High-precision micro-nano size two-dimensional material electrode preparation method

A two-dimensional material, high-precision technology, applied in circuits, electrical components, electrical digital data processing, etc., can solve the problems of difficult electrodes, low precision, irregular shapes, etc., to achieve accurate positioning, high precision, and wide application range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

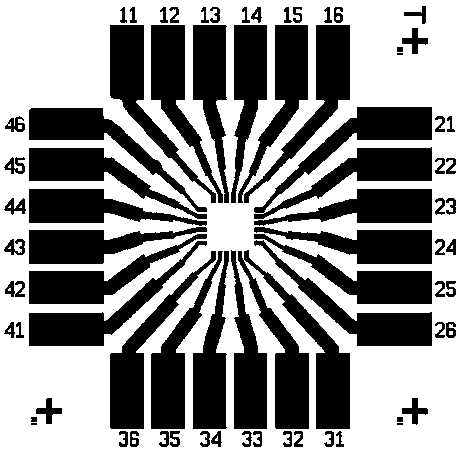

[0022] 1) Save the photolithographic layout of the preset electrodes into the computer;

[0023] 2) Molybdenum disulfide was prepared by mechanical exfoliation and then transferred to a silicon substrate with preset electrodes by adhesive tape;

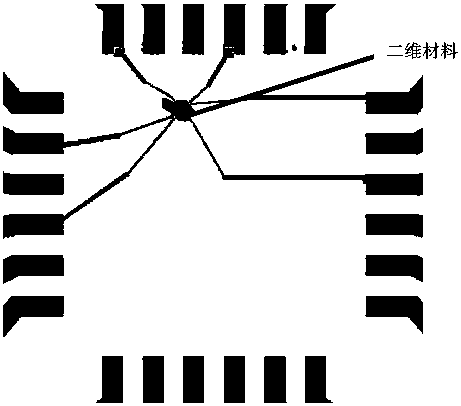

[0024] 3) Place the silicon substrate in step 2) under an optical microscope, measure the length of the molybdenum disulfide to be 15.2 microns, and the width to be 7.5 microns, and take pictures of the molybdenum disulfide and surrounding electrodes;

[0025] 4) Open the picture taken in step 3) in the image processing software, select the molybdenum disulfide and the electrode, paint red, and paint the rest white, and save it; image processing uses photoshop software;

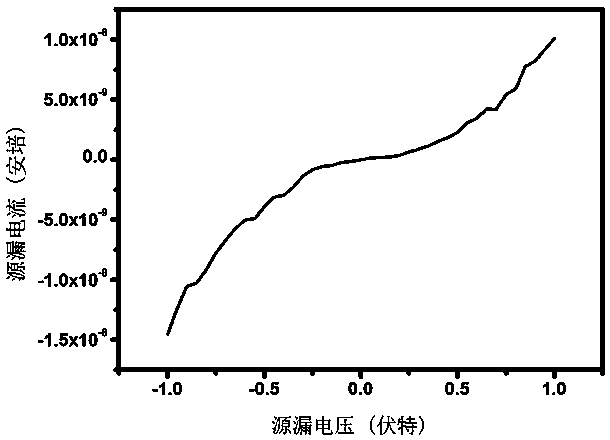

[0026] 5) Open the picture saved in step 4) in the layout software, adjust the unit under the layout software, rotate the figure, and move the position of the figure, so that the electrode pattern in the picture overlaps with the electrode in the lithography layout o...

Embodiment 2

[0031] 1) Save the photolithographic layout of the preset electrodes into the computer;

[0032] 2) Prepare tantalum disulfide by mechanical exfoliation method and then transfer it to silicon substrate with preset electrodes through adhesive tape;

[0033] 3) Place the silicon substrate in step 2) under an optical microscope, measure the length of the tantalum disulfide to be 30.1 microns, and the width to be 5.2 microns, and take pictures of the tantalum disulfide and surrounding electrodes;

[0034] 4) Open the picture taken in step 3) in the image processing software, select the tantalum disulfide and the electrode, paint red, and paint the rest white, and save it; image processing uses photoshop software;

[0035] 5) Open the picture saved in step 4) in the layout software, adjust the unit under the layout software, rotate the figure, and move the position of the figure, so that the electrode pattern in the picture overlaps with the electrode in the lithography layout of t...

Embodiment 3

[0040] 1) Save the photolithographic layout of the preset electrodes into the computer;

[0041] 2) Prepare tungsten diselenide by mechanical stripping method and then transfer it to the silicon substrate with preset electrodes through adhesive tape;

[0042] 3) Place the silicon substrate in step 2) under an optical microscope, measure the length of tungsten diselenide to be 23 microns, and the width to be 7 microns, and take pictures of tungsten diselenide and surrounding electrodes;

[0043] 4) Open the picture taken in step 3) in the image processing software, select tungsten diselenide and the electrode, paint red, and paint the rest in white, and save it; image processing uses photoshop software;

[0044] 5) Open the picture saved in step 4) in the layout software, adjust the unit under the layout software, rotate the figure, and move the position of the figure, so that the electrode pattern in the picture overlaps with the electrode in the lithography layout of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com