Method for continuous casting and rolling with an increased casting rate and subsequent hot-rolling of relatively thin metal strands, especially steel strands, and continuous casting and rolling devic

A technology of casting speed and thin metal, which is applied in the direction of metal rolling mill stand, metal rolling, forging and pressing equipment, etc., and can solve the problem of low conveying speed of hot-rolled strip finishing mill

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

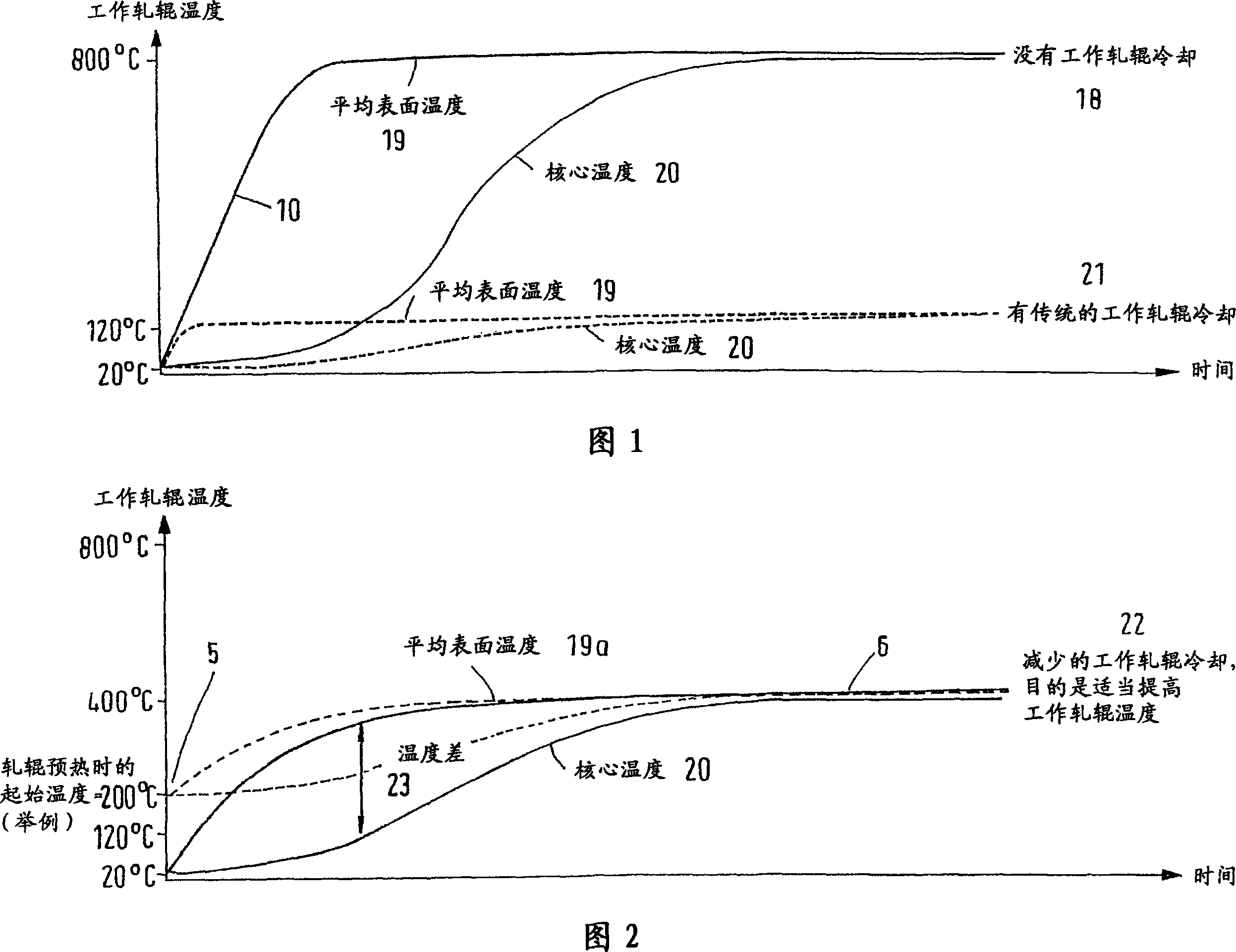

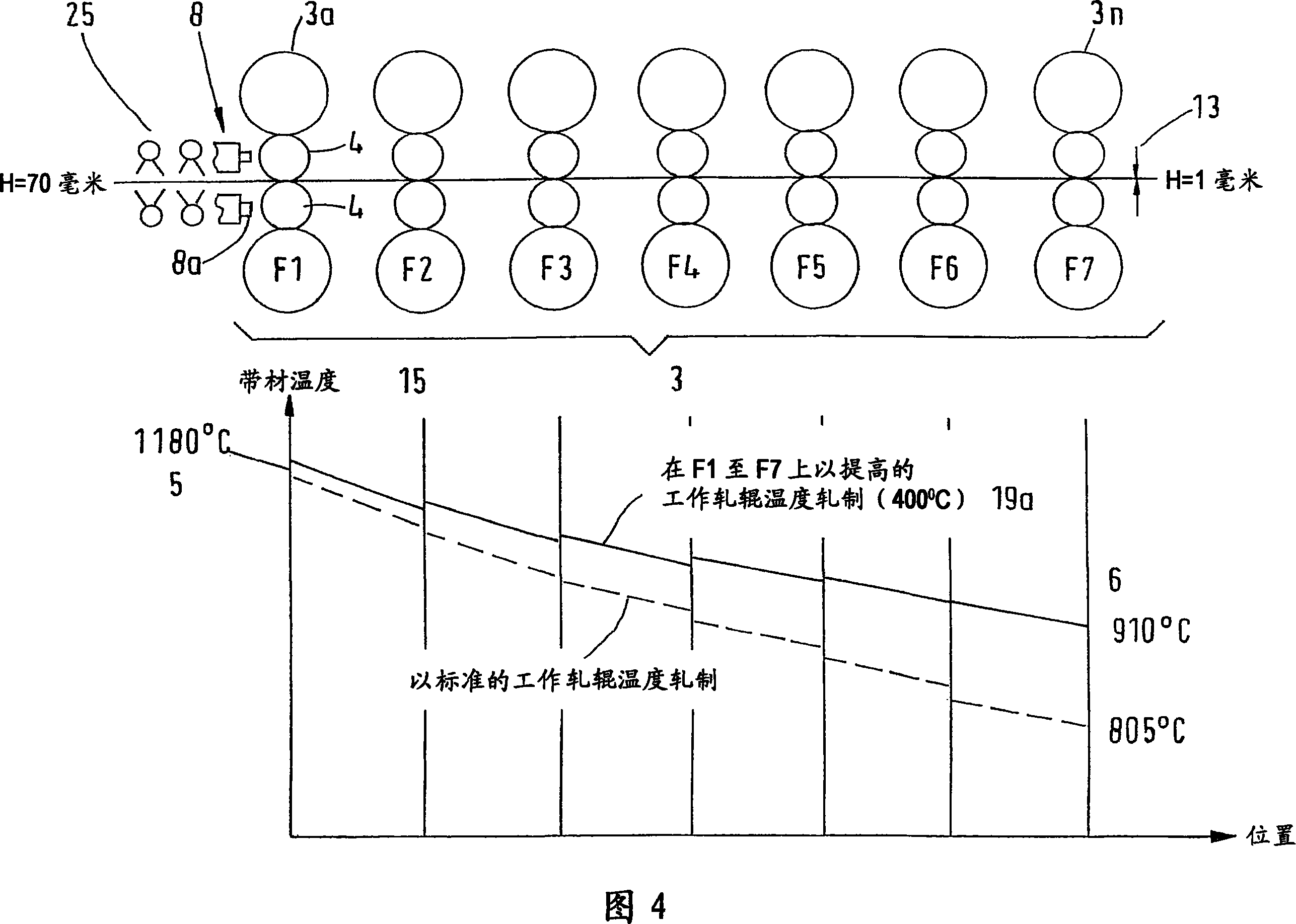

[0045] In a conventional hot strip finishing mill 3 for continuous casting of metals, especially steel slabs 1, thin strips are produced in discontinuous operation, for example rolling for approximately 180 seconds followed by approximately 20 seconds rolling interval. An average work roll surface temperature of approximately 120°C19 occurs during rolling, and the surface will cool to near water temperature during the batch process. After the hot strip 2 has been rolled several times, a roll temperature of approximately 90° C. can be measured at the end of the rolling program.

