Patents

Literature

40results about How to "Control size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

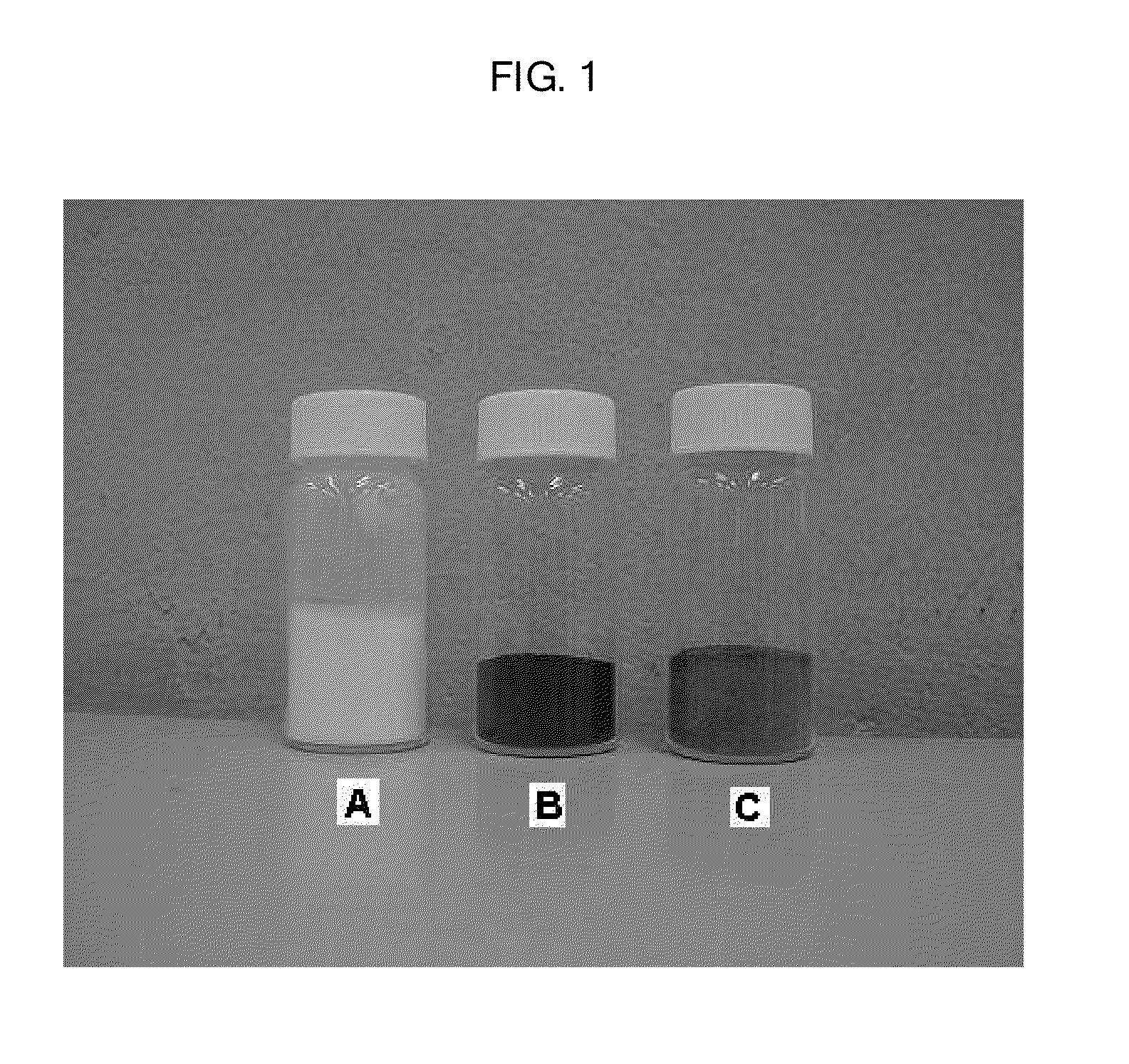

Porous sintered metal-containing materials

InactiveUS20060211802A1Adversely affecting the physical and/or chemical stabilityInhibit aggregationAdditive manufacturingTransportation and packagingSolvent freeMetallic materials

A process for manufacturing a porous metal-containing material is provided. For example, a composition is provided comprising particles dispersed in at least one solvent, the particles comprising at least one polymer material and at least one metal-based compound. The solvent can be substantially removed from the composition, and the polymer material can be substantially decomposed, thereby converting the solvent-free particles into a porous metal-containing material. In addition, metal-containing materials produced in accordance with the above process and their use in implantable medical devices can be provided.

Owner:CINVENTION AG

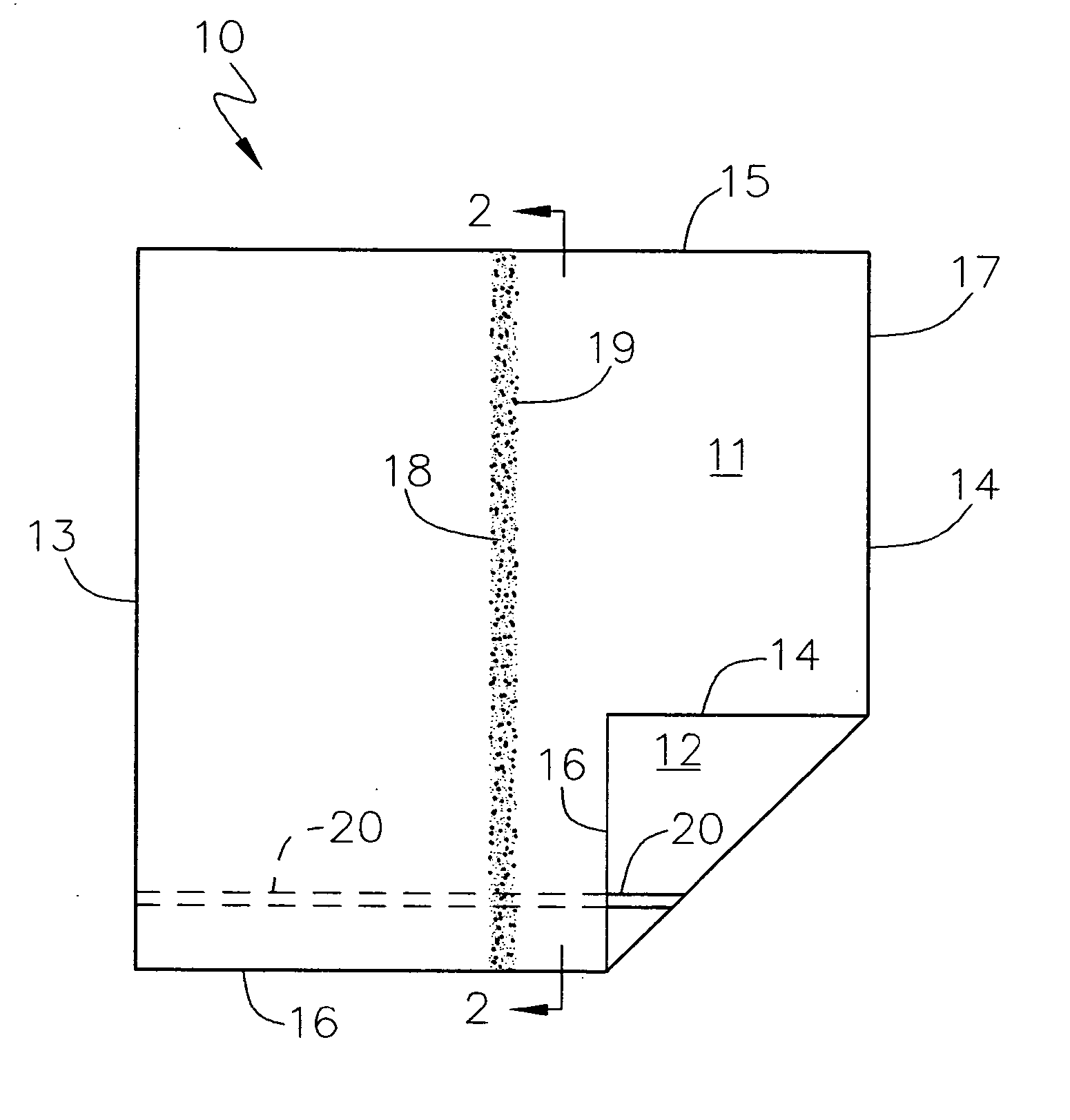

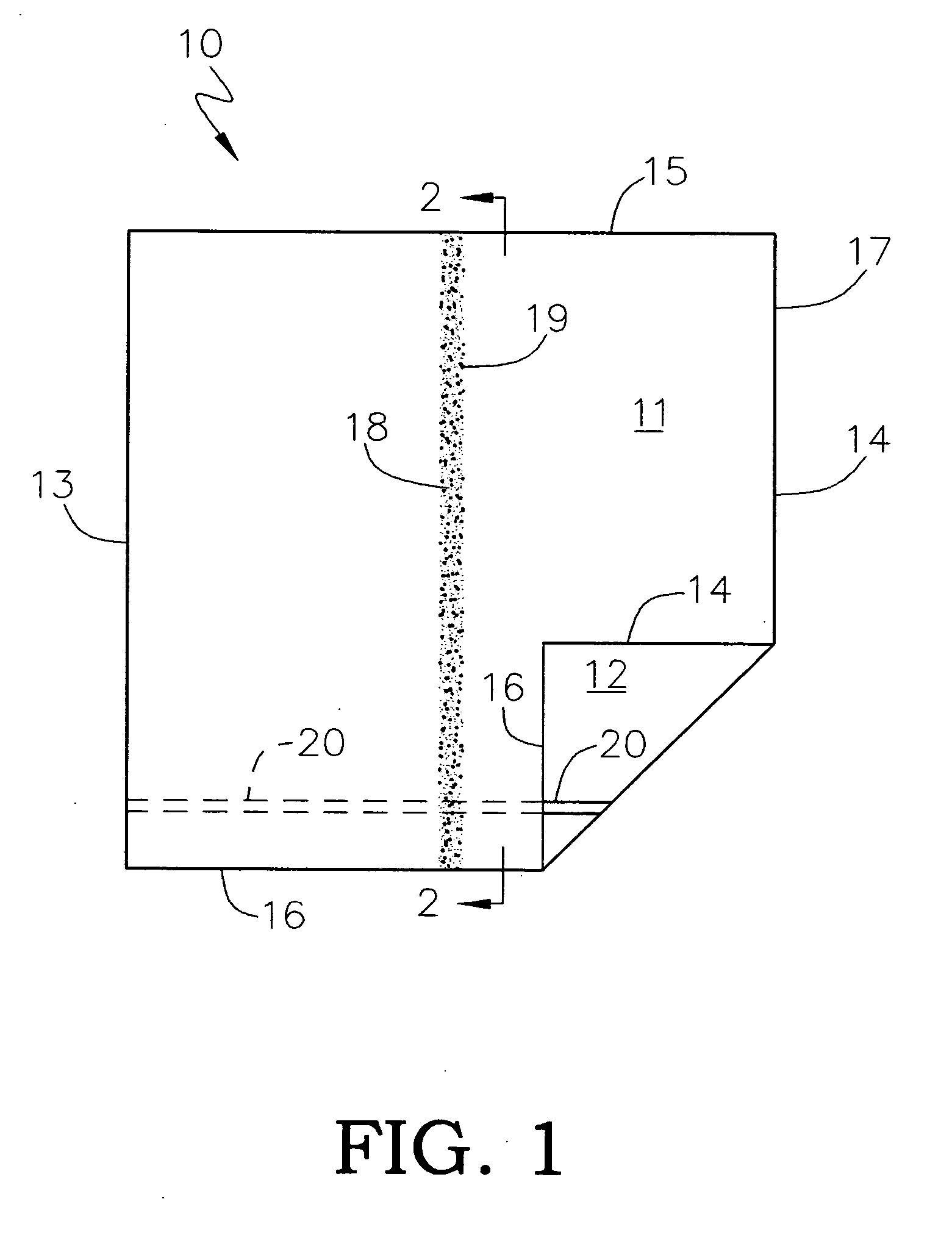

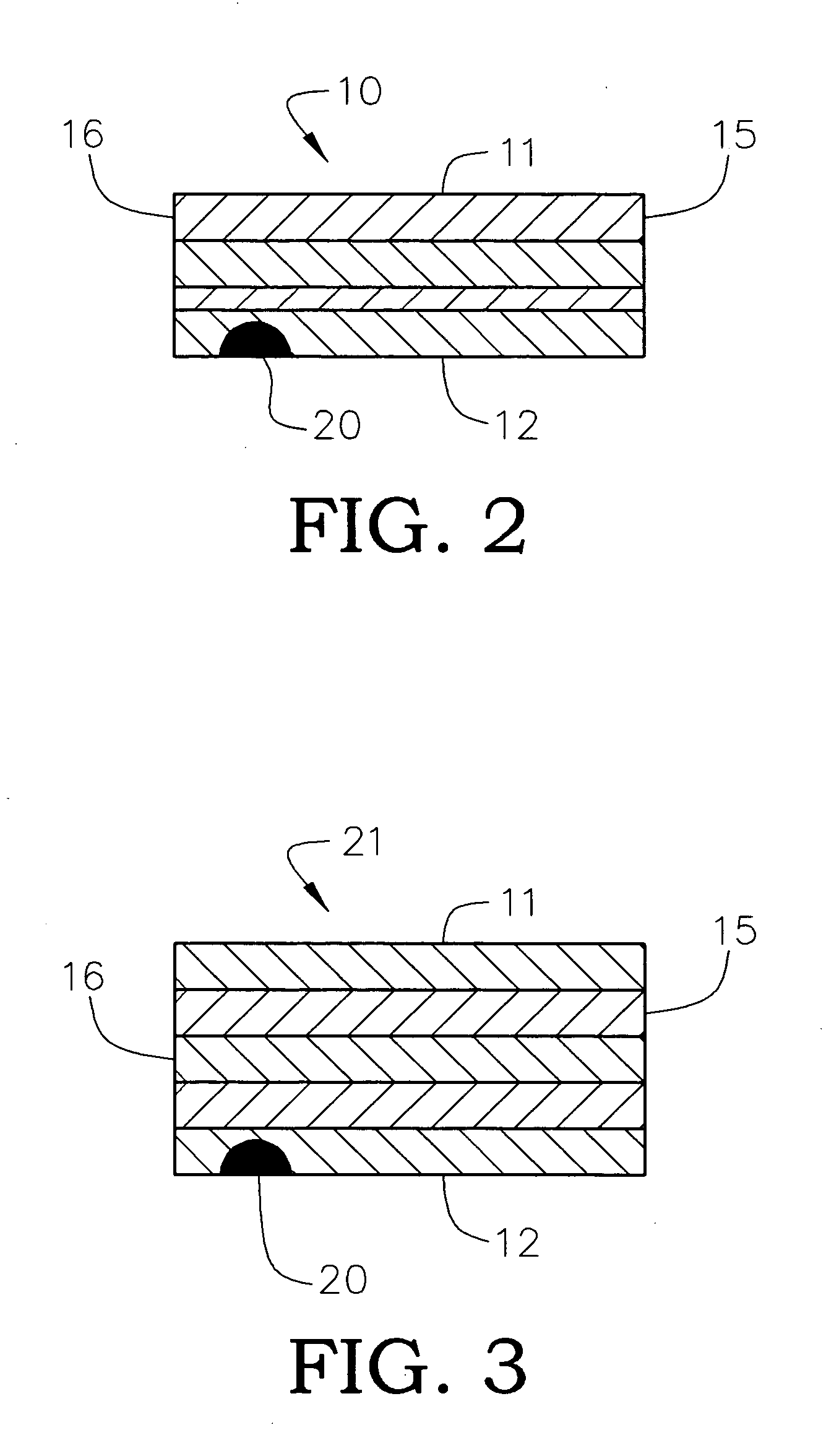

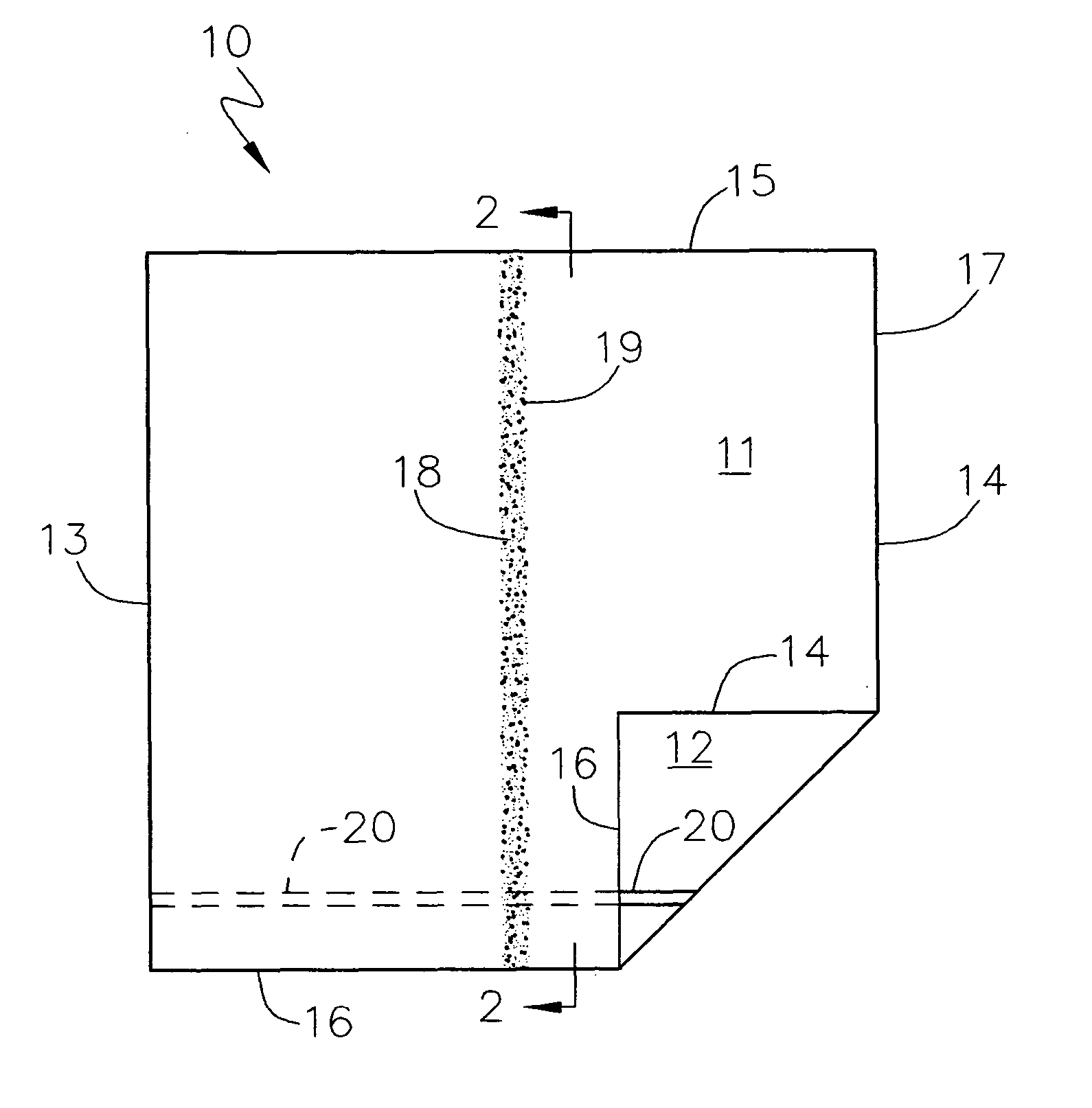

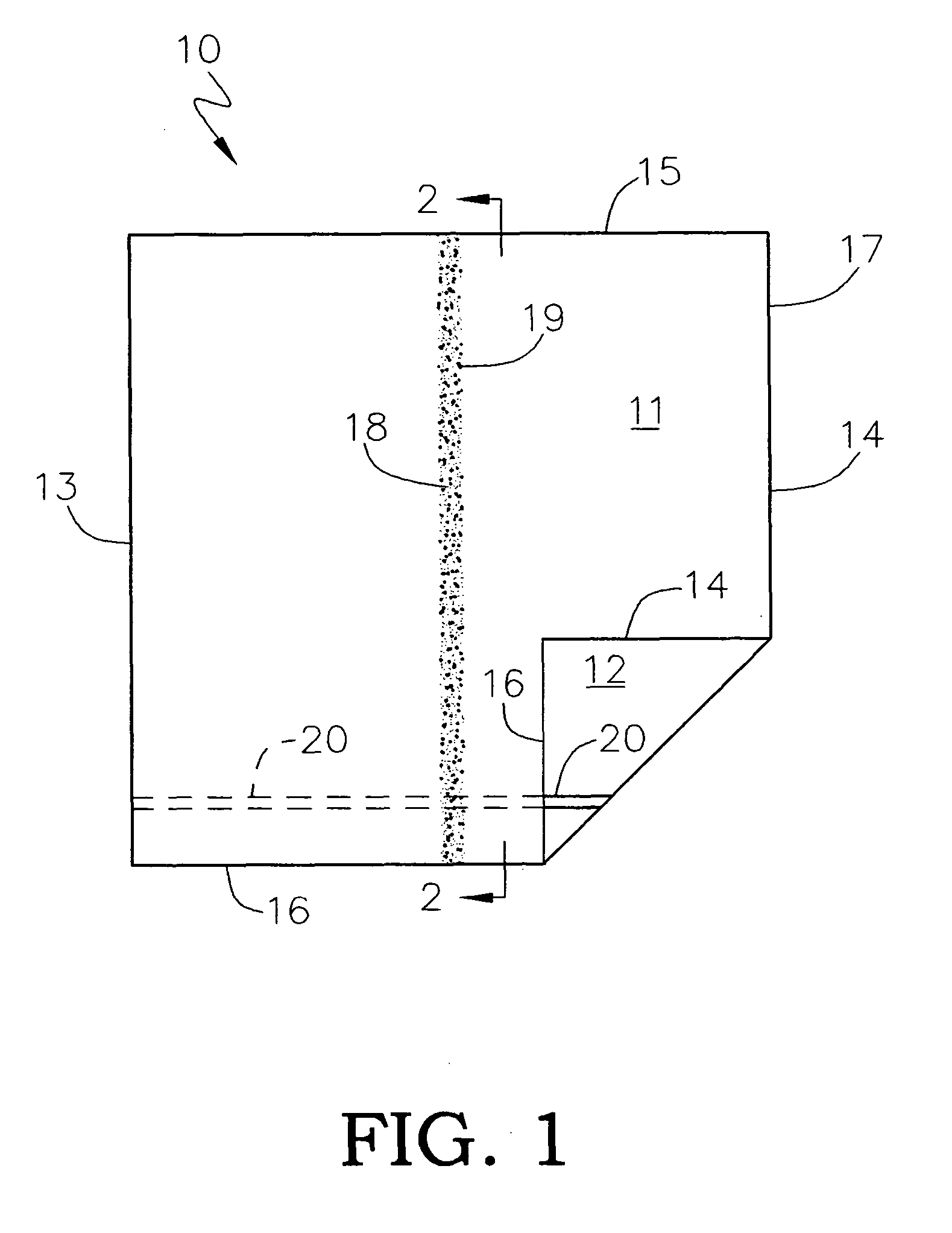

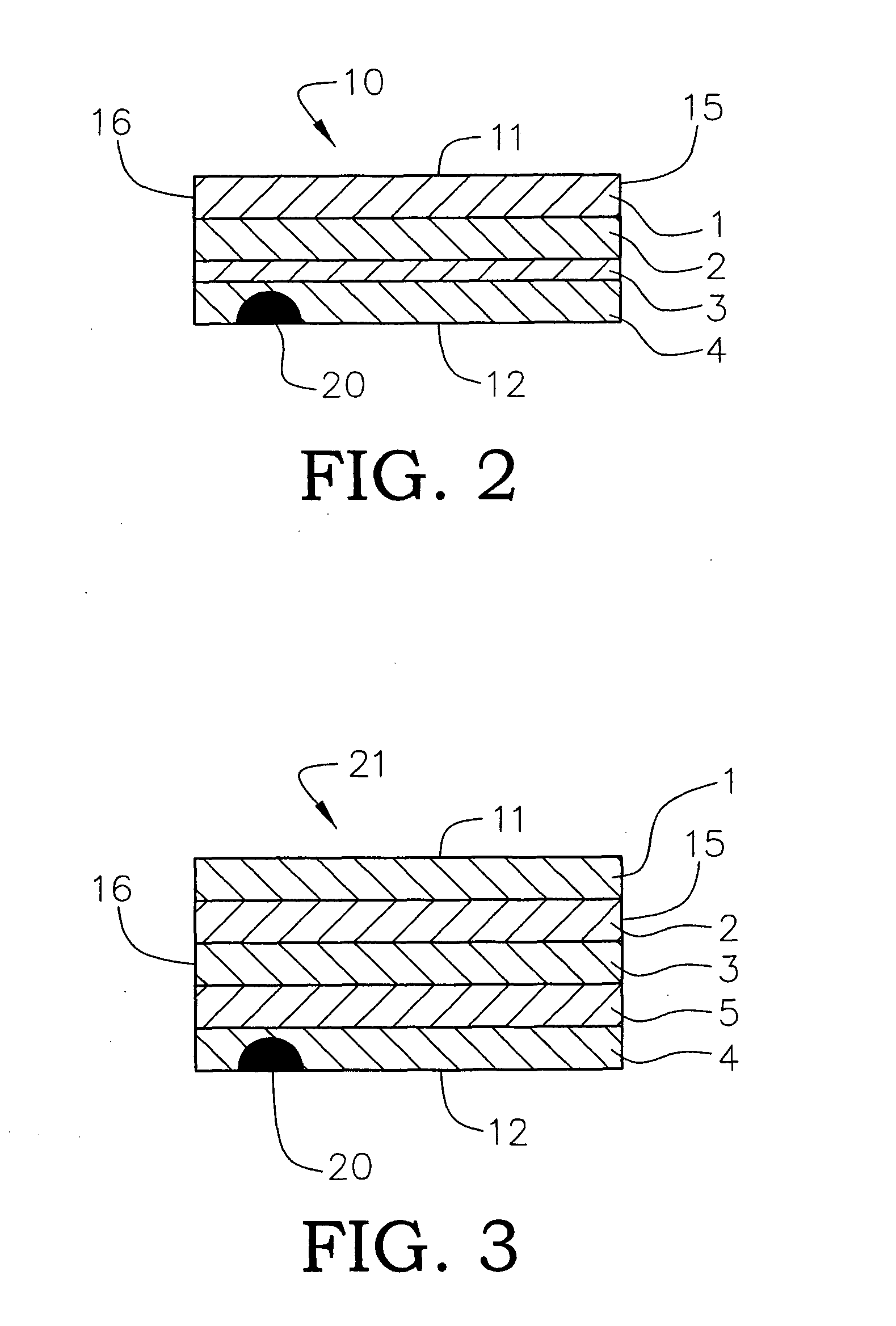

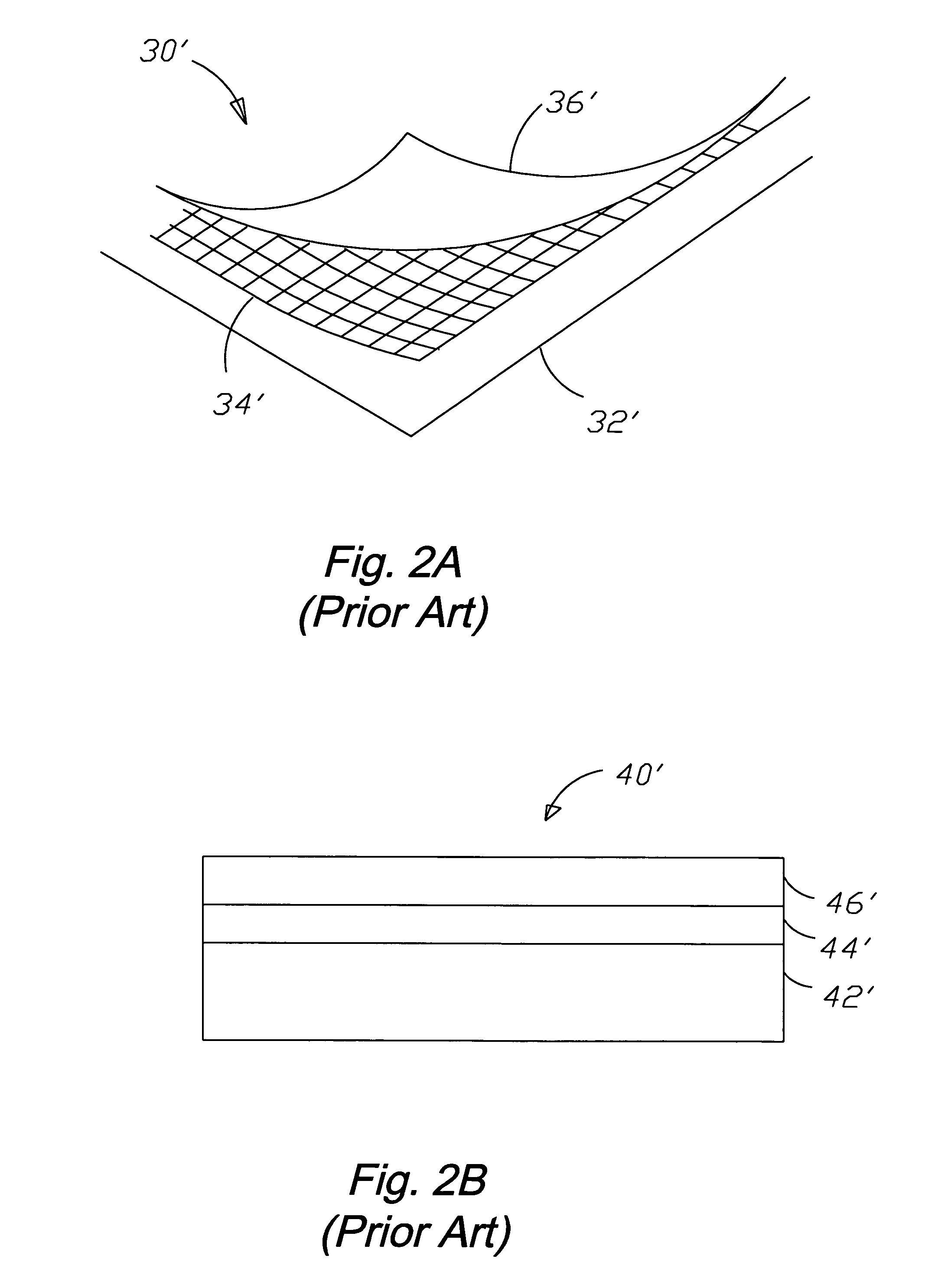

Tear initiation and directional tear films and packages made therefrom

ActiveUS20050084636A1Control depthControl shapeEnvelopes/bags making machineryStampsPolyesterPolyolefin

The present invention provides a flexible multilayer packaging film and packages formed therefrom wherein the films include a first film layer comprising a first biaxially-oriented polymer selected from the group consisting of a polyester, a polyolefin, a polyamide, and a blend thereof and a surface-roughened portion, a second film layer comprising an adhesive, a third film layer comprising a barrier material, a fourth film layer comprising a second biaxially-oriented polymer selected from the group consisting of a polyester, a polyolefin, a polyamide, and a blend thereof and at least one score-line; wherein the packages comprise a tear-initiation area and a directional tear zone.

