SSZ-13 molecular sieve, method for regulating crystal morphology of SSZ-13 molecular sieve and application of SSZ-13 molecular sieve

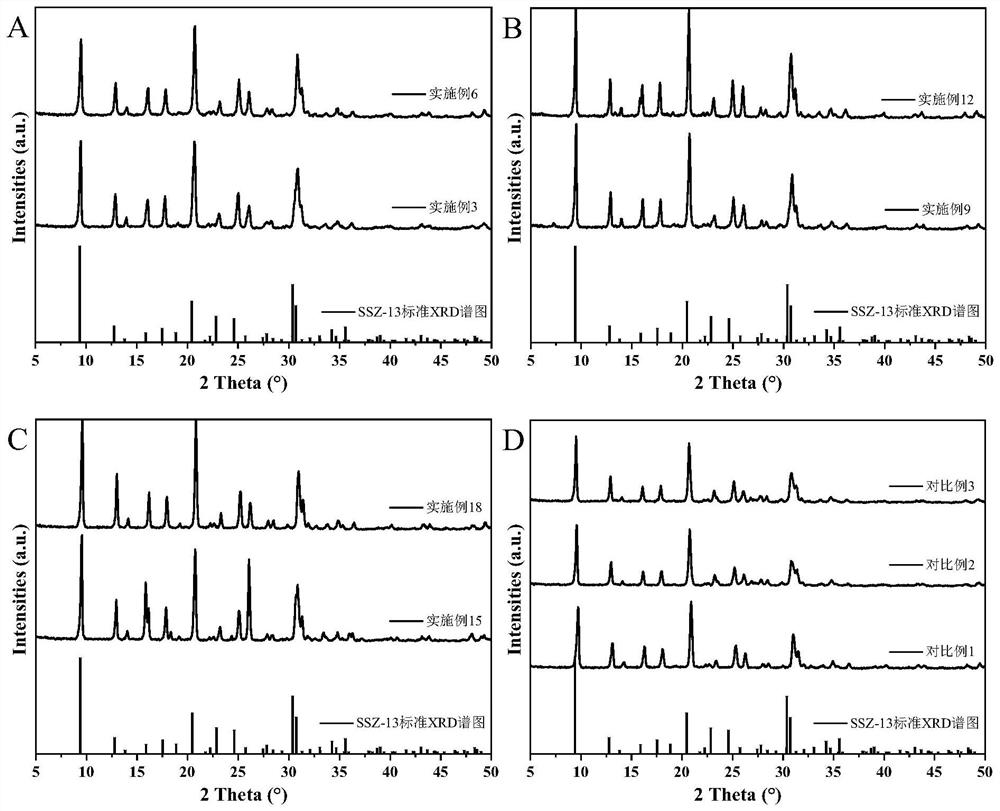

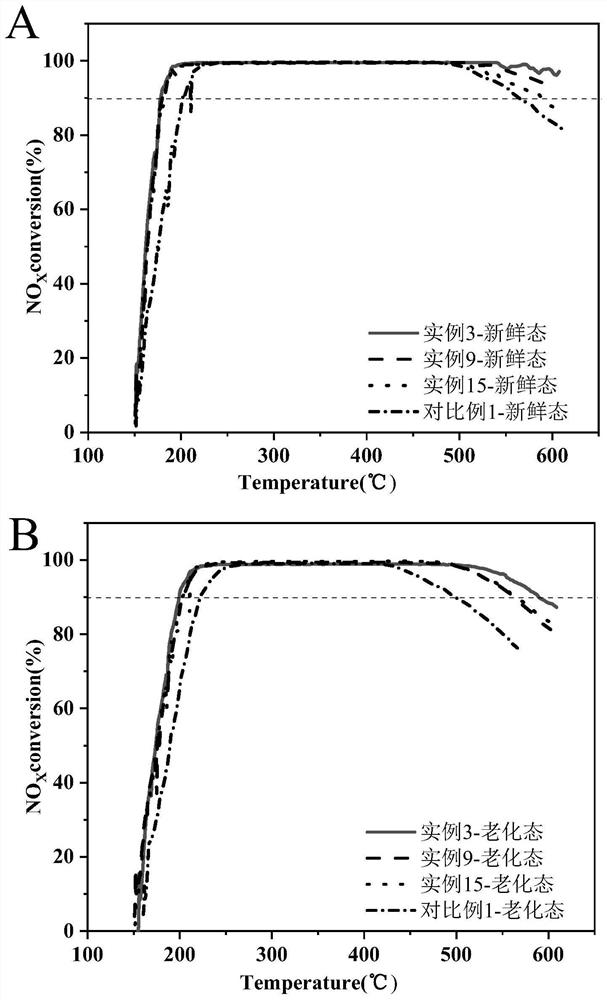

A molecular sieve and crystal technology, which is applied in the field of molecular sieve preparation, can solve the problems of uneven particle size distribution and large particle size of SSZ-13 molecular sieve, and achieve uniform particle size distribution, excellent catalytic activity, hydrothermal aging resistance and stability, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for regulating the crystal morphology of SSZ-13 molecular sieve according to this embodiment includes the following steps: adding silica sol, aluminum sulfate, flake caustic soda, and tetraethylammonium hydroxide in sequence to pure water to mix well, and then adding lauric acid to mix The reaction mother liquid was obtained uniformly; the reaction mother liquid was transferred to the hydrothermal reaction kettle, stirred and heated to 110 °C at a speed of 80 r / min, kept stirring for 2.5 h, then continued to stir and heated to 160 °C, kept stirring for 96 h, filtered, washed with water, and dried. , roasting at 550°C for 8h to obtain SSZ-13 molecular sieve, wherein the molar ratio of aluminum sulfate, silica sol, tetraethylammonium hydroxide, flake alkali, lauric acid and pure water is 1:10:0.2:10:0.02:600 .

