Method and system for preparing multi-scale precipitated nano heterogeneous magnesium alloy plates

A magnesium alloy, multi-scale technology, applied in manufacturing tools, metal rolling, metal rolling, etc., can solve the problems of difficult interface oxidation control, affect product quality, low production efficiency, etc., and achieve large microstructure design directionality and flexibility, reducing control difficulty, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] In the following, the present invention will be further described in detail in conjunction with the embodiments. This embodiment is implemented on the premise of the technical solution of the present invention, and provides detailed implementation methods and operating procedures.

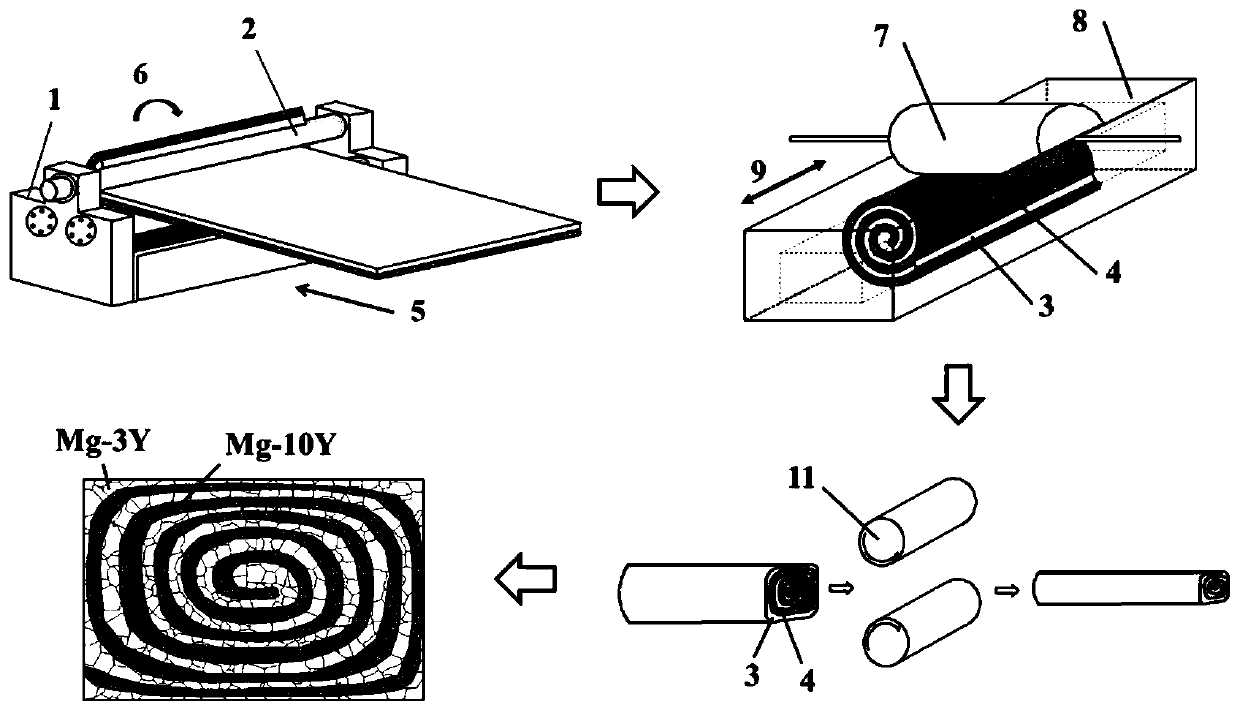