Owner:BEMIS COMPANY INC

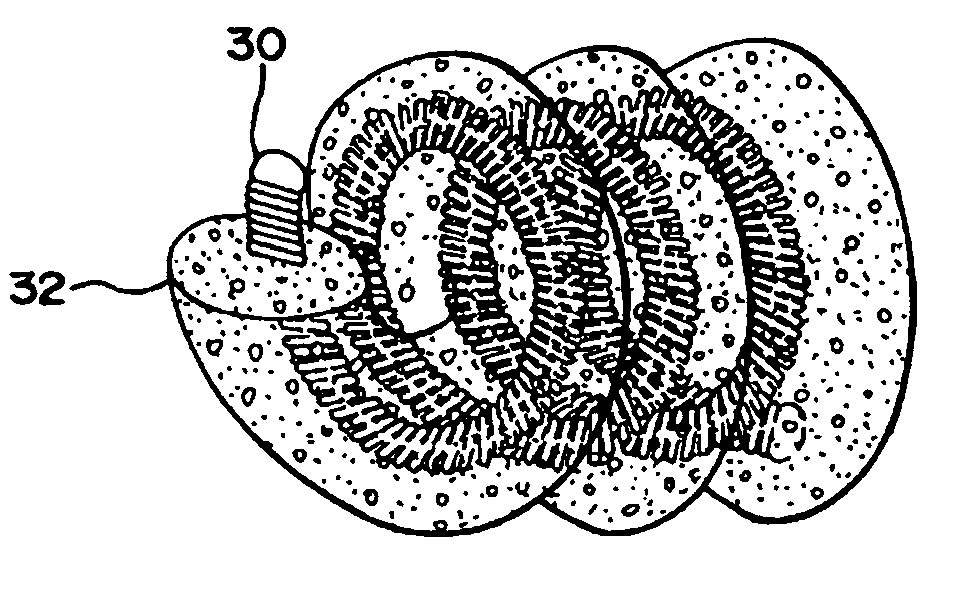

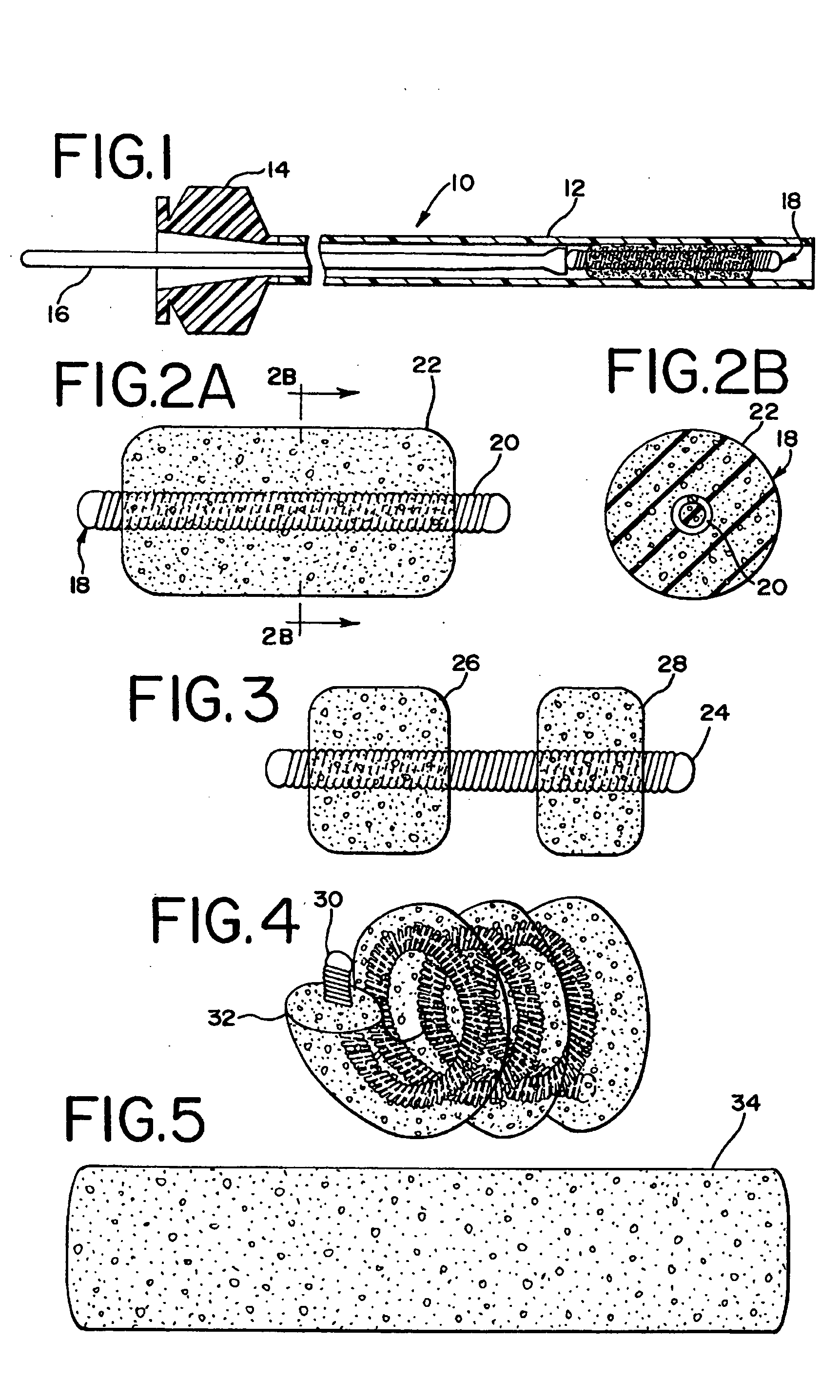

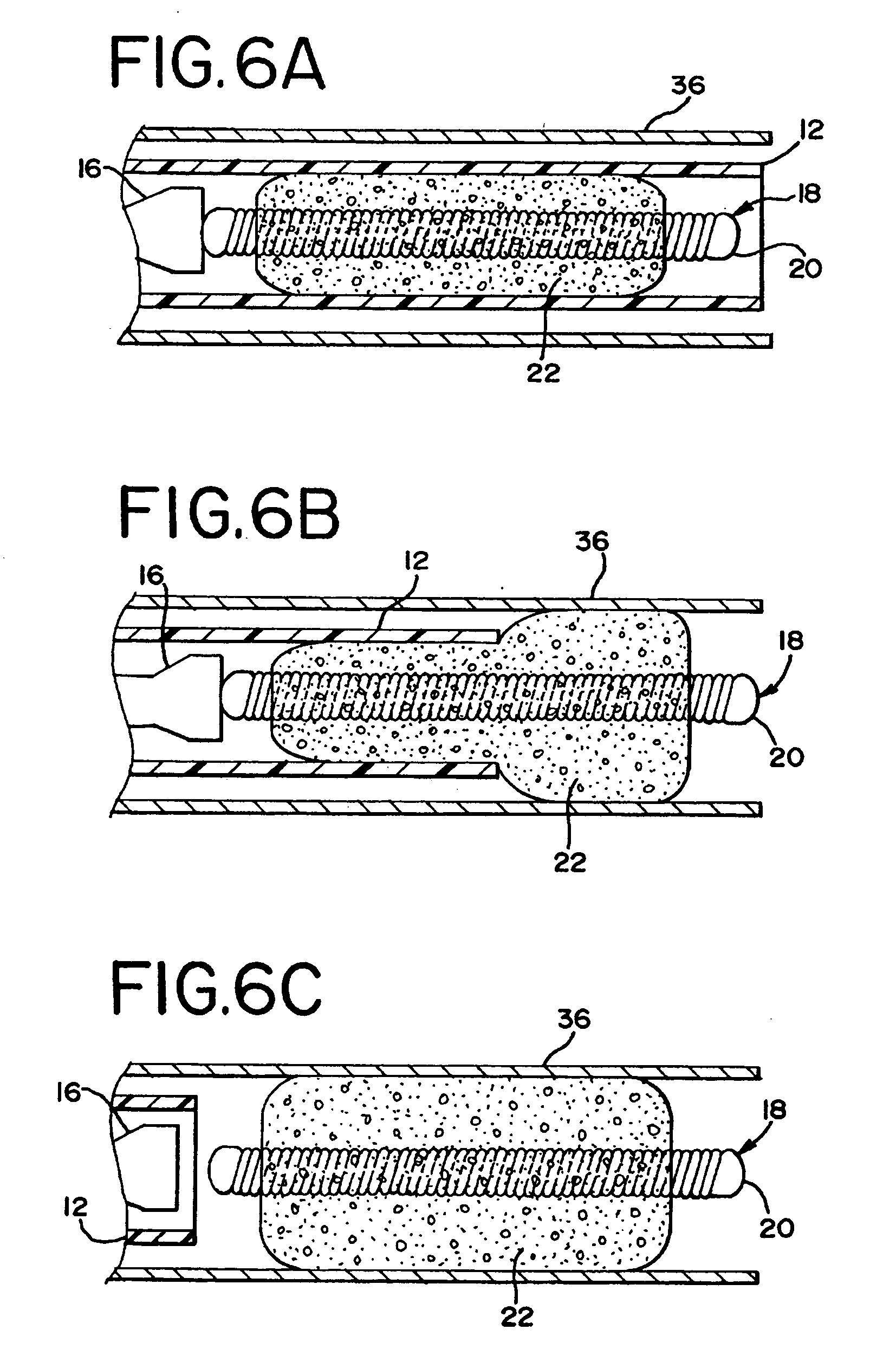

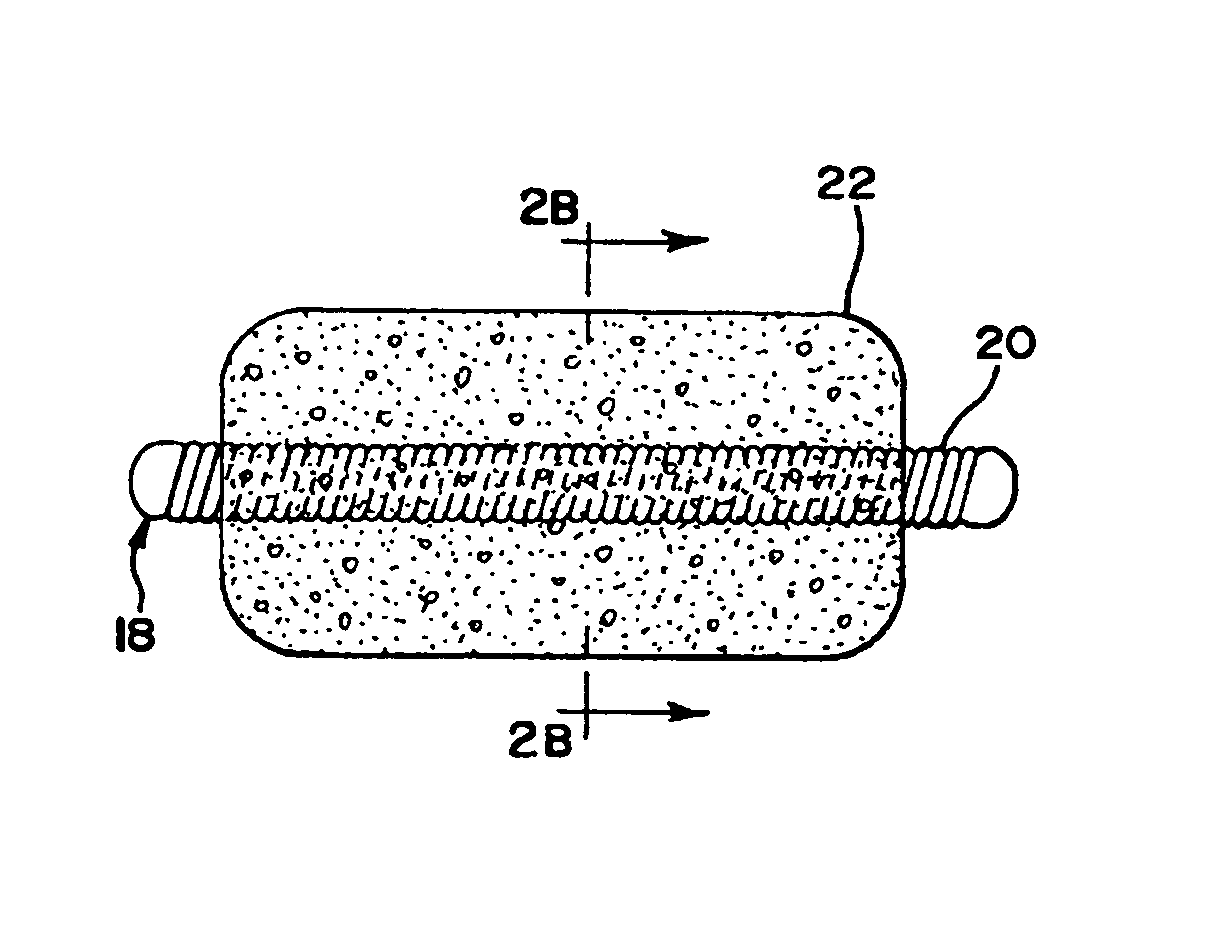

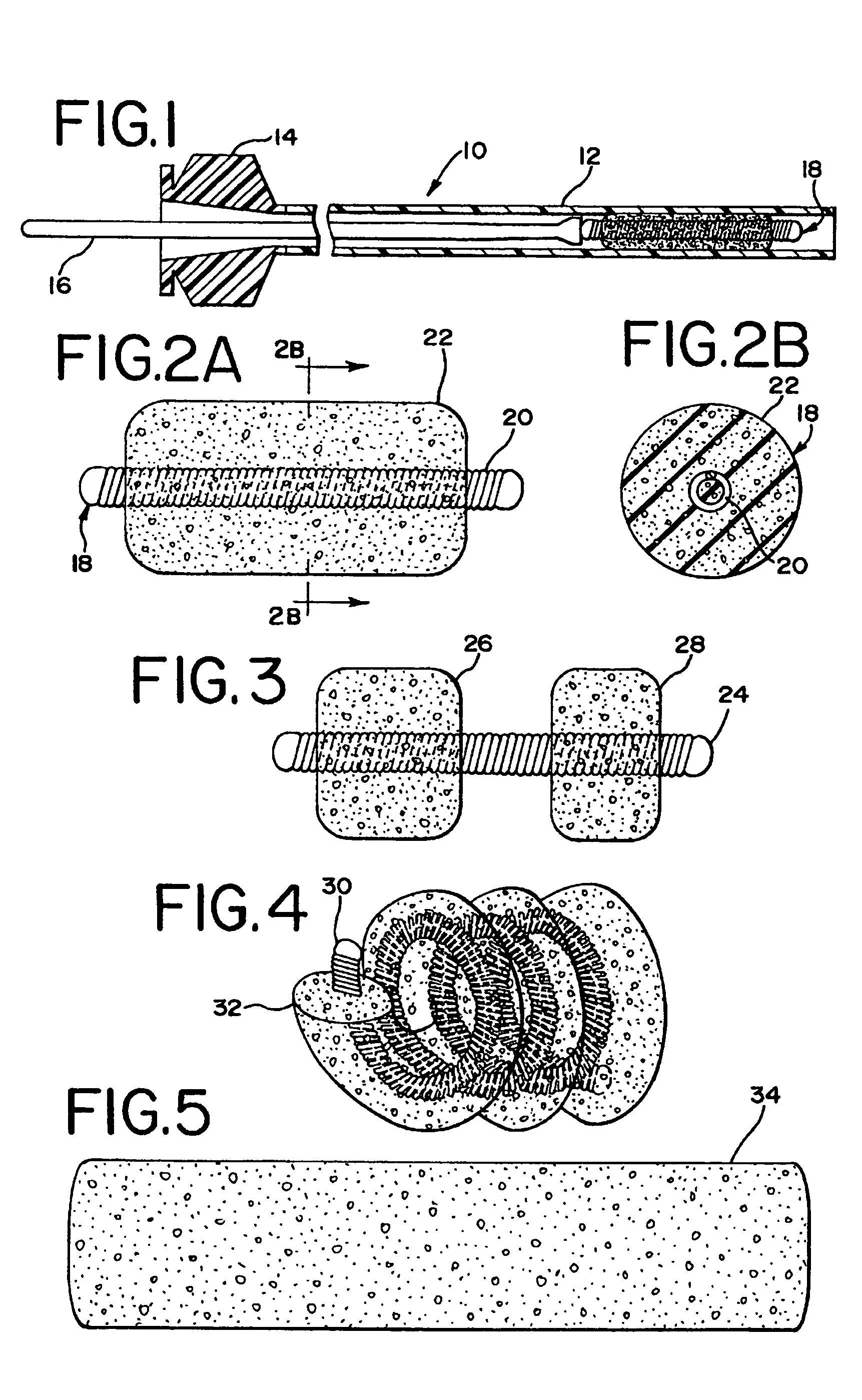

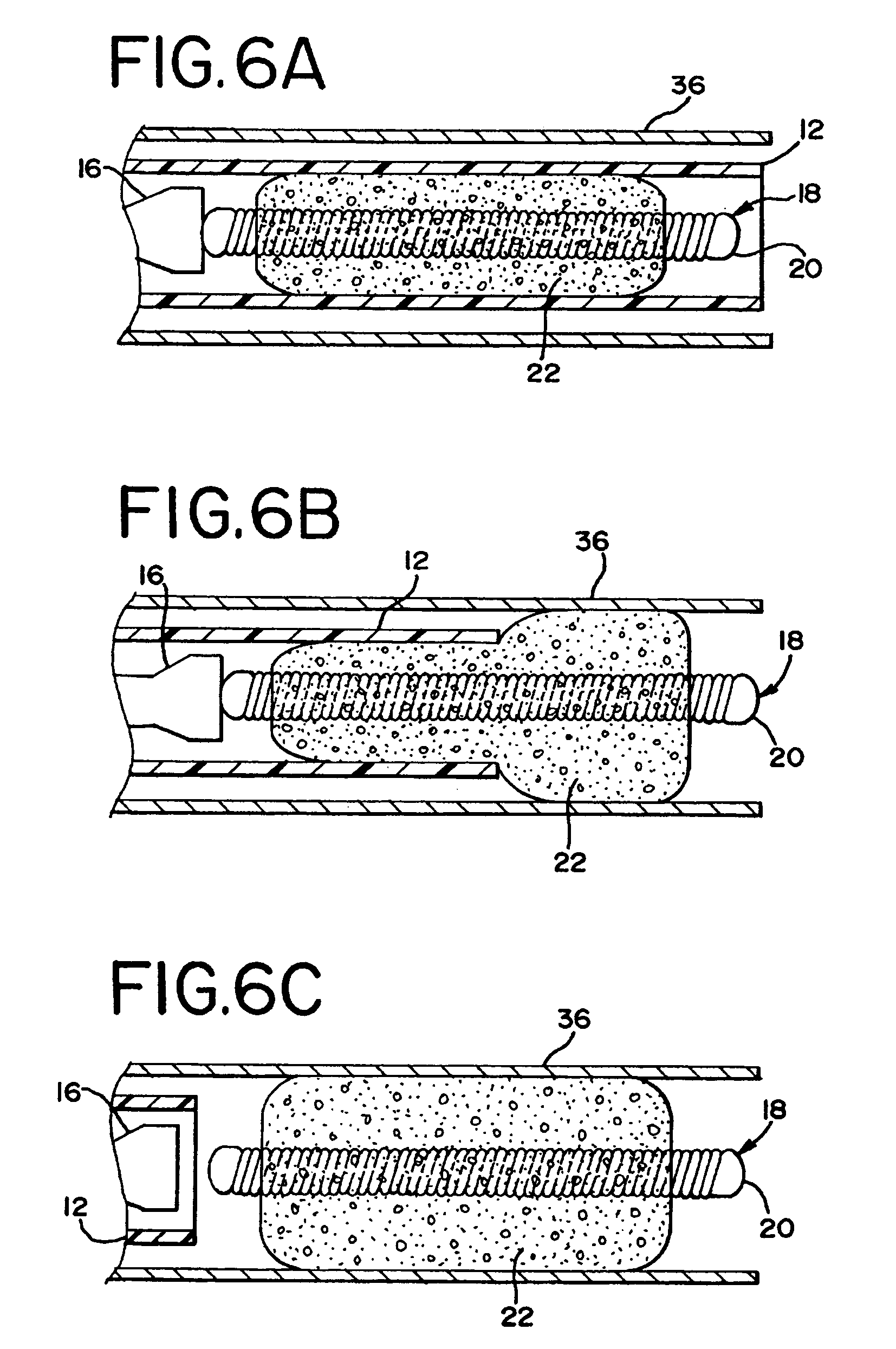

Foam matrix embolization device

InactiveUS20060058834A1Reduce coil stretchingImprove sponge mechanical integrityStentsDilatorsHuman bodyWater insoluble

The present invention relates to a medical device for placement at a predetermined location within a passageway of the human body, and more particularly, relates to a flexible embolization device which may be delivered by a catheter to a pre-selected position within a blood vessel to thereby embolize a blood vessel or a blood vessel defect, such as an aneurysm or fistula. Specifically, the embolization device comprises an elongated coil having a lumen, the coil and lumen being at least partially embedded in an elongated foam member comprising, in some embodiments, a flexible, biodegradable, water insoluble, open, interconnecting-cell foam material having embolic characteristics, and capable of allowing cell proliferation into the open cell foam interior.

Owner:CORDIS CORP

Platinum/carbon nanotube catalyst and preparation method and application thereof

InactiveCN102039121AMild conditionsEasy to manufactureOrganic reductionMaterial nanotechnologyCarbon nanotubeRoom temperature

The invention relates to a platinum / carbon nanotube catalyst suitable for multiphase asymmetric hydrogenation reaction. Platinum is loaded on a carbon nanotube carrier. A preparation method comprises the following steps of: heating a purified carbon nanotube in nitric acid, washing, filtering, washing by using water until the pH value of filtrate is neutral, drying to obtain the carbon nanotube carrier, soaking in aqueous solution of chloroplatinic acid, and performing ultrasonic treatment at room temperature; and stirring and impregnating a mixture of the carbon nanotube and the aqueous solution of chloroplatinic acid, raising the temperature to 110 DEG C from room temperature, drying at the temperature of 110 DEG C, grinding into fine powder, reducing by using aqueous solution of sodiumformate with heating, filtering, washing by using deionized water and drying. The invention also provides the preparation method of the catalyst and application of the catalyst to the multiphase asymmetric hydrogenation reaction.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

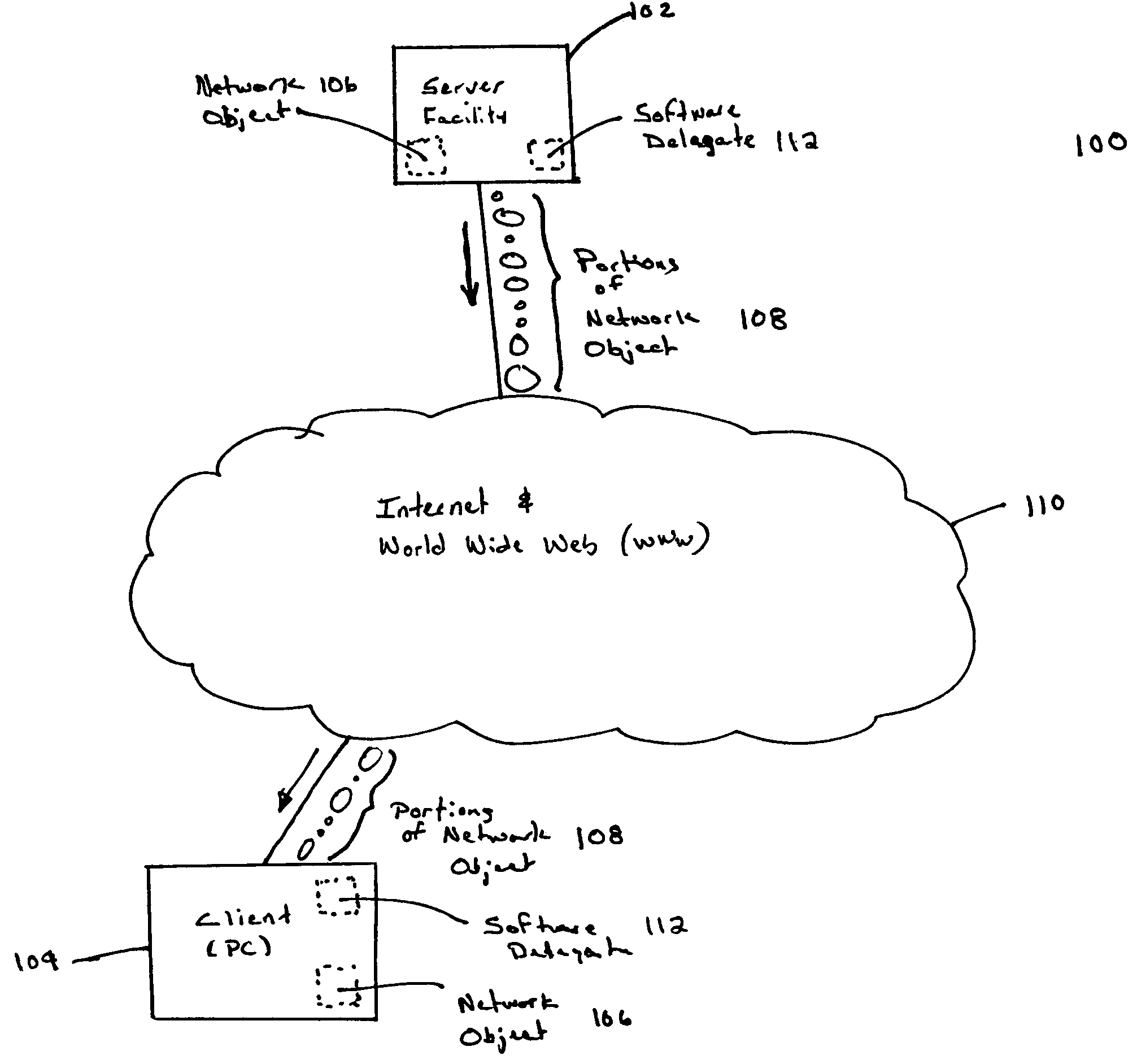

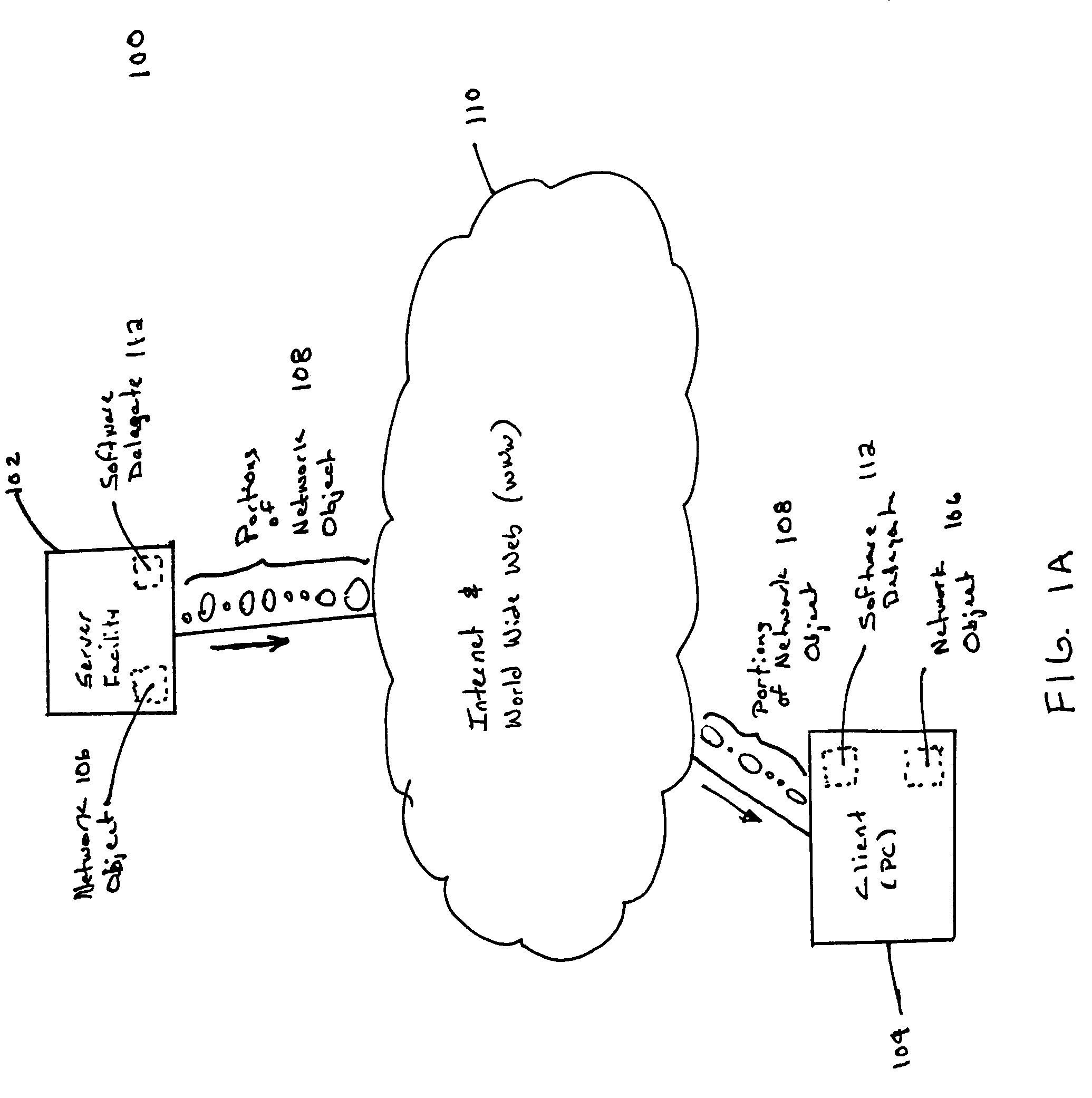

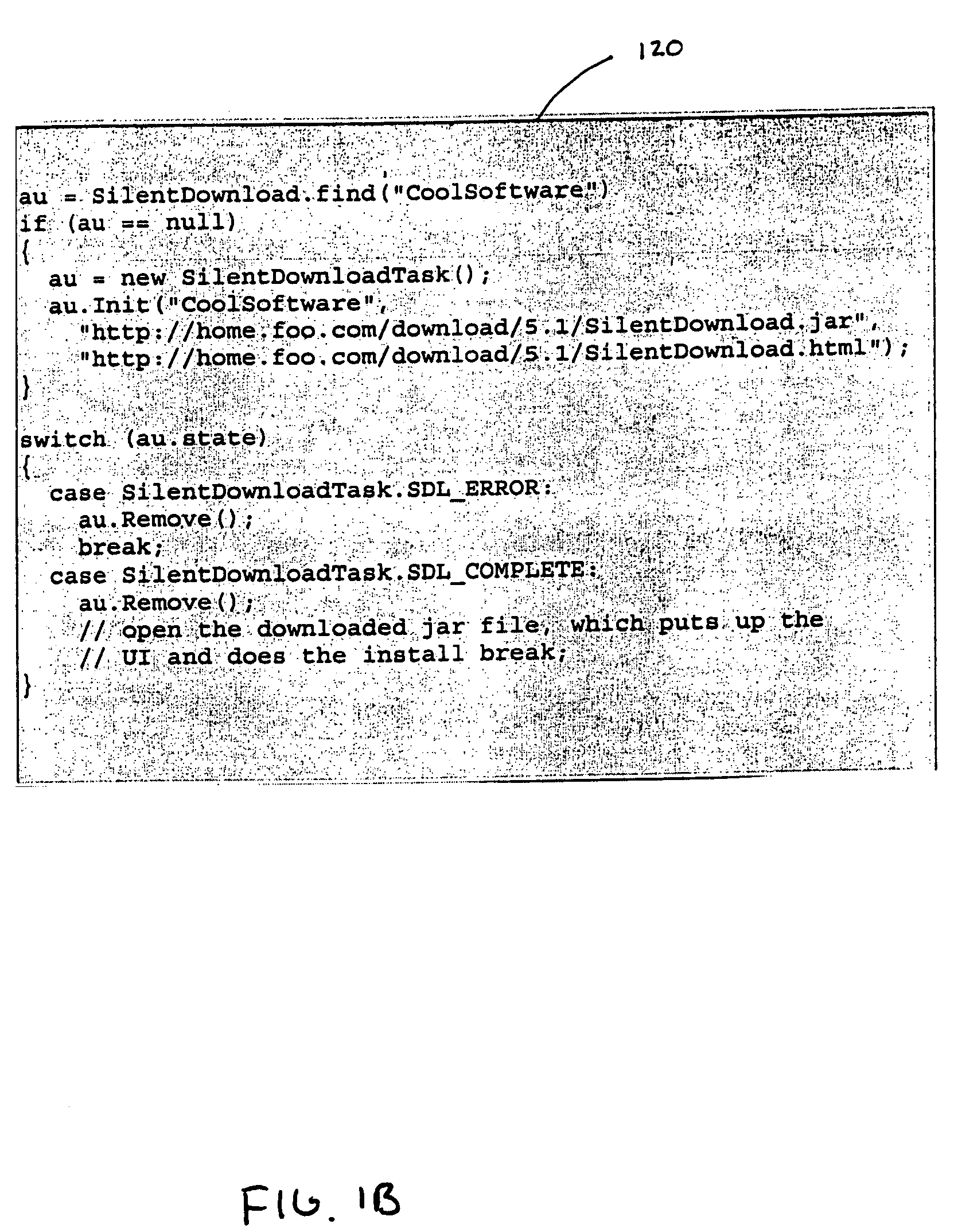

System and method for downloading portions of a remotely located network object to produce a completely downloaded local copy of the network object

InactiveUS7003554B1Control sizeMultiple digital computer combinationsTransmissionClient-sideObject system

System and method for downloading portions of a remotely located network object to produce a completely downloaded local copy of the network object. The system and method include and involve a server facility and a software delegate. The server facility is configured to store and to serve the software delegate and a network object. The server facility is further configured to be accessed by a client via an electronic data network, such as the Internet and WWW. The software delegate can reside and be executed on a client, and is configured to control the downloading of portions of a network object from the server facility to the client via the electronic data network, until a completely downloaded copy is stored locally on the client.

