Yttria-stabilized zirconia ceramic and preparation method thereof

A technology for stabilizing zirconia and yttria, applied in the field of ceramics, can solve the problems of reducing the light transmittance, strength and toughness of yttria-stabilized zirconia ceramics, and coarsening the grain size of ceramics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The invention provides a method for preparing yttria-stabilized zirconia ceramics, comprising the following steps:

[0042] (1) Provide nano-ceramic powders comprising zirconia, yttrium oxide and alumina;

[0043] (2) Pressing the nano-ceramic powder to obtain a ceramic green body;

[0044] (3) firing the ceramic body obtained in the step (2) to obtain yttria-stabilized zirconia ceramics;

[0045] The calcination temperature is 1350-1520°C.

[0046] The invention provides nano ceramic powder comprising zirconia, yttrium oxide and aluminum oxide. In the present invention, the particle size of the nano-ceramic powder is preferably 100 nm or less, more preferably 80 nm or less, and more preferably 20-75 nm.

[0047] In the present invention, the mass ratio of zirconia, yttrium oxide and alumina in the nano-ceramic powder is preferably (942-952): (45-58): (1-5), more preferably (948-950): (50-52): (2-4), more preferably 948:52:3.

[0048] In the present invention, the ...

Embodiment 1

[0079] Based on the total mass of zirconia and yttrium oxide as 1000 parts, accurately weigh 942 parts of zirconia, 58 parts of yttrium oxide, 1 part of aluminum oxide, 2 parts of polyammonium methacrylate as a dispersant, add distilled water, and adjust the solid content of the slurry to 55%, the material is milled for 2 hours by a stirring ball mill, the grinding body is a zirconia ball with a particle size of 5-6mm, and the milling speed is 160r / min;

[0080] The slurry after stirring ball milling is introduced into the sand mill, and the solid content of the slurry is adjusted to 35% by adding deionized water, and the grinding body is zirconia beads with a particle size of 0.6-0.8 mm as the grinding body, and sanded for 6 hours, Sanding speed is 2000r / min;

[0081] Spray and dry the sand-milled slurry, adjust the atomization frequency to 45Hz, the air inlet temperature to 240°C, and the air outlet temperature to 90°C to obtain nano-ceramic powders with a particle size belo...

Embodiment 2

[0085] Based on the total mass of zirconia and yttrium oxide as 1000 parts, accurately weigh 945 parts of zirconia, 55 parts of yttrium oxide, 2 parts of aluminum oxide, 4 parts of dispersant polyammonium methacrylate, add distilled water, and adjust the solid content of the slurry to 58%, the material is milled for 4 hours by a stirring ball mill, the grinding body is a zirconia ball with a particle size of 7-8mm, and the milling speed is 140r / min;

[0086] The slurry after stirring ball milling is introduced into the sand mill, and the solid content of the slurry is adjusted to 40% by adding deionized water. The grinding body is zirconia beads with a particle size of 0.5-0.6 mm as the grinding body, and sanded for 5 hours. Sanding speed is 2100r / min;

