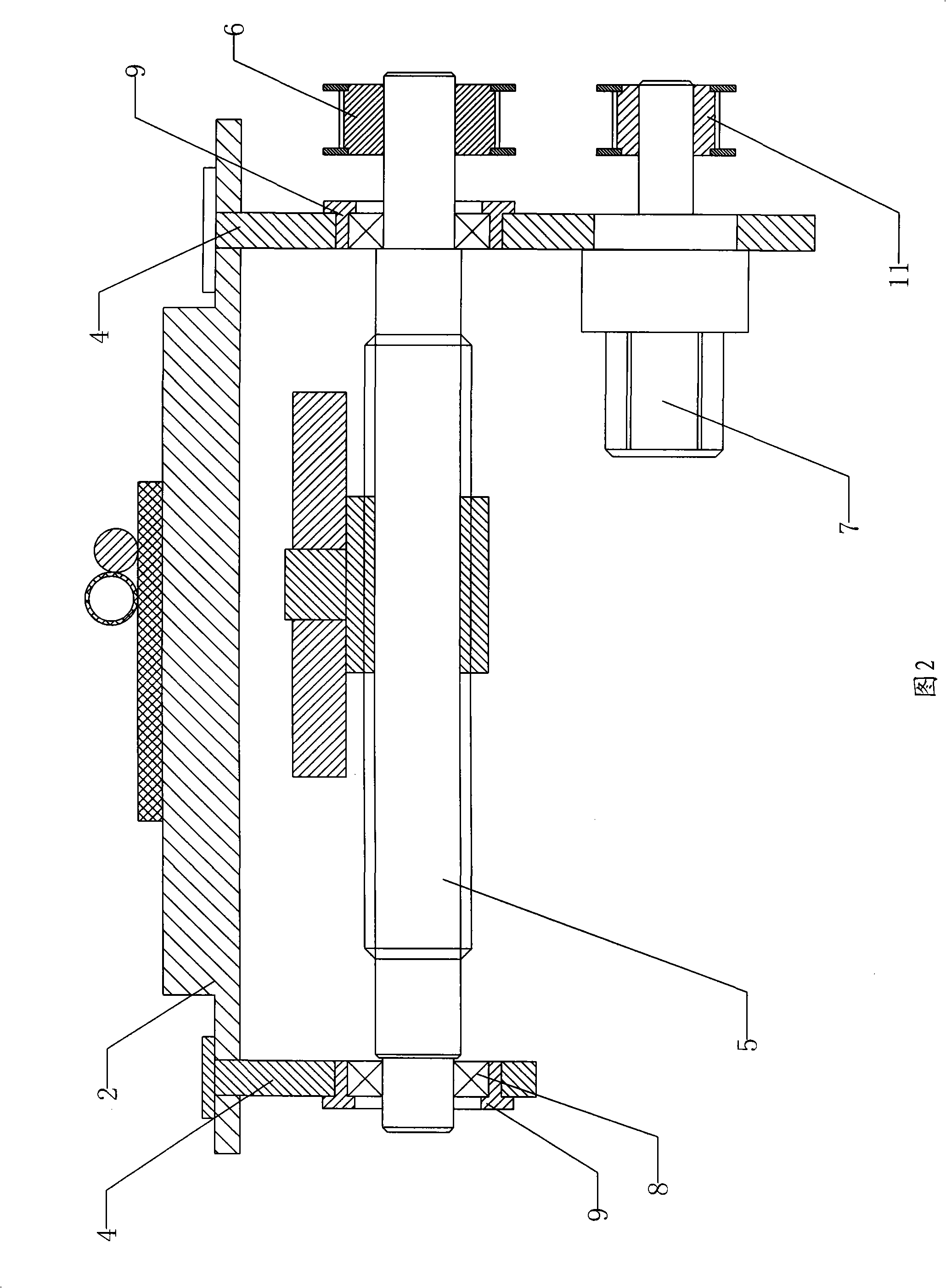

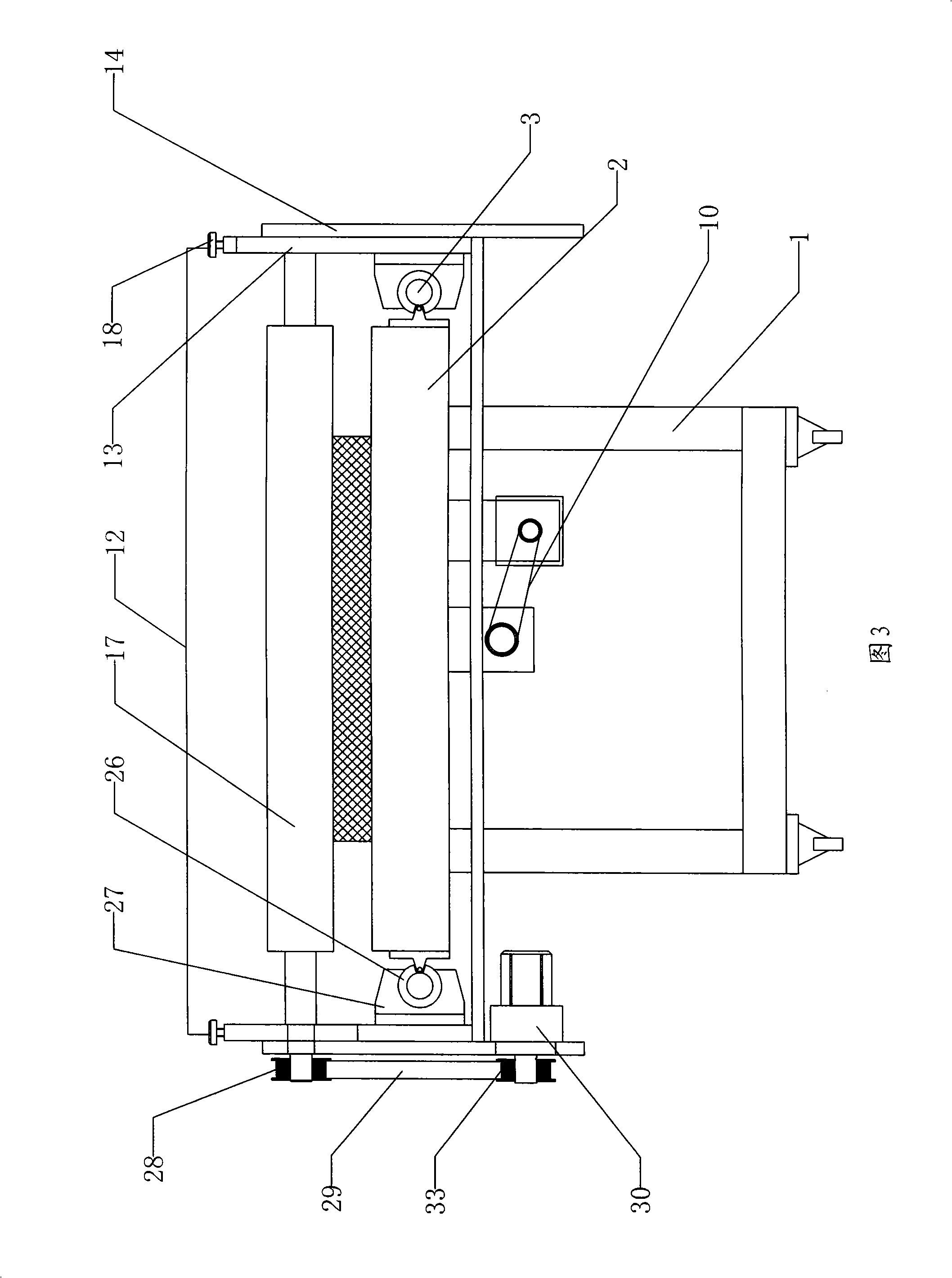

[0019] As shown in Figures 1-3, the new film coating machine described in the embodiment of the present invention includes a frame 1, a workbench 2, a guide rail 3, a hanging plate 4, a lead screw 5 and a motor 7, and the upper part of the frame 1 is fixed to work Table 2, guide rails 3 are arranged on both sides of workbench 2, hanging boards 4 are hung at both ends of workbench 2, and two hanging boards 4 are connected to two ends of lead screw 5 through bearing 8, and bearing sleeve 9 is overcoated on bearing 8, and said lead screw 5 The right end is connected with the belt pulley 6; the motor 7 is fixed at the bottom of the right hanging plate 4, the belt pulley 11 connected on the motor 7 shaft is connected with the belt pulley 6 at the right end of the screw 5 through the timing belt 10, and the motor 7 can drive the screw through the timing belt 10 after starting up 5 rotates, and the lead screw 5 is sleeved in the screw nut 26 at the bottom of the coating device 12.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com