Visible light catalytic material, and preparation method and application thereof

A catalytic material and visible light technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, polycrystalline material growth, etc., can solve the problems of limited catalytic performance, easy agglomeration, unfavorable dyes, etc., and achieve cheap and easy-to-get raw materials. The effect of large surface area and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

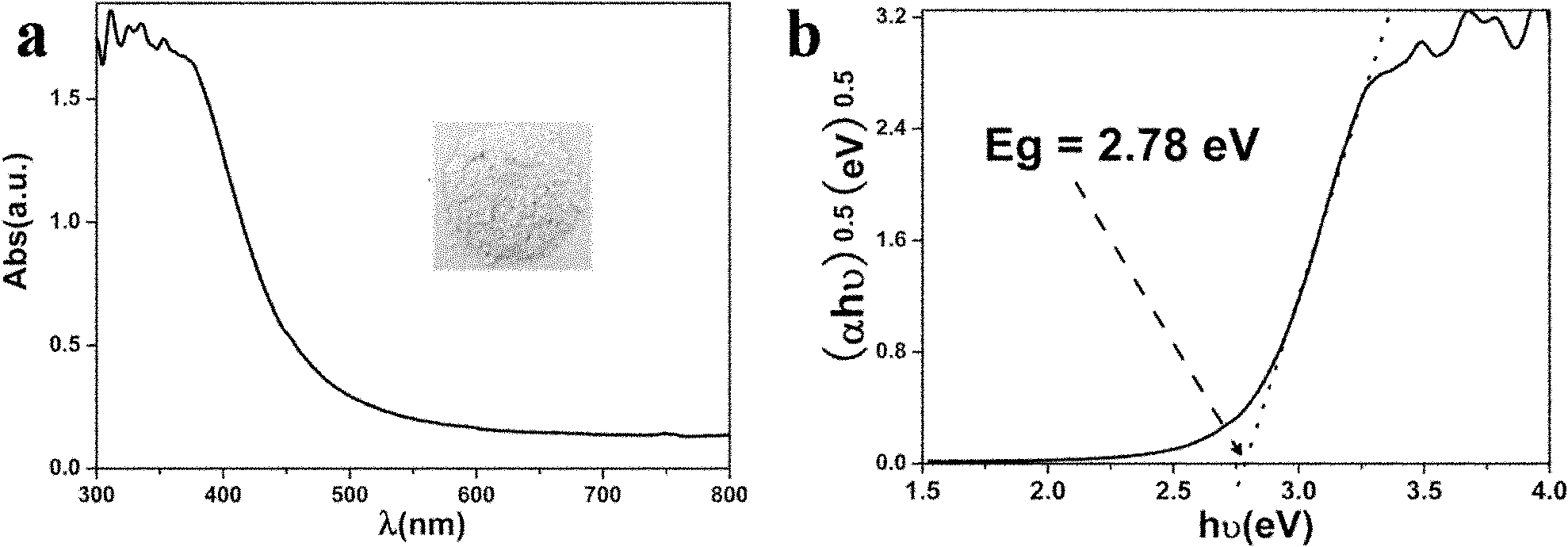

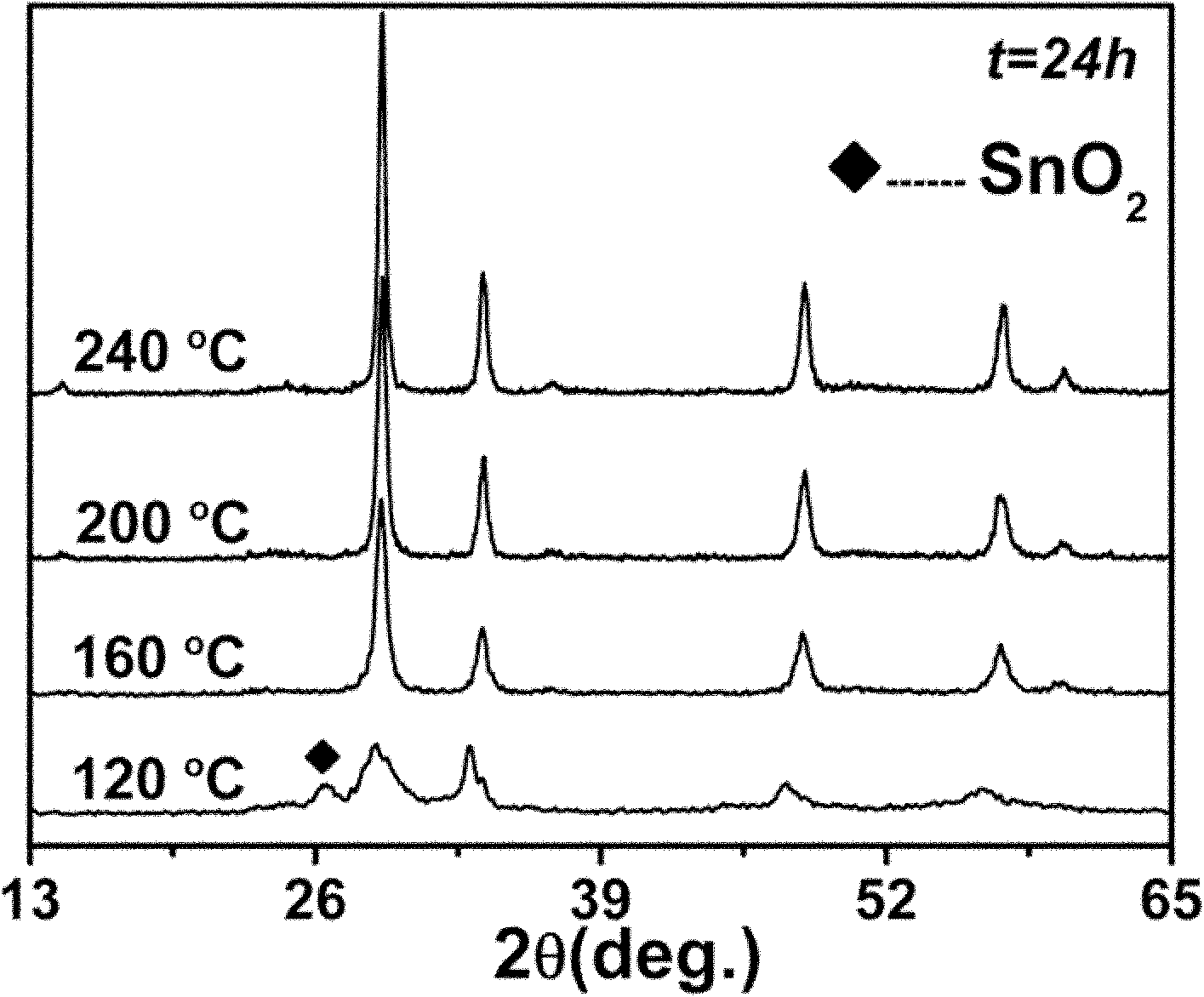

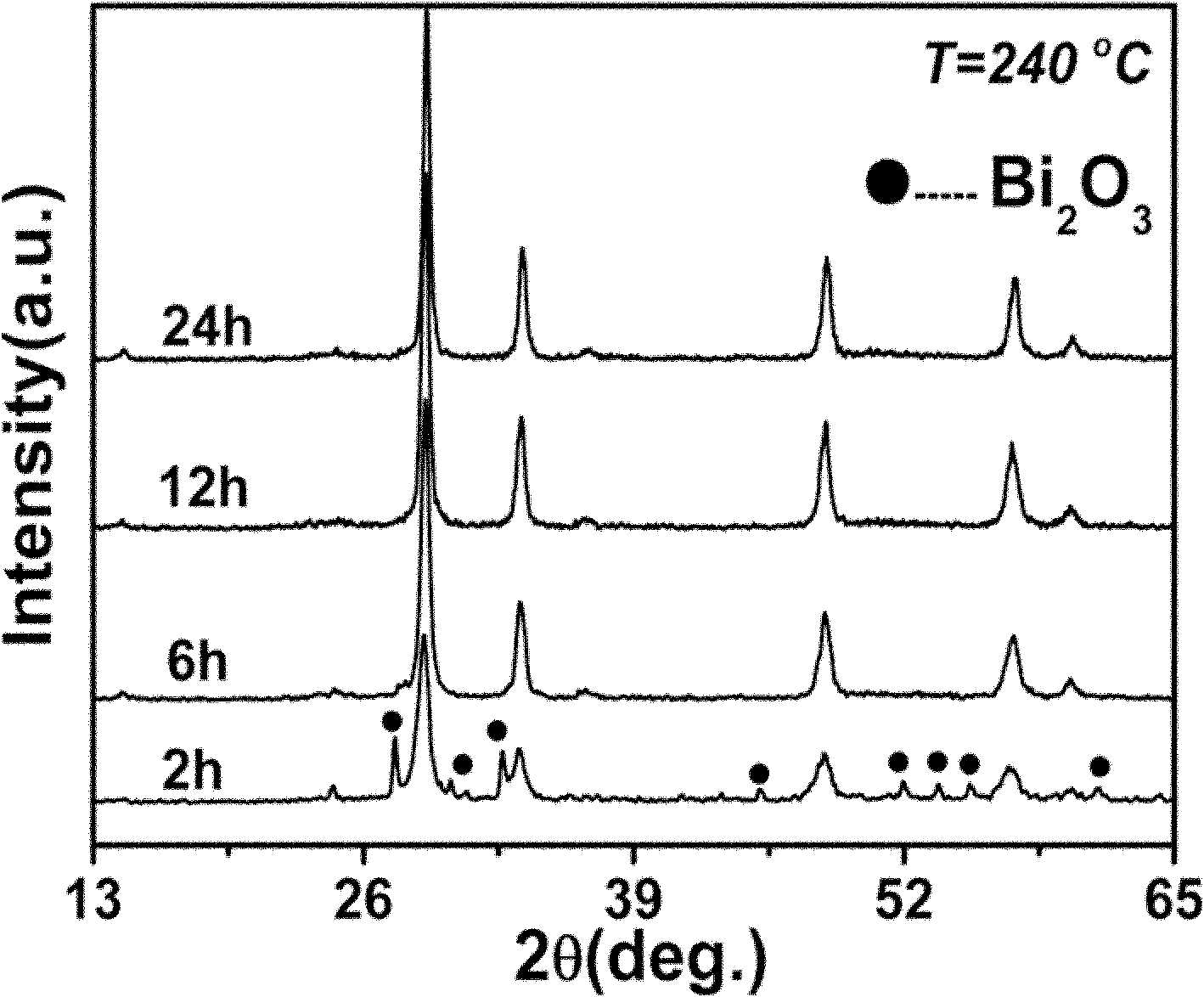

[0047] Take 0.9701g Bi(NO 3 ) 3 ·5H 2 O and 0.7012g SnCl 4 ·5H 2 O was added to a 1mol / L aqueous solution of 40mL NaOH, and the amorphous precursor solution was obtained after thorough stirring. The precursor solution was transferred into a hydrothermal reaction kettle, reacted at 240° C. for 24 hours, cooled to room temperature naturally, filtered and dried to collect the obtained pale yellow powder. UV-vis test shows that its absorption edge is around 446nm, the corresponding optical band gap is 2.78eV, and it has visible light response, such as figure 1 shown. According to the XRD test, the pure phase