Mn13 high-manganese steel welding technology

A welding process, high manganese steel technology, applied in the field of steel welding, can solve the problems of strict welding process requirements, expensive welding materials, low welding efficiency, etc., to achieve the effect of ensuring joint performance, lower cost, and improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

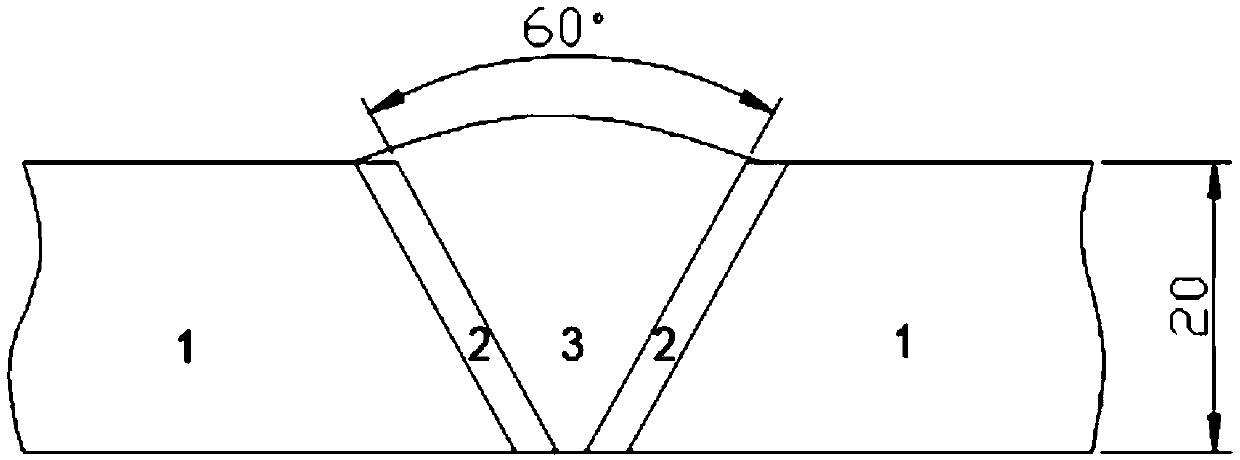

[0036] Take butt welding of 20mm thick Mn13 steel plate as an example, process 60° V-shaped welding groove, the schematic diagram of the joint is as follows figure 1 shown.

[0037] Use φ4.0mm stainless steel electrodes for manual arc welding of the transition layer, and water-cool and hammer the welding area in time. Use 60kg low-alloy steel welding wire with a specification of φ1.2mm for argon-rich gas shielded welding of filled welds, using 80% Ar+20% CO 2 As a shielding gas, the gas flow rate is 20L / min, and a walking trolley is used to realize automatic welding. The specific welding parameters are shown in Table 1.

[0038] Table 1 welding process parameters

[0039]

[0040] Macrophotographs of welded joint sections (see figure 2 ), indicating that the joints are well fused, and there are no welding defects such as cracks, pores, and slag inclusions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com