Owner:MICROSOFT TECH LICENSING LLC

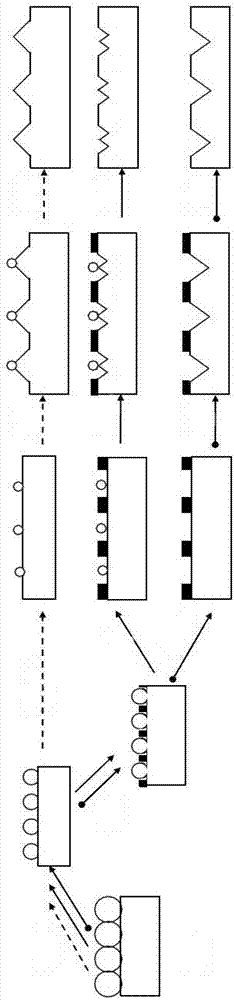

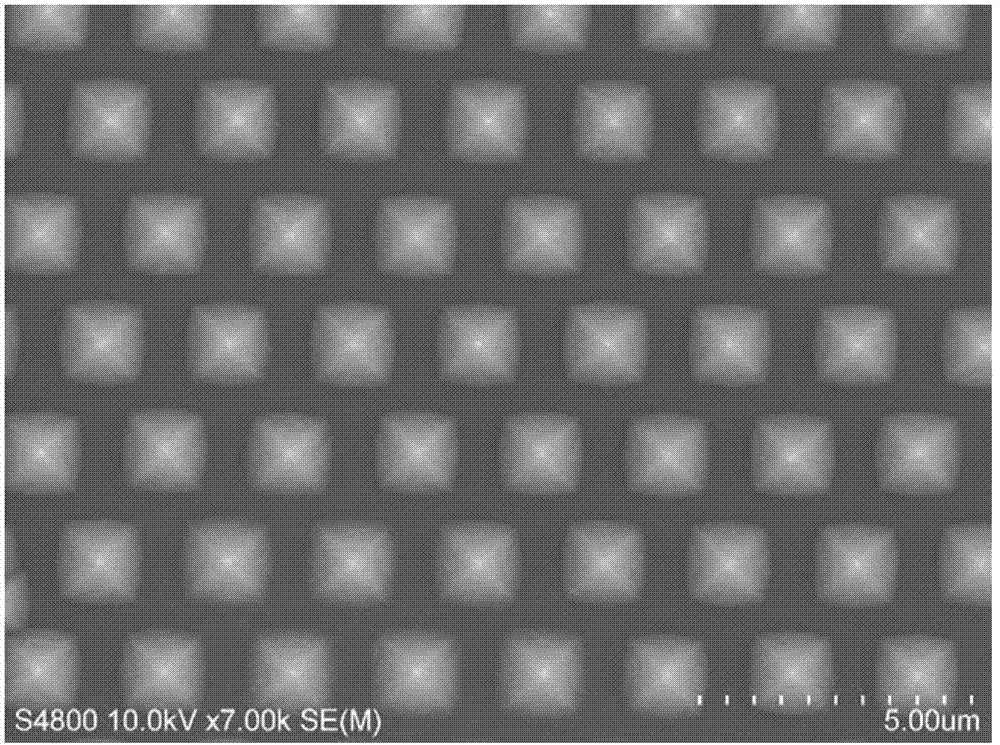

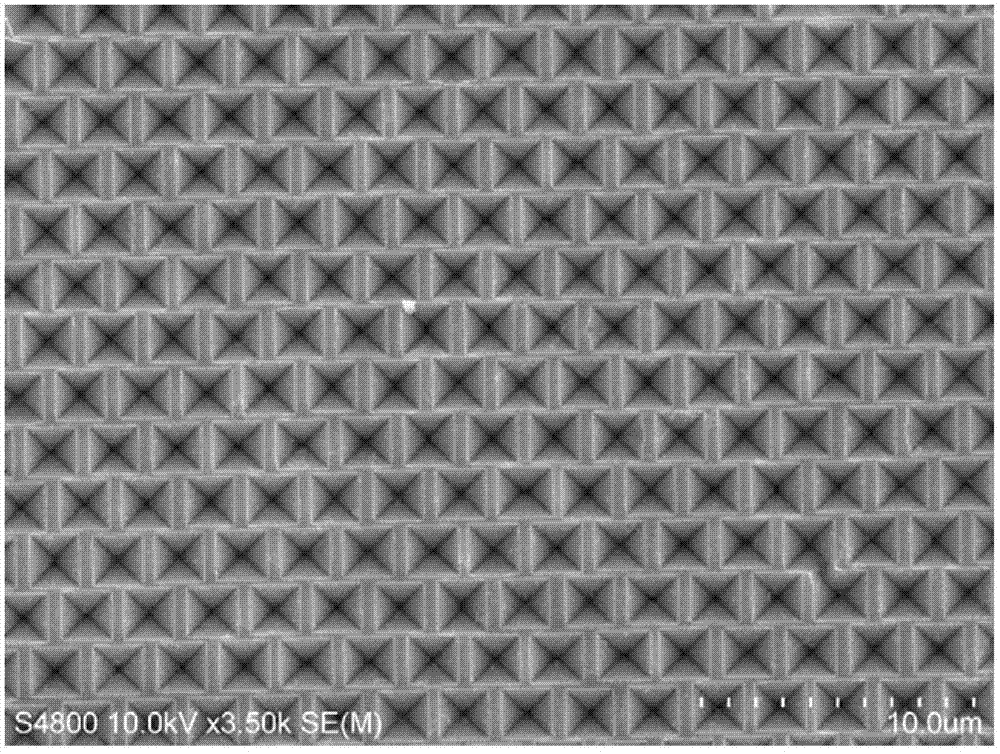

Method for preparing pyramid array on monocrystalline silicon substrate

ActiveCN103112816ALow costEasy to operateDecorative surface effectsChemical vapor deposition coatingMicrosphereGas phase

The invention relates to a method for preparing a pyramid array on a monocrystalline silicon substrate, and belongs to the technical field of manufacture of photovoltaic and semiconductor devices. The method comprises the following steps of: covering microballons in periodic arrangement on the surface of a monocrystalline silicon piece, and annealing near the glass transition temperature point of the microballoon; in oxygen atmosphere, obtaining a microballoon array in separation arrangement after etching by use of inductive coupling plasma; depositing a metallic titanium membrane on the monocrystalline silicon piece uniformly by a physical vapor deposition manner; and putting a silicon wafer with a masking film into an alkaline solution containing a surfactant for corrosion so as to obtain the pyramid array in order arrangement. The method is simple in process, short in preparation period and mature in technology; and three structures such as a positive pyramid array, an inverted pyramid array and a positive and inverted pyramid combined array can be obtained by a method for preparing a template through selecting and fine turning. The method has wide application value in the fields of photovoltaic, magnetic memory devices, nano photoelectric devices, nano sensors, surface raman enhancement and surface plasma effect and the like.

Owner:HUANGSHAN AKENT SEMICON TECH

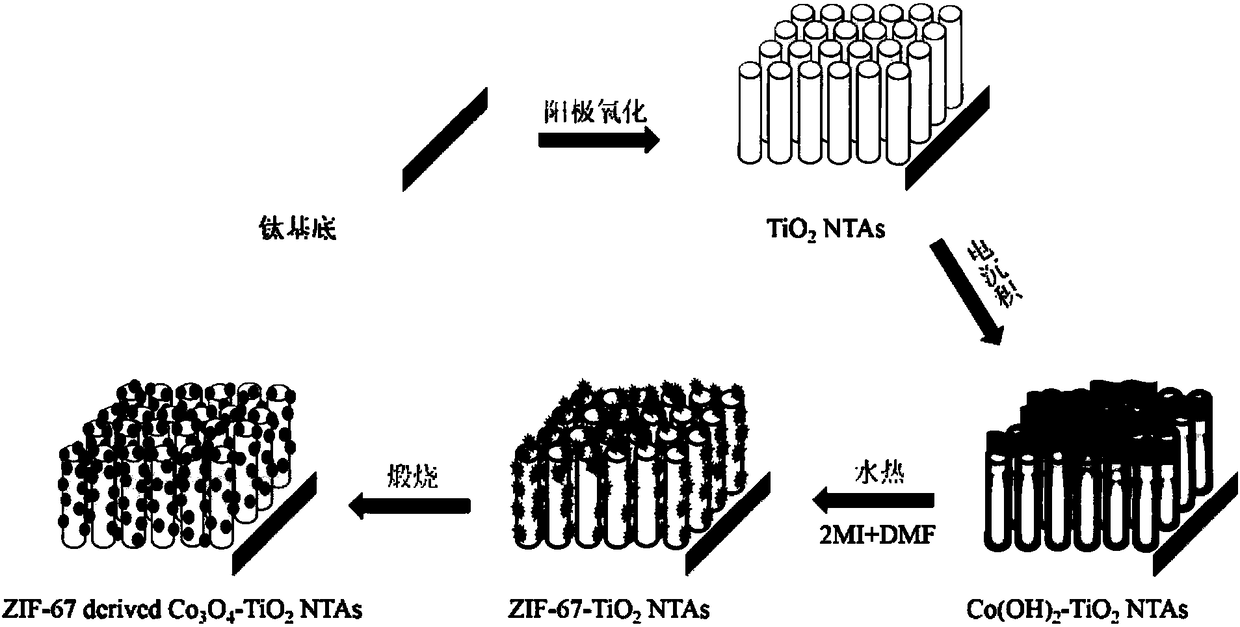

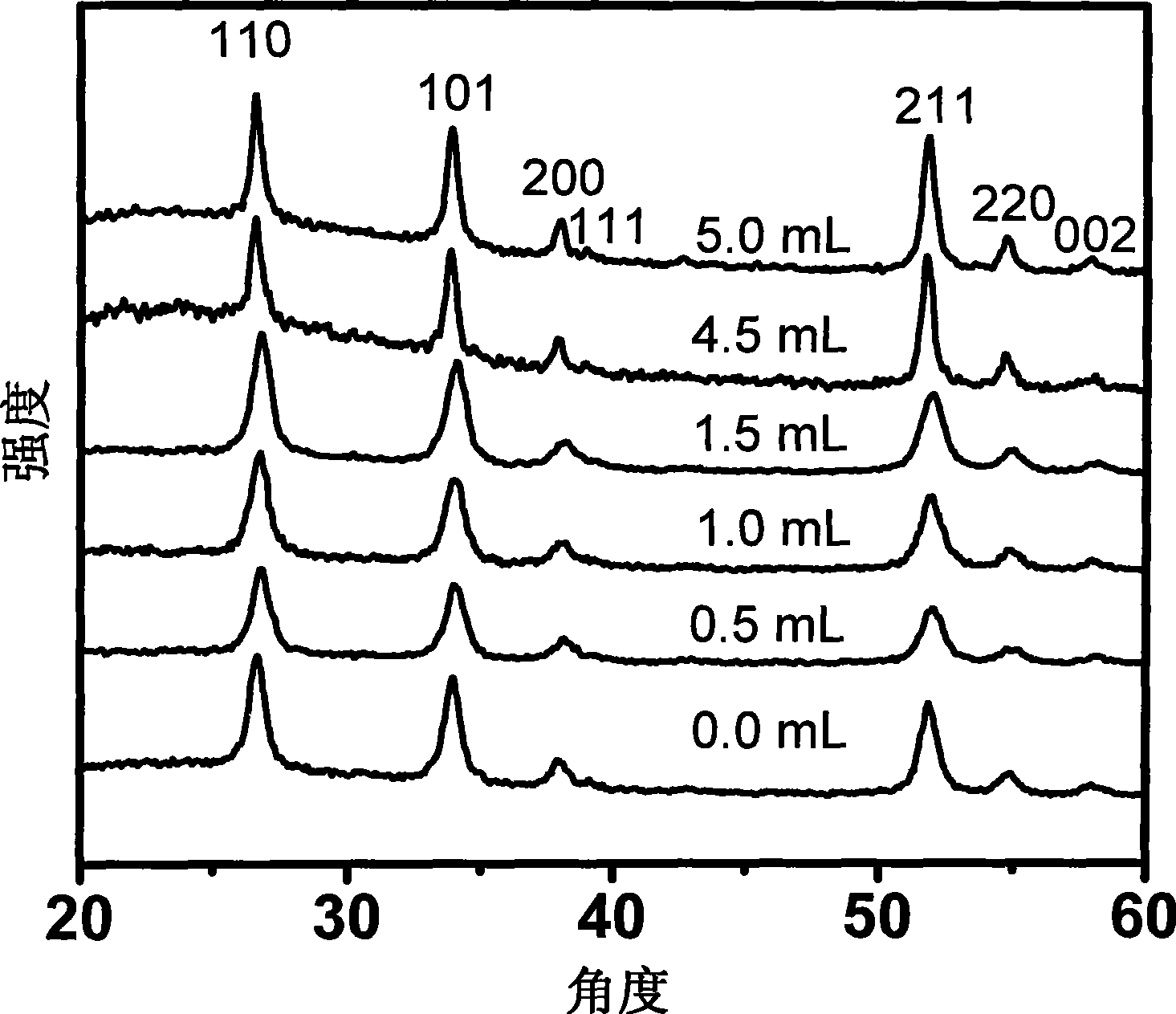

Preparation method for metal organic framework-derived tricobalt tetroxide-modified titanium dioxide nanotube array

InactiveCN108525667ASolve the repeatabilityFix stability issuesWater/sewage treatment by irradiationElectrolytic inorganic material coatingAbsorption capacityWorkstation

The invention discloses a preparation method for a metal organic framework-derived tricobalt tetroxide-modified titanium dioxide nanotube array. The method comprises the following steps: firstly performing pretreatment on a titanium sheet substrate material; performing electrochemical treatment on the treated titanium substrate material by using an ethylene glycol solution containing ammonium fluoride and water as an electrolyte, and performing calcination by using a muffle furnace to change a titanium dioxide crystal form; secondly, performing cobalt hydroxide electrodeposition by means of athree-electrode electrochemical workstation and by using cobalt nitrate hexahydrate as an electrolyte, a titanium dioxide nanotube array as a working electrode, a platinum sheet as a negative electrode and silver / silver chloride as a reference electrode; performing hydrothermal treatment on the titanium dioxide nanotube array to form ZIF-67 in situ; and finally, performing secondary calcination byusing a muffle furnace to obtain the ZIF-67-derived porous tricobalt tetroxide-modified titanium dioxide nanotube array. The method disclosed by the invention can effectively improve absorption capacity of TiO2 on visible light, promote separation of electron hole pairs, and improve photocatalytic degradation efficiency of organic pollutants.

Owner:SUZHOU UNIV

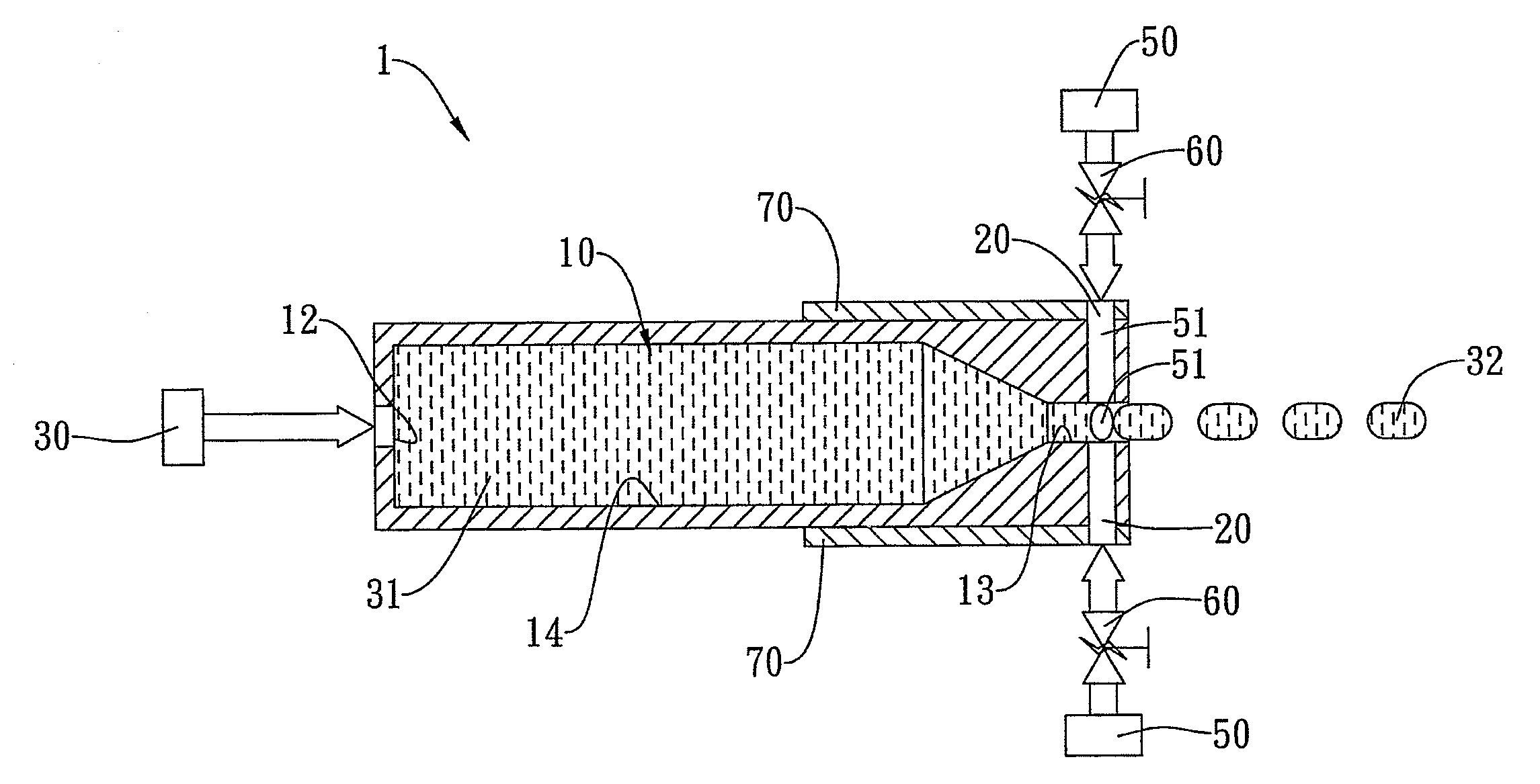

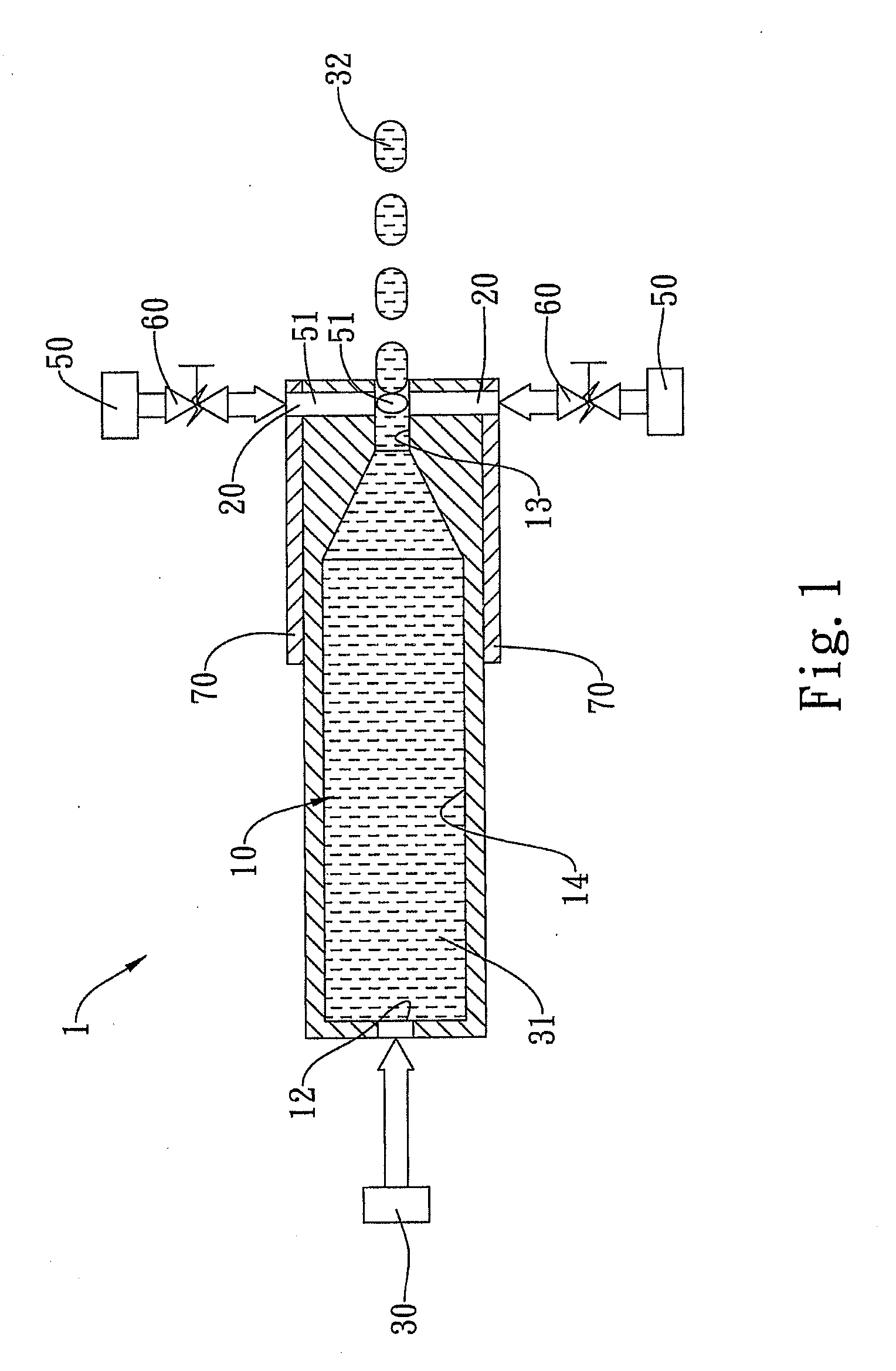

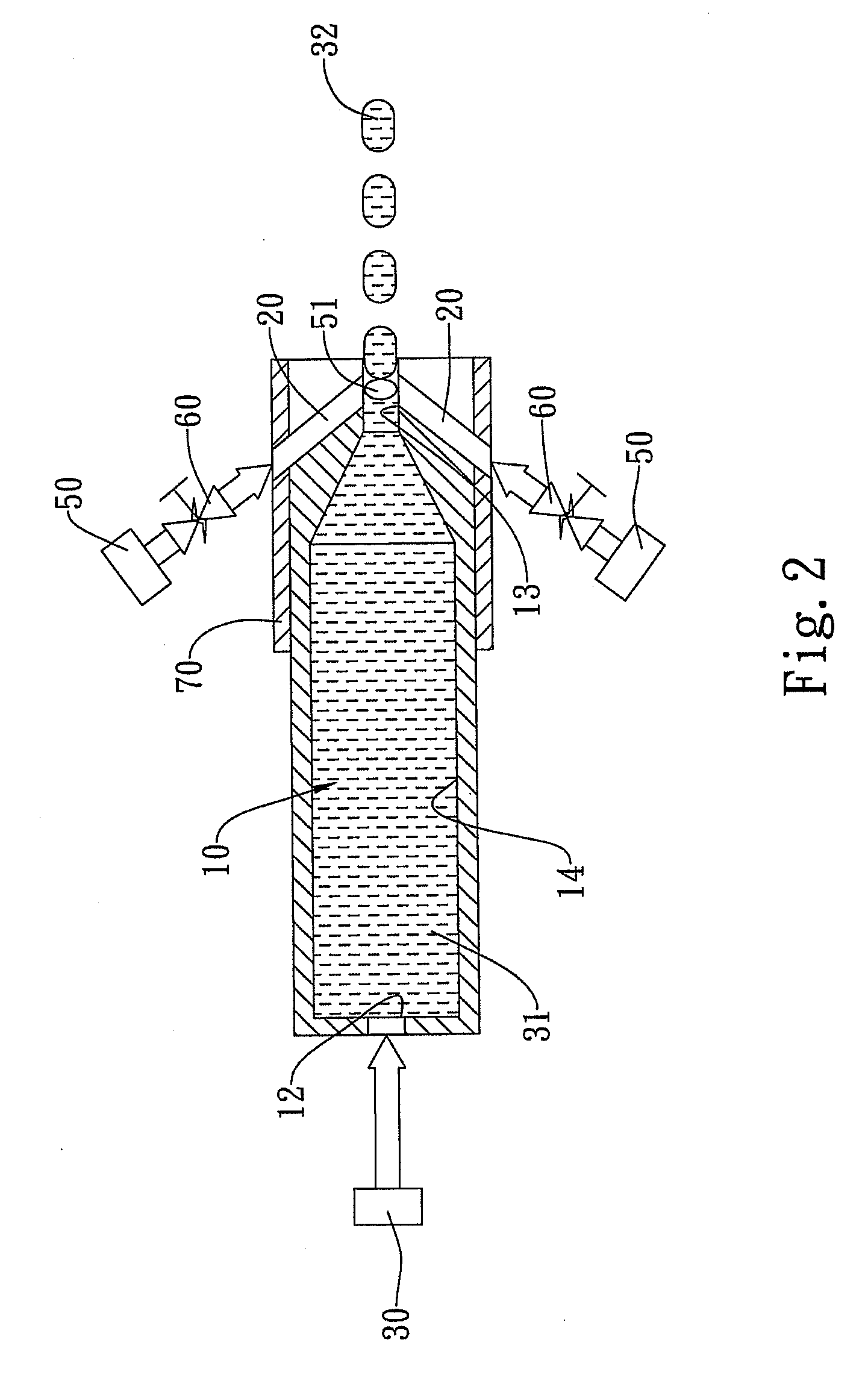

Droplet ejection device for a highly viscous liquid

A droplet ejection device for a highly viscous liquid includes a micro flow channel filled with a highly viscous liquid and having an inlet and an outlet channel; at least a branch channel communicated with the outlet channel; a highly-viscous-liquid supply device connected to the inlet so as to supply the highly viscous liquid to the micro flow channel; a gas supply device connected to the branch channel so as to supply a gas to the outlet channel by way of the branch channel; and at least a control valve mounted between the branch channel and the gas supply device so as to control an intermittent supply of the gas from the branch channel to the outlet channel to interrupt the highly-viscous-liquid flow in the outlet channel and to prompt the highly viscous fluid to form a droplet to be ejected out of the micro flow channel.

Owner:IND TECH RES INST

Tear initiation and directional tear films and packages made therefrom

ActiveUS7862869B2Avoid hard activationEasy to openEnvelopes/bags making machineryStampsPolyesterPolyolefin

The present invention provides a flexible multilayer packaging film and packages formed therefrom wherein the films include a first film layer comprising a first biaxially-oriented polymer selected from the group consisting of a polyester, a polyolefin, a polyamide, and a blend thereof and a surface-roughened portion, a second film layer comprising an adhesive, a third film layer comprising a barrier material, a fourth film layer comprising a second biaxially-oriented polymer selected from the group consisting of a polyester, a polyolefin, a polyamide, and a blend thereof and at least one score-line; wherein the packages comprise a tear-initiation area and a directional tear zone.

Owner:BEMIS COMPANY INC

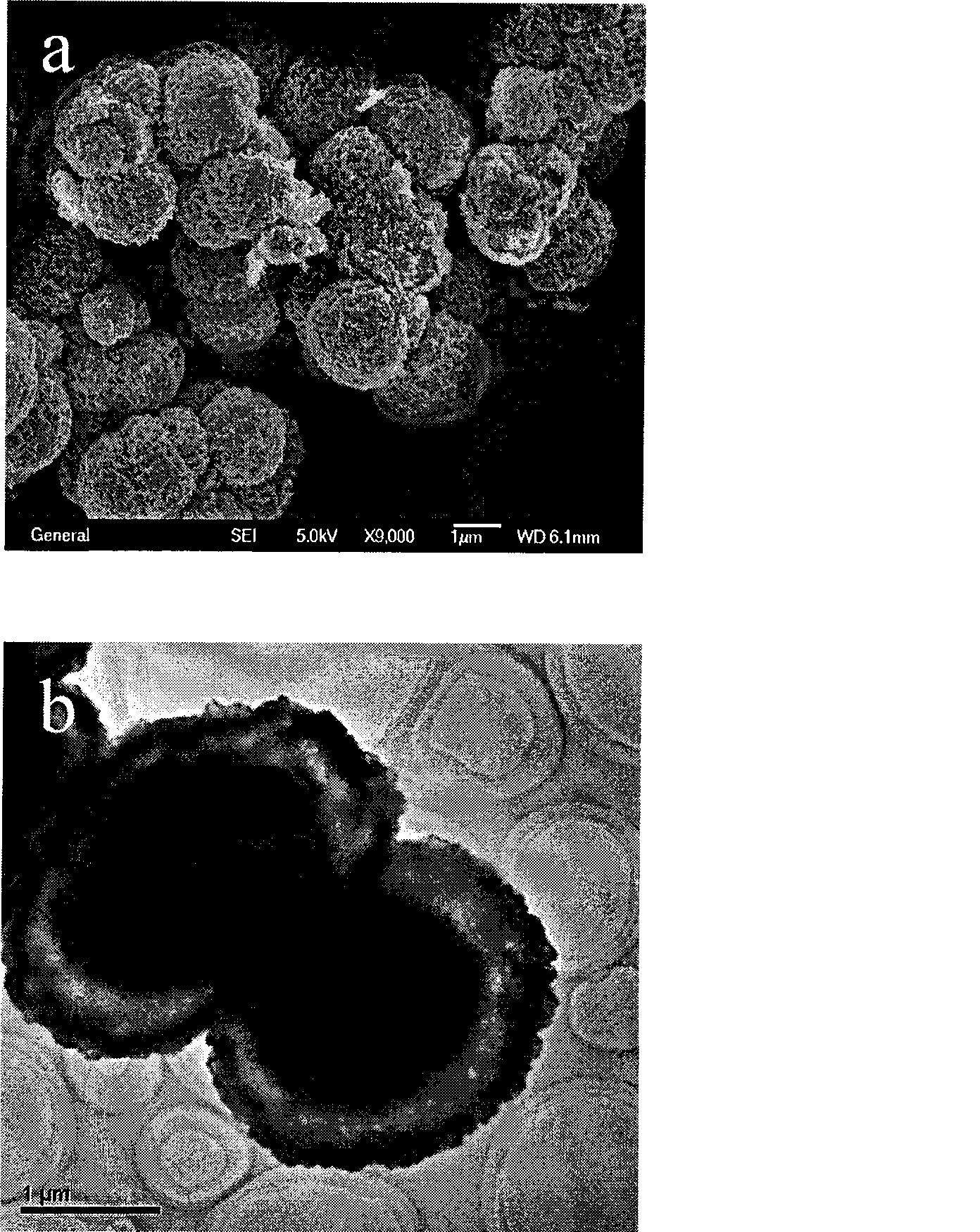

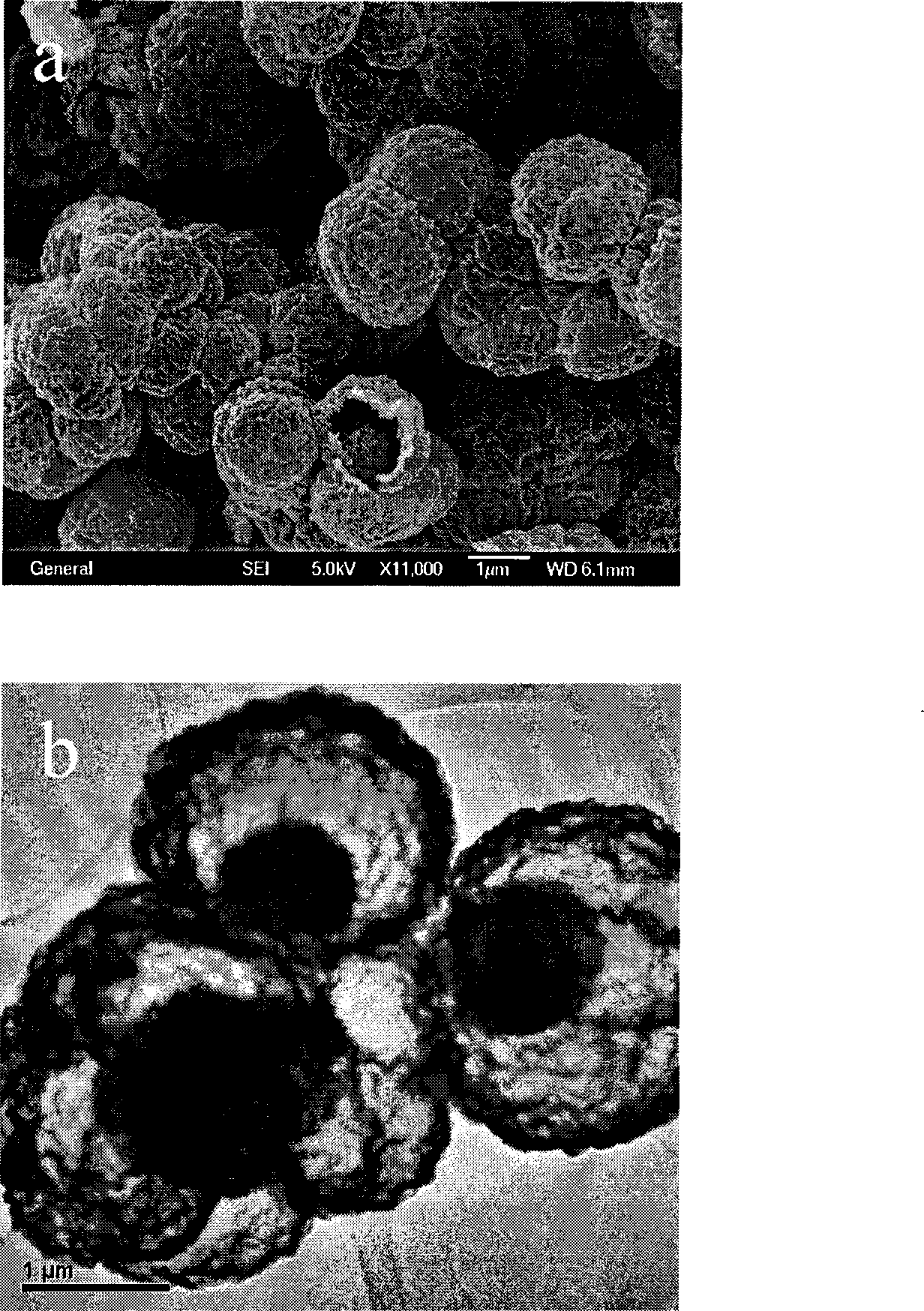

Process for producing nanostructured tin dioxide lithium ion battery negative pole material

InactiveCN101428847AControl structure sizeControl sizeCell electrodesTin oxidesTin dioxideSynthesis methods

The invention belongs to the preparation field of the anode material of a lithium ion battery, and in particular relates to a method for preparing metal oxide electrode material with a nanometer structure by utilizing the in-situ synthesis method. The internal structure and the dimension of a hollow micro-sphere obtained are controlled through adjusting the pH value of a system by utilizing hydrochloric acid. Raw materials in the invention are common and are easy to obtain; an organic solvent is not required during the preparation process; the preparation process is simple; the synthesis of template materials and the participation of a surface active agent are not required during the synthetic process; the requirements to the device are low, the time consumption is less and the preparation process is simple; and a main by-product during the preparation process is water and carbon dioxide and is environment-friendly. The raw materials used in the invention are common; and the preparation conditions are not restricted by areas. The hollow tin dioxide micro-spheres have higher application prospect in the filed of electrode material, catalyst carriers and the like. The method has the advantages of cheap and easily obtained raw materials, simple preparation process, and unrestricted preparation conditions by areas, and is suitable for massive industrial production.