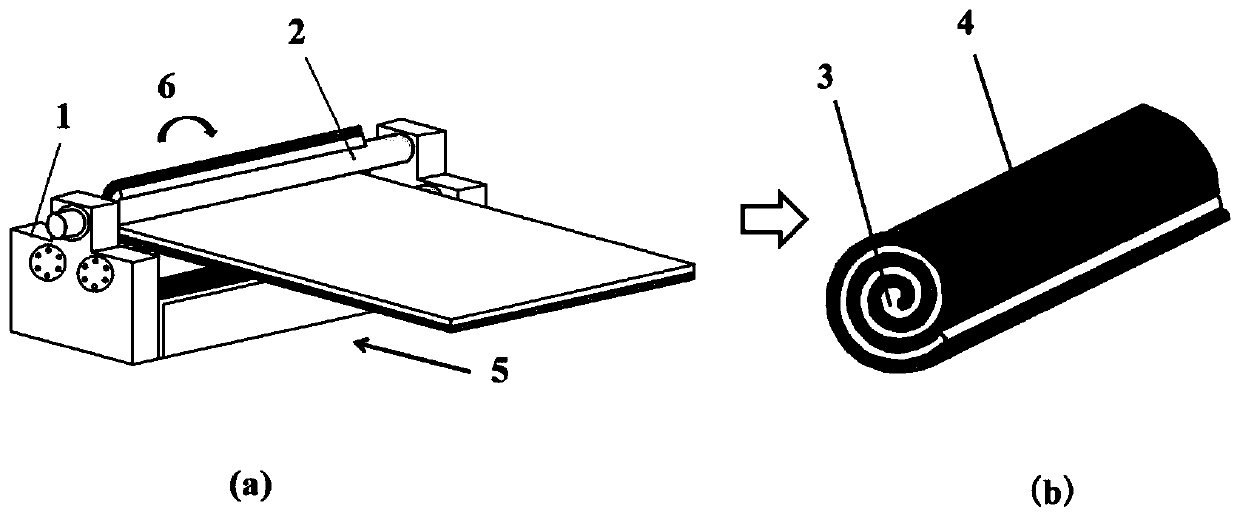

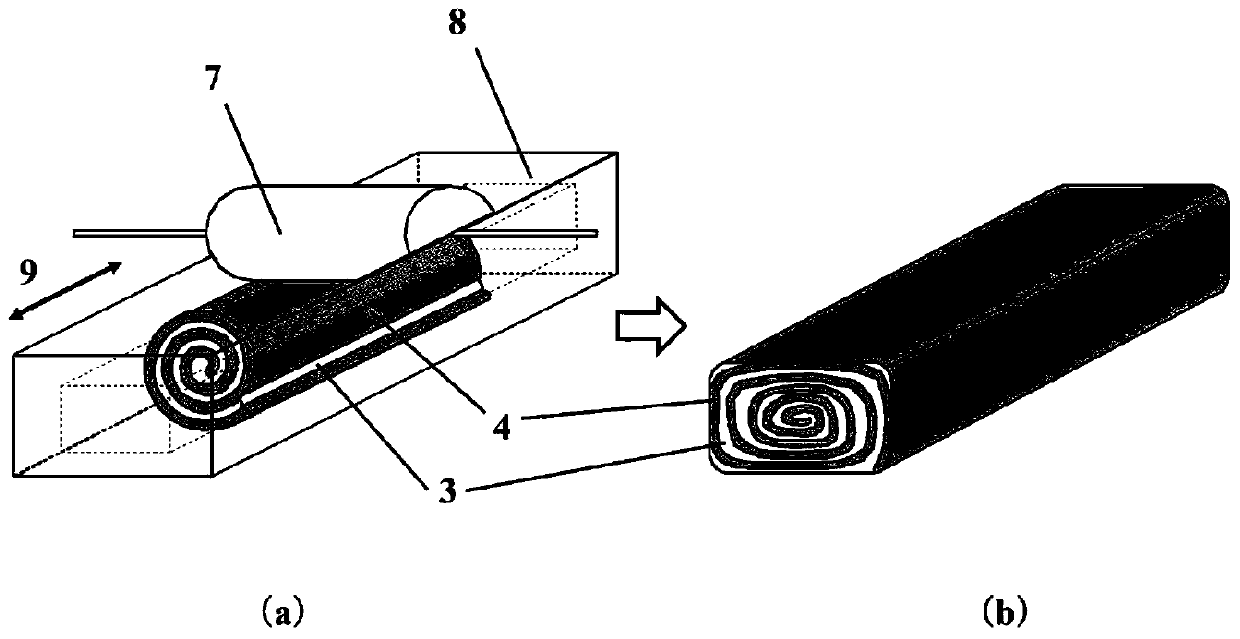

[0048] (1) Choose a length of 0.6m, a width of 0.4m, a Mg-3Y magnesium alloy plate 3 of 3mm and a Mg-10Y magnesium alloy plate 4 of the same size, and polish the surface of the selected magnesium alloy plate and cleaning to remove surface oil and scale, and stack the Mg-3Y magnesium alloy plate 3 on top of the Mg-10Y magnesium alloy plate 4.

[0049] (2) Set the speed of the upper and lower rolls of the three-roll asynchronous rolling mill 1, the speed of the upper roll 2 is 6rpm, and the lower roll is 12rpm, and the two stacked plates are rolled into bars by the three-roll asynchronous rolling mill. The left end of the upper roll 2 stretches out from the part of the three-high rolling mill,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com