Smelting method for modifying sulfide inclusions in non-quenched and tempered steel or pinion steel

A technology of non-quenched and tempered steel and smelting method, applied in the field of iron and steel metallurgy, can solve the problem that the improvement of the free cutting performance and fatigue resistance of non-quenched and tempered steel and gear steel is not ideal, the effect of calcium modification process is not ideal, and the sulfide Problems such as low ellipsoid rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In this embodiment, a smelting method for sulfide inclusion modification in gear steel includes the following steps for sulfide inclusion modification treatment in 20MnCr5 gear steel:

[0037] a. The molten iron is initially smelted in an electric furnace, then LF refined and vacuum treated, so that the C, Si, Mn, P and Cr alloy elements in the molten steel meet the composition requirements of 20MnCr gear steel, and the molten steel is obtained for preliminary refining treatment;

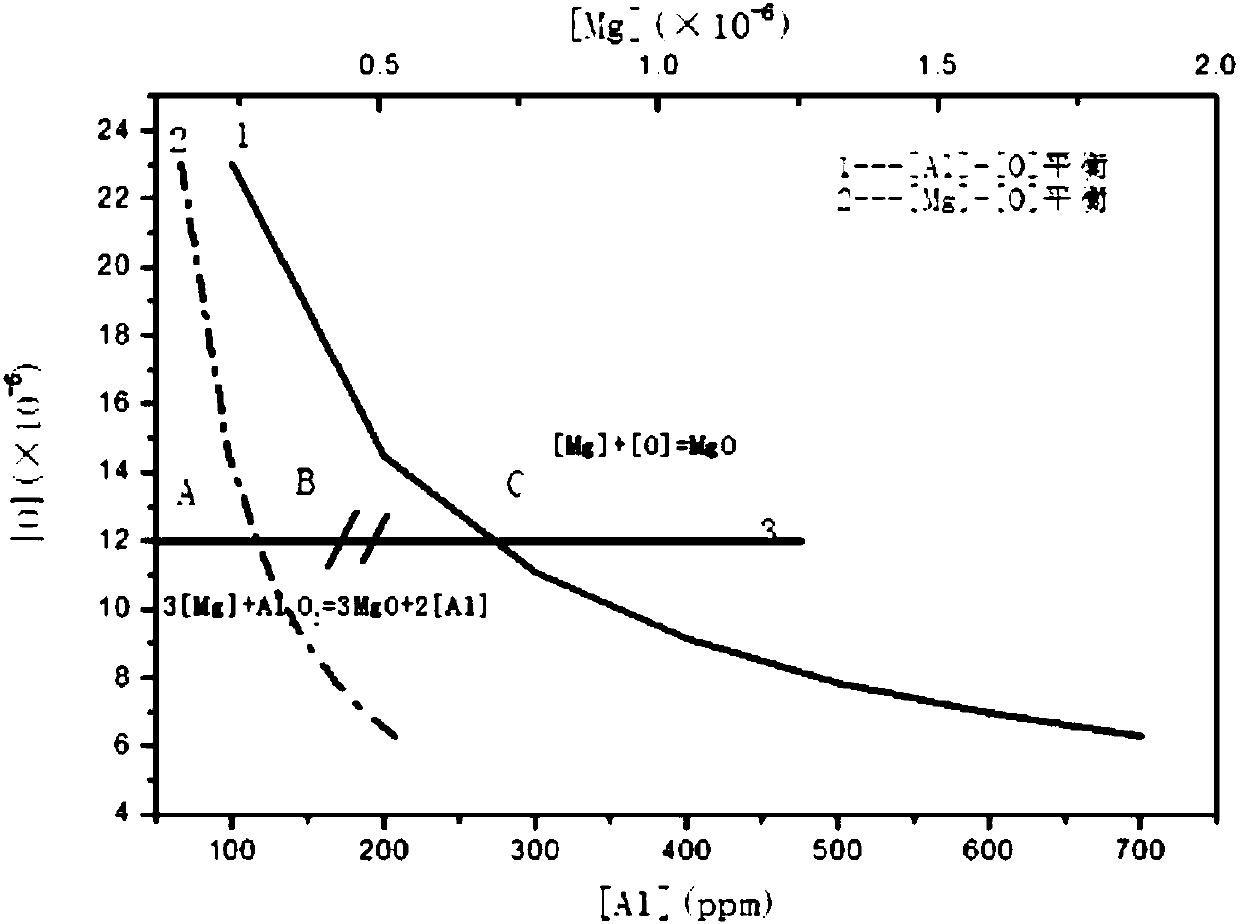

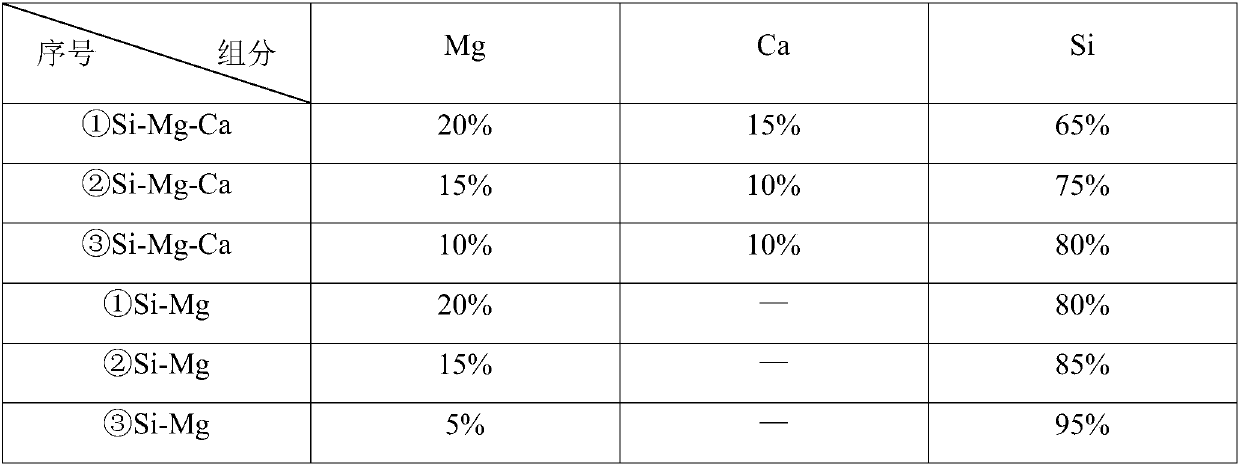

[0038] b. control the mass percentage content of sulfur in the molten steel prepared in said step a to be no higher than 0.005%, the oxygen content to be no higher than 6ppm, and the mass percentage content of aluminum to be no higher than 0.012%, and to control the molten steel temperature At 1566 ~ 1596 ℃, then start to feed the cored wire into the molten steel to refine and modify the molten steel; during the refining and modifying process, feed silicon magnesium calcium (Mg: 20% , Ca: 15%...

Embodiment 2

[0043] This embodiment is basically the same as Embodiment 1, especially in that:

[0044] In this embodiment, a smelting method for modifying sulfide inclusions in non-quenched and tempered steel includes the following steps:

[0045] a. The molten iron is first smelted in a converter, then LF refined and vacuum treated, so that the C, Si, Mn, P and Cr, Ni, V, N alloy elements in the molten steel meet the composition requirements of 45MnVS non-quenched and tempered steel, and get a preliminary Refining molten steel;

[0046] b. control the mass percentage content of sulfur in the molten steel prepared in said step a to be no higher than 0.005%, the oxygen content to be no higher than 6ppm, and the mass percentage content of aluminum to be no higher than 0.012%, and to control the molten steel temperature At 1566 ~ 1596 ℃, then start to feed the cored wire into the molten steel, and carry out refining and modification treatment on the molten steel; during the refining and mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com