Owner:JILIN UNIV

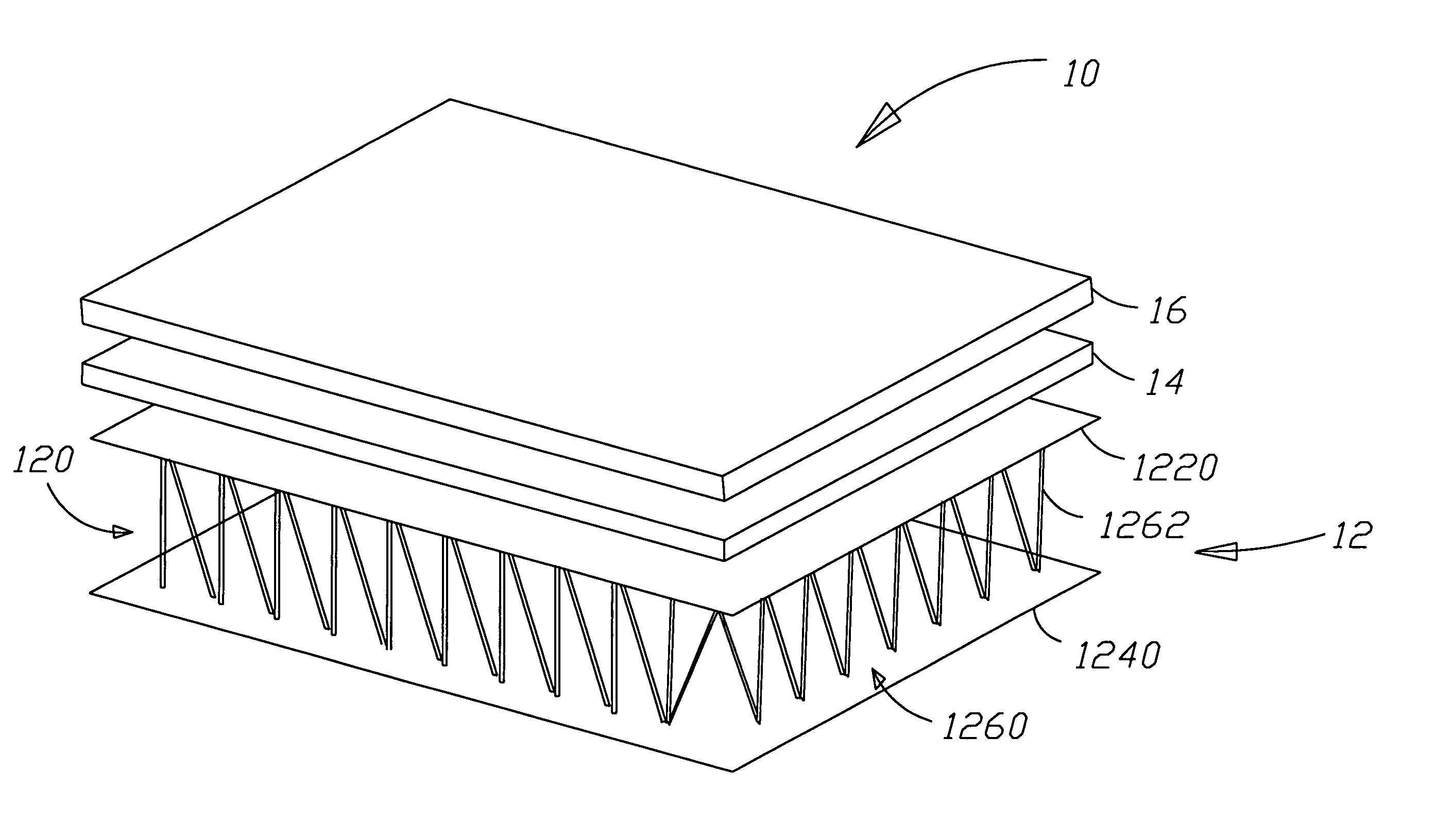

Fabric membrane texture and manufacturing method thereof

InactiveUS20050142971A1Improve efficiencyImprove dynamic characteristicsOrnamental textile articlesFibre treatmentFiberUltimate tensile strength

A fabric membrane texture and manufacturing method thereof explores a texture of fabric membrane comprising of 3D fabric. An upper and a lower fiber texture layers of the 3D fabric membrane are stretched to build up an air sandwich through plural middle connecting fibers. The 3D fabric enables to execute the functions of anti-bump, thermal insulating, thermal conductivity, air permeability and elastic strength. Additionally, a polymer membrane is used to adhere to at least one of the 3D fabric to build up a better function of shielding, insulating, or the capacity of ambiance impedance. Besides, this polymer membrane adheres to the 3D fabric using the process of low-pressure fixation that is applied to the product enables to obtain the better distance of spacer.

Owner:CHINA TEXTILE INST

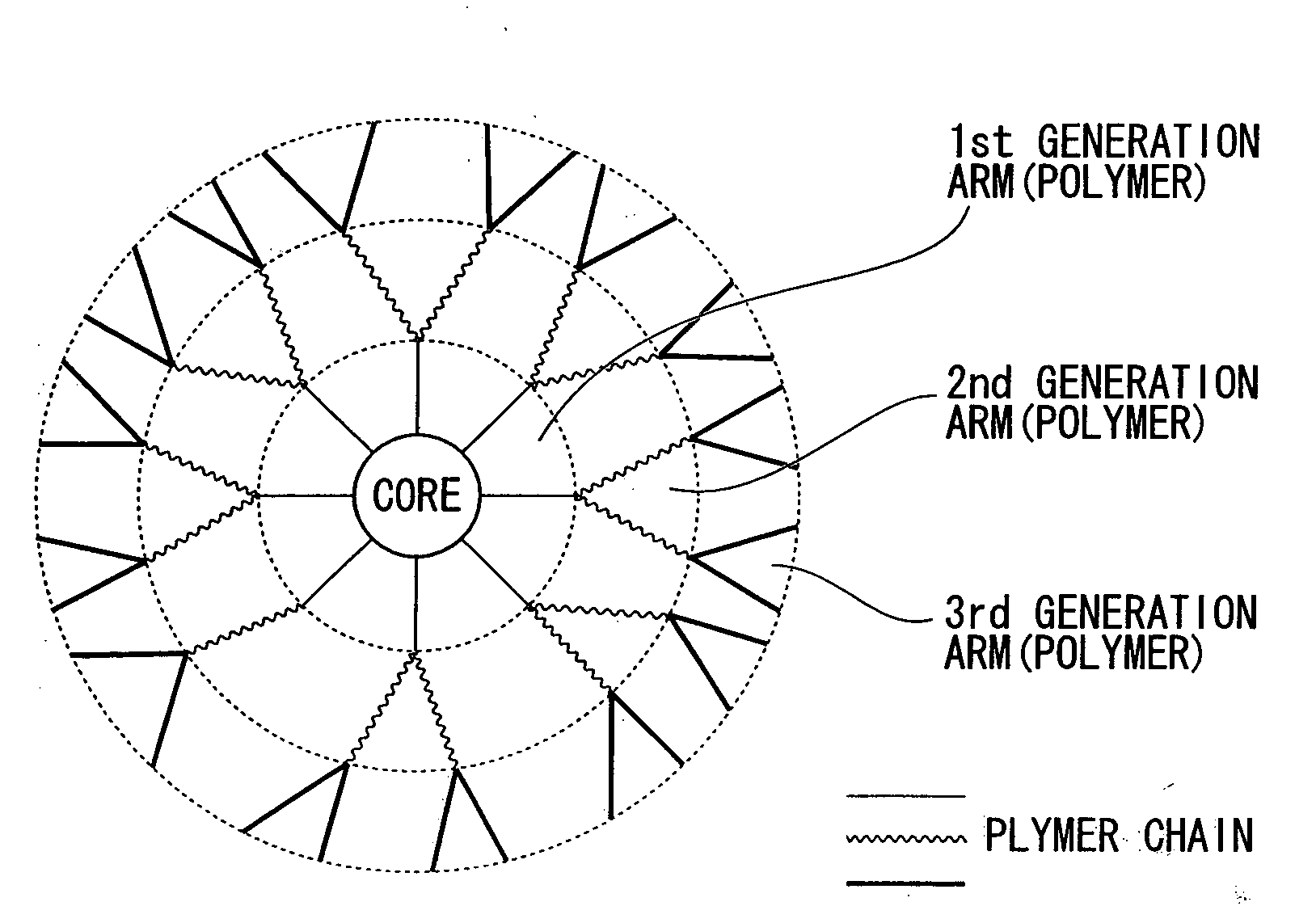

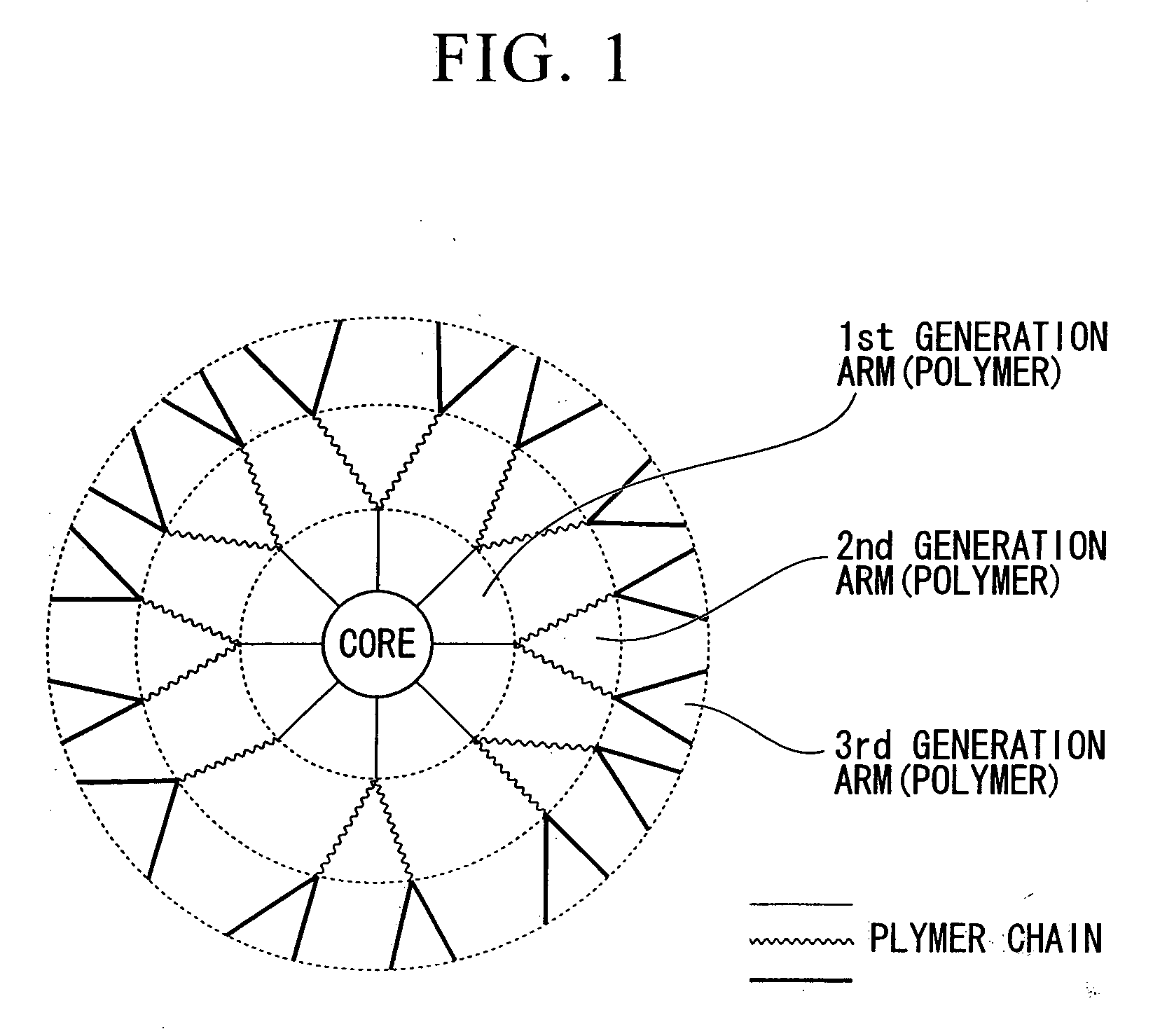

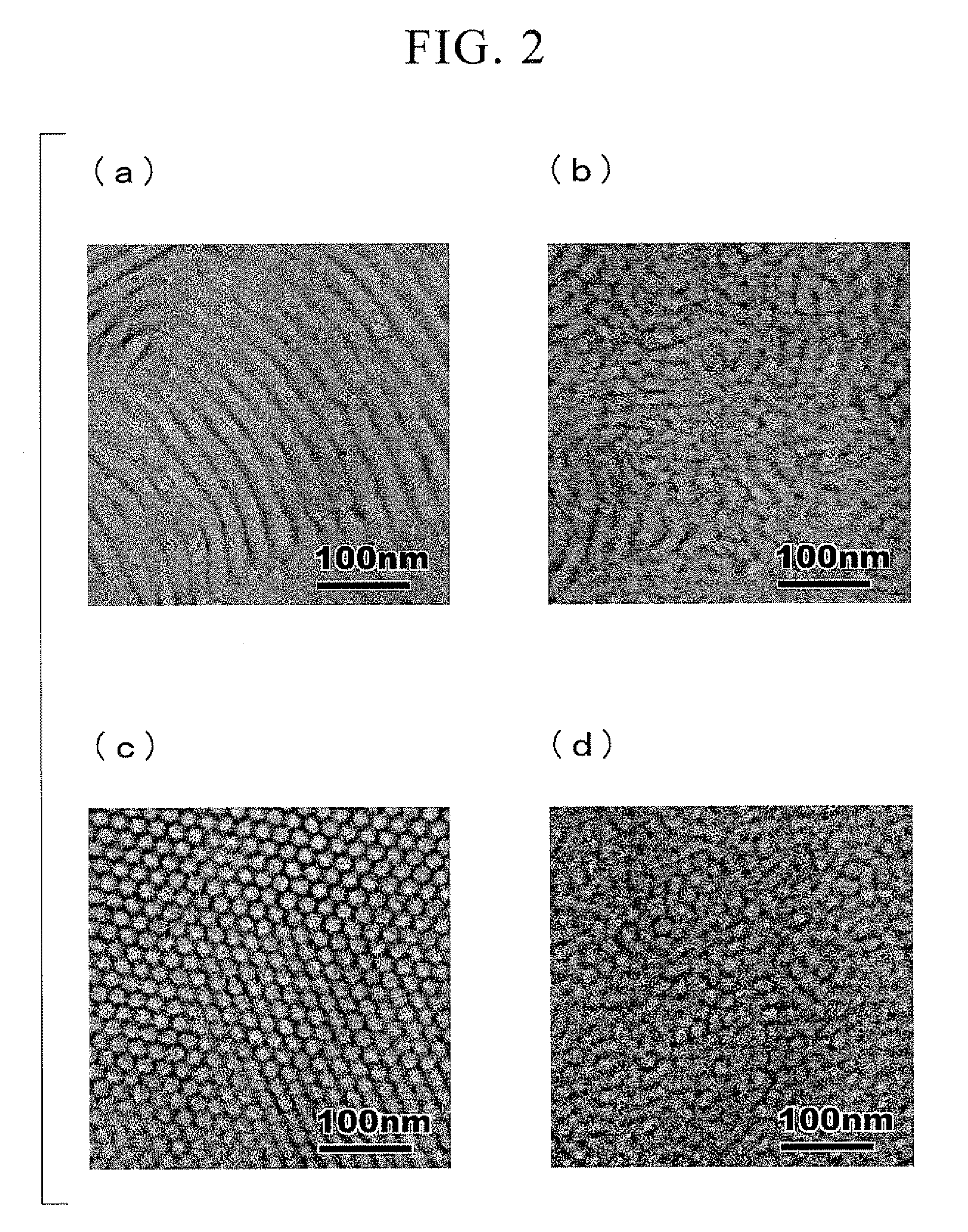

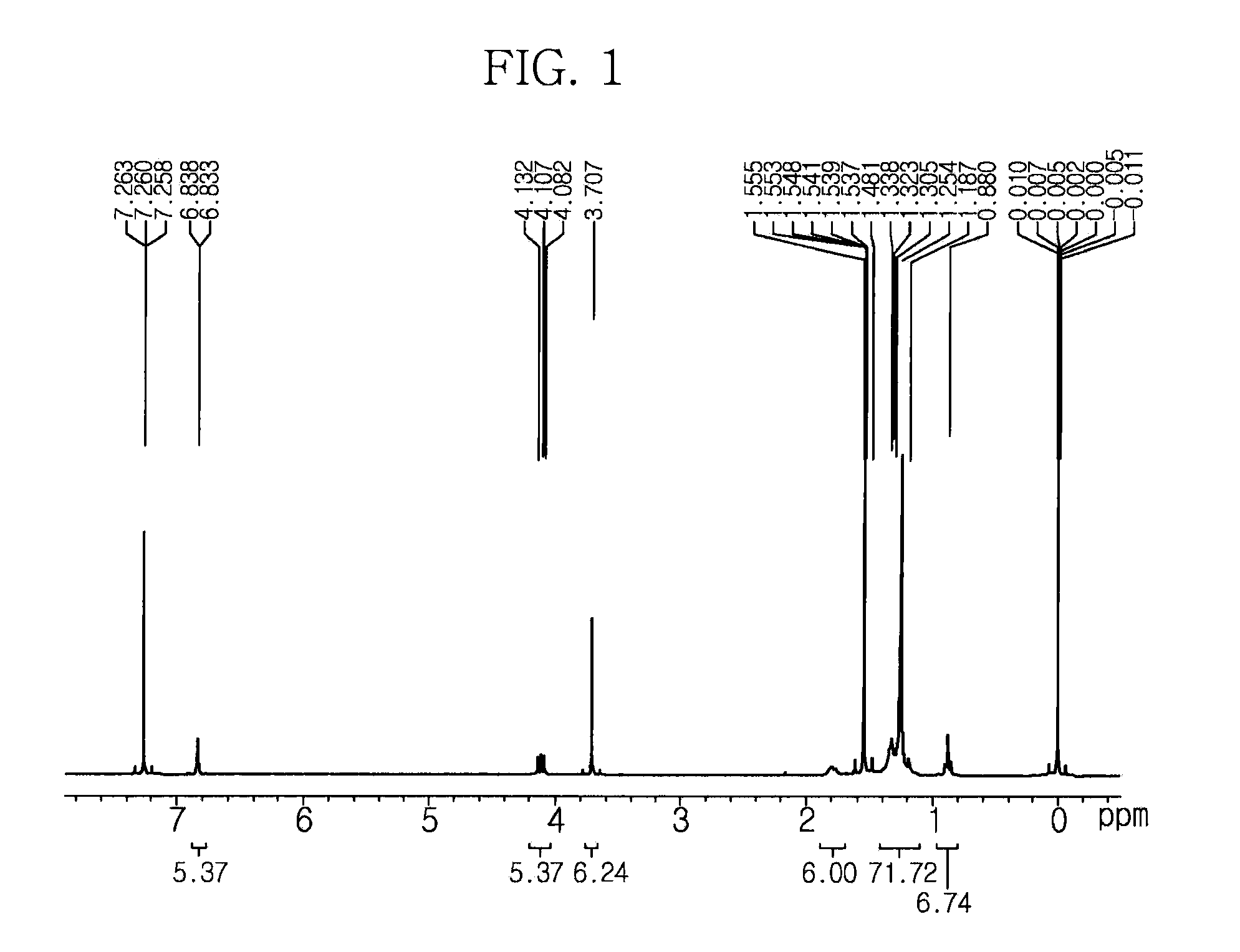

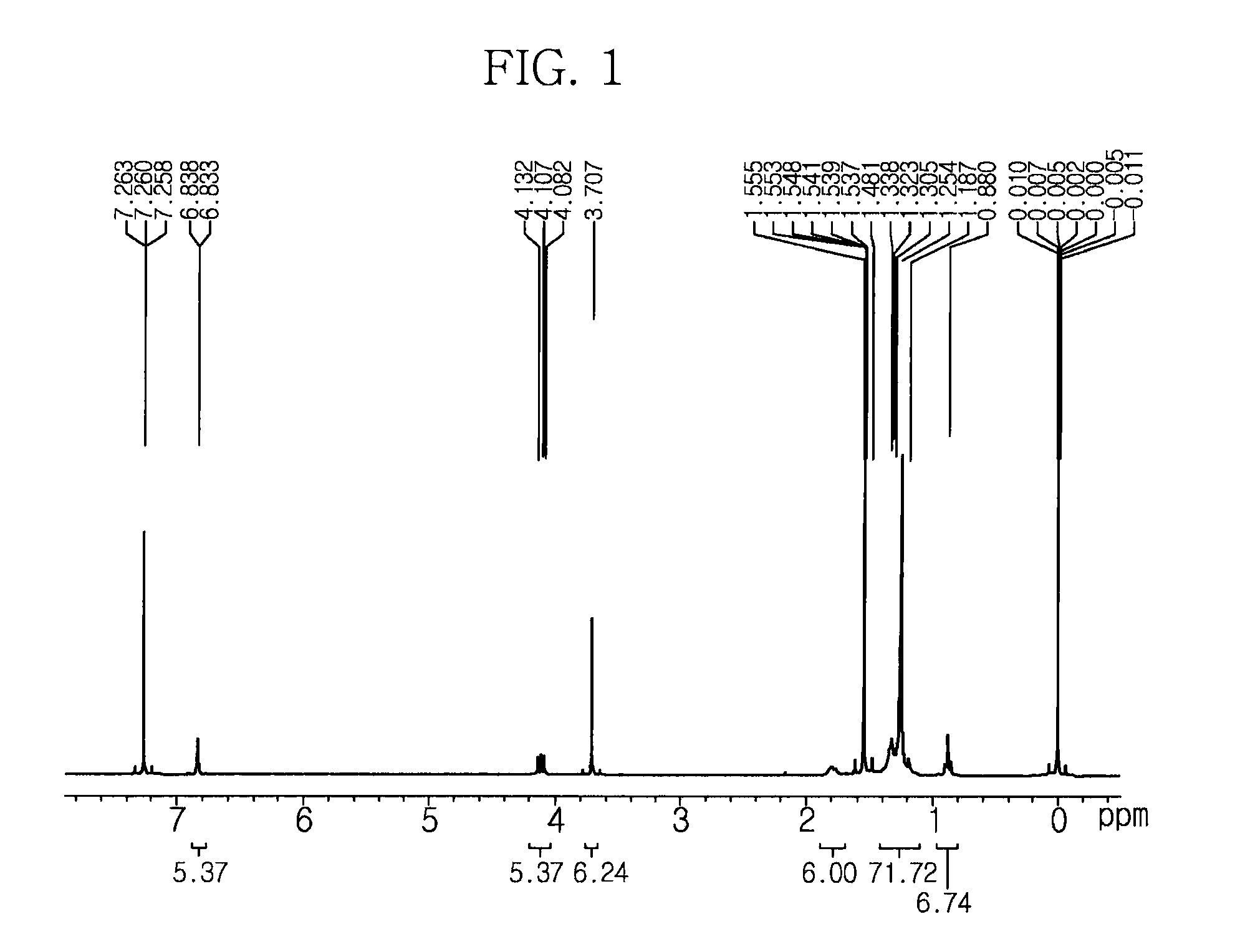

Star Polymer and Method of Producing the Same

The present invention provides a novel narrow distribution dendrimer-like star polymer having a controlled molecular structure, and a method capable of easily producing the star polymer.Disclosed is a polymer comprising a core portion and an arm portion, wherein the arm portion includes a first generation composed of a polymer chain and a second generation composed of a polymer chain formed at the outer shell of the first generation, the number of arms of the second generation is larger than the number of arms of the first generation, the first generation composed of the polymer chain is a polymer chain derived from a monomer having a polymerizable double bond, and the ratio of the weight average molecular weight (Mw) to the number average molecular weight (Mn), (Mw / Mn), of the star polymer is within a range from 1.001 to 2.50. A compound containing a functional group capable of reacting with an anion, which serves as a core portion, is reacted with a polymer chain containing two or more functional groups and an anion end which serves as an arm portion.

Owner:NIPPON SODA CO LTD

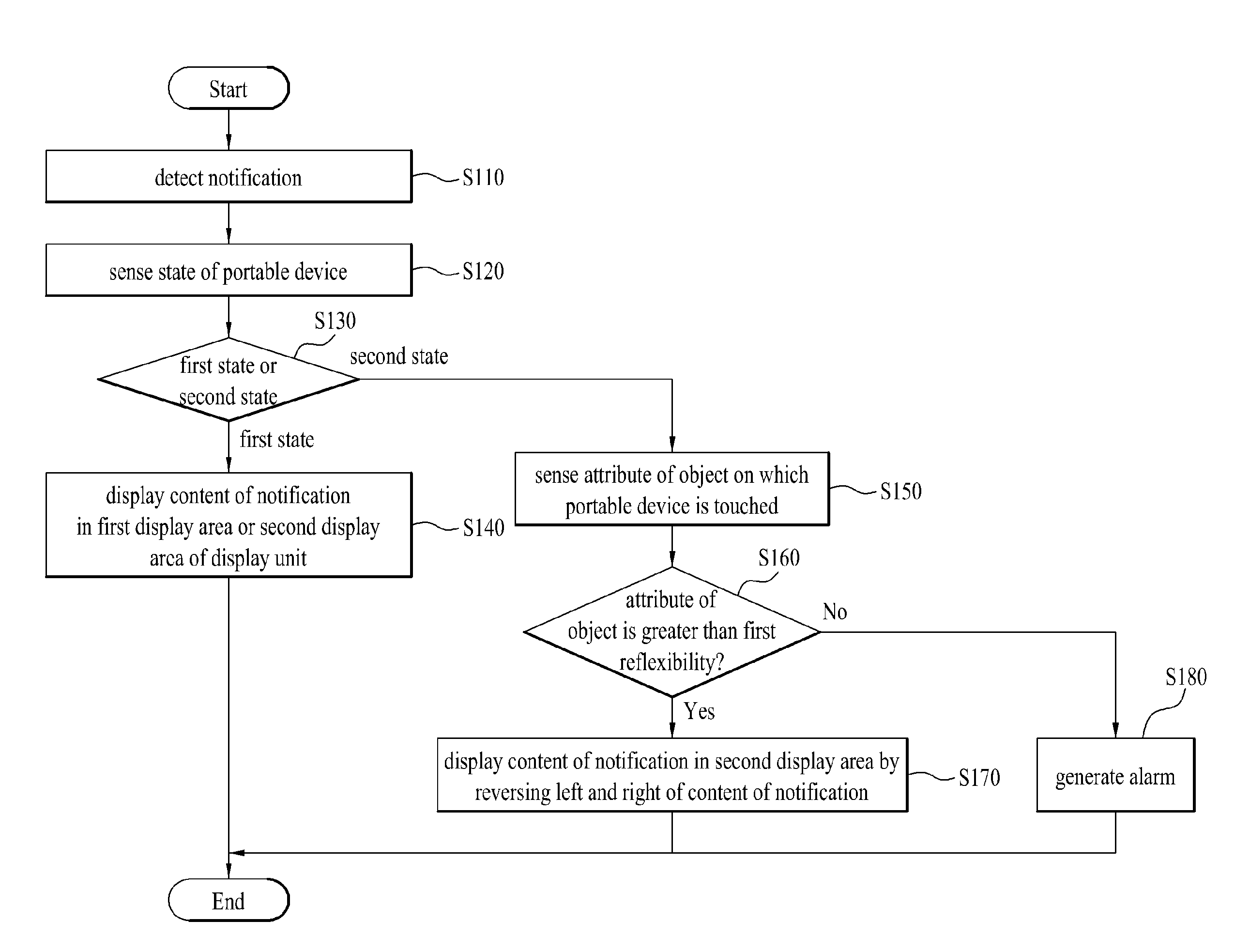

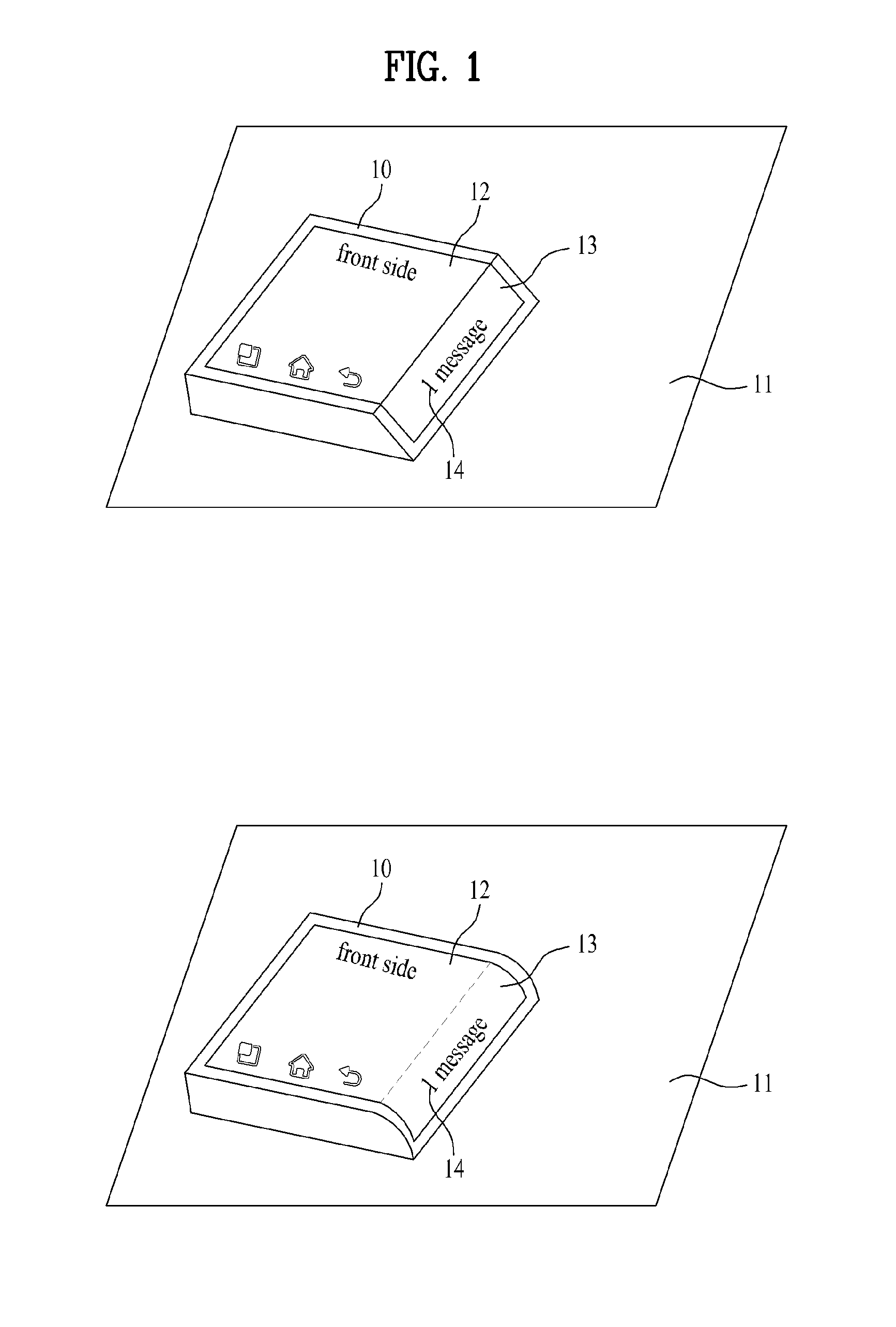

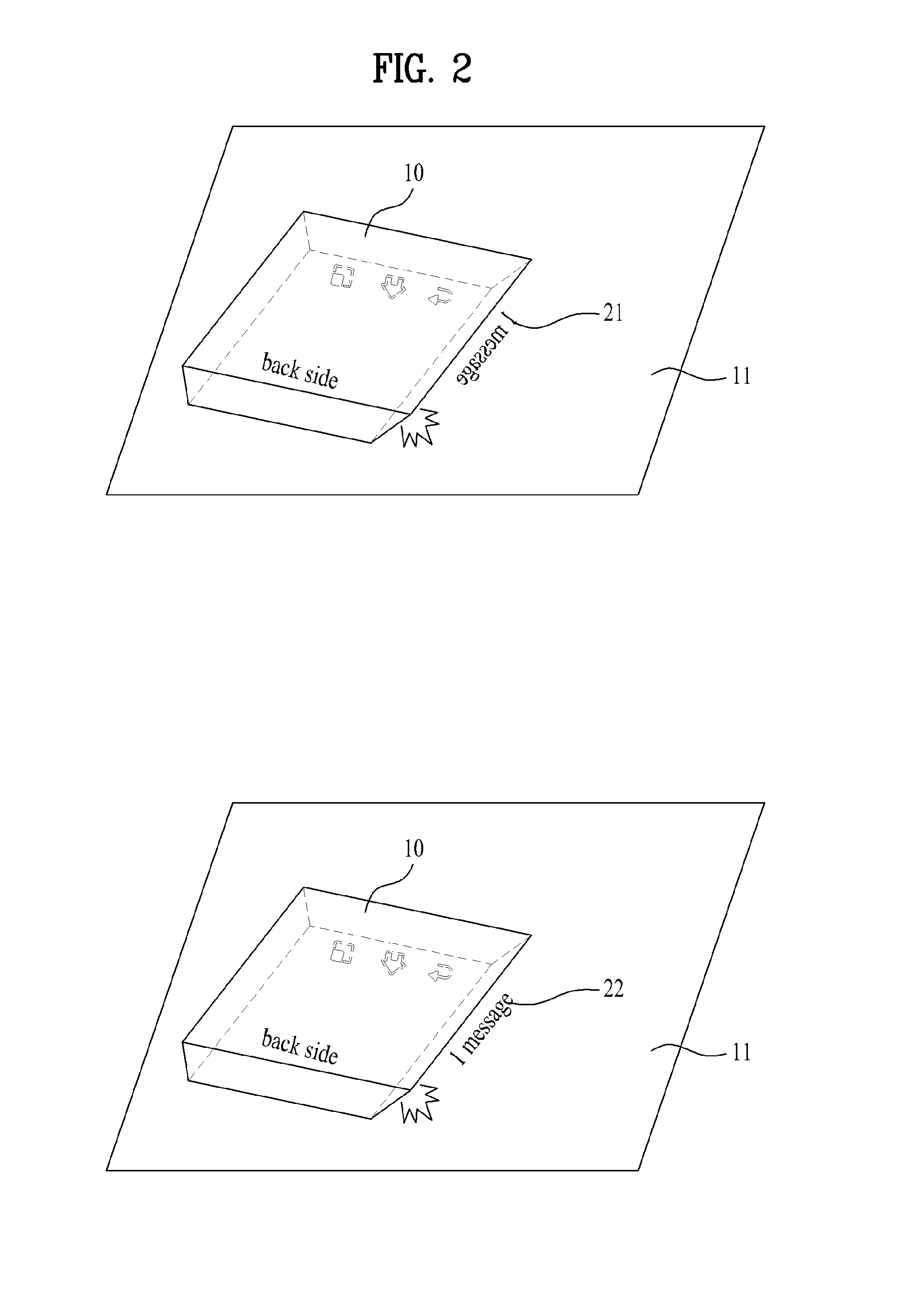

Portable device providing a reflection image and method of controlling the same

ActiveUS20140300533A1Control sizeEnhance visibility and readabilityInput/output for user-computer interactionDigital data processing detailsEmbedded system