pyrochlore Bi 2 sn 2 o 7 ,Such as figure 2 and image 3 shown. Using VASP-GGA to calculate the energy band, the results show that the conduction band composition is Bi6p+Sn 5s+O2p, and the valence band composition is O2p+Bi 6s, which is an indirect transition material, such as Figure 4 and Figure 5 shown.

[0048] The Bi obtained in this example 2 sn 2 o 7 ...

Embodiment 2

[0051] Take 0.9701g Bi(NO 3 ) 3 ·5H 2 O and 0.7012g SnCl 4 ·5H 2 O was added to 40 mL of KOH in 10 M aqueous solution, and the amorphous precursor solution was obtained after thorough stirring. The precursor solution was transferred into a hydrothermal reaction kettle, reacted at 240° C. for 6 h, cooled to room temperature naturally, filtered and dried to collect the obtained pale yellow powder. UV-vis test shows that its absorption edge is around 452nm, the corresponding optical bandgap is 2.75eV, and it has visible light response. After XRD test, the pure phase pyrochlore Bi was also obtained 2 sn 2 o 7 ,Such as image 3 shown.

[0052] The Bi obtained in this example 2 sn 2 o 7 The particle size of nanoparticles is 5-10nm, and the specific surface area is 62.6m 2 / g.

[0053] Will get Bi 2 sn 2 o 7 Nanoparticles were used in the UV photodegradation experiment of methyl orange, and the results showed that its photocatalytic activity was significantly better ...

Embodiment 3

[0055] Take 0.9701g Bi(NO 3 ) 3 ·5H 2 O and 0.7012g SnCl 4 ·5H 2 O was added to 40 mL of ammonia solution, the pH value of the solution was adjusted to about 11, and the amorphous precursor solution was obtained after fully stirring. The precursor solution was transferred into a hydrothermal reaction kettle, reacted at 240° C. for 96 h, cooled down to room temperature naturally, filtered and dried to collect the obtained pale yellow powder. UV-vis test shows that its absorption edge is around 460nm, the corresponding optical bandgap is 2.70eV, and it has visible light response. After XRD test, the pure phase pyrochlore Bi was also obtained 2 sn 2 o 7 .

[0056]The Bi obtained in this example 2 sn 2 o 7 The particle size of nanoparticles is 5-10nm, and the specific surface area is 50.8m 2 / g.

[0057] Will get Bi 2 sn 2 o 7 Nanoparticles were used in the experiment of visible light degradation of acetaldehyde, after 5h of visible light irradiation, the produced ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com