Organic hydrophobic modified cobalt-based fischer-tropsch synthesis catalyst, preparation thereof and application thereof

A hydrophobic modification and catalyst technology, which is applied in the direction of molecular sieve catalysts, preparation of liquid hydrocarbon mixtures, physical/chemical process catalysts, etc., can solve problems such as complex preparation processes, and achieve simple preparation methods, good selectivity, and low selectivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

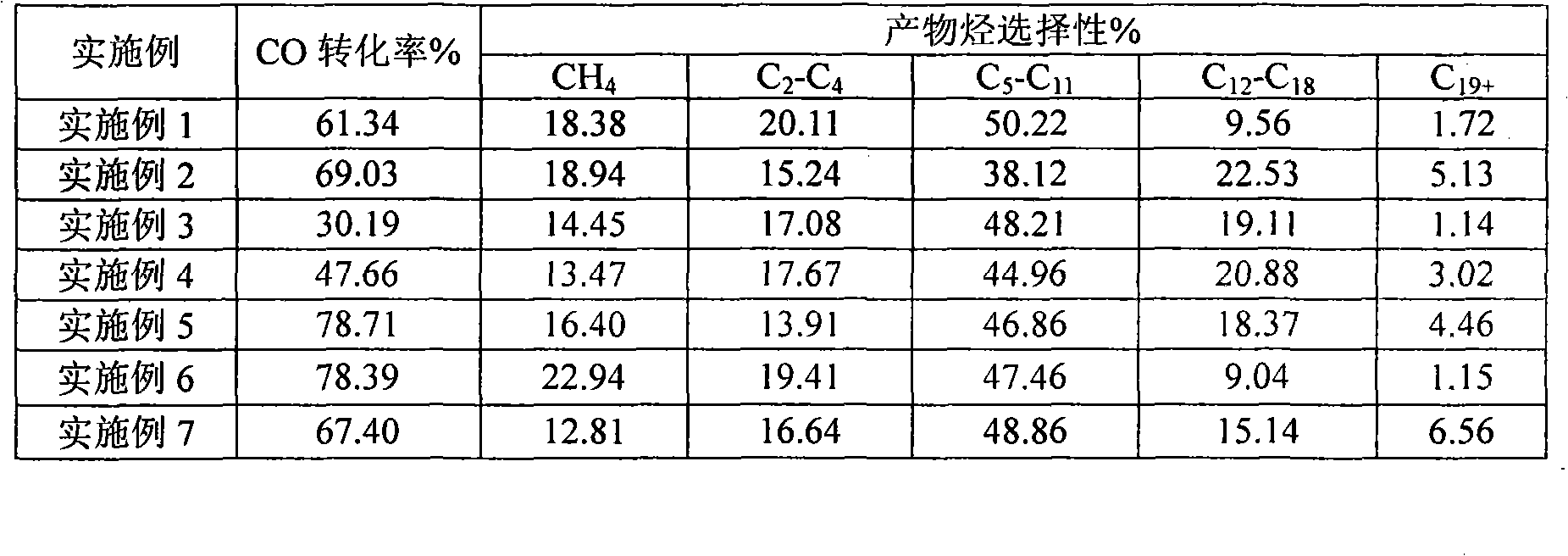

Examples

Embodiment 1

[0028] Catalyst preparation: Weigh 10.0 g of vacuum-dried mesoporous titanium dioxide (average pore size is 23.0 nm) and evenly spread it on a piece of filter paper, then place the filter paper on a self-made small shelf and move it into the container, then add 24mmol of hexamethyldisilazane, the container was sealed and moved into an oven, and the temperature was raised to 50°C for a constant temperature reaction. After 24h of reaction, the sample was taken out, and vacuum-dried at 60°C for 24h to obtain a hydrophobic modified carrier. Then weigh 13.7g Co(NO 3 ) 2 ·6H 2 O was dissolved in 45ml of propanol solution, impregnated with 10.0g of the above-mentioned hydrophobically modified carrier, left to stand for 12h, and then dried in an oven at 90°C for 24h, after the dried solid was fully ground, roasted in a muffle furnace at 350°C for 8h to obtain Cobalt samples are loaded. Then weigh 10.0g of the above-mentioned loaded cobalt sample and carry out a secondary modificati...

Embodiment 2

[0031] Catalyst preparation: Weigh 10.0g of vacuum-dried SBA-15 molecular sieve carrier (average pore size is 6.0nm) and evenly spread it on a piece of filter paper, then place the filter paper on a self-made small shelf and move it into the container, then put it in the container Add 20 mmol of vinyltriethoxysilane, seal the container and move it into an oven, raise the temperature to 80°C for a constant temperature reaction, take out the sample after 48 hours of reaction, and vacuum dry at 55°C for 48 hours to obtain a hydrophobic modified carrier. Then weigh 5.7g Co(NO 3 ) 2 ·6H 2 O was dissolved in 50ml of methanol solution, impregnated with 10.0g of the above-mentioned hydrophobically modified carrier, stood still for 24h, and then dried in an oven at 120°C for 12h, after the dried solid was fully ground, baked in a muffle furnace at 400°C for 6h to obtain the support Cobalt samples. Then weigh 10.0g of the above-mentioned loaded cobalt sample and carry out a secondary...

Embodiment 3

[0034] Catalyst preparation: Weigh 10.0g vacuum-dried commercial carbon nanotubes (average pore size is 15.0nm) and spread evenly on a piece of filter paper, then place the filter paper on a self-made small shelf and move it into the container, and then put it in the container Add 15 mmol of trimethylchlorosilane, seal the container and move it into an oven, raise the temperature to 80°C for a constant temperature reaction, take out the sample after 48 hours of reaction, and vacuum dry at 50°C for 36 hours to obtain a hydrophobic modified carrier. Then weigh 25.3g Co(NO 3 ) 2 ·6H 2 O was dissolved in 40ml of propanol solution, impregnated with 10.0g of the above-mentioned hydrophobically modified carrier, left to stand for 24h, then dried in an oven at 100°C for 12h, after the dried solid was fully ground, roasted in a muffle furnace at 500°C for 8h to obtain Cobalt samples are loaded. Then weigh 10.0g of the above-mentioned loaded cobalt sample and carry out a secondary mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com