Owner:LG ELECTRONICS INC

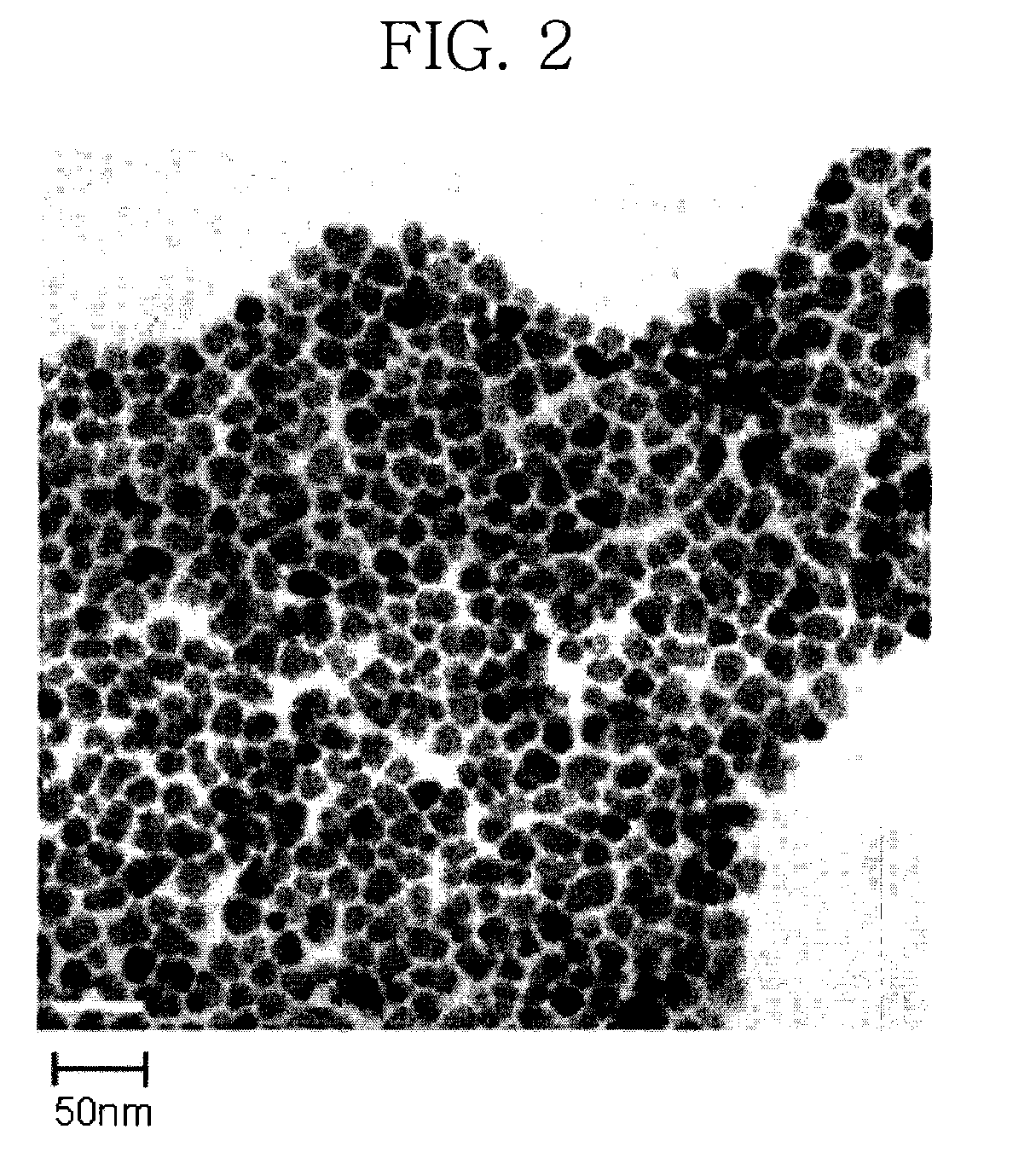

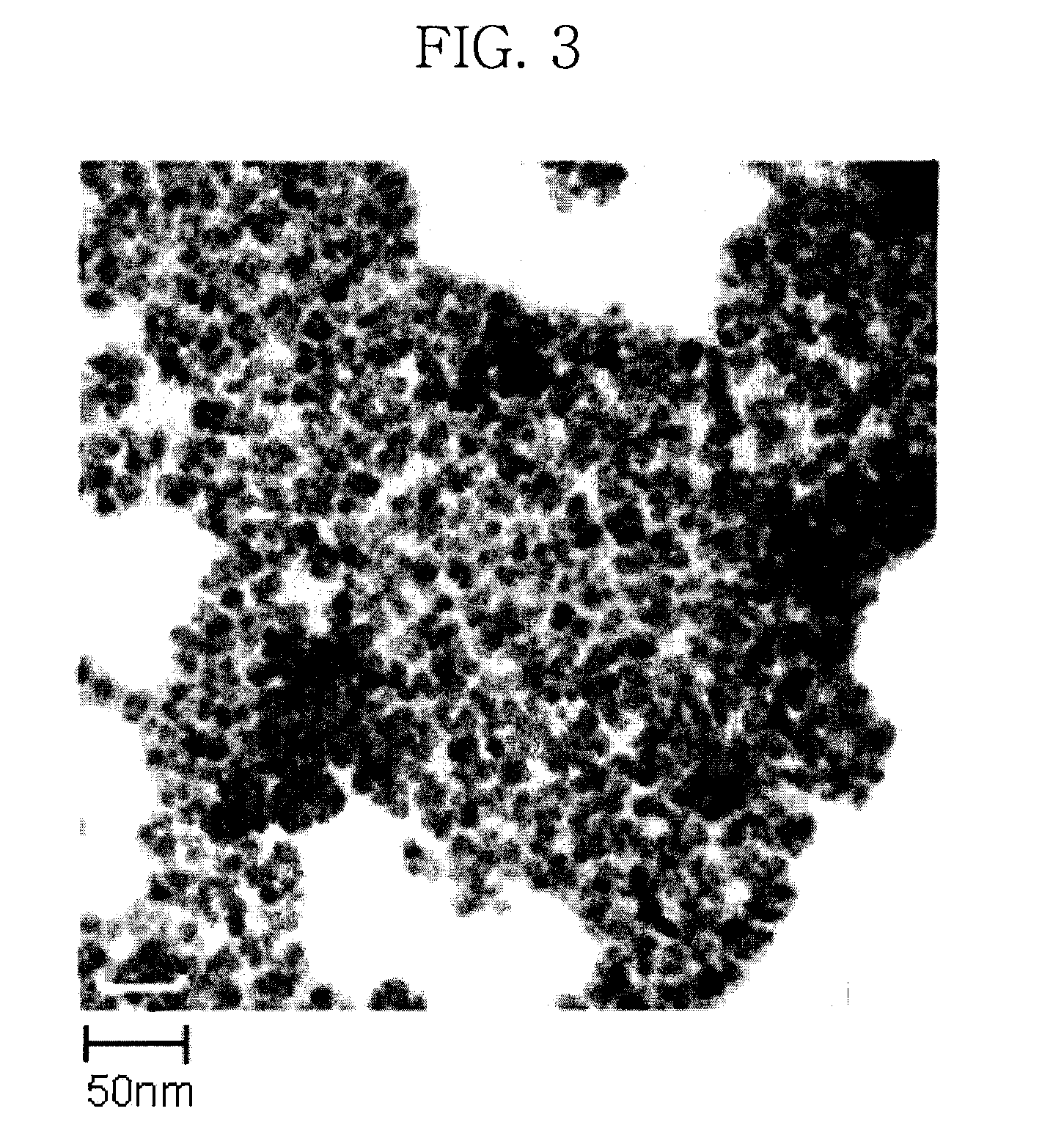

Method for preparing nanoparticles using carbene derivatives

ActiveUS20090289233A1Control shapeControl sizeNanostructure manufactureSelenium/tellurium compundsCarbeneOrganic solvent

Disclosed herein is a method for synthesizing a nanoparticle using a carbene derivative. More specifically, provided is a method for synthesizing a nanoparticle by adding one or more precursors to an organic solvent to grow a crystal, wherein a specific carbene derivative is used as the precursor.

Owner:SAMSUNG ELECTRONICS CO LTD

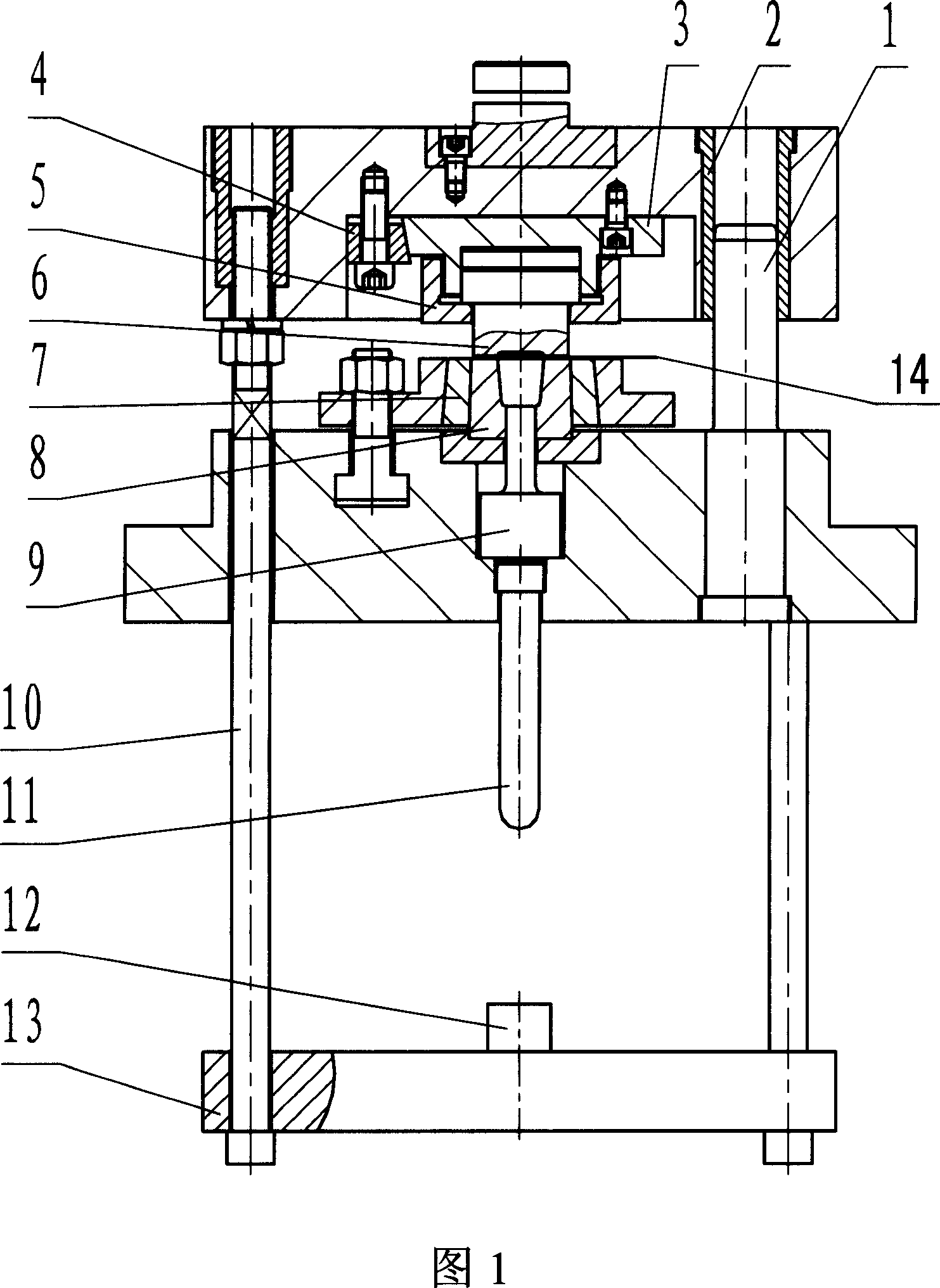

Large roller hot forging process

The large roller hot forging process belongs to the field of roll bearing machining technology. The process includes the following technological steps: cold cutting the soft ground rod into material section and eliminating burrs, heating to 120-180 deg.c before soaking with graphite lubricant, heating in a MF induction furnace to the hot forging temperature below the metal critical point, mold forging to complete the plastic deformation forming the roller, pushing out the roller blank with one pushing mechanism, and cutting off the technological ring from the roller blank. The present invention has the features of high production efficiency, high fatigue tolerance, high impact performance, etc and is used in large roller production.

Owner:XIANGYANG AUTOMOBILE BEARING CO LTD

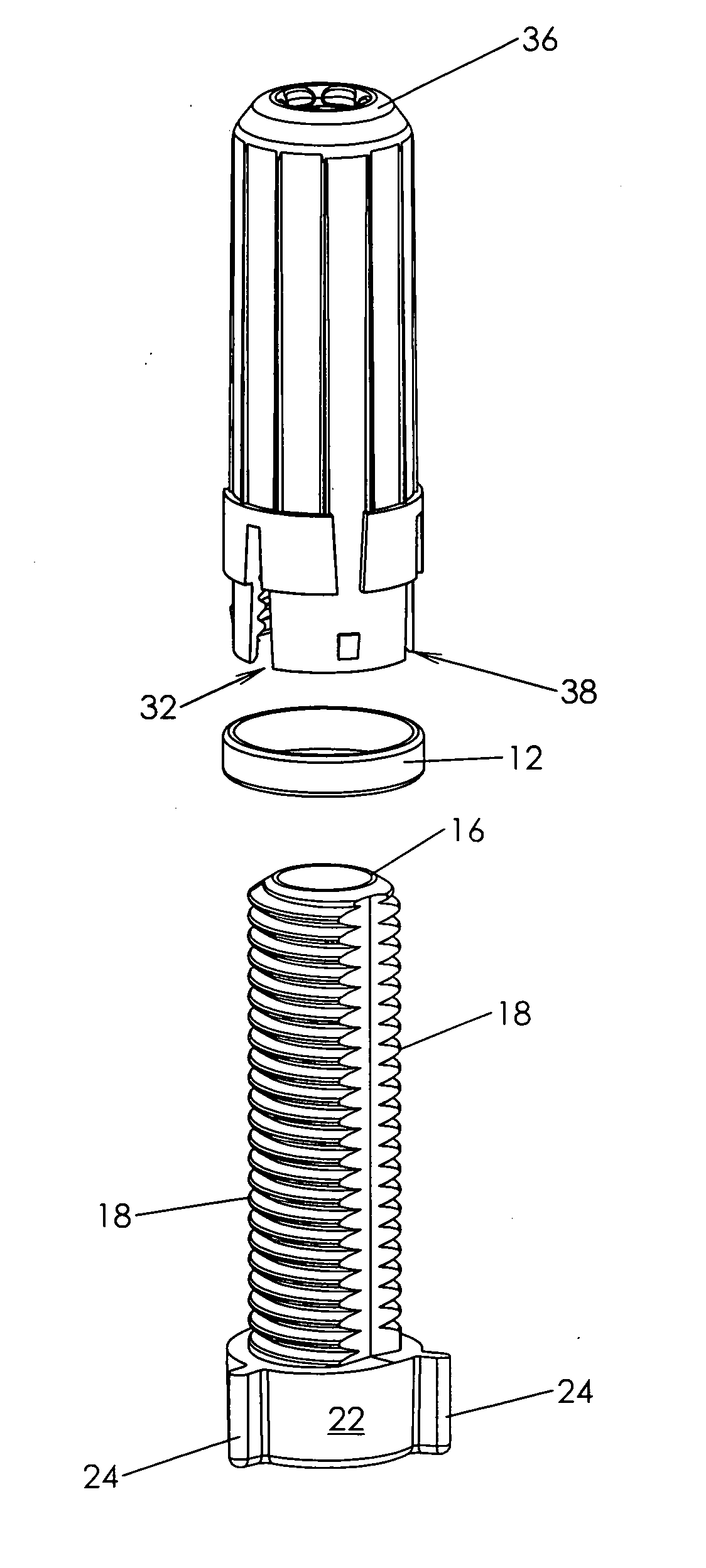

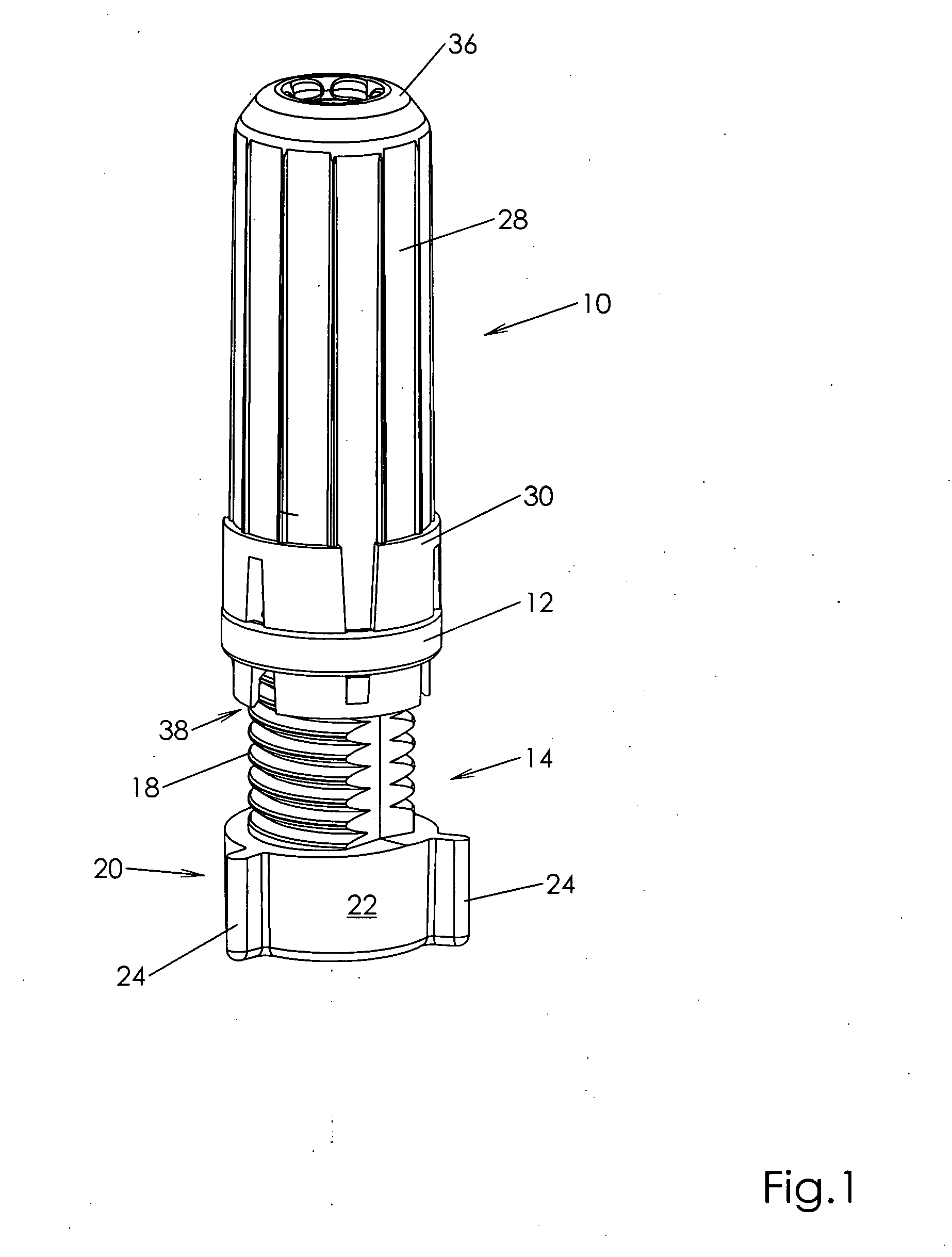

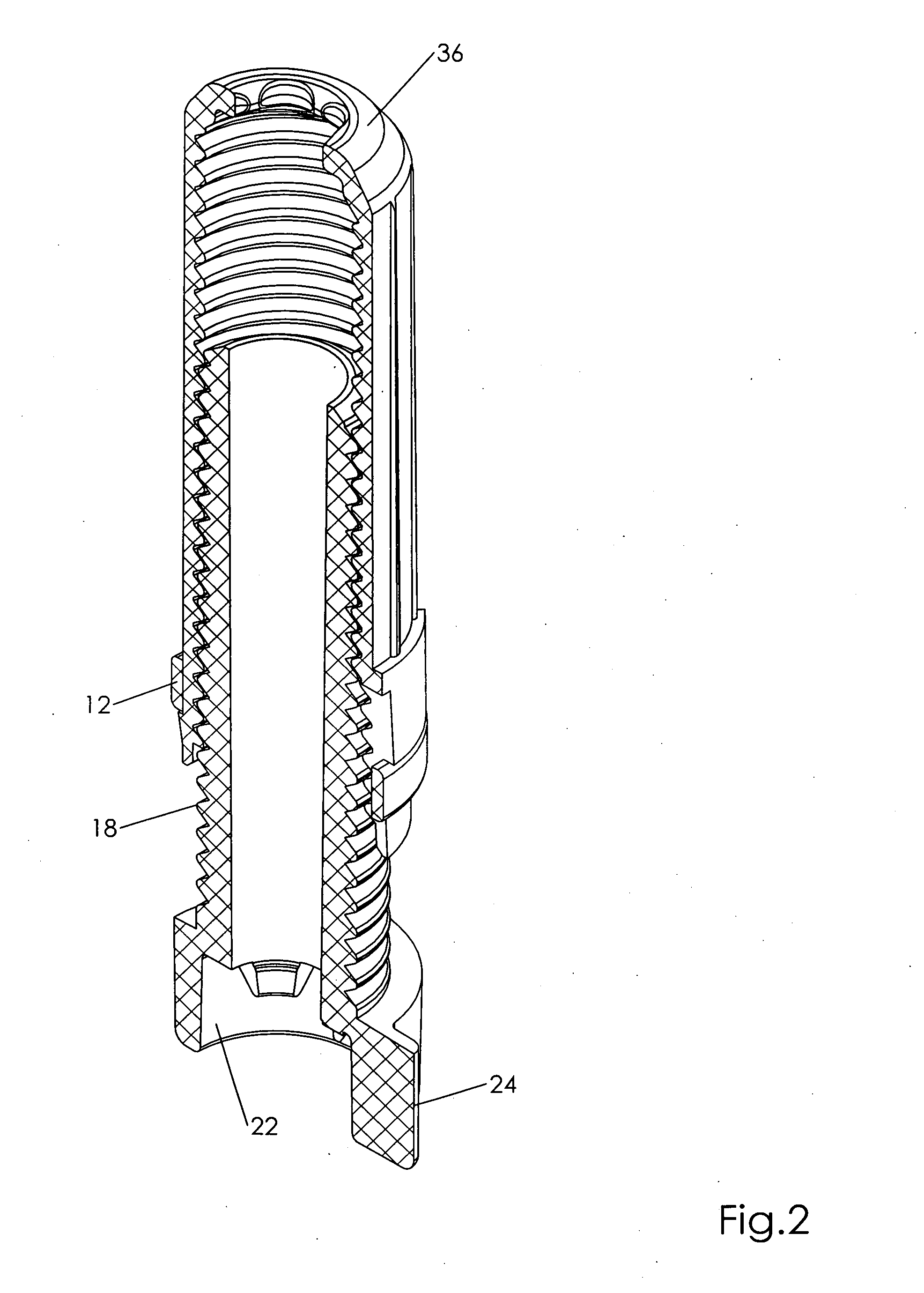

Adjustable Torque Nut

Owner:BROME BIRD CARE

Foam matrix embolization device

The present invention relates to a medical device for placement at a predetermined location within a passageway of the human body, and more particularly, relates to a flexible embolization device which may be delivered by a catheter to a pre-selected position within a blood vessel to thereby embolize a blood vessel or a blood vessel defect, such as an aneurysm or fistula. Specifically, the embolization device comprises an elongated coil having a lumen, the coil and lumen being at least partially embedded in an elongated foam member comprising, in some embodiments, a flexible, biodegradable, water insoluble, open, interconnecting-cell foam material having embolic characteristics, and capable of allowing cell proliferation into the open cell foam interior.

