Platinum/carbon nanotube catalyst and preparation method and application thereof

A carbon nanotube and platinum nanotechnology, which is applied in the field of platinum/carbon nanotube catalysts to achieve the effect of simple preparation and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

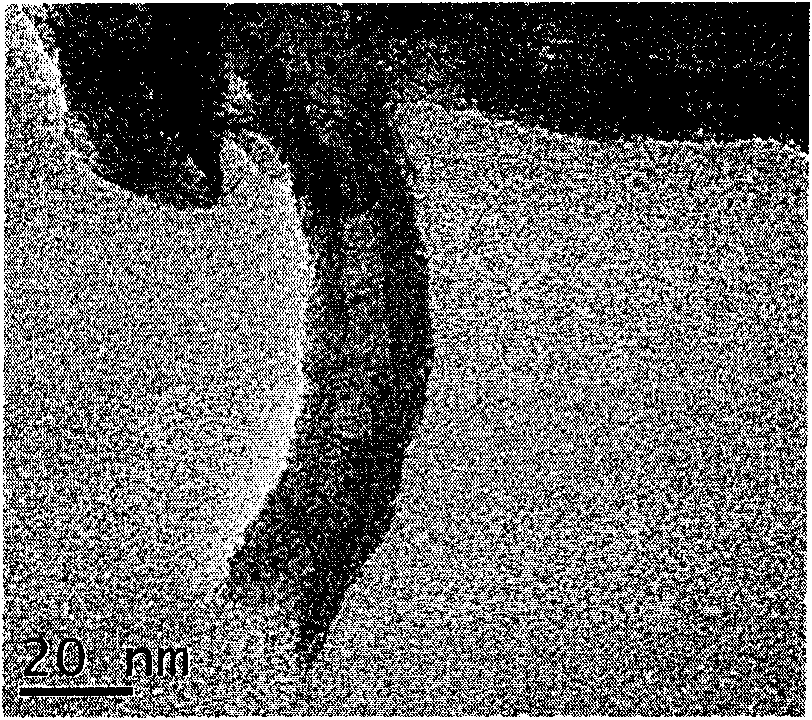

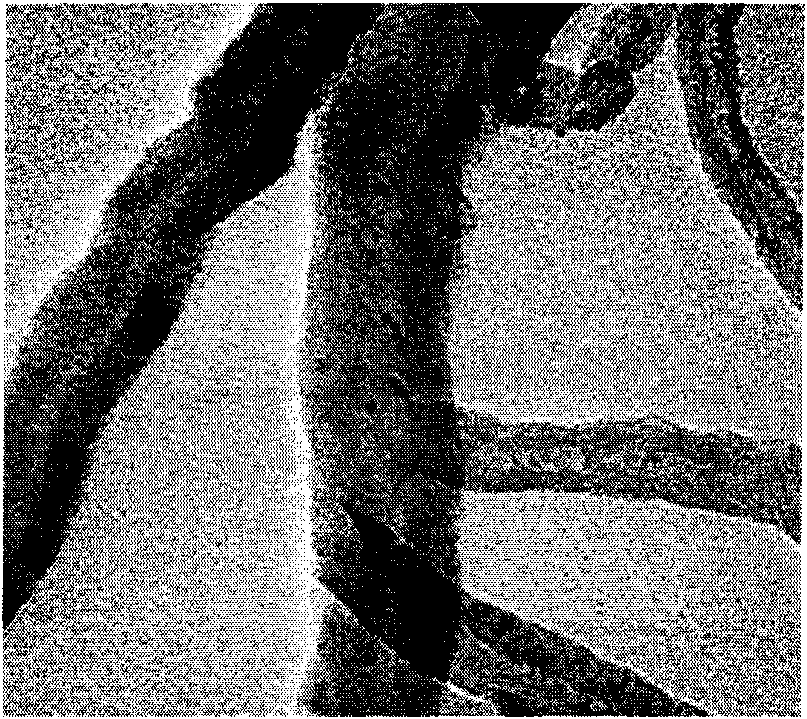

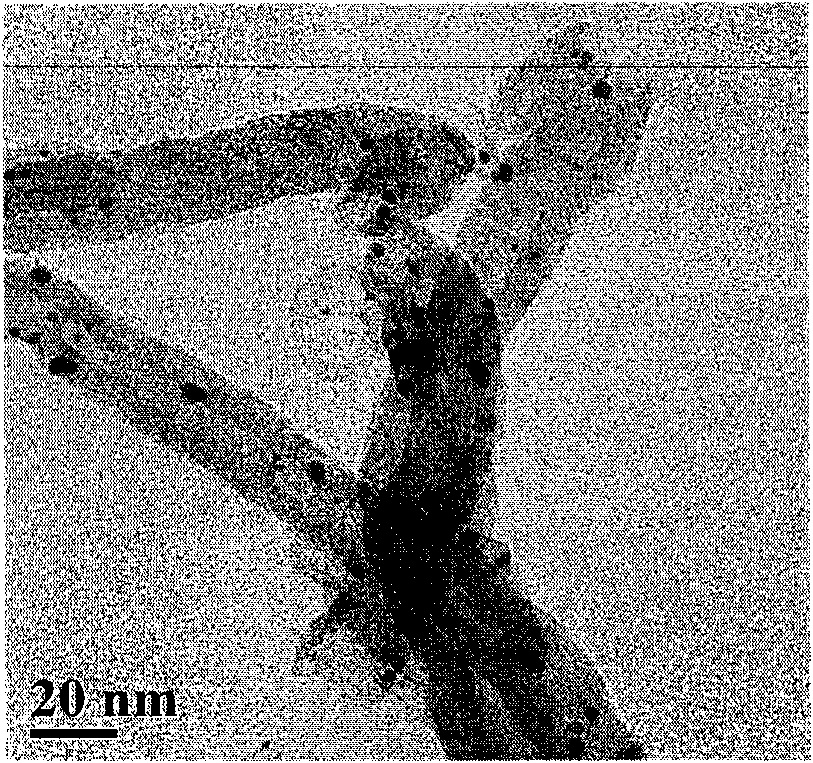

[0055] The preparation and asymmetric hydrogenation reaction of the platinum-carbon nanotube catalyst according to the present invention are respectively detailed as follows:

[0056] (1) Preparation of carbon nanotube support

[0057] Treat the purified carbon nanotubes with a certain geometric size with concentrated nitric acid (65-68%), heat them under stirring for 4-16 hours, and heat them at a temperature of 110-160°C, then wash and filter them, wash with water until the pH value of the filtrate is neutral, and place in 50 ~ 120 ℃ drying oven for 12 ~ 24h, to obtain functionalized carbon nanotube black carrier, used to prepare platinum / carbon nanotube catalysts (coded as Pt-in-CNTs) and Platinum / carbon nanotube catalyst (coded as Pt-out-CNTs) loaded on the outer surface of the carbon nanotube lumen.

[0058] (2) Ultrasonic treatment impregnation

[0059] Submerge the functionalized carbon nanotube carrier in an aqueous solution of chloroplatinic acid of a certain concen...

Embodiment 1

[0086] Preparation of functionalized carbon nanotube supports.

