Solar cell grid line slurry, preparation method thereof and solar cell

A technology for solar cells and grid lines, applied in the field of solar cells, can solve the problems of slurry overflow at the edge of grid lines, low aspect ratio, etc., and achieve the effects of improving efficiency, high aspect ratio, and low contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

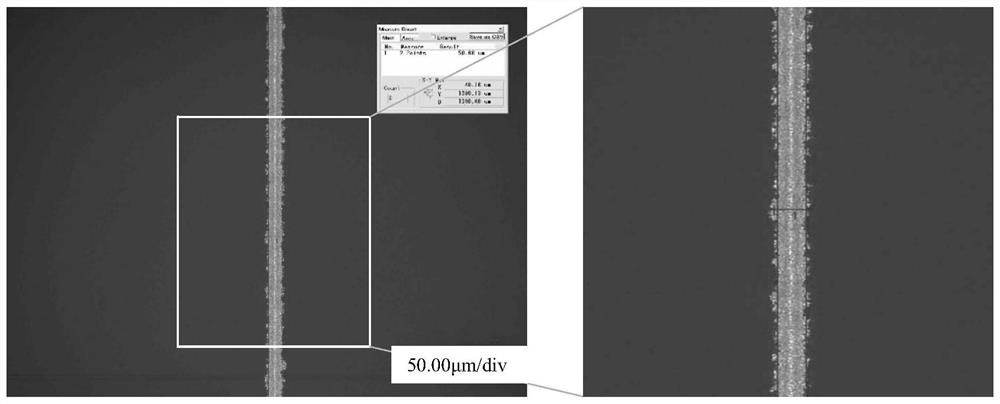

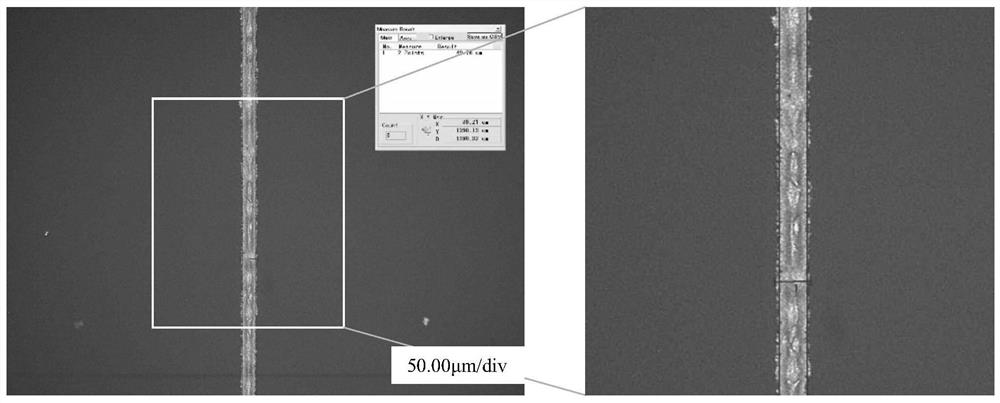

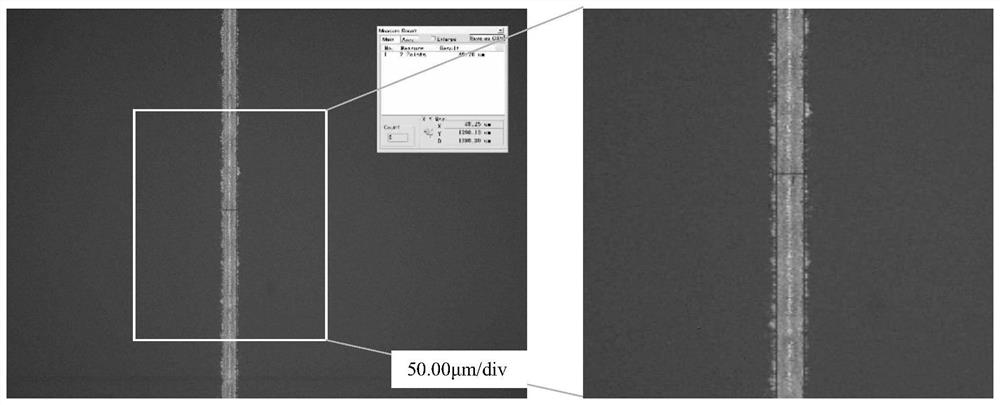

Image

Examples

preparation example Construction

[0071] The embodiment of the present invention also provides a preparation method of solar cell grid wire paste, comprising the following steps:

[0072] S10. Obtain the mixed slurry of conductive filler, polymer resin, curing agent, solution and auxiliary agent;

[0073] S20. Grinding the mixed slurry to obtain solar cell grid wire slurry.

[0074] The preparation method of the solar cell grid wire slurry in the embodiment of the present invention is to obtain the mixed slurry of conductive filler, polymer resin, curing agent, solution and auxiliary agent, and then grind the mixed slurry to obtain the solar cell grid wire slurry, the above-mentioned grid line slurry with high content of conductive filling factor and low contact resistance with the battery can be obtained, and the interaction force between the components of the slurry forms a cohesive force inside the grid line slurry, effectively controlling the grid line The precipitation of the solvent and the overflow of ...

Embodiment 1

[0084] A solar cell grid wire slurry, comprising the steps of:

[0085] ① Weigh 4.49g of Huntsman GY6010 epoxy resin is uniformly dispersed in 5.55g terpineol solvent I to obtain mixed solution A, which is an epoxy resin solution system. Weigh another 1.01g of Huntsman's curing agent 2844, uniformly dispersed in the mixed solution of 2.0g solvent I terpineol and 1.14g auxiliary agent I ethylene glycol diacetate to obtain mixed solution B, which is the curing agent solution system. The epoxy resin solution and the curing agent solution are mixed to obtain the bonding system of the slurry.

[0086] ② Weigh again 85.81g of submicron silver powder I, and mix the silver powder with the above-mentioned bonding system to obtain a mixed slurry. In the rotation-revolution mixer, the prepared silver paste was thoroughly mixed for 15 seconds at a speed of 3000 rpm. Finally, roll and disperse on a three-roll machine to obtain the final product—solar cell grid wire paste.

Embodiment 2

[0088] A solar cell grid wire slurry, comprising the steps of:

[0089] ① Weigh 3.11g of bisphenol F epoxy resin from Hexion 862, uniformly dispersed in 5.41g terpineol solvent I to obtain mixed solution A, which is an epoxy resin solution. Another 0.22g of imidazole curing agent 2MZ-Azine produced by CVC Thermal Specialties was weighed and uniformly dispersed in 3.0g of solvent I terpineol, 3.01g of auxiliary agent I ethylene glycol diacetate and 0.82g of auxiliary agent II 2,5- In the ternary mixed solution composed of dimethyl-2,5-hexanediol diacetate, the mixed solution B is obtained, which is the curing agent solution. The epoxy resin solution and the curing agent solution are mixed to obtain the bonding system of the slurry.

[0090] ② Weigh again 83.58g of submicron silver powder I, and mix the silver powder with the above-mentioned solution bonding system to obtain a mixed slurry. The prepared silver paste was thoroughly mixed for 15 seconds at a speed of 3000 rpm i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com