Owner:CORDIS CORP

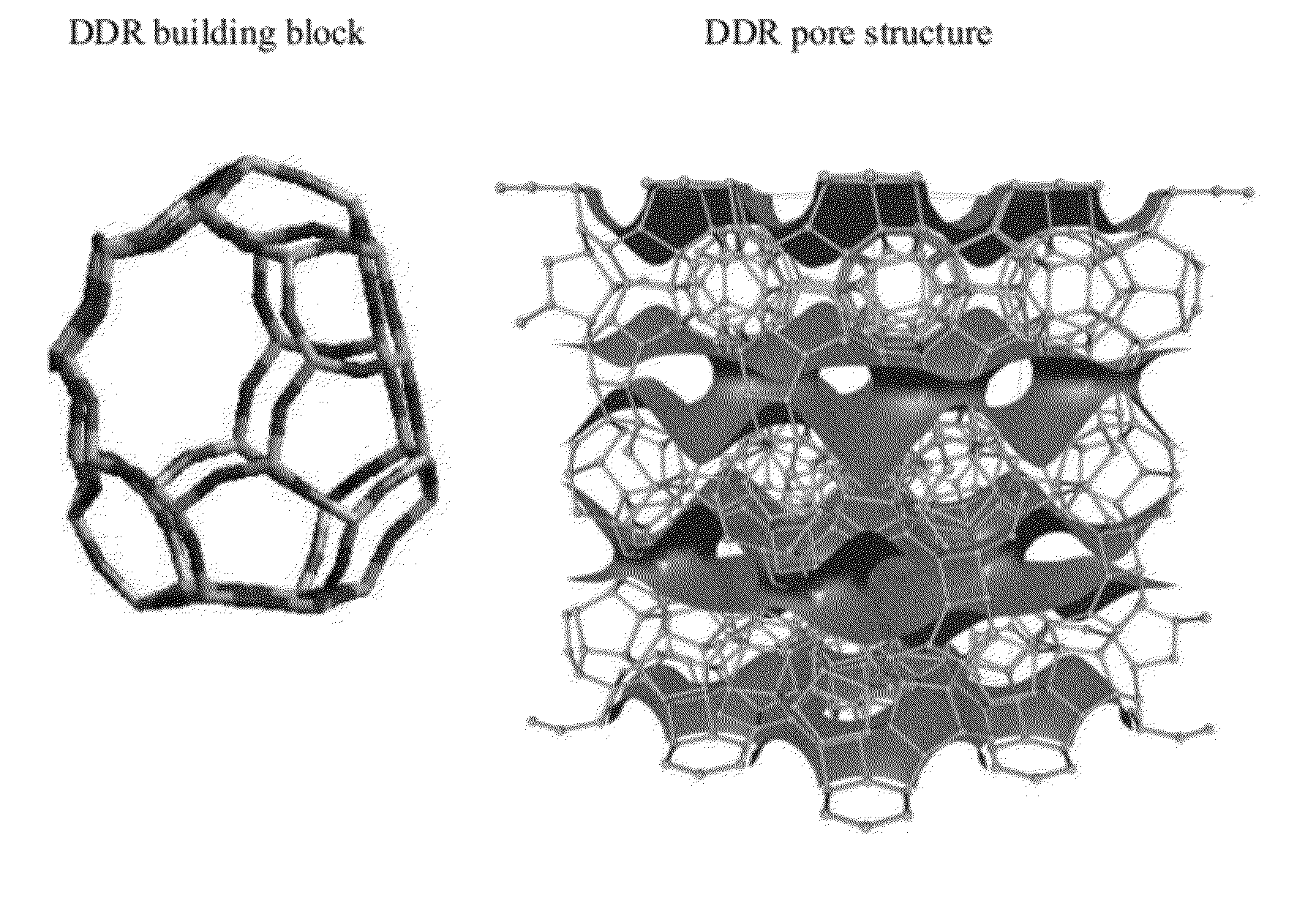

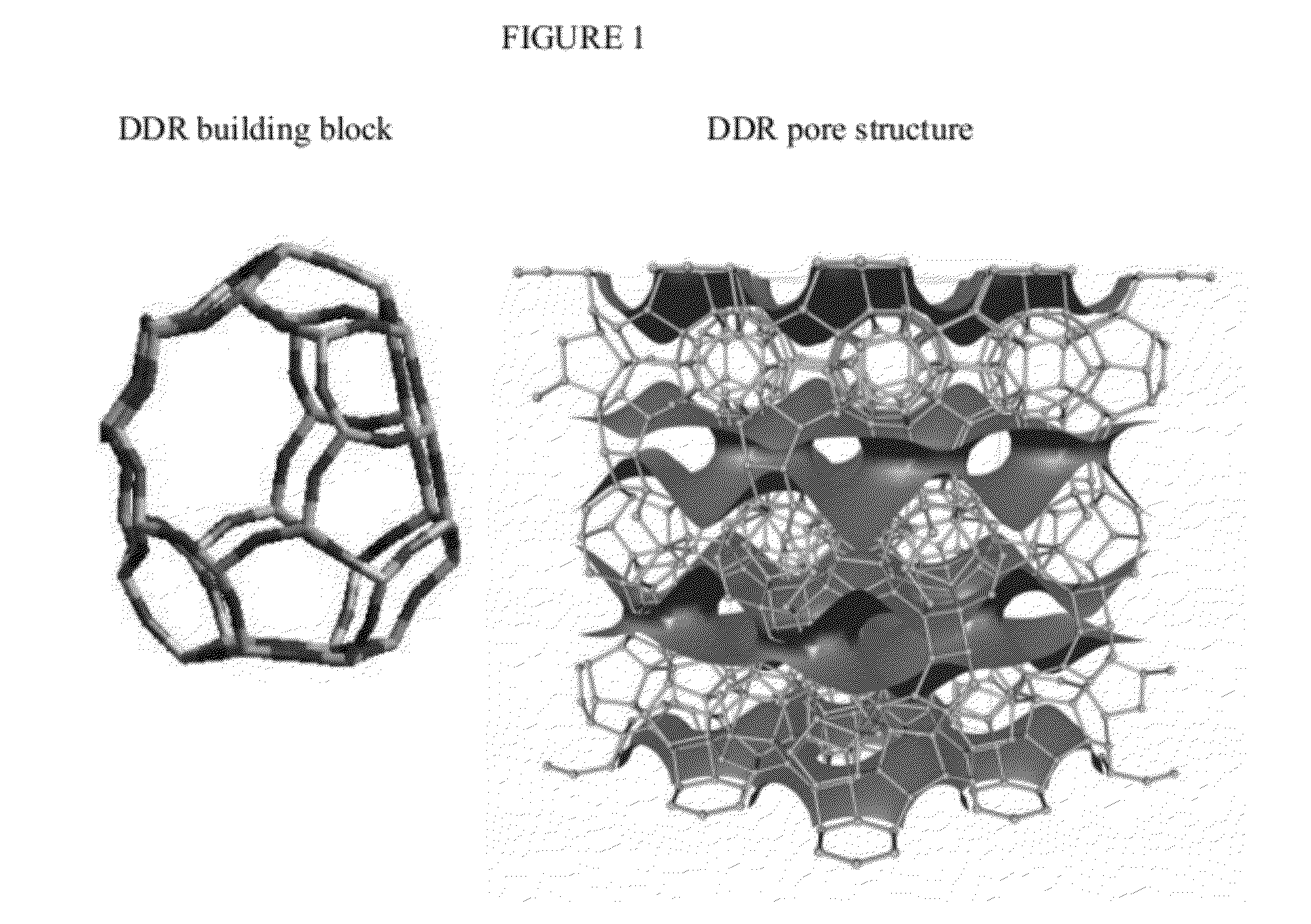

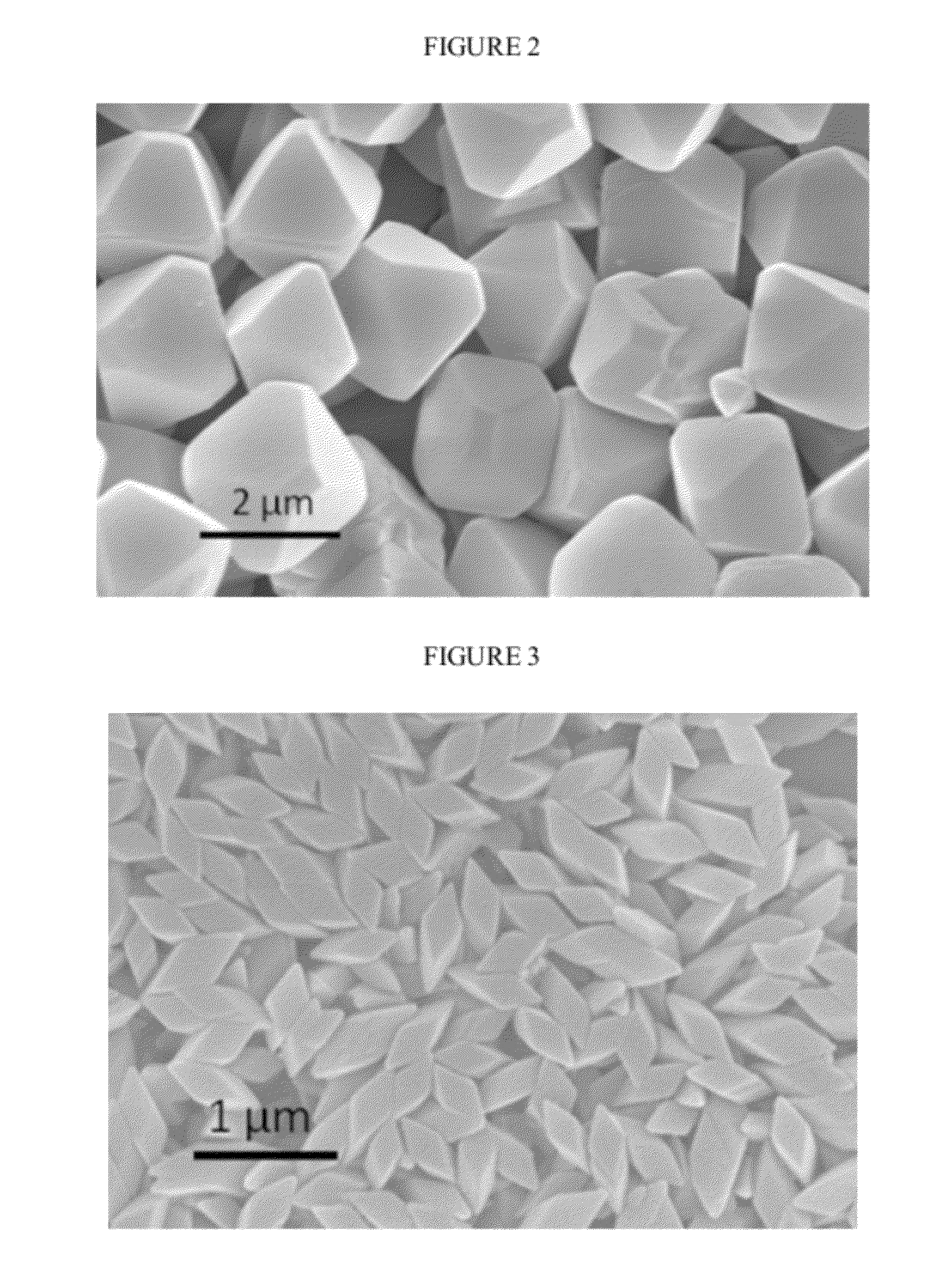

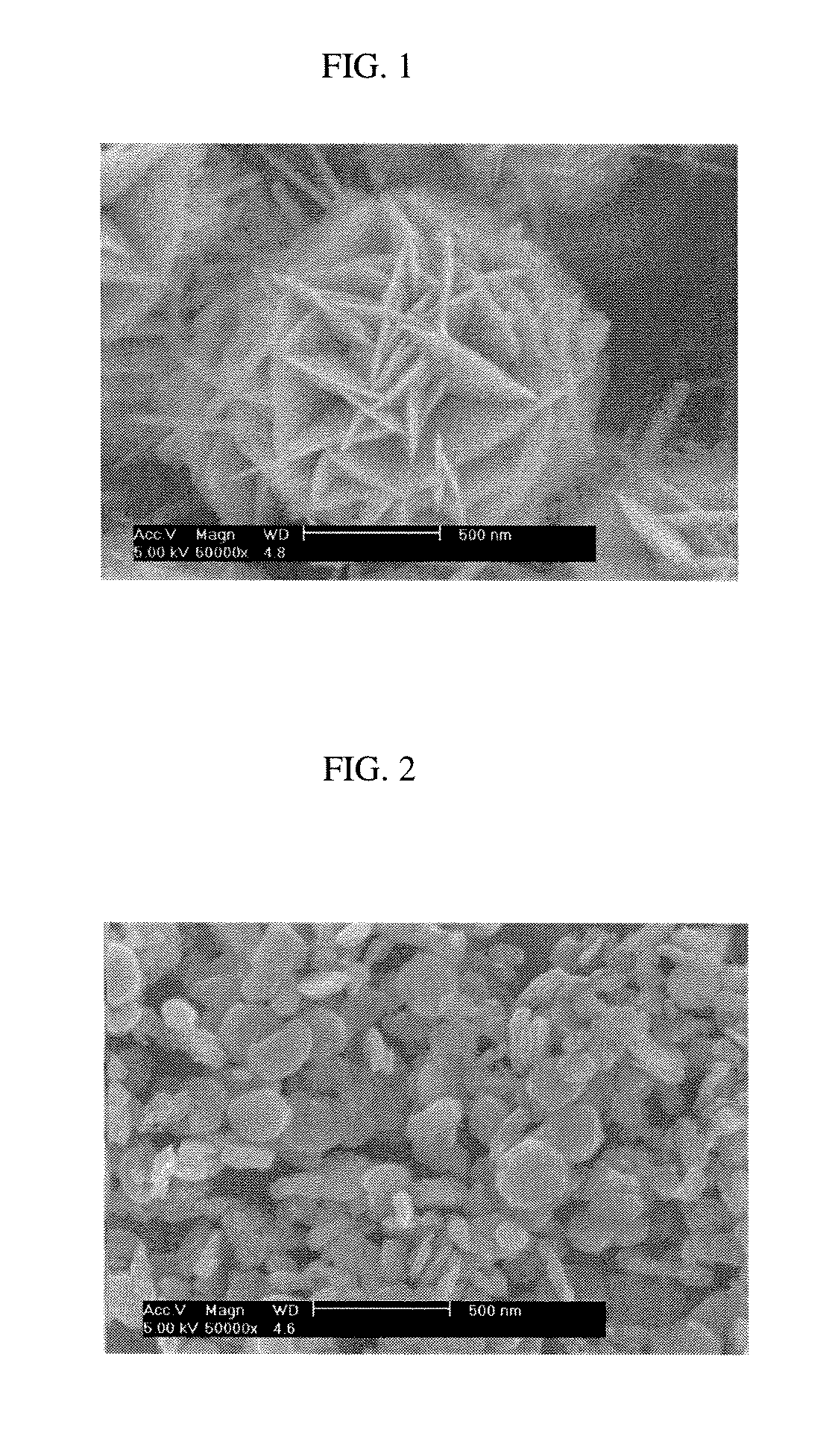

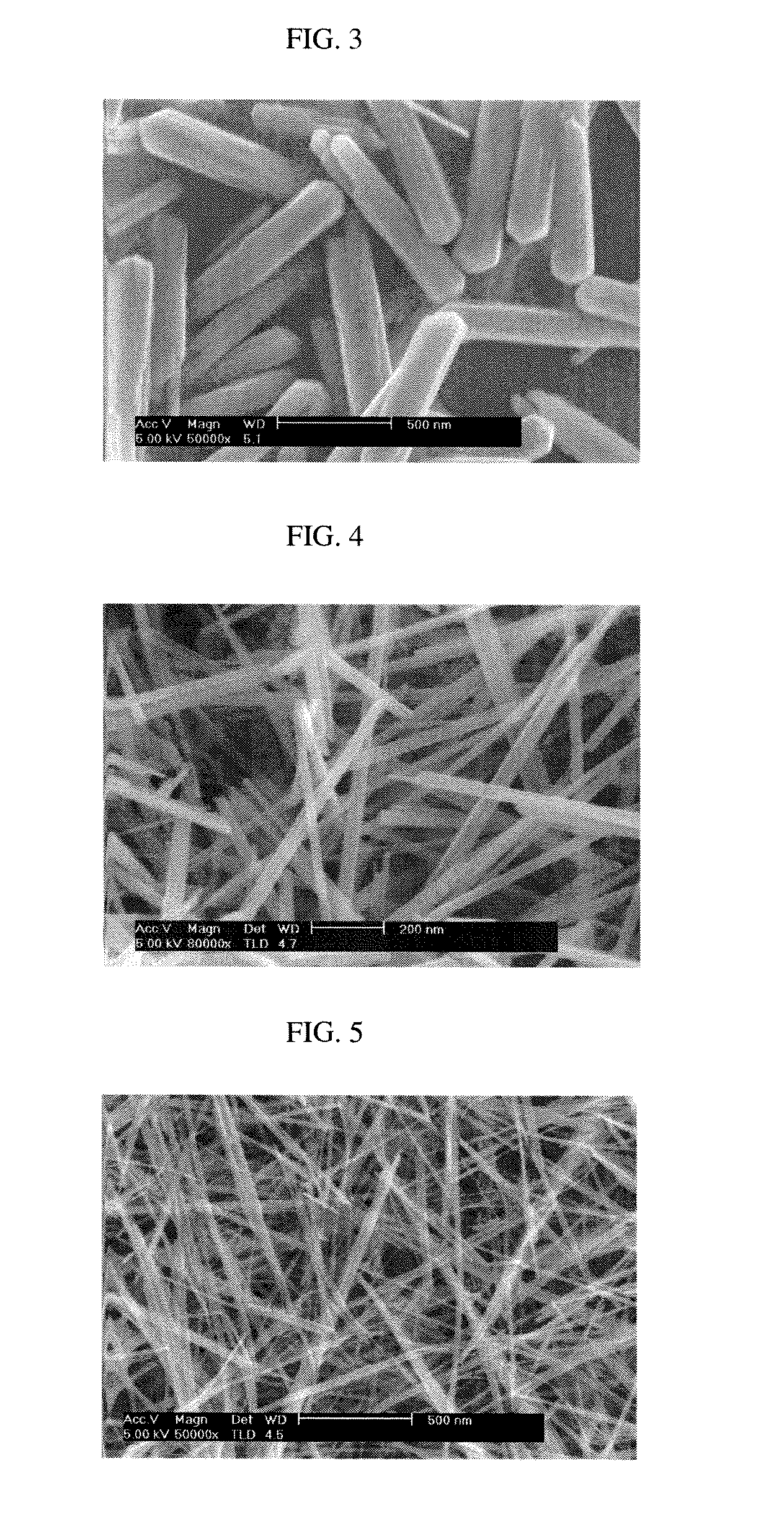

Zeolite DDR nanoparticles

DDR nanocrystals were synthesized using hydrothermal secondary growth. The morphology of the nanoparticles can be manipulated by changing the ratio of silica to water, the synthesis temperature, and the mineralizing agents. Specifically, nanocrystals with morphology of hexagonal plates, octahedral, and diamond-like plates are disclosed. These nanoparticles can be used as seed coatings for DDR membrane growth on substrates, and for the fabrication of mixed matrix membranes, and for any other use where uniform, small DDR zeolite crystals are beneficial.

Owner:GEORGIA TECH RES CORP

Method for manufacturing porous body

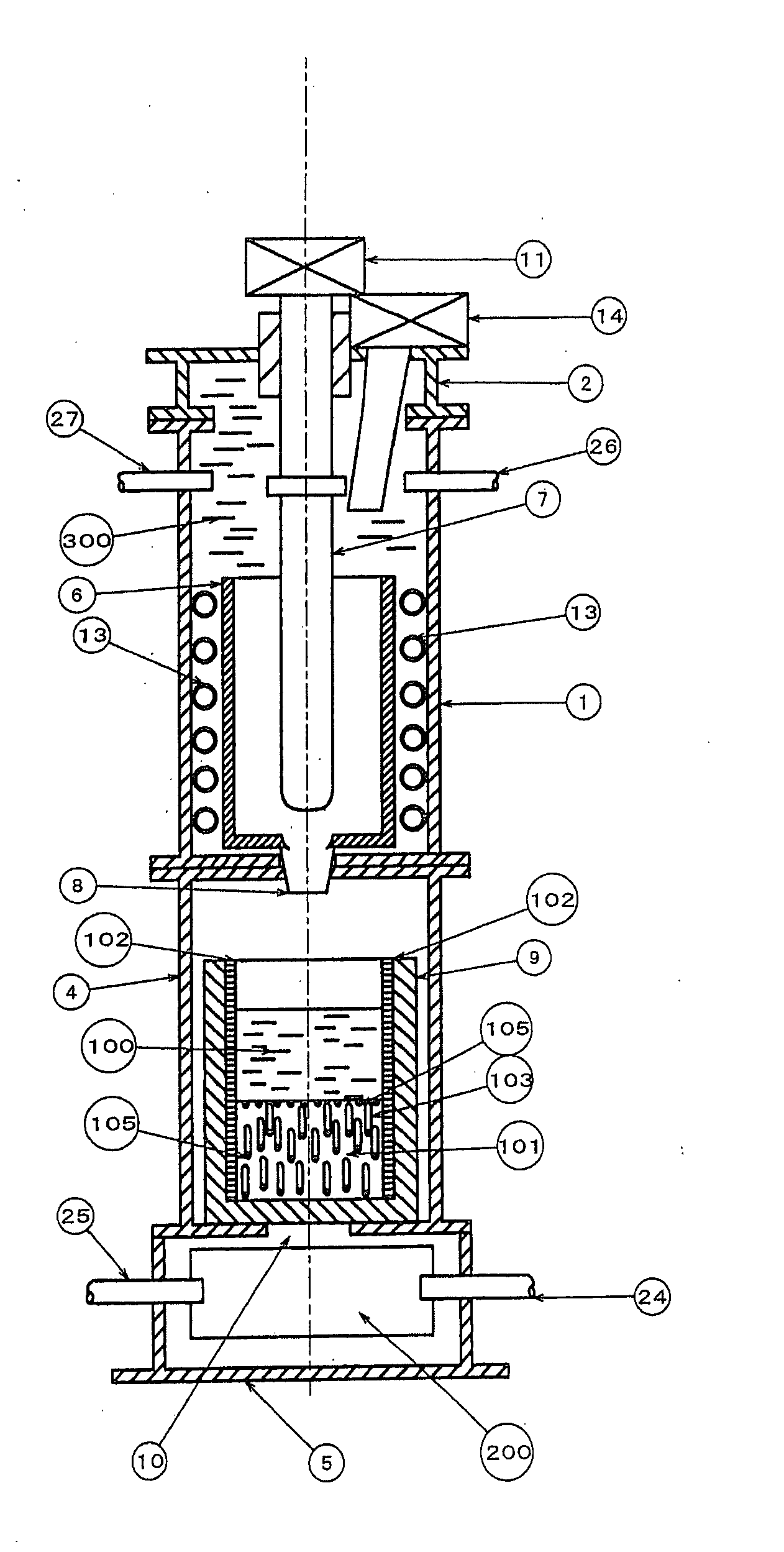

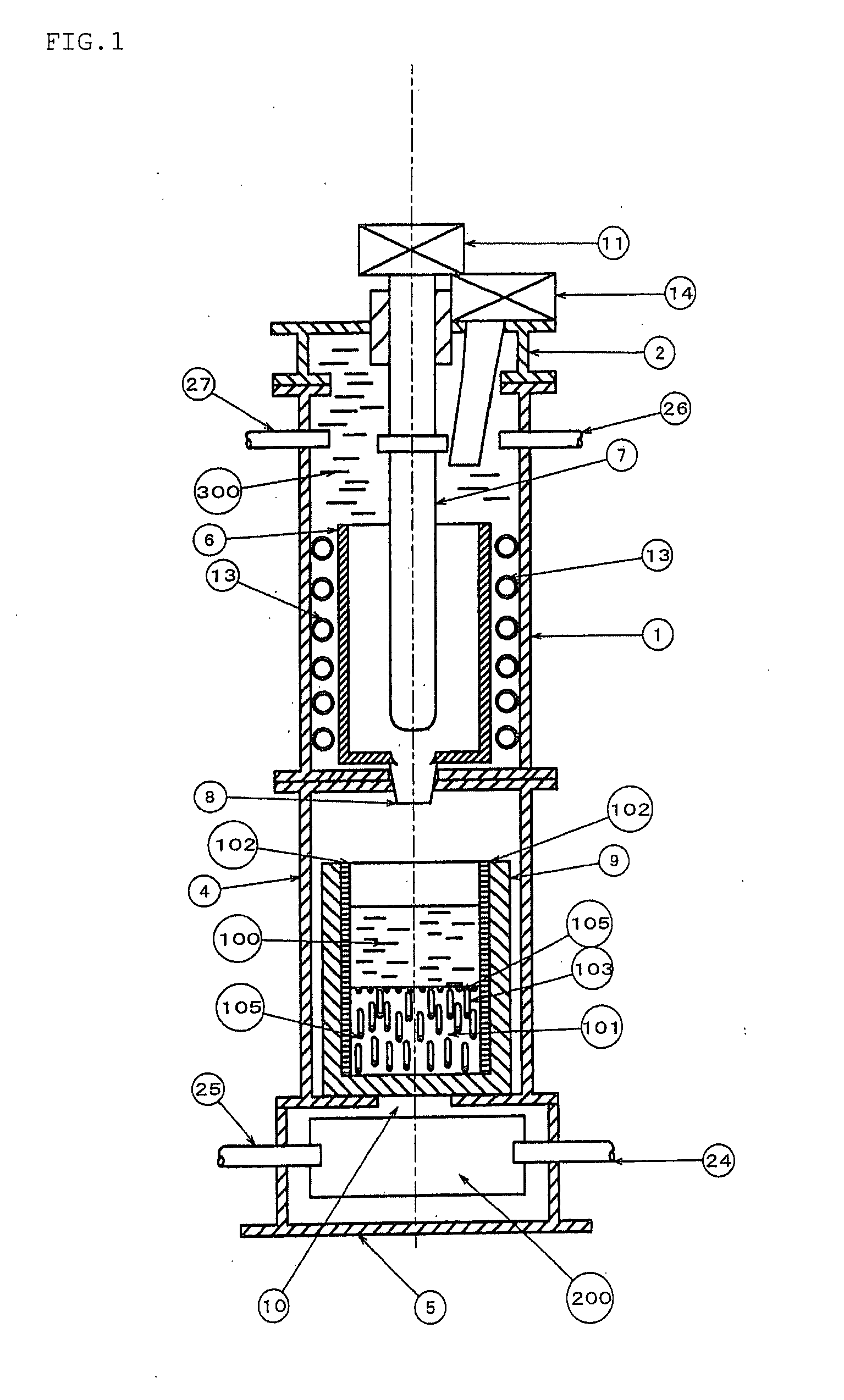

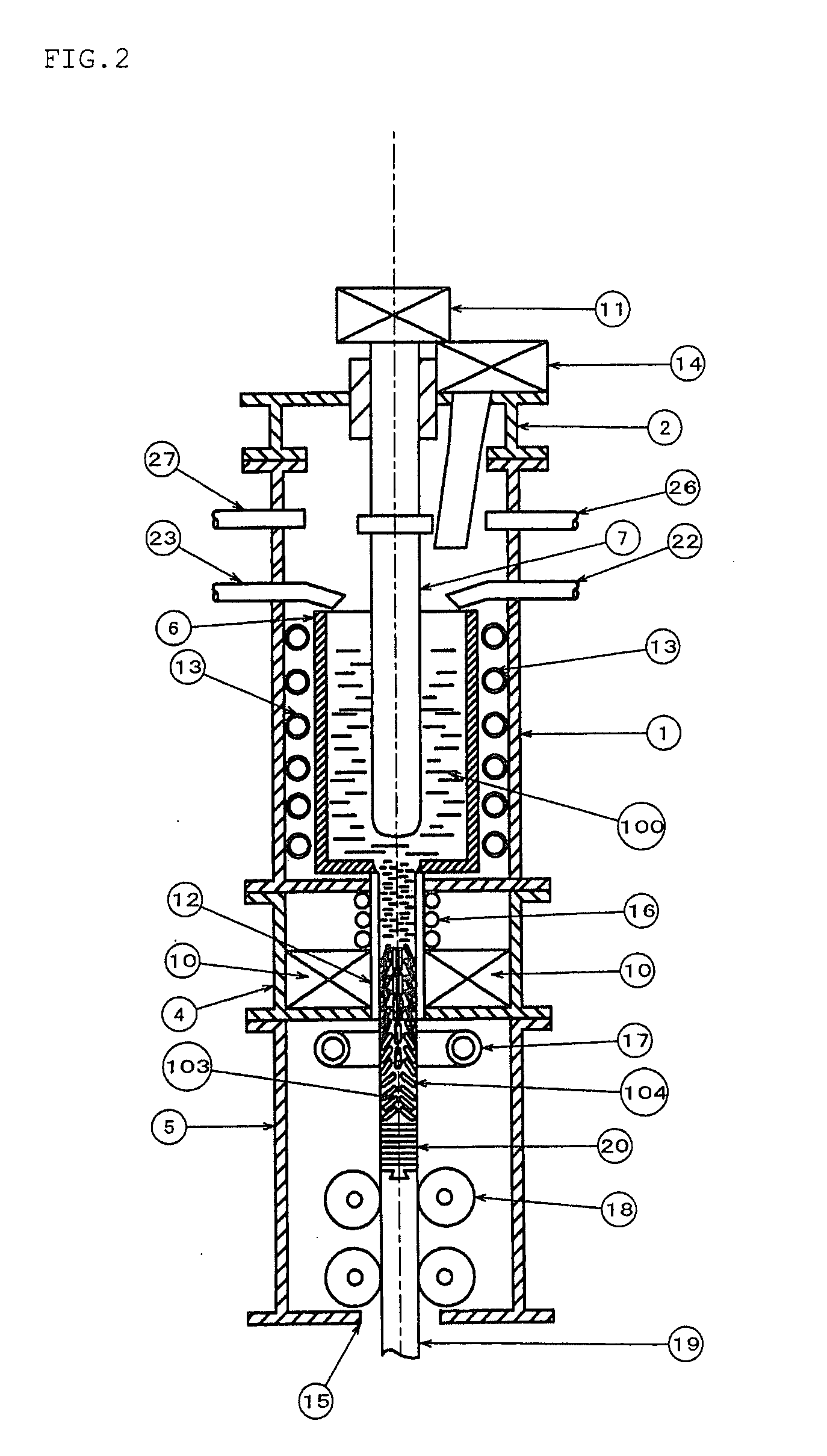

InactiveUS20090317282A1High qualityEnable mass productionMelt-holding vesselsSiliconHigh pressureMolten material

The present invention provides a process for producing a porous body which comprises dispersing a gas-forming compound in a molten porous body-forming material, and then solidifying the molten material. With this process, the present invention enables manufacture of high quality and highly uniform porous bodies even under an atmospheric pressure, without requiring high pressure ambience.

Owner:LOTUS ALLOY

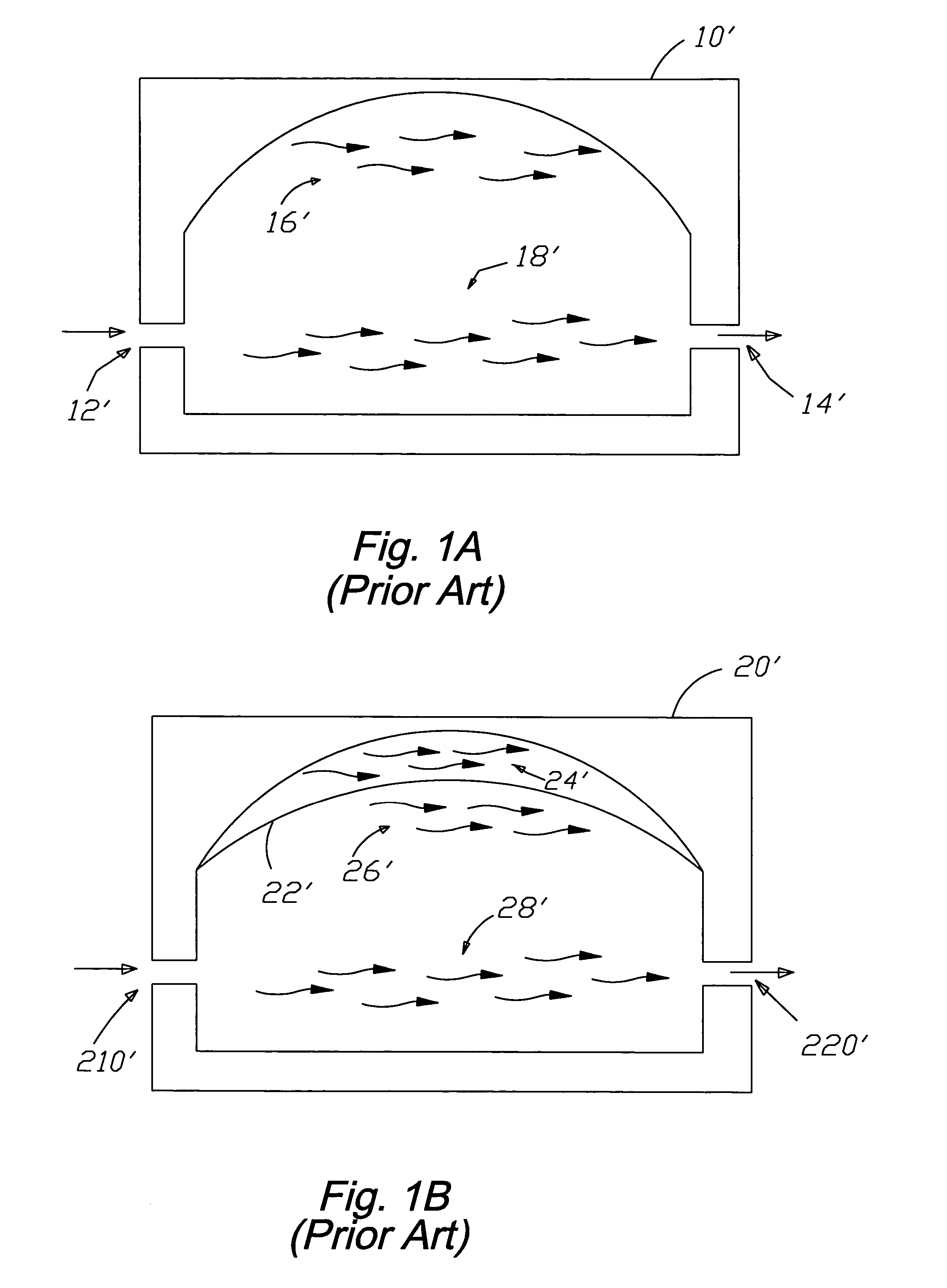

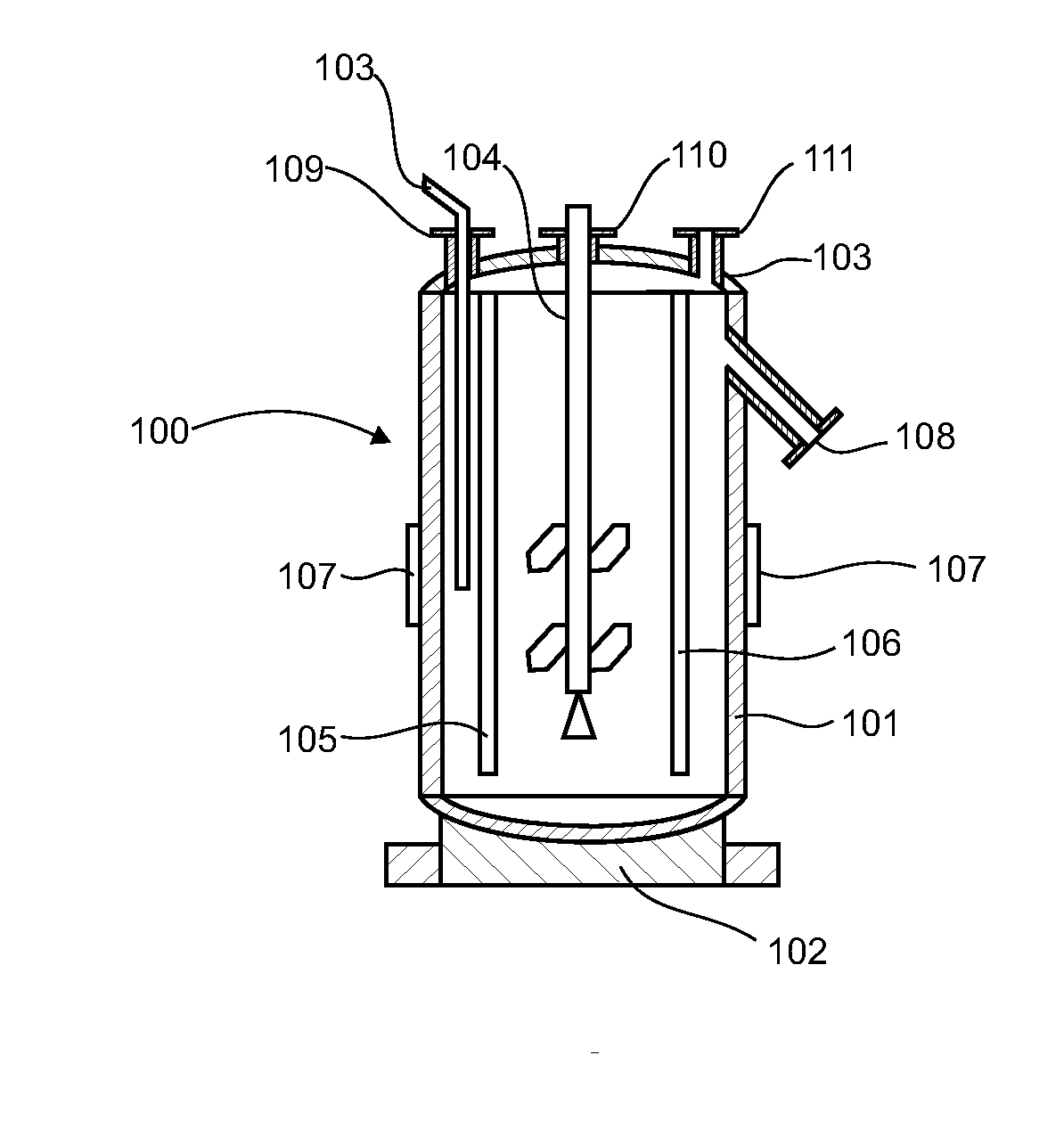

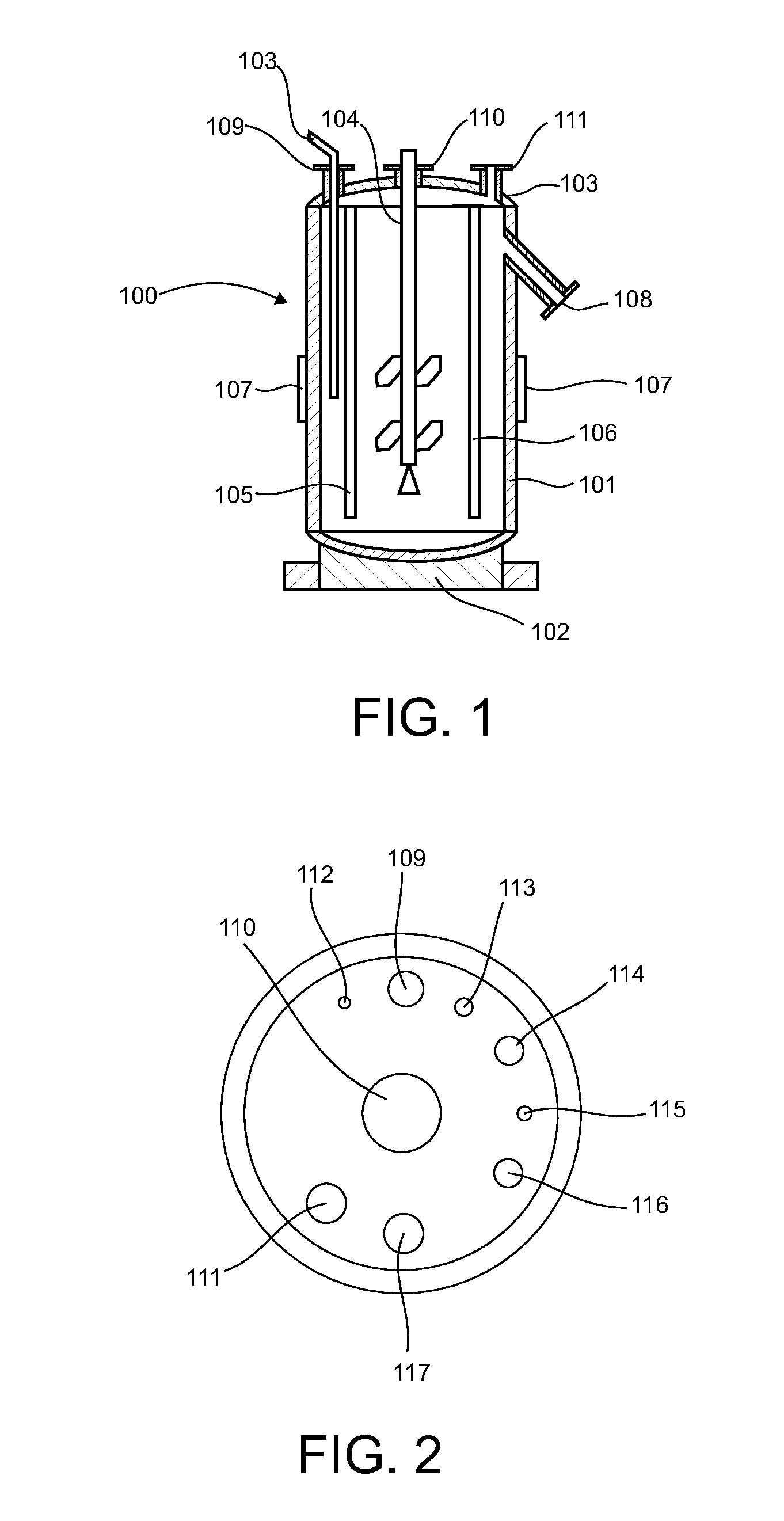

Bioleaching bioreactor with a system for injection and diffusion of air

ActiveUS20140239561A1Improve oxygen and carbon dioxide distributionControl sizeRotary stirring mixersTransportation and packagingCarbon dioxideEngineering

The present invention is related to a bioleaching bioreactor having an air injection and diffusion system, which allows to control the air bubble fine size, improving the oxygen and carbon dioxide distribution required by the microorganisms promoting the bioleaching process, in order to maintain the cellular concentration during the process. The bioleaching bioreactor comprises a reactor body to contain the pulp to be processed and to allow the reaction to proceed; a support base to secure the reactor body; a pulp feeding device, protruding inwards the reactor body; an air injection and diffusion system to mix and to supply the air required by the reaction process; at least four vortex breaking elements located inside the reactor body; at least a heating element surrounding the reactor body to maintain the reaction temperature; a pulp outlet port to deliver the pulp already processed; an inlet port for the pulp to be processed; an air inlet port, located at the upper end of the reactor body; and, a vapor outlet port, located at the upper end of the reactor body.