[0087]Weigh 4.0 grams of purified carbon nanotubes (average inner diameter 4-8nm, outer diameter 10-20nm) and place in a 250ml round-bottomed flask, put into a magnetic stirrer, add 200ml of concentrated nitric acid (65-68%), and put it under reflux Condenser, heated to 110-160°C in an oil bath, treated with stirring for 4-16 hours (h), cooled, washed and filtered with deionized water, washed until the pH of the filtrate was neutral, and then placed in an oven at 50-120°C The temperature is kept constant for 12-24 hours to obtain a functionalized carbon nanotube carrier.

Embodiment 2

[0089] Preparation of Platinum / Carbon Nanotube Catalysts Loaded with Platinum Nanoparticles in the Lumen of Carbon Tubes

[0090] 1) In a round bottom flask, add 2.72ml chloroplatinic acid aqueous solution (concentration is 18.5mg Pt / ml, 5% Pt load) into 20ml deionized water, mix evenly with electromagnetic stirring, then add 1.0g dry carbon nanotubes The carrier (which has been functionalized) is then placed in an ultrasonic oscillator, and the ultrasonic treatment is started for 1-4 hours.

[0091] 2) Take it out and continue to immerse under stirring for more than 12h.

[0092] 3) Slowly dry the material after step 2 from room temperature to 110°C at a rate of 0.5°C / min, and keep drying at this temperature for 48h.

[0093] 4) The catalyst precursor obtained in step 3 is reduced in an aqueous solution of sodium formate (the amount of sodium formate is about 10 to 20 times the molar amount of platinum carried on the catalyst, 70 to 120° C.). After reduction, filter, wash w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com