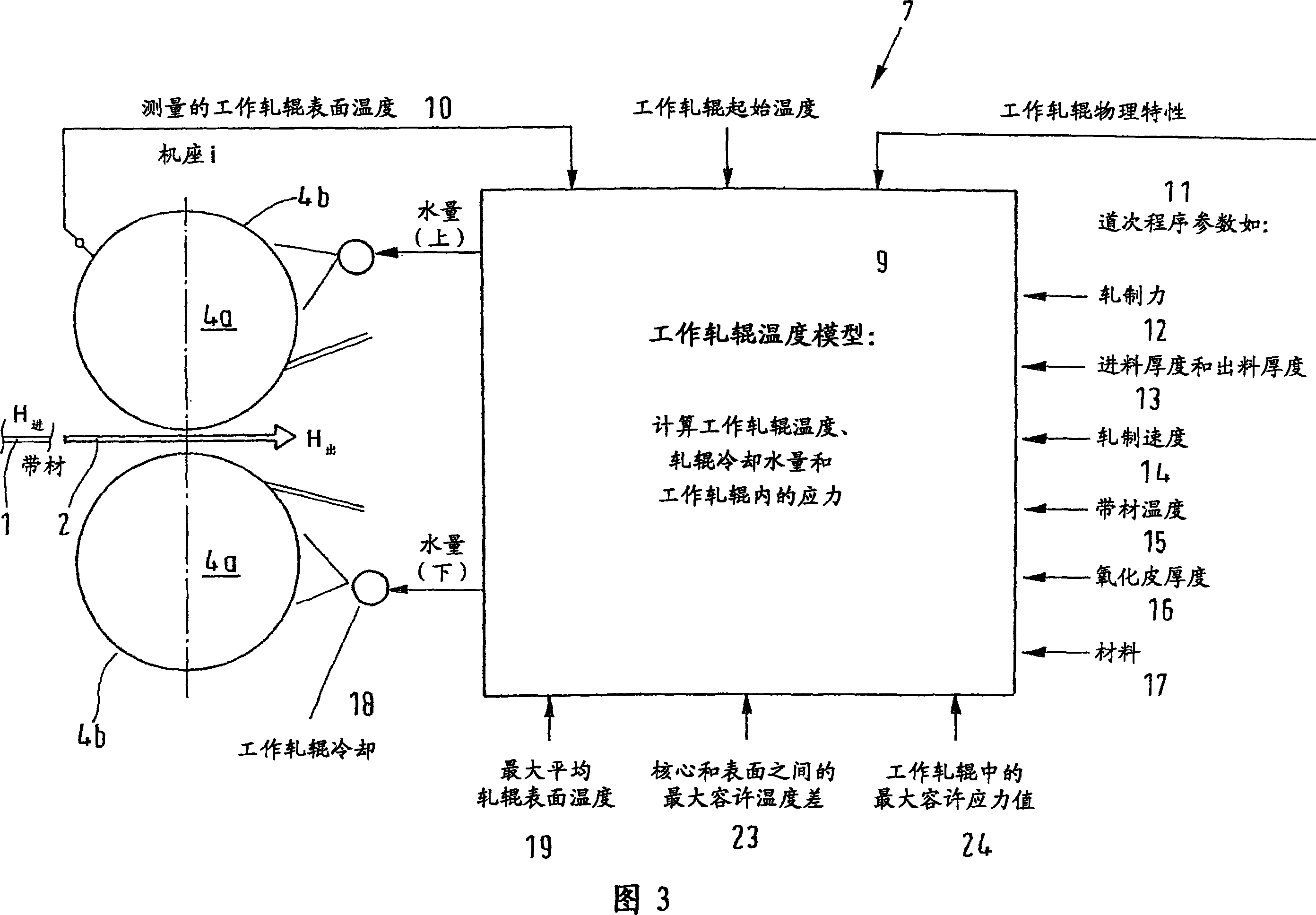

[0046] In the direct connection between the continuous casting plant and the hot-strip finishing mill 3 , during continuous rolling in the hot-strip finishing mill 3 , strip temperature losses occur which need to be minimized by suitable measures. For this reason it is proposed that the rolls should be operated at a higher working roll temperature for all or part of the rolling stands 3a...3n.

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com