Owner:SERVICIOS CONDUMEX DE C V

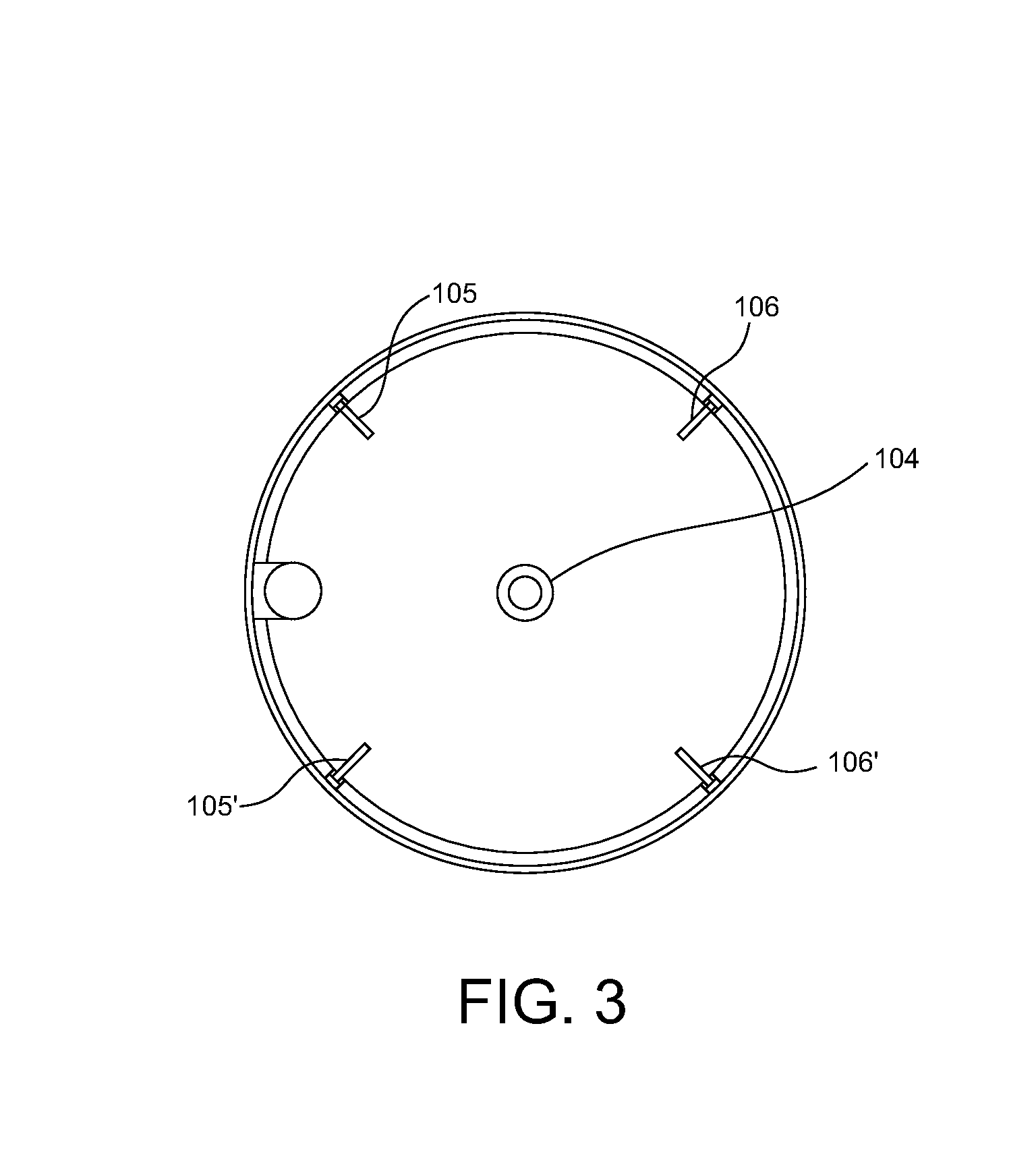

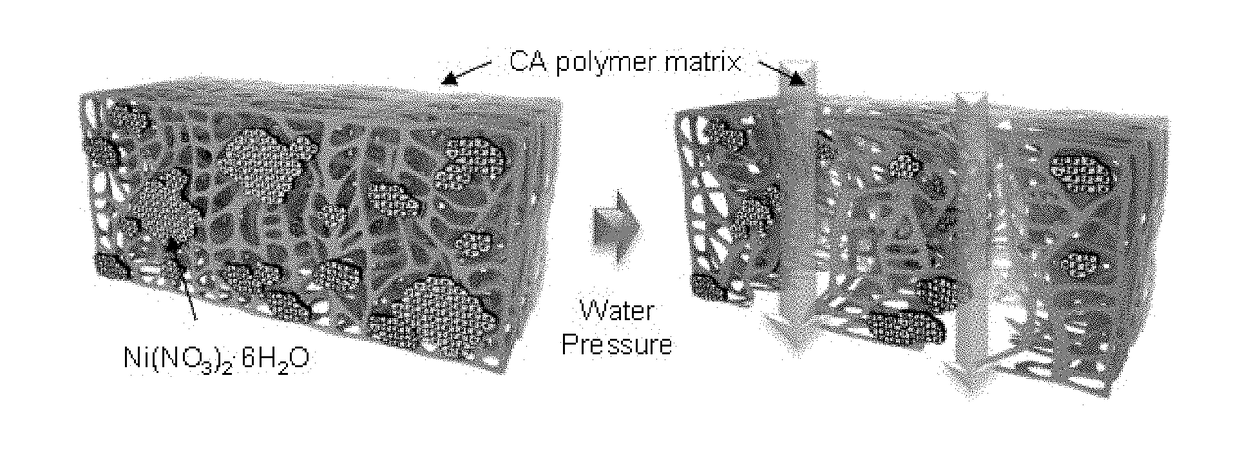

Method of manufacturing porous polymer membrane using water pressure and battery separator comprising porous polymer membrane manufactured by the method

InactiveUS20170271637A1Increase in sizeSmall average pore sizeSemi-permeable membranesCation exchanger materialsPolymer sciencePore water pressure

Owner:SANGMYUNG UNIV SEOUL IND ACAD COOP FOUND

Absorbent polymeric foam for shoe insoles

The present invention relates to a polymeric foam, and a process for making the polymeric foam comprising the steps of a) providing a monomeric solution consisting of a polymerizable, ethylenically unsaturated monomer containing one or more acid groups, water and one or more crosslinkers having more than one polymerizable group per molecule; b) introducing a blowing agent to the monomer solution; c) treating the monomer solution with an ultrasonic treatment; d) introducing one or more initiation agents to the monomer solution; and e) polymerizing the monomer solution.

Owner:EVONIK SUPERABSORBER GMBH

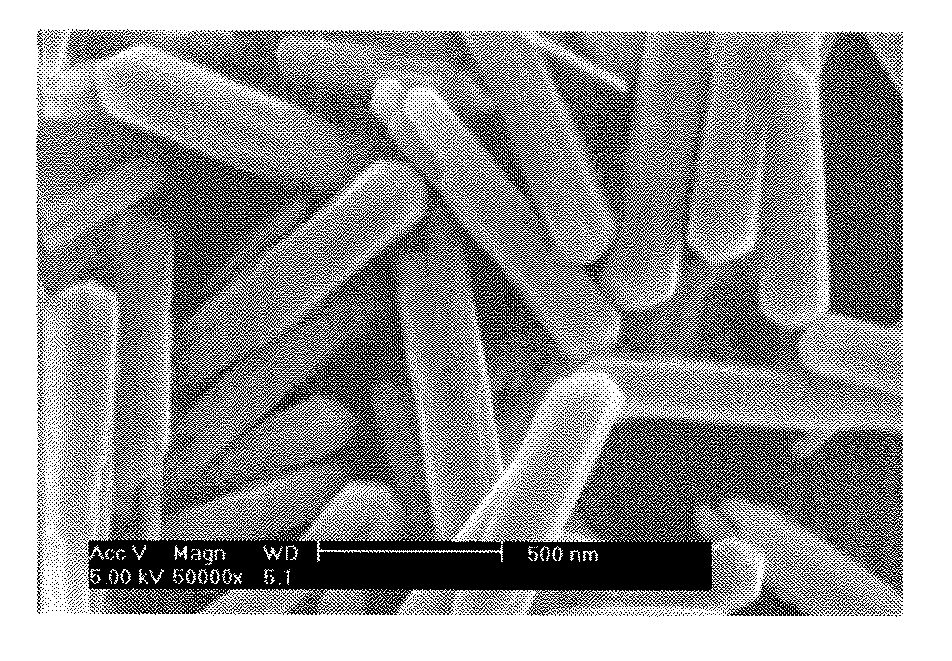

Method of controlling aspect ratio of nano-structure, method of producing nano-structure using the same and nano-structure produced thereby

ActiveUS20120282164A1Control sizeEasy to controlMaterial nanotechnologyIndividual molecule manipulationControl aspectsOxidizing agent

Provided are a method of easily controlling the aspect ratio of a nano-structure, which can be effectively used in various fields of application, including a positive active material for a rechargeable battery, an electrode material for a storage battery, a redox catalyst, a molecule support, and so on, and by which various nano-structures of desired sizes can be easily produced according to the necessity. The method includes preparing a mixed solution including a manganese salt and an oxidant, adding a pH controlling additive to the mixed solution and controlling a pH level of the mixed solution using the following equation, and heating the pH-controlled mixed solution at a temperature in a range of 50□ to 200□ for 1 hour to 10 days to cause a reaction to take place:Specific surface area (m2 / g)=0.2 pH2+2.

Owner:SAMSUNG CORNING PRECISION MATERIALS CO LTD

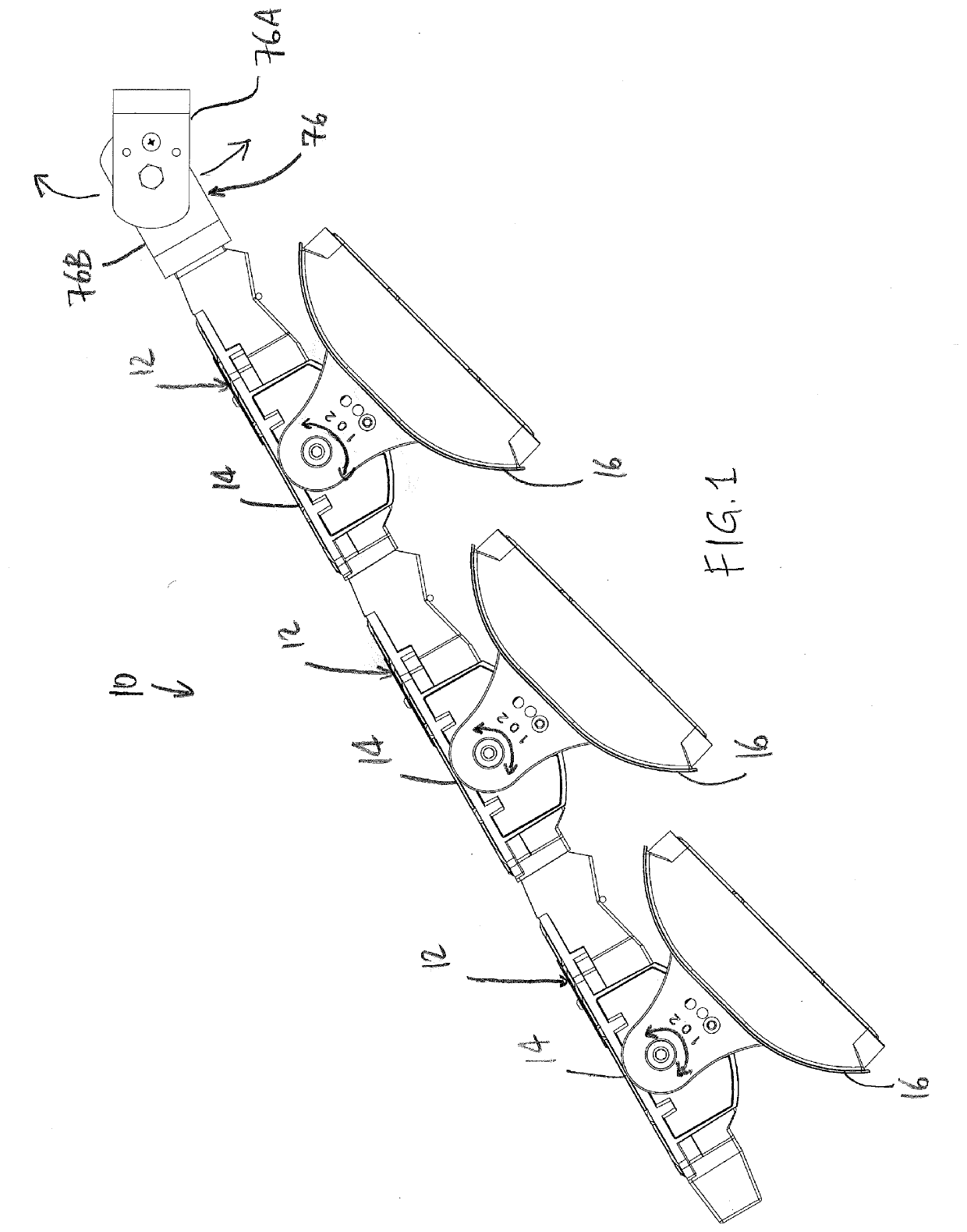

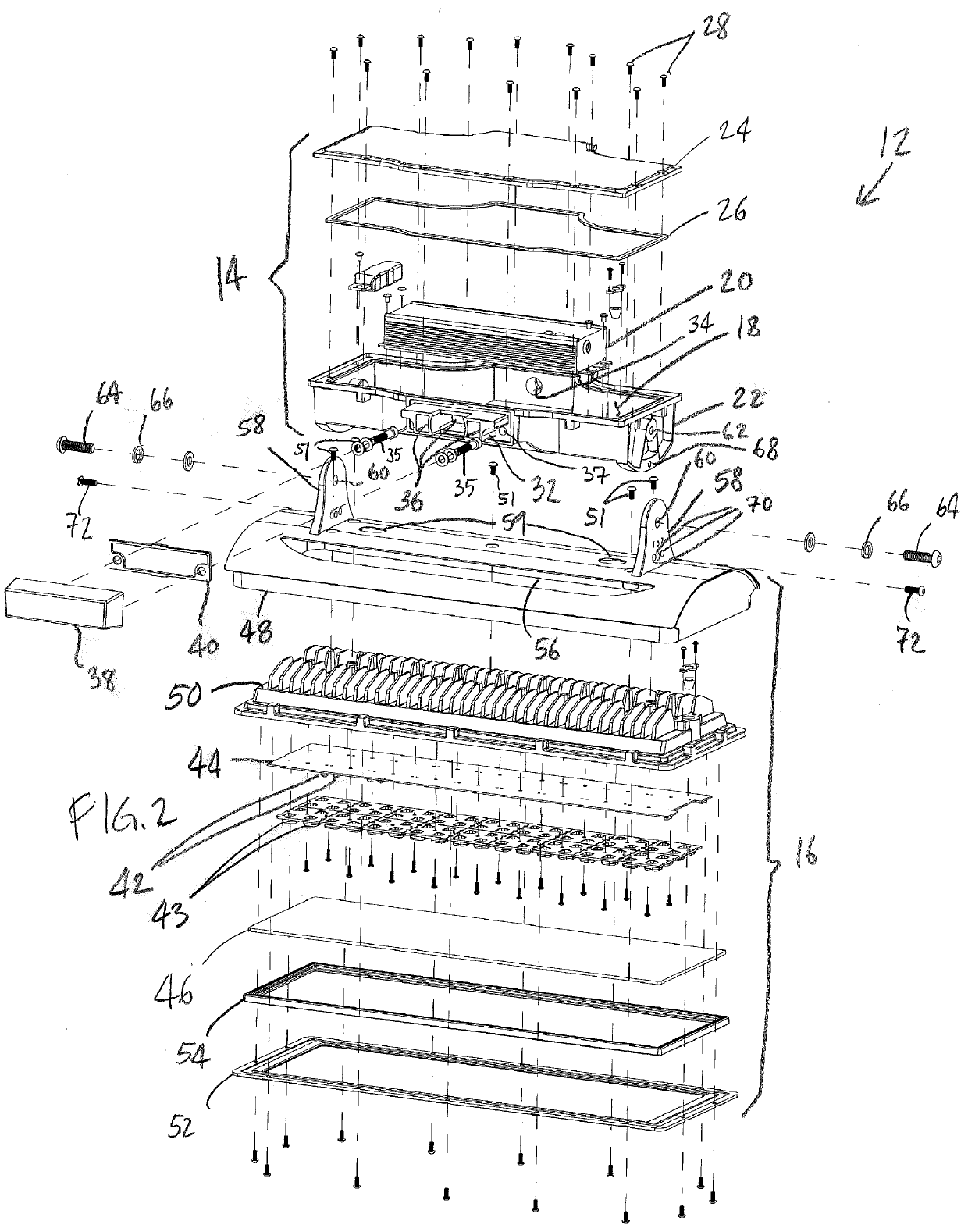

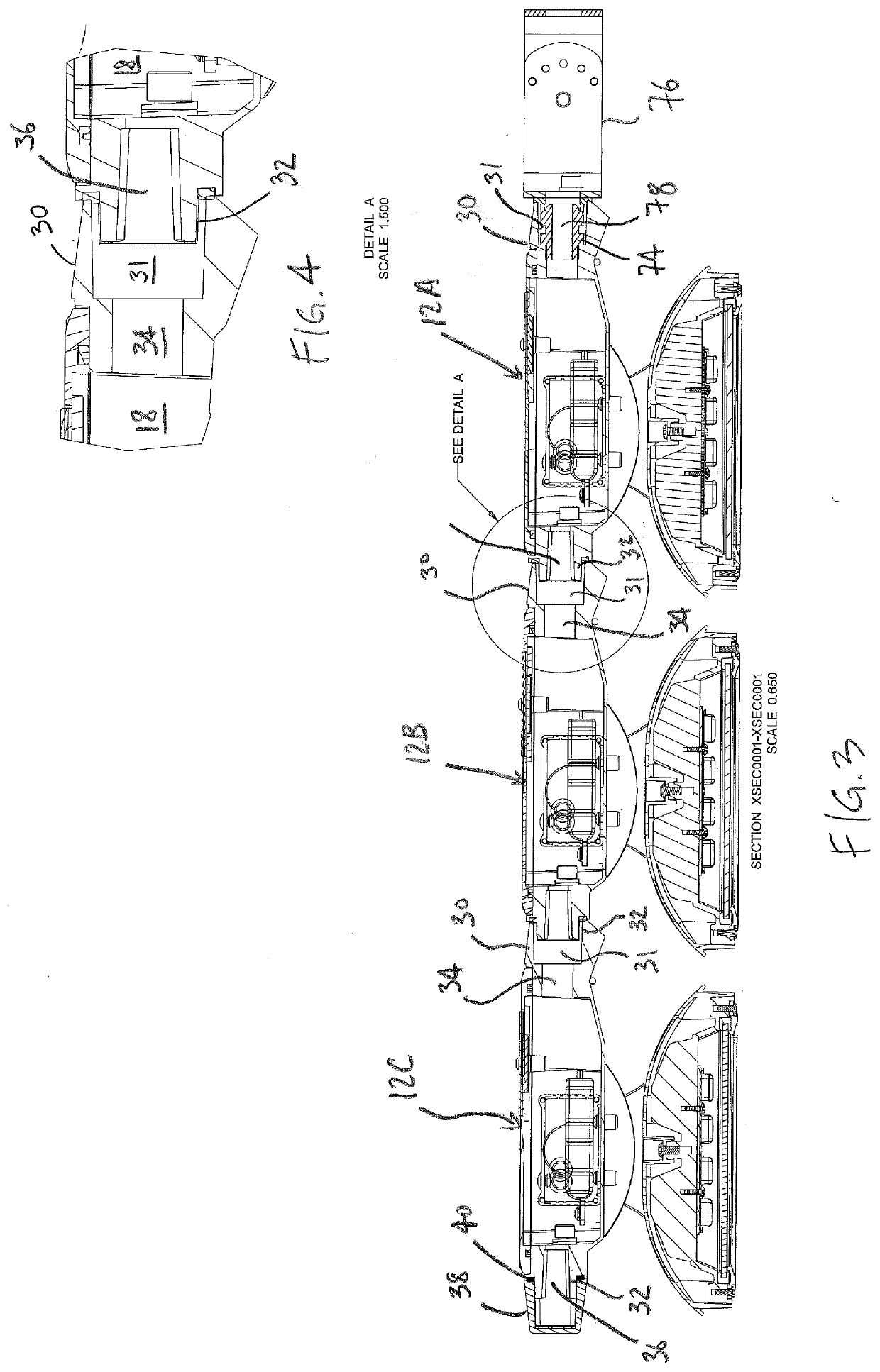

Adjustable, modular flood light fixture

ActiveUS20200191369A1Control sizeSizeLighting support devicesLighting heating/cooling arrangementsLight fixtureFloodlight

An adjustable, modular flood light fixture is provided herein which includes a plurality of light modules, each including an enclosure and a luminaire configured to generate light, the luminaire being pivotably mounted to the enclosure. The light modules are serially connected with the luminaires of the light modules being each independently, pivotably adjustable. Advantageously, with the subject invention, the size of an illuminated area may be controlled by the number of light modules being used, with pivoting adjustment allowing further control over how light from each of the light modules is directed.

Owner:MAXLITE

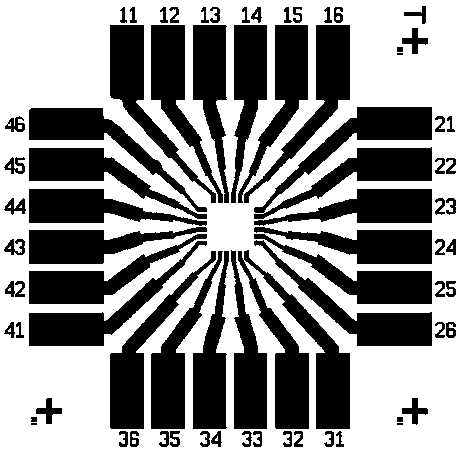

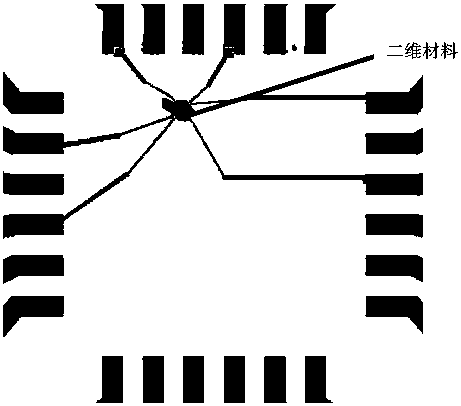

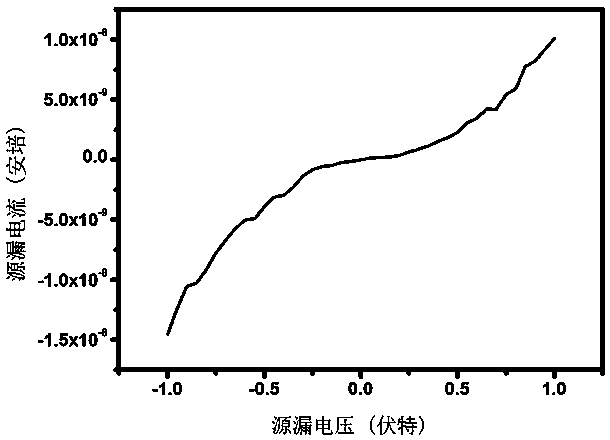

High-precision micro-nano size two-dimensional material electrode preparation method

ActiveCN107946188AControl sizeControl shapeSemiconductor/solid-state device manufacturingDesign optimisation/simulationMicro nanoImaging processing

The invention discloses a high-precision micro-nano size two-dimensional material electrode preparation method. The high-precision micro-nano size two-dimensional material electrode preparation methodcomprises the steps of: transferring a two-dimensional material to a silicon substrate provided with a preset electrode; subjecting the silicon substrate to observation and photographing under a microscope; performing image processing on a photographed image on image processing software; opening the processed image in layout software, and drawing electrodes as required; and preparing the electrodes by means of electron beam exposure. The high-precision micro-nano size two-dimensional material electrode preparation method is low in cost and high in efficiency, draws different electrode patterns on the layout processing software according to different requirements, efficiently controls the size and shape of the electrodes, and is wide in application range.

Owner:EAST CHINA NORMAL UNIV

Method for preparing nanoparticles using carbene derivatives

ActiveUS8057780B2Control shapeControl sizeNanostructure manufactureSelenium/tellurium compundsOrganic solventNanoparticle

Disclosed herein is a method for synthesizing a nanoparticle using a carbene derivative. More specifically, provided is a method for synthesizing a nanoparticle by adding one or more precursors to an organic solvent to grow a crystal, wherein a specific carbene derivative is used as the precursor.

