Preparation method for gold-coated zinc oxide flower-like microspheres

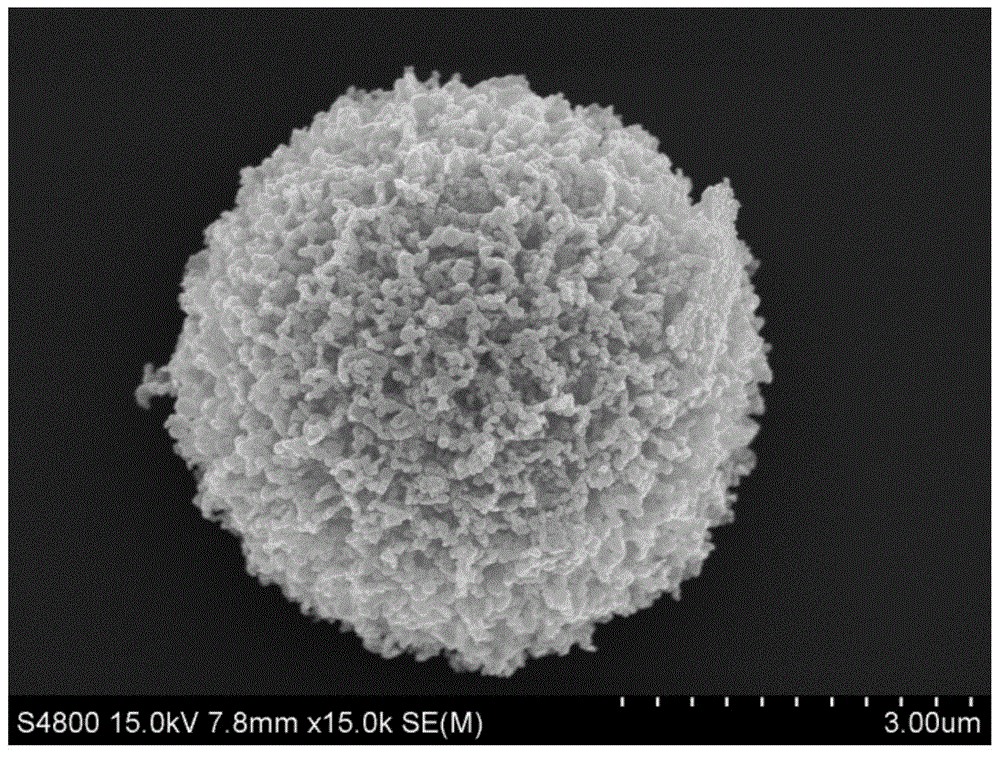

A flower-shaped microsphere, zinc oxide technology, applied in the direction of zinc oxide/zinc hydroxide, nanotechnology, nanotechnology, etc., can solve the problem of lack of gold-coated zinc oxide flower-shaped microsphere preparation method, etc., to achieve good gas sensor performance and light. The effect of catalytic performance, large synthesis amount, and strong detection ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention provides a method for preparing gold-coated zinc oxide flower-shaped microspheres, comprising the following steps:

[0032] (1) Weigh Zn(CH 3 COOH) 2 2H 2 O powder, trisodium citrate dihydrate powder, and hexamethylenetetraammonium were dissolved in 100ml of deionized water, so that the molar ratio of the three substances was 10:1:10, and stirred for 0.5h;

[0033] (2) Put the mixed solution in a serum bottle, react at 90-100°C for 3-5h, then take out the serum bottle and cool it at room temperature;

[0034] (3) Alternately centrifuging the obtained precipitate with deionized water and absolute ethanol, and drying the product at 50-70° C. for 12 hours;