Embodiment 2

[0041]A method for regulating the crystal morphology of SSZ-13 molecular sieve, comprising the following steps: adding silica sol, aluminum sulfate, flake alkali and tetraethylammonium hydroxide in sequence to pure water and mixing, and then adding lauric acid and mixing to obtain a reaction mother liquor ; Transfer the reaction mother liquid to the hydrothermal reaction kettle, stir and heat up to 110°C at a speed of 80r / min, keep stirring for 2.5h, then continue to stir and heat up to 160°C, keep stirring for 96h, filter, wash with water, dry at 550°C The SSZ-13 molecular sieve is obtained by roasting for 8h, wherein the molar ratio of aluminum sulfate, silica sol, tetraethylammonium hydroxide, flake alkali, lauric acid and pure water is 1:30:0.5:20:0.5:1000.

Embodiment 3

[0043] A method for regulating the crystal morphology of SSZ-13 molecular sieve, comprising the following steps: adding silica sol, aluminum sulfate, flake alkali and tetraethylammonium hydroxide in sequence to pure water and mixing, and then adding lauric acid and mixing to obtain a reaction mother liquor ; Transfer the reaction mother liquid to the hydrothermal reaction kettle, stir and heat up to 110°C at a speed of 80r / min, keep stirring for 2.5h, then continue to stir and heat up to 160°C, keep stirring for 96h, filter, wash with water, dry at 550°C After roasting for 8 hours, SSZ-13 molecular sieve was obtained, wherein the molar ratio of aluminum sulfate, silica sol, tetraethylammonium hydroxide, flake alkali, lauric acid and pure water was 1:15:0.3:10:0.05:800.

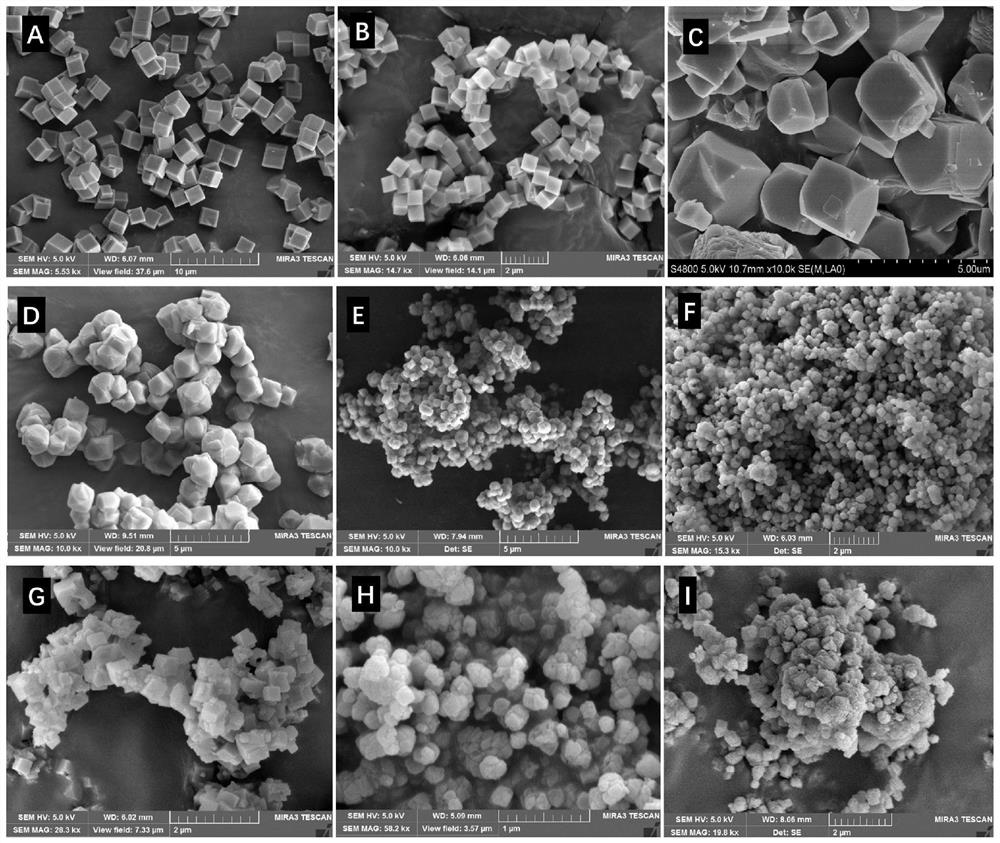

[0044] Take the SSZ-13 molecular sieve obtained above and carry out scanning electron microscope detection, and the results are shown in figure 2 A.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com