Preparation method for metal organic framework-derived tricobalt tetroxide-modified titanium dioxide nanotube array

A metal-organic framework and nanotube array technology is applied in the field of photocatalytic degradation of pollutant materials, and achieves the effects of increasing reaction sites, simple and easy operation, and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

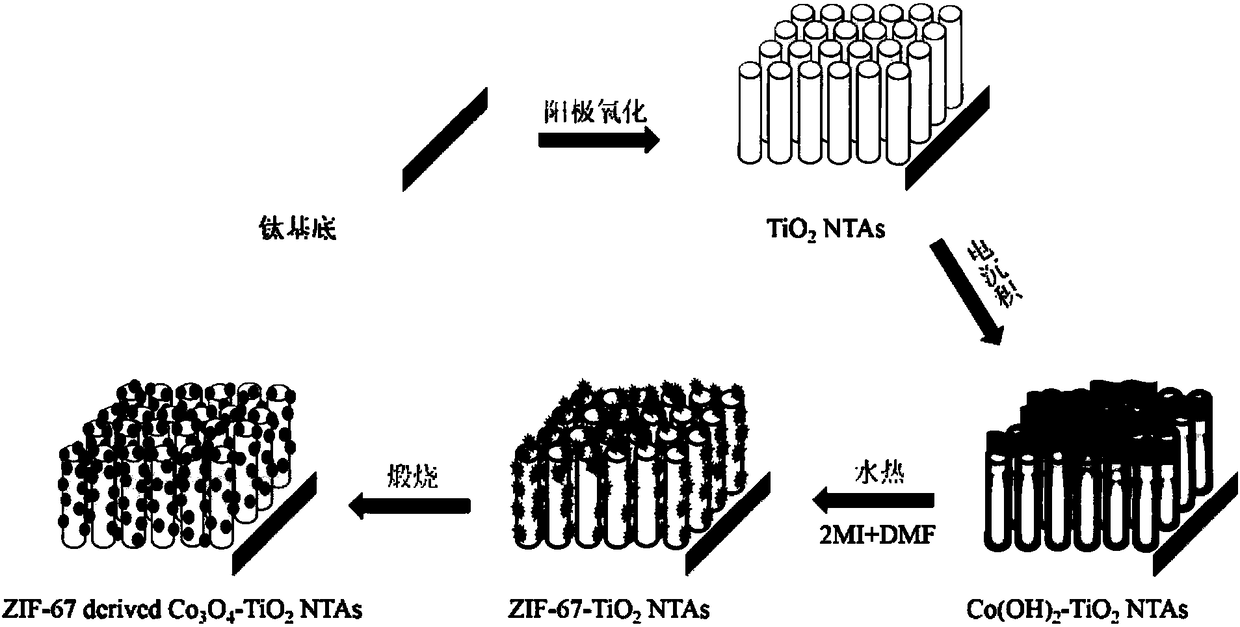

[0035] see figure 1 , figure 1 It is a schematic flow chart of the preparation method of the metal-organic framework-derived tricobalt tetroxide-modified titanium dioxide nanotube array of the present invention. Such as figure 1 As shown, the present invention provides a method for preparing a metal-organic framework-derived tricobalt tetroxide-modified titanium dioxide nanotube array, comprising the following steps:

[0036] Pretreatment of titanium sheet;

[0037] Preparation of TiO by Anodic Oxidation 2 NTAs;

[0038] TiO 2 NTAs as the working electrode, platinum sheet as the counter electrode, silver / silver chloride as the reference electrode, and cobalt nitrate hexahydrate solution as the electrolyte, using a three-electrode electrochemical workstation to prepare Co(OH) 2 -TiO 2 NTAs;

[0039] Co(OH) 2 -TiO 2 NTAs were put into the reactor, and the dimethylimidazole solution with N,N-dimethylformamide as solvent was poured into the reactor for hydrothermal r...

Embodiment 1

[0060] This implementation case shows a method for preparing a metal-organic framework-derived cobalt tetroxide-modified titanium dioxide nanotube array according to the following steps:

[0061] (1) Pretreatment of the titanium sheet: Ultrasonic cleaning of the pure titanium sheet substrate with acetone, absolute ethanol and water for 20 min respectively. Using a platinum sheet electrode as a cathode, insert it into an electrolyte solution containing 98v% ethylene glycol and 2v% water (ammonium fluoride 0.5wt%) at the same time, and apply a voltage of 50V for anodic oxidation for 2h to obtain TiO 2 NTAs were calcined at 450°C for 2h in air to transform from amorphous state to anatase crystal form.

[0062] (2) Preparation of Co(OH) by electrodeposition 2 -TiO 2 NTAs. Prepare an aqueous solution of 0.005 wt% cobalt nitrate hexahydrate, the solution is uniformly dispersed and used as an electrolyte, and the TiO 2 NTAs were used as the working electrode, platinum as the c...

Embodiment 2

[0065] This implementation case shows a method for preparing a metal-organic framework-derived cobalt tetroxide-modified titanium dioxide nanotube array according to the following steps:

[0066] (1) Pretreatment of the titanium sheet: Ultrasonic cleaning of the pure titanium sheet substrate with acetone, absolute ethanol and water for 20 min respectively. Using a platinum sheet electrode as a cathode, insert it into an electrolyte solution containing 98v% ethylene glycol and 2v% water (ammonium fluoride 0.5wt%) at the same time, and apply a voltage of 50V for anodic oxidation for 2h to obtain TiO 2 NTAs were calcined at 450°C for 2h in air to transform from amorphous state to anatase crystal form.

[0067] (2) Preparation of Co(OH) by electrodeposition 2 -TiO 2 NTAs. Prepare an aqueous solution of 0.005 wt% cobalt nitrate hexahydrate, the solution is uniformly dispersed and used as an electrolyte, and the TiO 2 NTAs were used as the working electrode, platinum sheets w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com