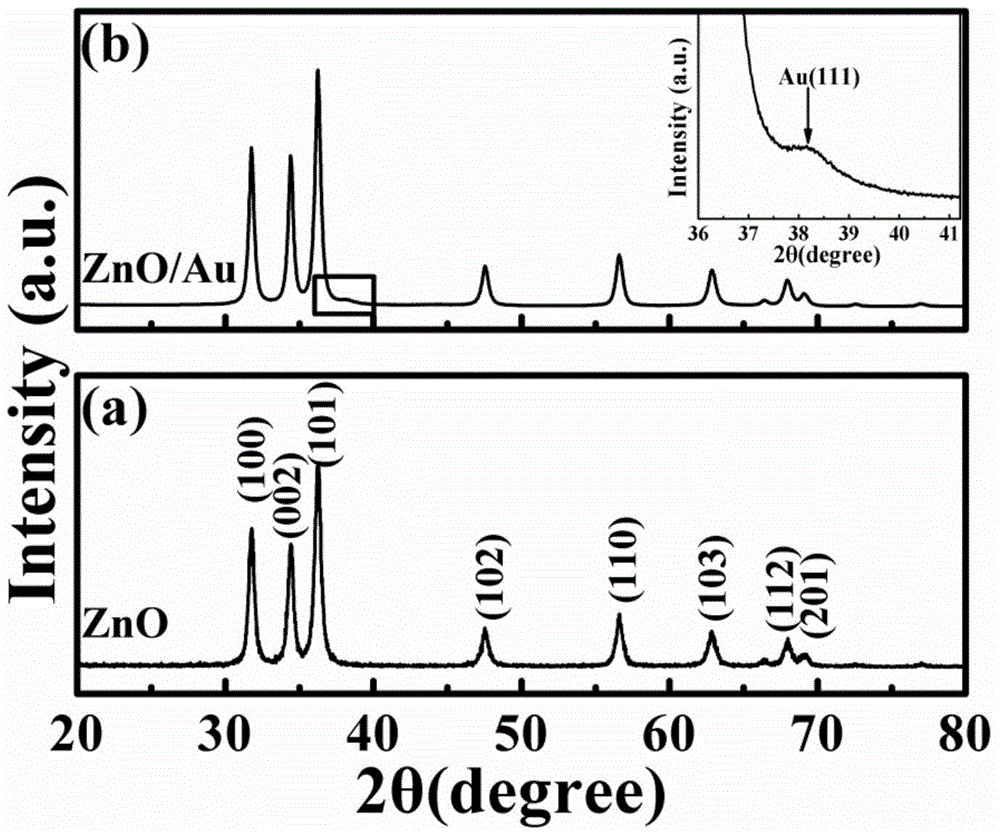

[0035] (4) Take out the dried product and anneal at 400°C for 30 minutes to obtain flower-shaped ZnO powder;

[0036] (5) Add ZnO powder to 100ml deionized water, then add 110ul of 1% HAuCl by mass 4 4H 2 O was added therein, and after heating for 15 minutes at 100-110°C in an oil bath, 3ml of triso...

Embodiment 1

[0040] The invention provides a method for preparing gold-coated zinc oxide flower-shaped microspheres, comprising the following steps:

[0041] (1) Weigh 0.01mol of Zn(CH 3 COOH) 2 2H 2 O powder 2.1951g, the purity is 99.99%, Sigma-Aldrich; 0.001mol trisodium citrate dihydrate powder 0.2941g, the purity is 99.99%, Sigma-Aldrich; 0.01mol hexamethylenetetramine 1.40186g, the purity is 99.99%, Sigma-Aldrich dissolved in 100ml deionized water, stirred for 0.5h;

[0042] (2) Put the mixed solution in a serum bottle, react at 90° C. for 3 hours, then take out the serum bottle and cool it at room temperature; the serum bottle is 200 ml.

[0043] (3) Alternately centrifuging the obtained precipitate with deionized water and absolute ethanol, and drying the obtained product at 50° C. for 12 hours;

[0044] (4) Take out the dried product and anneal at 400°C for 30 minutes to obtain flower-shaped ZnO powder;

[0045] (5) Add ZnO powder to 100ml deionized water, then add 110ul of 1%...

Embodiment 2

[0048] The invention provides a method for preparing gold-coated zinc oxide flower-shaped microspheres, comprising the following steps:

[0049] In step (1), weigh 13.1706g of Zn(CH 3 COOH) 2 2H 2 O powder, 1.7646g of trisodium citrate dihydrate powder, 8.4112g of hexamethylenetetraammonium dissolved in 100ml of deionized water, so that the molar ratio of the three substances is 10:1:10, stirred for 0.5h;

[0050] In step (2), the mixed solution is placed in a serum bottle, reacted at 95° C. for 4 hours, and then the serum bottle is taken out and cooled at room temperature;

[0051] In step (3), the obtained precipitate was alternately centrifuged with deionized water and absolute ethanol, and the obtained product was dried at 60° C. for 12 hours;

[0052] In step (5), ZnO powder was added to 100ml deionized water, followed by 110ul of 1% HAuCl 4 4H 2 O was added therein, after heating at 105° C. in an oil bath for 15 minutes, 3 ml of trisodium citrate dihydrate with a ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com