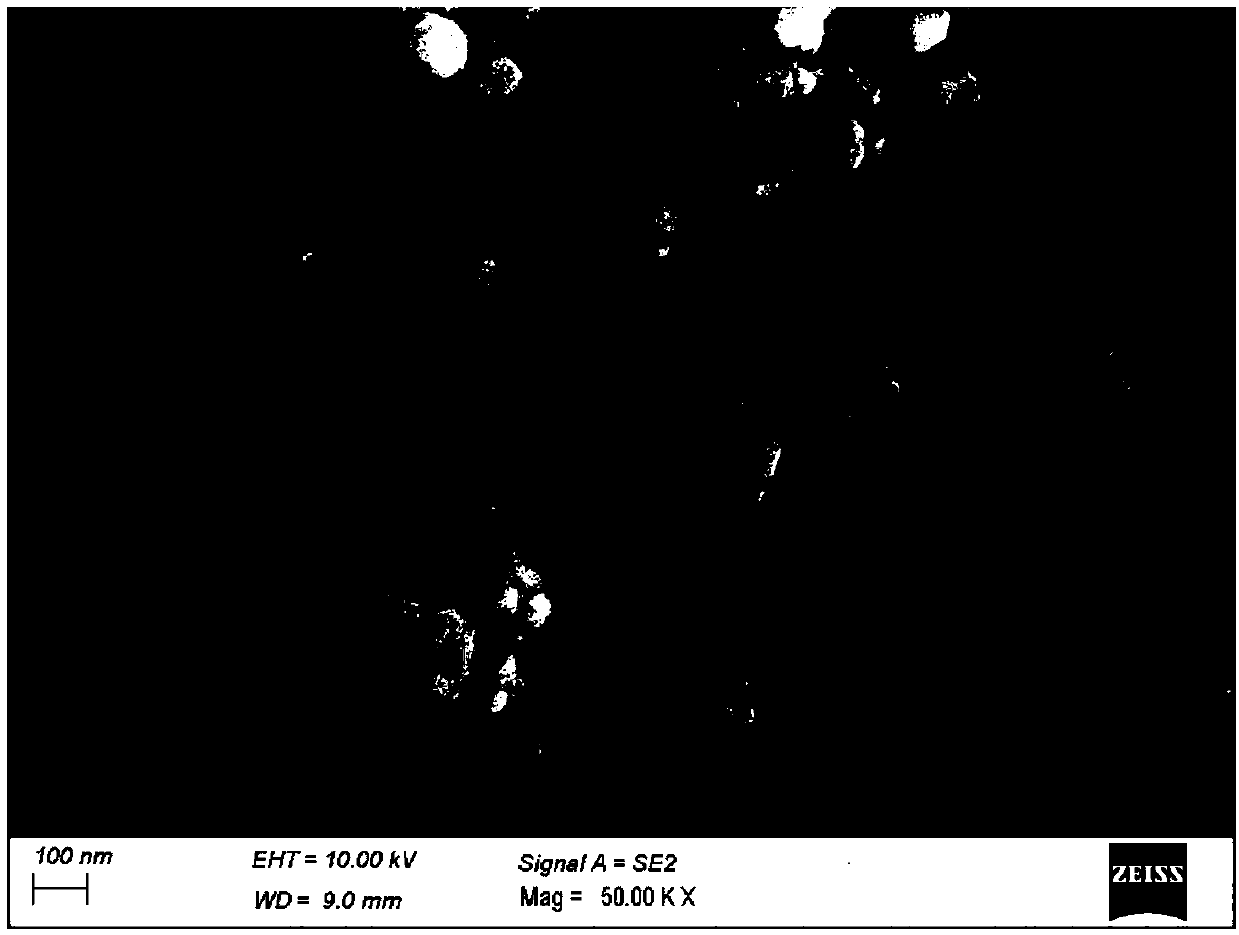

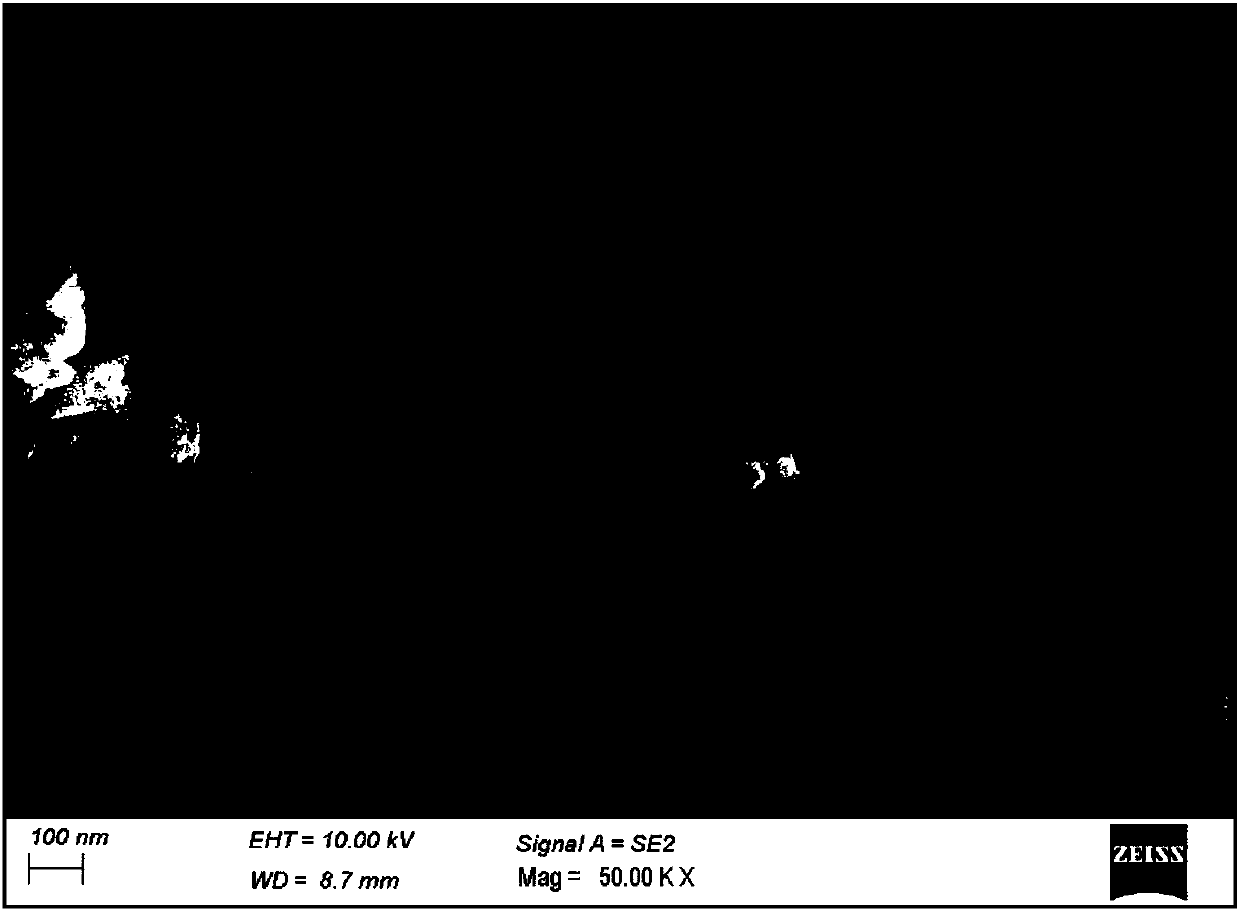

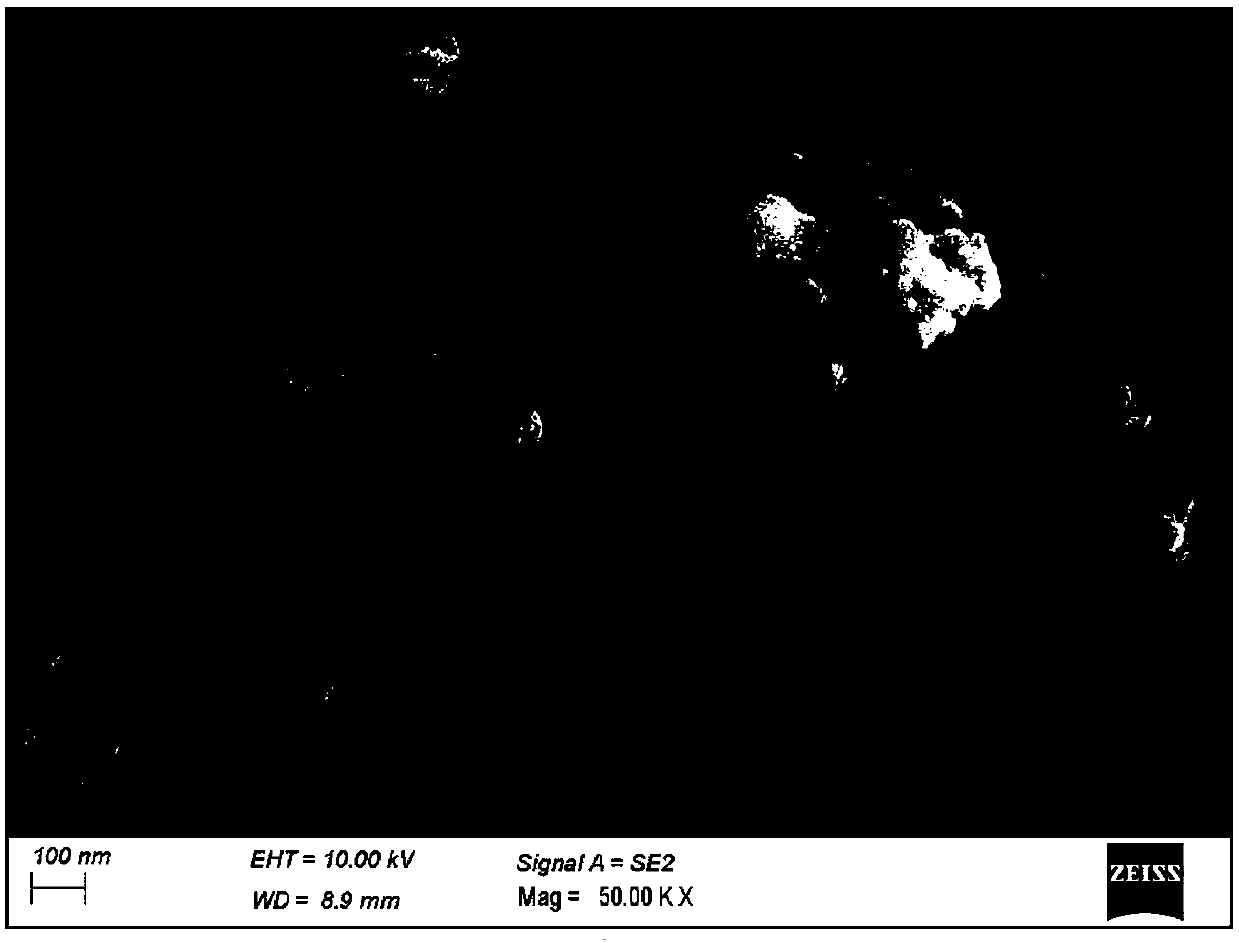

[0087] The sand-milled slurry is directly dried in an electric oven at 90° C. for 12 hours to obtain nano-ceramic powder with a particle size of 100 nm or less. Field emission electron microscopy was carried out on the prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com