Owner:SAMSUNG ELECTRONICS CO LTD

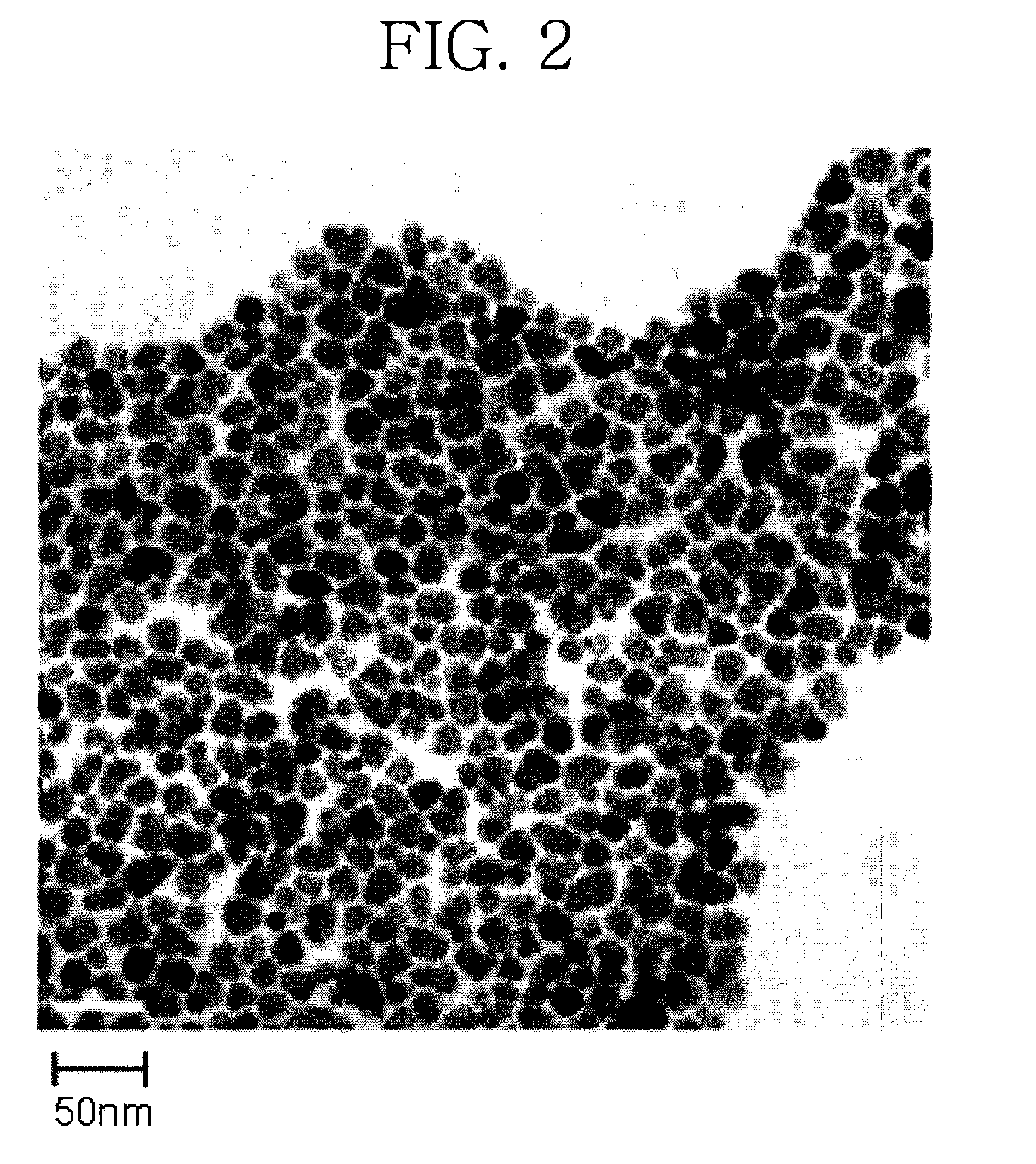

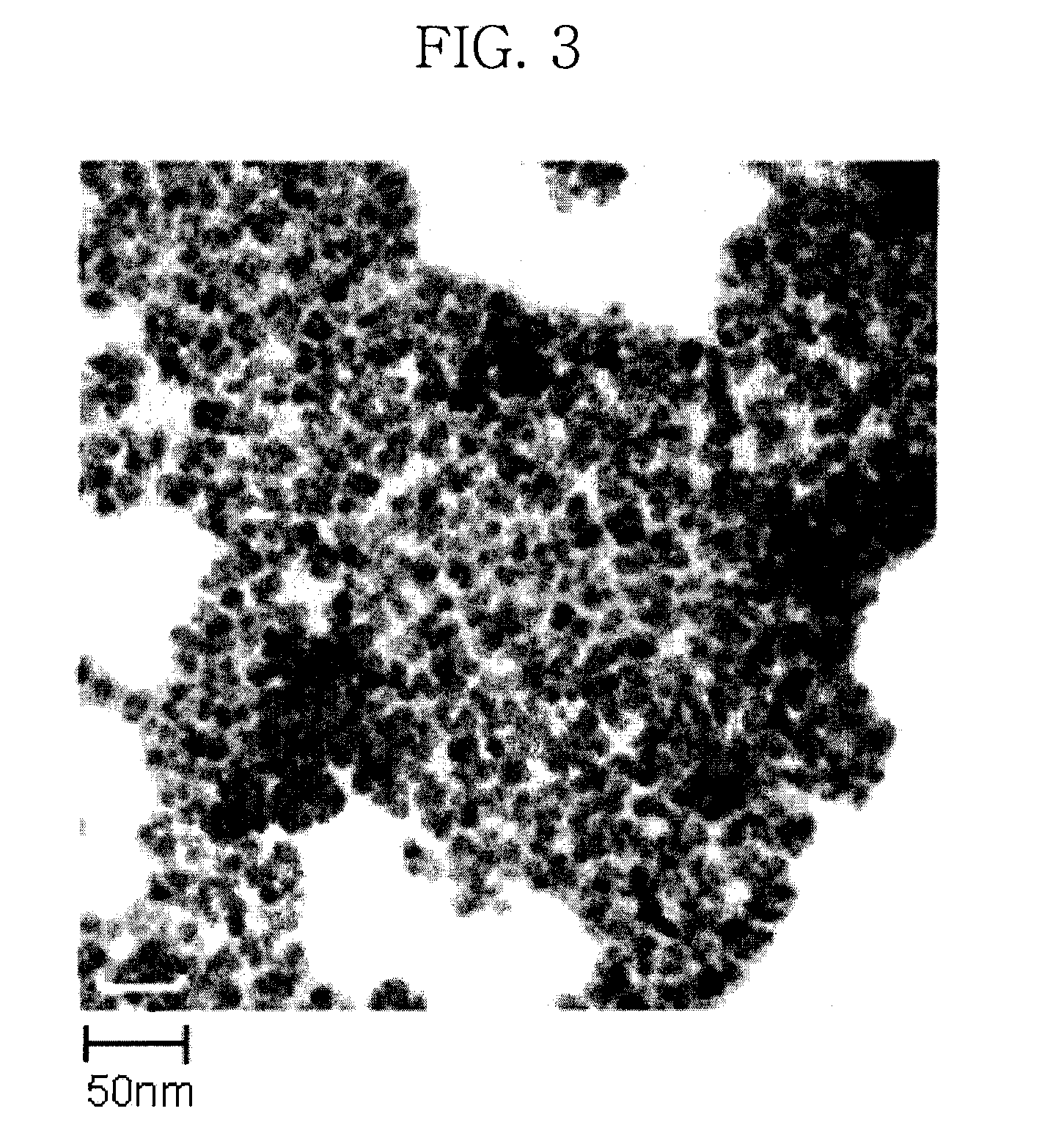

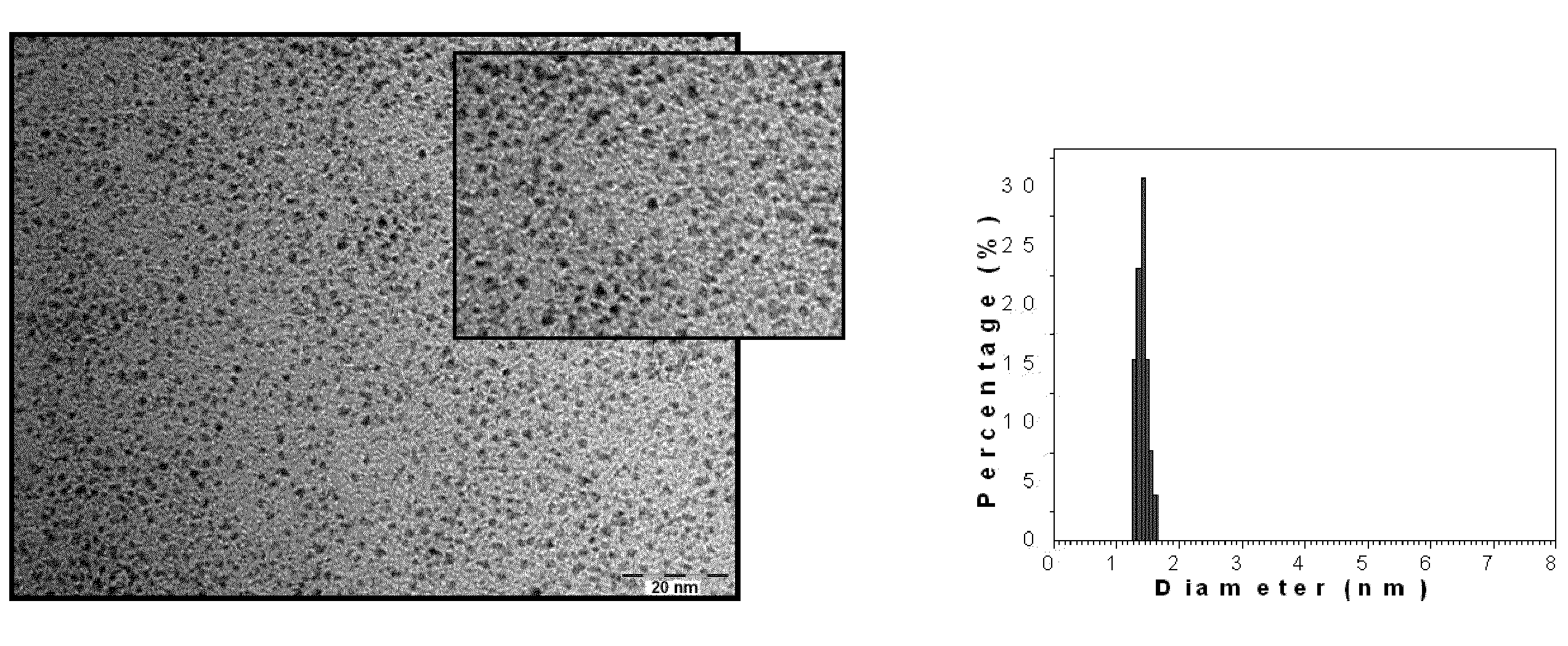

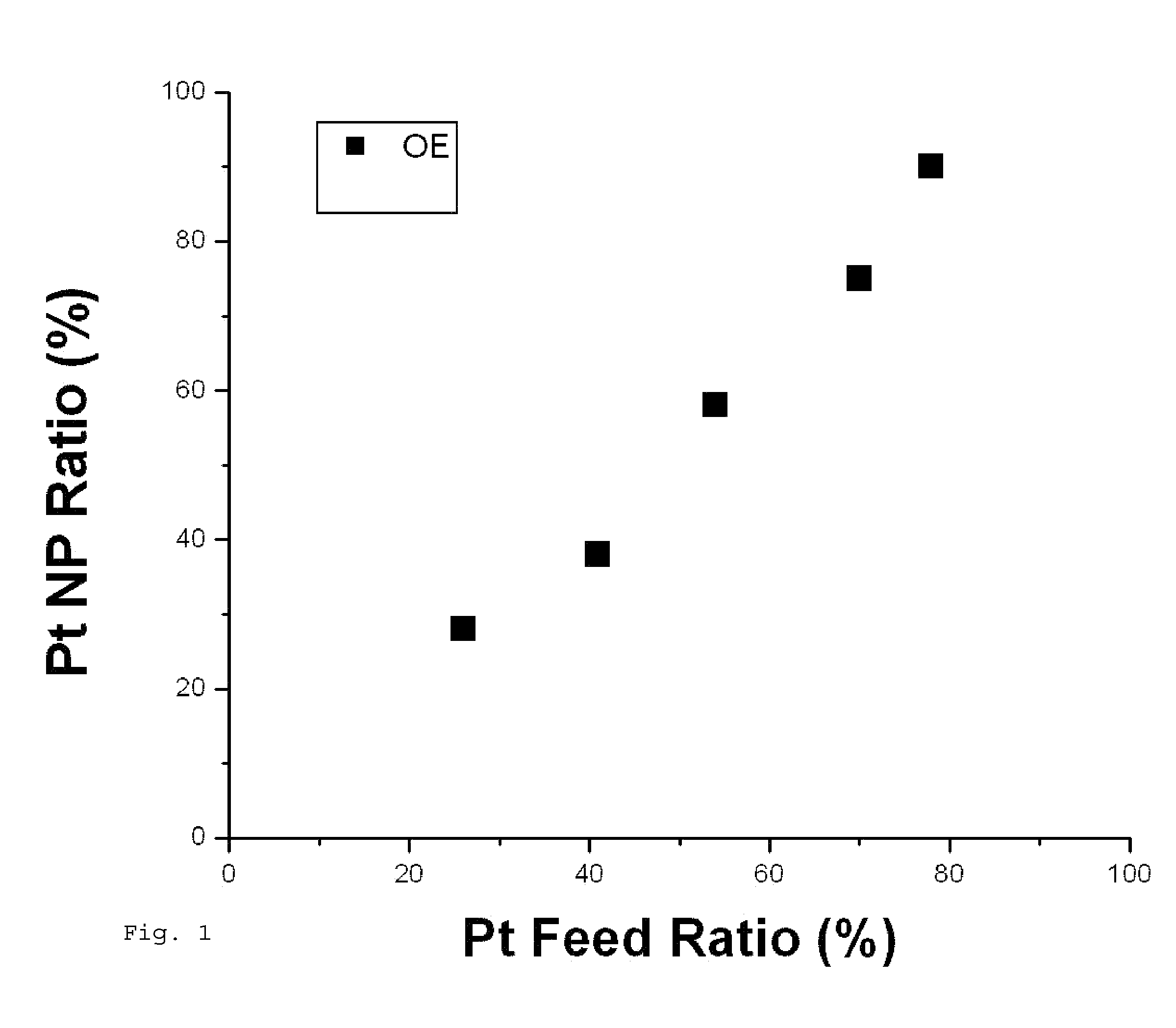

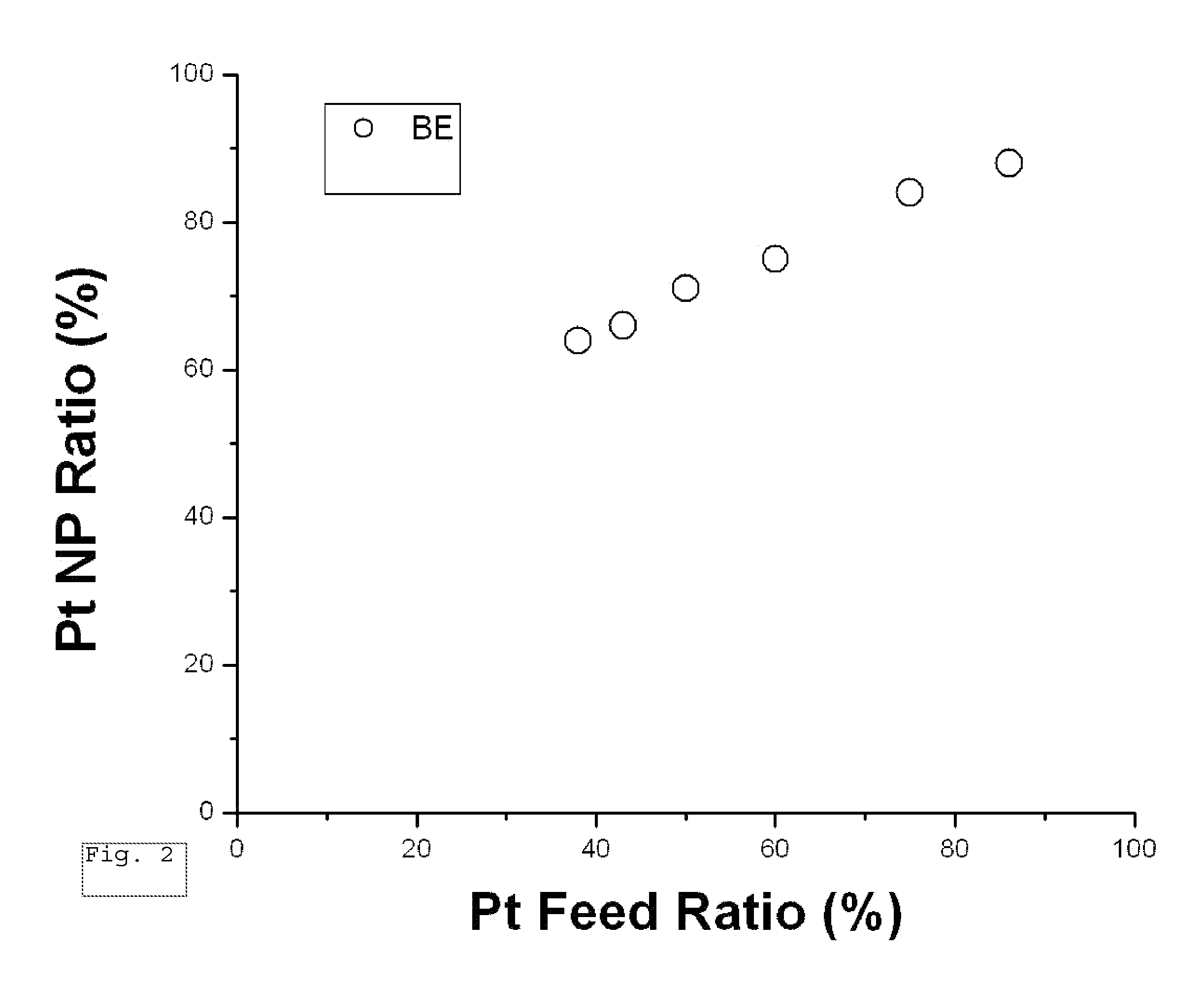

Synthesis of PtCo Nanoparticles

ActiveUS20100018346A1Increase diameterControl sizeMaterial nanotechnologyTransportation and packagingSolventNanometre

Synthesis of nanoparticles with particle size control is provided by the method of using two different metal-containing precursors, a capping component, an optional reducing agent, and then contacting the two precursors with the capping component to form a reaction solution, which is heated to produce first and second metals-containing nanoparticles. By controlling the ratio of the concentration of the capping component to the total concentration of the two metal-containing precursors, the nanoparticles can have diameters ranging between about 1 nm to about 15 nm. A decrease in the concentration of the capping component typically increases the size of the nanoparticles. Preferred compositions include Pt and Co-containing alloy nanoparticles. Controlled synthesis of larger, about 6 nm to about 12 nm, sized nanoparticles can be achieved in a solvent-free reaction process.

Owner:HONDA MOTOR CO LTD +1

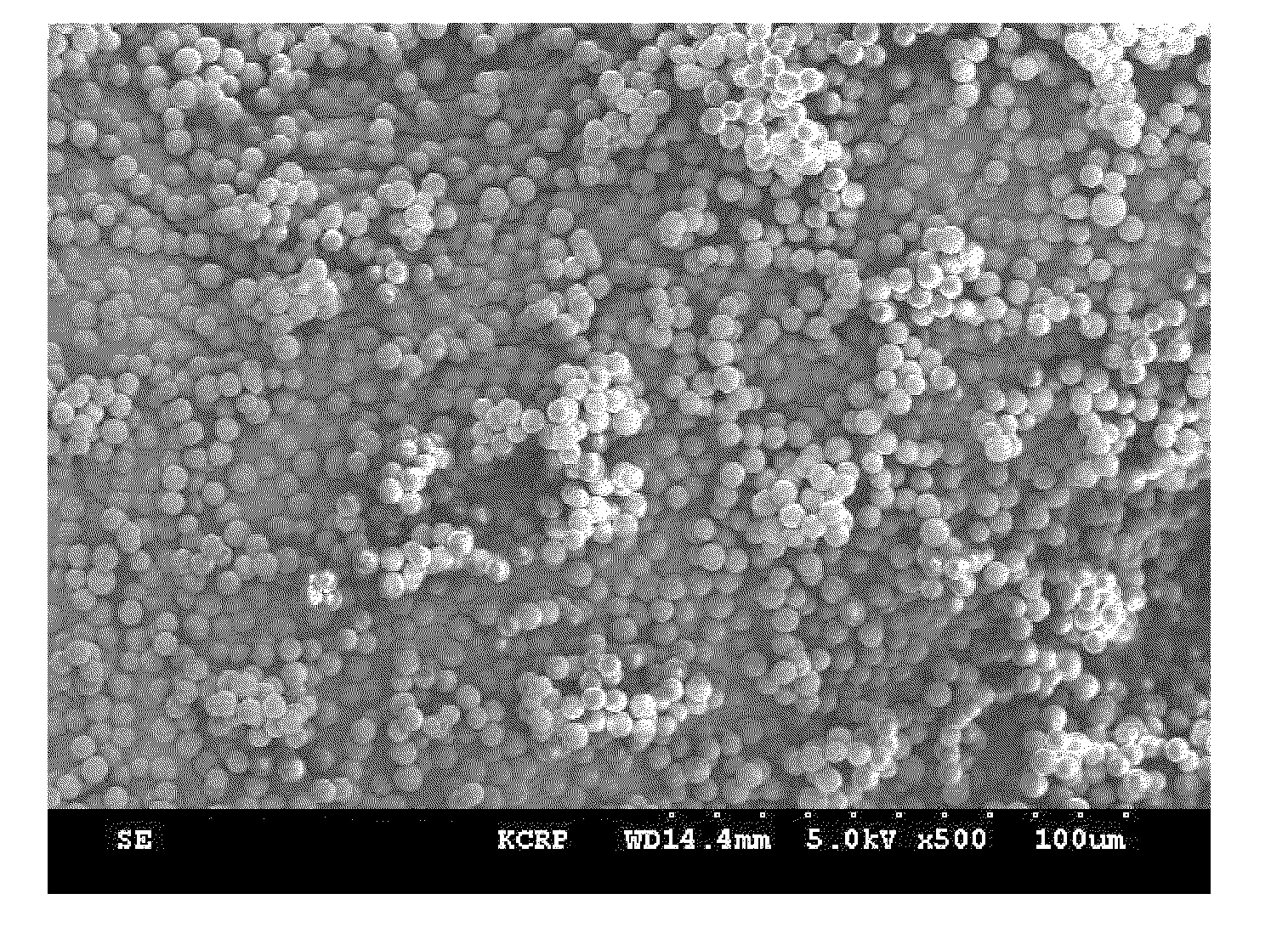

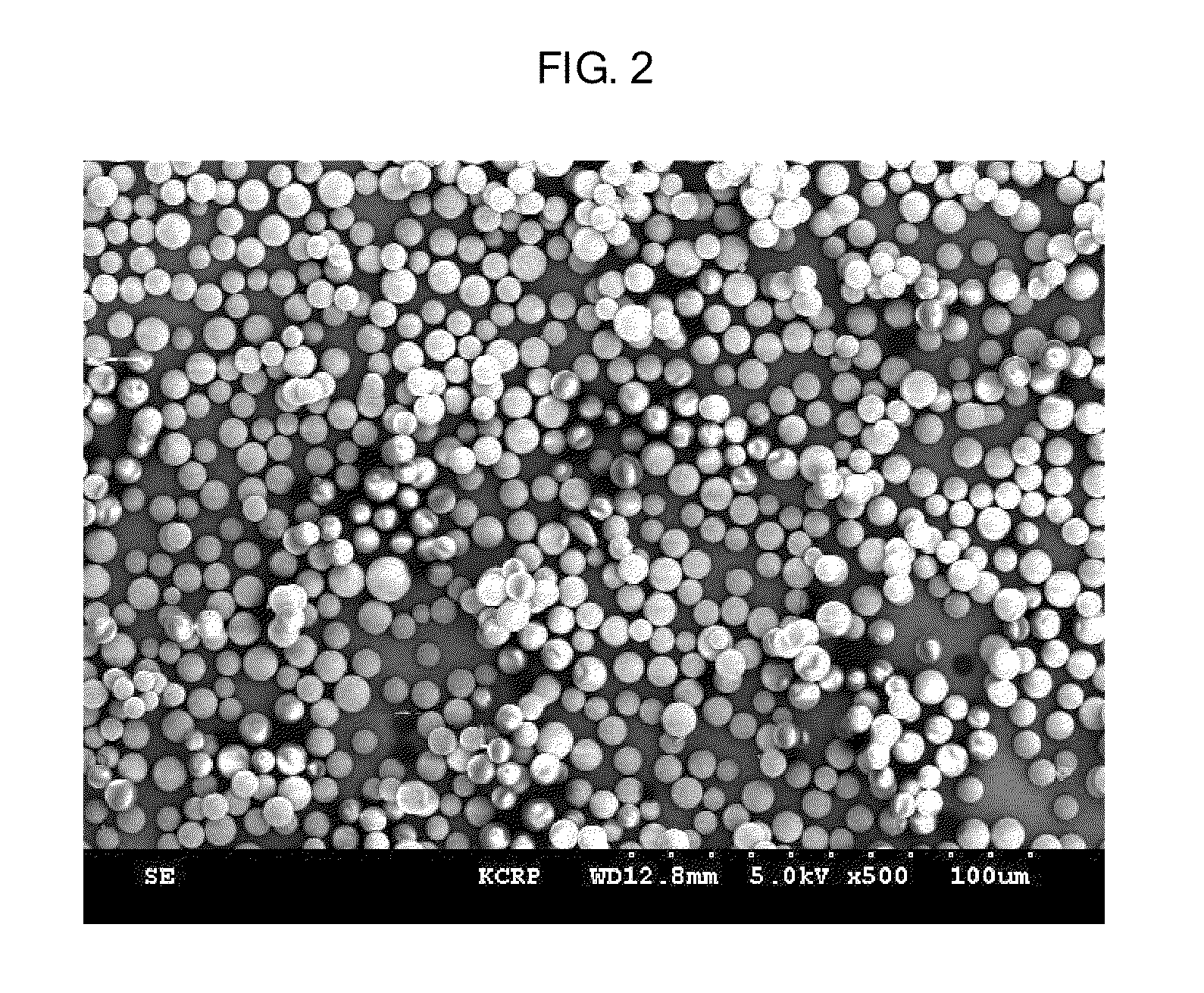

Process For Preparing Polyurethane Particulate and Polyurethane Particulate Prepared Therefrom

ActiveUS20100062254A1Easy to cleanUniform and regular size distributionSynthetic resin layered productsCellulosic plastic layered productsParticulatesPolymer science

Disclosed is a process for preparing polyurethane particulate and polyurethane particulate prepared therefrom. The polyurethane particulate has properties such that it is easy to control to a spherical form, the polyurethane particulate can be prepared in a desired particle size, the color thereof is stably exhibited, a washing process thereof is easy because almost no foam is generated in the washing process, and the preparation cost can be lowered because the particles do not lump and a separate grinding process is not needed, by using an inorganic suspension stabilizer in the manufacture process of the polyurethane particulate.

Owner:KOLON IND INC

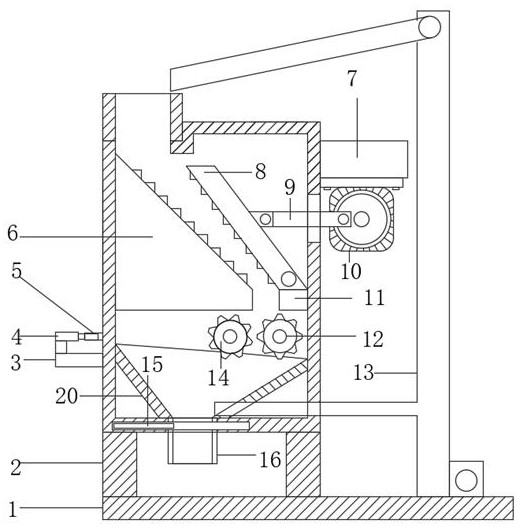

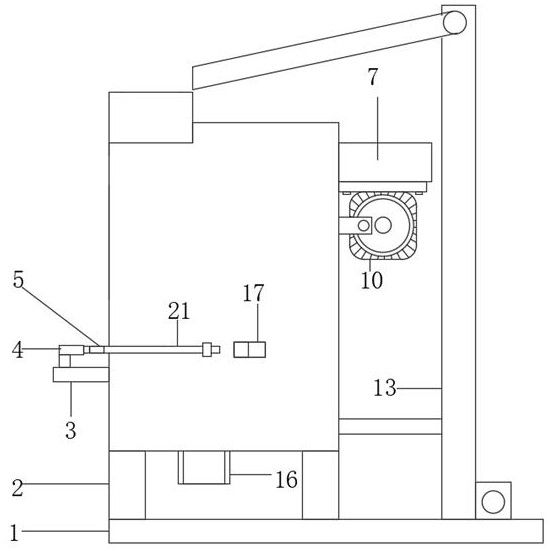

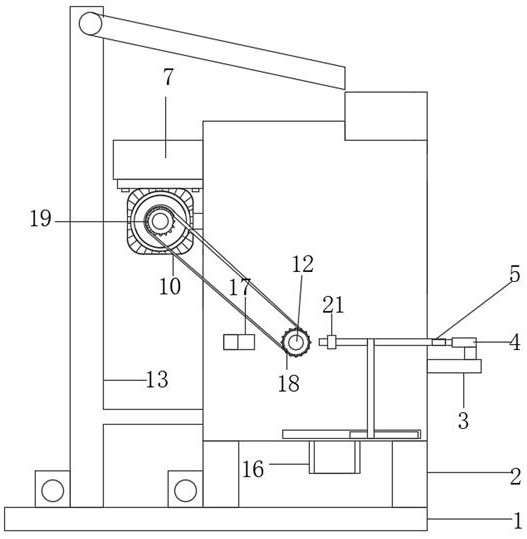

Stone crusher with cyclic stone crushing function

The invention discloses a stone crusher with a cyclic stone crushing function, relates to the technical field of stone crushing, and aims at solving the problems that a common crushing device cannot perform automatic cyclic crushing and cannot adjust the crushing degree. According to the scheme, the stone crusher comprises a base plate, wherein a box body is fixedly connected to the top of the base plate; two rotating shafts are arranged in the box body; the rotating shaft at the left side is rotationally connected to the inner wall of the box body; the back face of the rotating shaft at the left side movably penetrates through the box body; a first gear is fixedly arranged outside the back face of the rotating shaft at the left side in a sleeved mode; crushing wheels are fixedly arrangedoutside the rotating shafts in a sleeved mode; a first crushing plate is fixedly connected to the inner wall of the left side of the box body; and a fixed block is fixedly connected to the inner wallof the right side of the box body. The stone crusher is novel in design and easy to operate, cyclic stone crushing can be achieved, the stone crushing degree can be controlled, meanwhile, multiple functions are achieved through one motor, and the mechanical structure is simplified.

Owner:湘乡市旺达输送设备制造有限公司

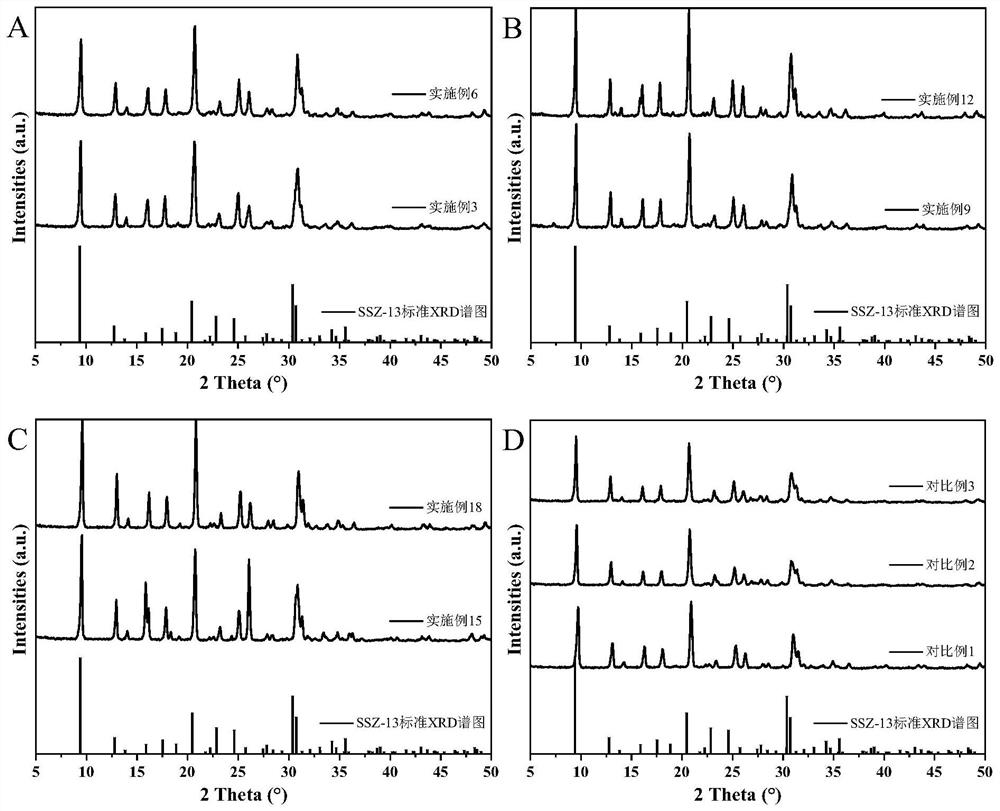

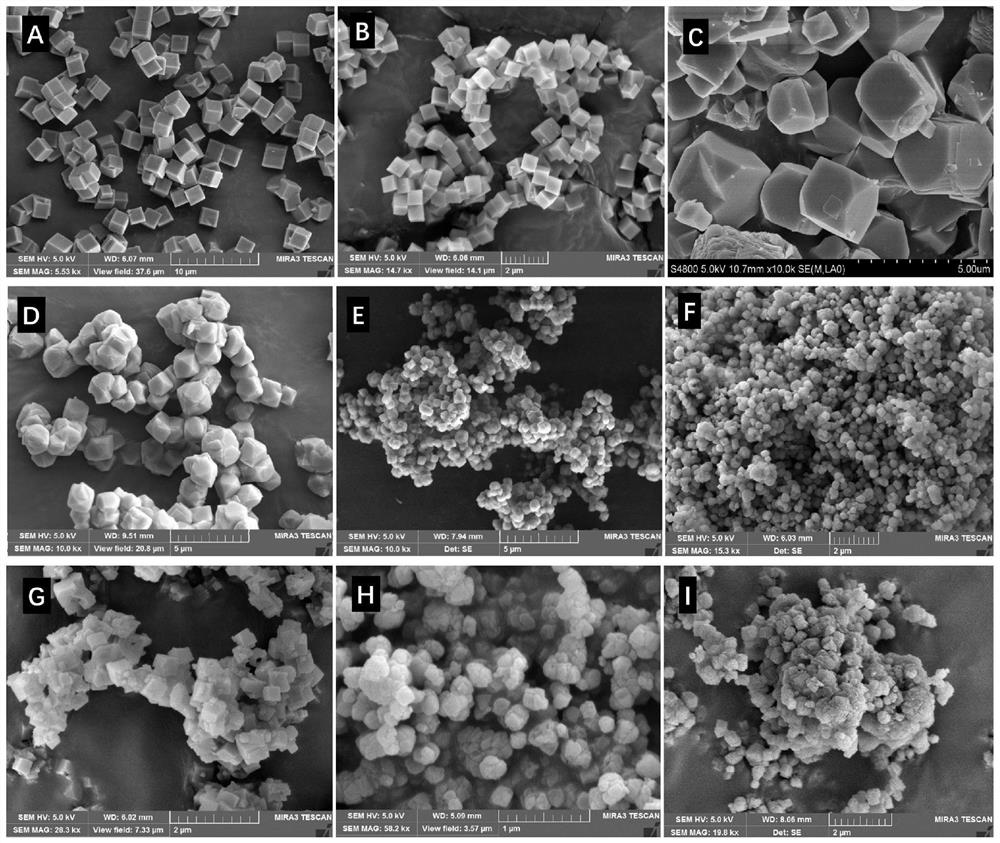

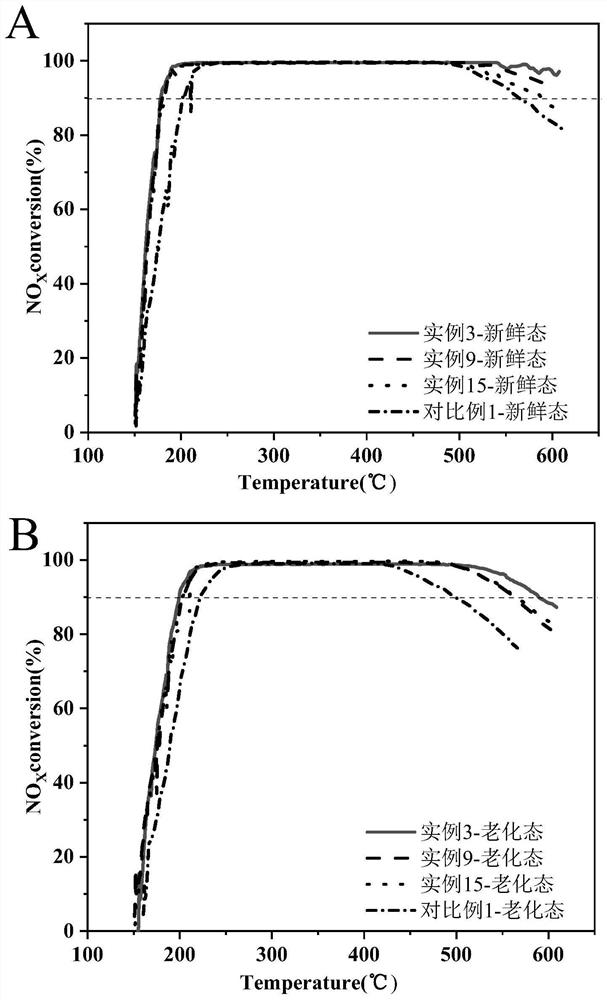

SSZ-13 molecular sieve, method for regulating crystal morphology of SSZ-13 molecular sieve and application of SSZ-13 molecular sieve

ActiveCN114538467AEffective control of crystal morphologyEffective size controlMolecular sieve catalystsInternal combustion piston enginesMolecular sieveCrystal morphology

The invention belongs to the technical field of molecular sieve preparation, and relates to an SSZ-13 molecular sieve, a method for regulating and controlling the crystal morphology of the SSZ-13 molecular sieve and application of the SSZ-13 molecular In order to solve the technical problems that the SSZ-13 molecular sieve is large in particle size and uneven in particle size distribution due to the fact that the SSZ-13 molecular sieve morphology control technology is difficult to control in the prior art, the method for controlling the SSZ-13 molecular sieve crystal morphology is provided, a silicon source, an aluminum source, alkali and a structure-directing agent are added into pure water to be mixed evenly, then a crystal morphology control agent is added for further treatment, and the SSZ-13 molecular sieve crystal morphology is obtained. According to the method, the crystal morphology and size of the SSZ-13 molecular sieve can be effectively controlled, the SSZ-13 molecular sieve of a cubic, polyhedral or spherical crystal can be prepared, the grain size of the crystal is small and can be adjusted within a certain range, and the grain size distribution is uniform. When being used as an SCR (selective catalytic reduction) denitration catalyst to be applied to the field of automobile exhaust treatment, the catalyst shows high denitration catalytic performance, high hydrothermal aging stability and wider effective working temperature range.

Owner:安徽纳蓝环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com