Line contact rolling-slipping friction vibration noise test bed and line contact rolling-slipping friction vibration noise test analysis method

A technology of friction vibration and noise testing, which is applied in the direction of analyzing materials, measuring ultrasonic/sonic/infrasonic waves, measuring devices, etc. It can solve the problems of shortage, high test accuracy, and high environmental requirements, so as to save costs, facilitate disassembly and assembly, and reduce volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

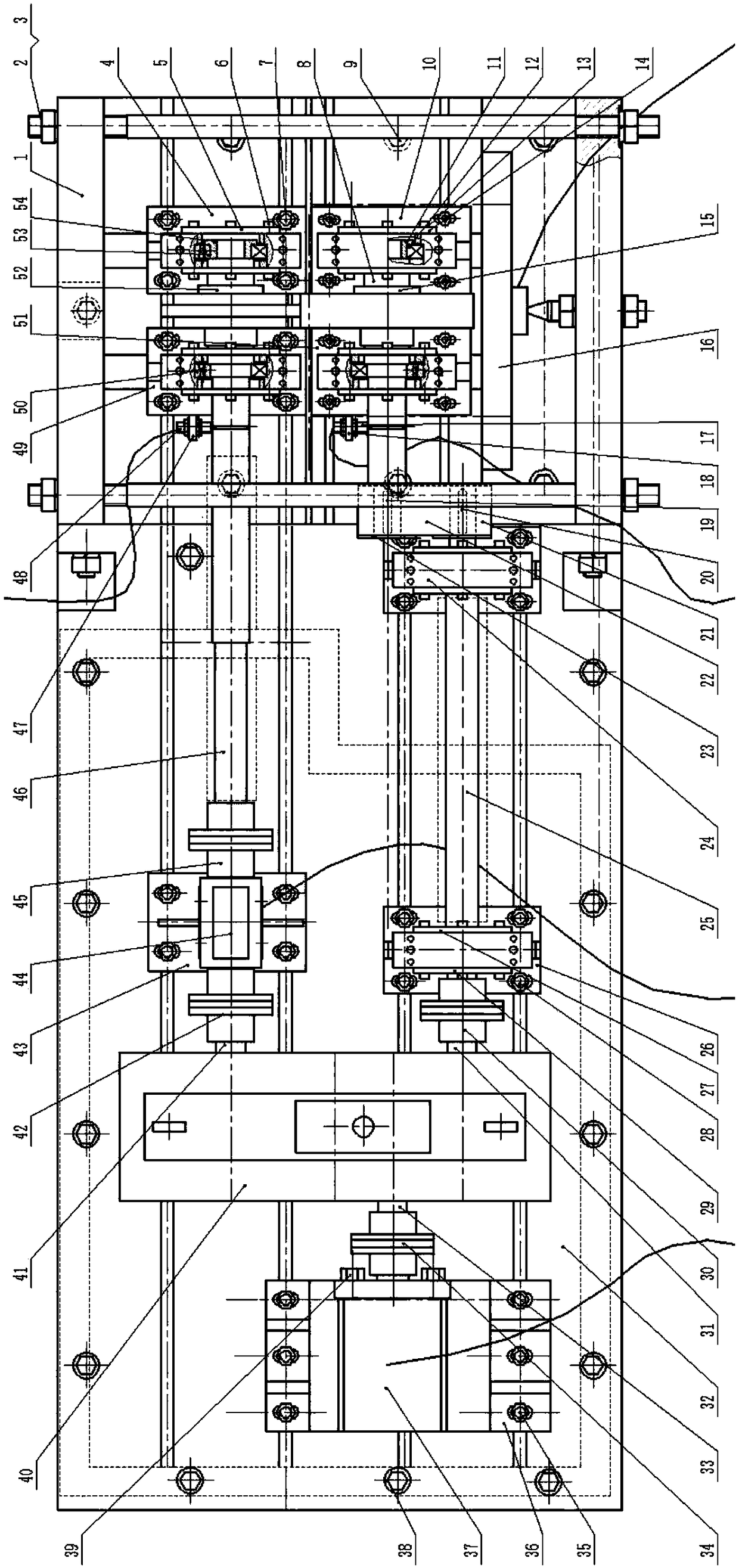

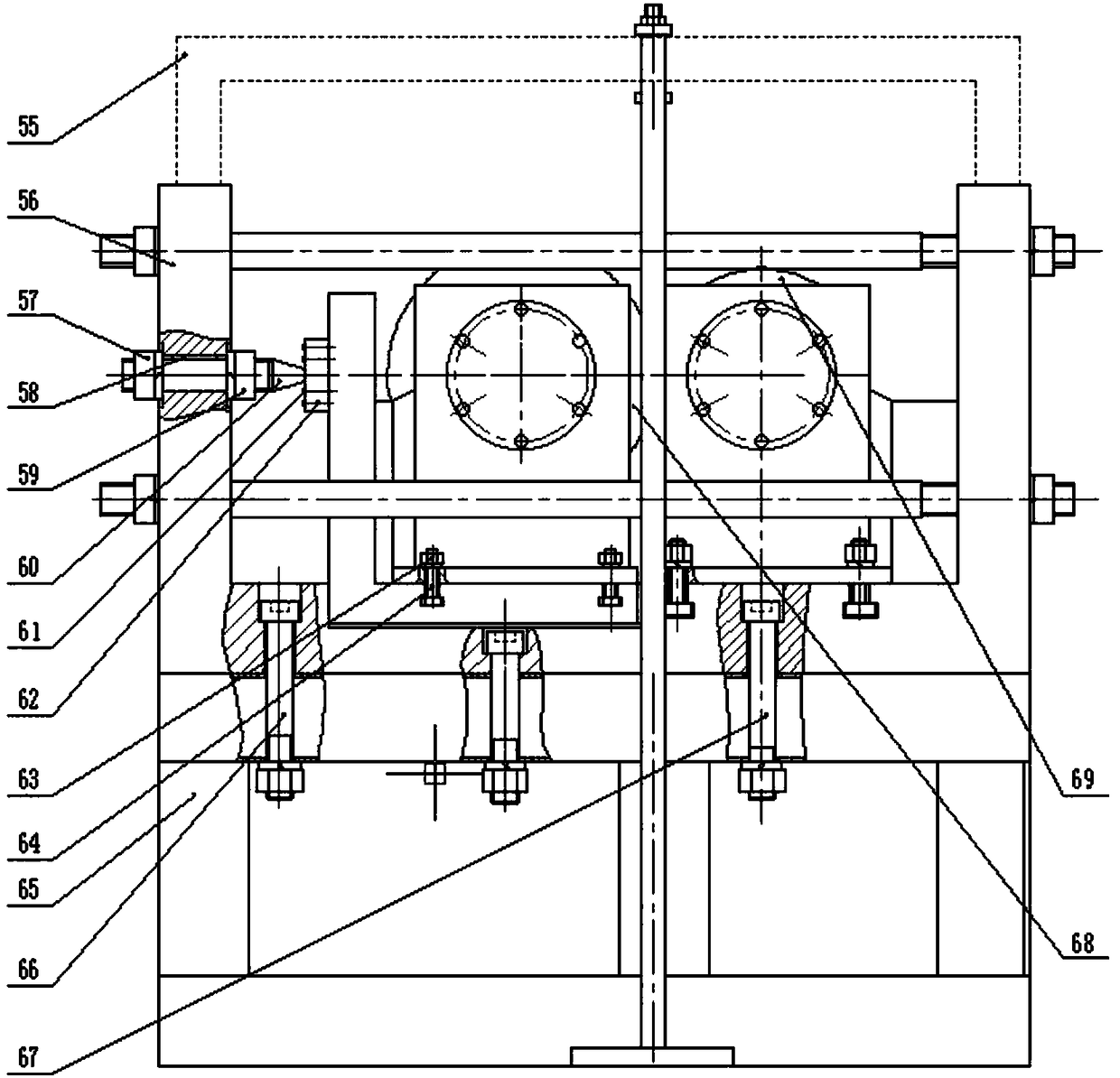

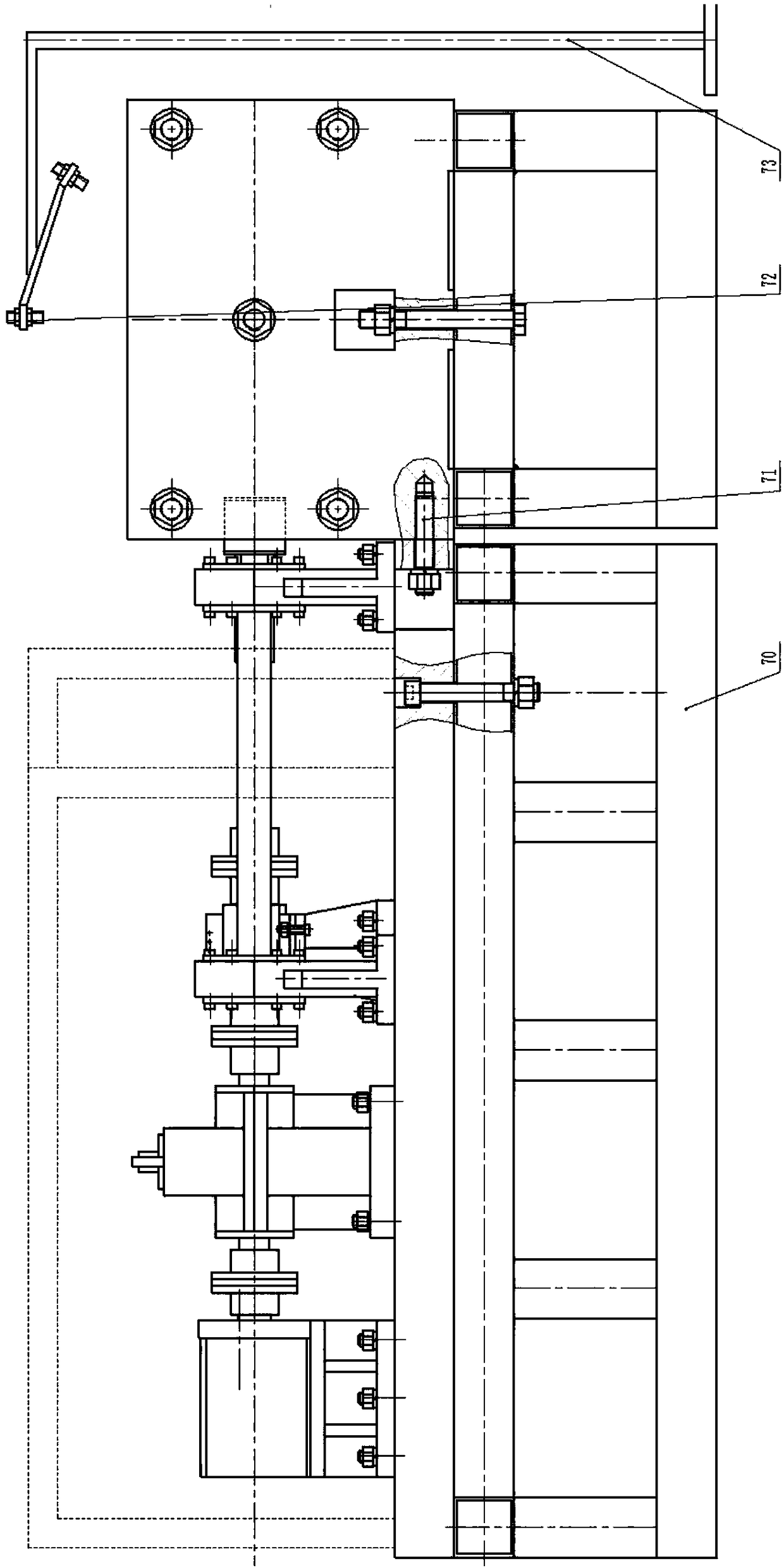

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, and the present invention includes but not limited to the following embodiments.

[0031] The invention provides a test bench for researching line contact rolling friction noise. The device can conveniently realize the research of line contact friction noise and can conduct tests under variable working conditions. Such as Figure 1-Figure 6 As shown, the test stand of the present invention mainly includes a small square steel support 65, a large square steel support 70, a T-slot platform 32, a fixed T-slot platform 1, a mobile T-slot platform 16, a sound insulation cover 55, and a fixed loading platform 56 , moving main shaft 8, first synchronous pulley 21, synchronous belt 22, second synchronous pulley 23, power transmission shaft 25, servo motor 37, shunt gear box 40, torque sensor 44, fixed main shaft 46, microphone 72.

[0032] The small square steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com