Method and production line for manufacturing metal strips made of copper or copper alloys

a production line and metal strip technology, applied in the direction of metal rolling stands, manufacturing tools, metal rolling arrangements, etc., can solve the problems of increased capacity, market (30,000 to 70,000 t/year), and inability to achieve economic benefits with the present cost structure, so as to reduce plant investment costs, increase capacity, and reduce operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

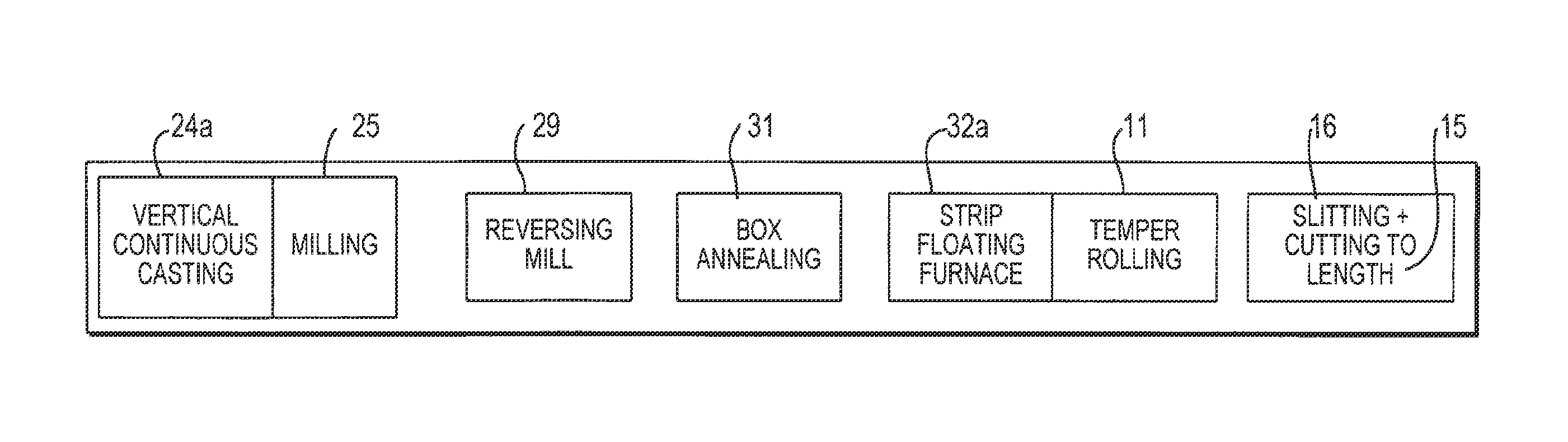

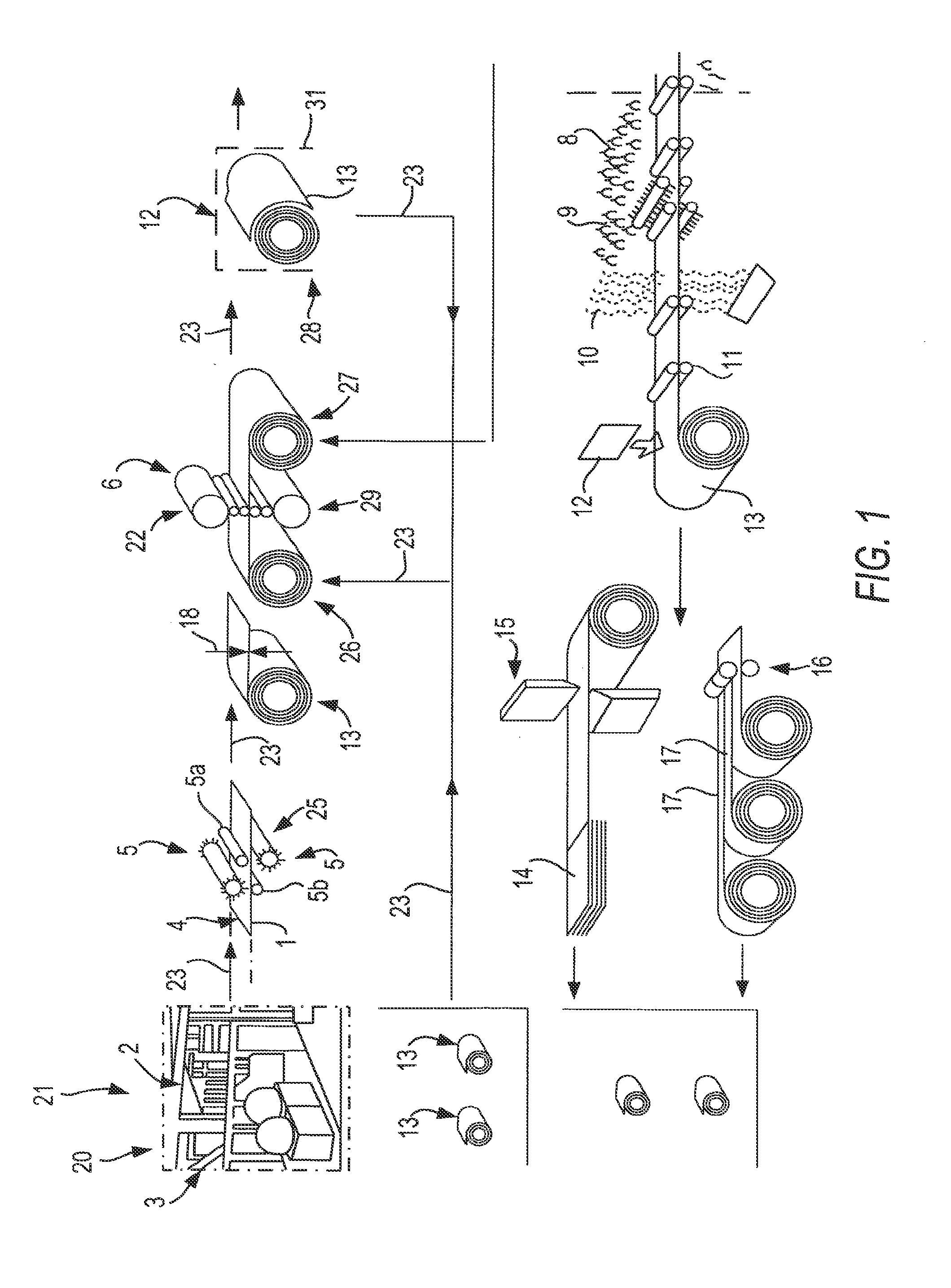

[0037]To produce a metal strip 1 from a soft material (FIG. 1), molten metal 2, e.g., copper or a copper alloy, is cast from a melting furnace (not shown in detail) in a continuous strip casting process, and the copper strip 4 is descaled by milling 5 with support rollers arranged obliquely opposite each other on the upper side 5a and the underside 5b of the copper strip 4, subjected to a cold rolling process 6, subjected to a surface inspection 12, coiled into a coil 13, and then prepared for shipment.

[0038]A coil 13 can also be returned to the cold rolling process 6 for further reduction of the thickness 18 of the copper strip. The microstructure, which is thus very strongly compressed, is coiled into an inspected coil in a treatment by annealing 7, pickling 8, washing 9, drying 10 and possibly a temper rolling step 11, followed by an inspection 12.

[0039]Stacked sheets 14 are then produced from the coils 13, whose surfaces have been inspected, by cutting the copper strip 4 to leng...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com