Method for preparing base oil of lubricating oil by dewaxing

A technology for lubricating base oil and dewaxing, which is used in lubricating compositions, base materials, petroleum industry, etc., can solve problems such as unreported applications of direct cooling crystallization dewaxing, and improve processing capacity, technology and production equipment. Simple, low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

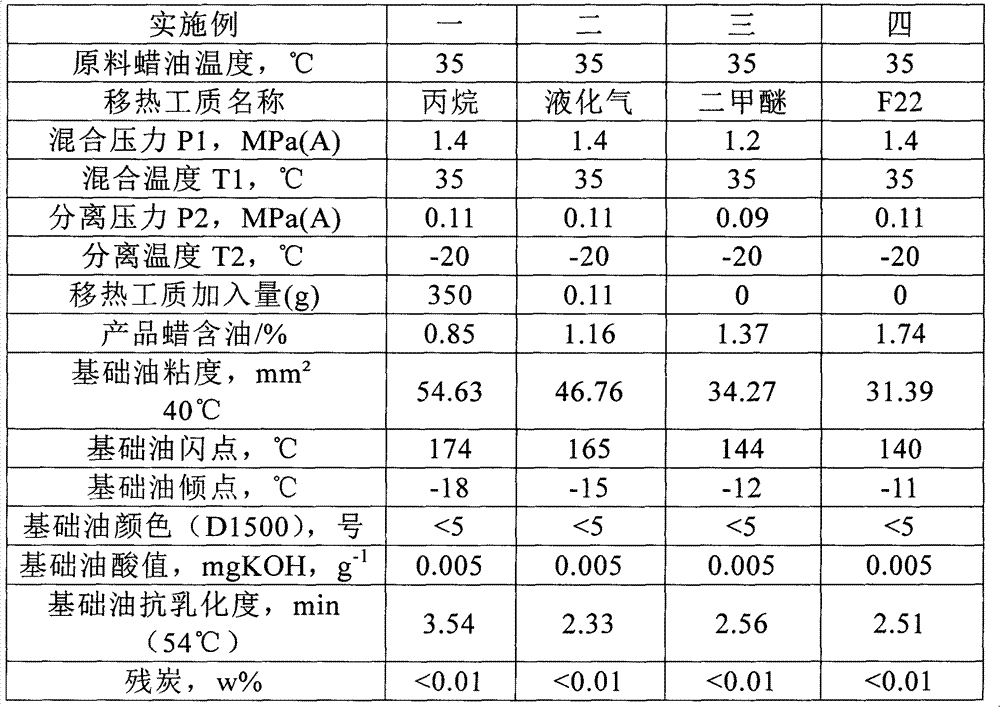

Embodiment 1

[0024] Heat the second-line wax oil to 35°C, and mix the heated wax oil with the liquid heat transfer medium of mass M (working condition P 1 , T 1 ) after fully mixing evenly, depressurize to P by throttling 2 , to vaporize the heat-removing working medium, and the system cools down to T under adiabatic conditions 2 , after the wax crystals are precipitated, they are sent to the filtration and separation system for filtration and separation to obtain lubricating oil base oil and wax products, see Table 2 for details. The gaseous heat transfer medium is pressurized to P 1 Condensate into a liquid state and cool down to T 1 spare.

Embodiment 2

[0026] According to the method of Example 1, the operating conditions were changed, and the properties of the obtained lubricating oil base oil and wax product were shown in Example 2 in Table 2 for details.

Embodiment 3

[0028] According to the method of Example 1, the operating conditions were changed, and the properties of the lubricating oil base oil and wax product obtained were shown in Example 3 in Table 2 for details.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com