Method for preparing high-solid-solubility ultrafine grain high-speed steel through electric pulses

A technology of ultra-fine grain, high-speed steel, applied in the direction of manufacturing tools, heat treatment equipment, heat treatment process control, etc., to achieve the effect of increasing solid solubility, realizing ultra-fine grain and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

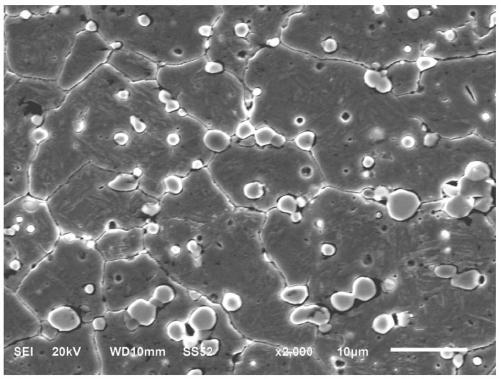

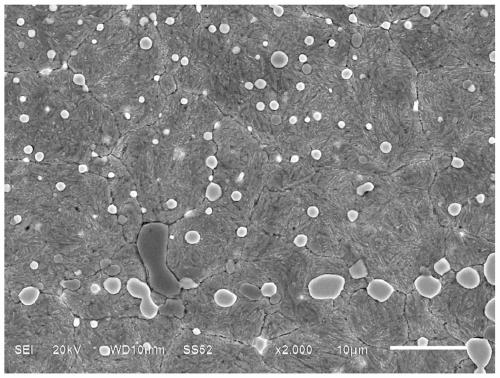

[0036] The material is M2 high-speed steel widely used in the market. A workpiece with a size of φ10x60mm is taken and heated to 1180°C in a vacuum tube furnace. After holding for 10 minutes, it is quenched and cooled to room temperature in quenching oil. figure 2 shown). Temper the pre-quenched high-speed steel workpiece at 550°C for 1 hour and then air-cool it to obtain the pre-heat treatment microstructure (such as image 3 shown). The average grain size of the preliminary heat treatment is 20 μm, and the matrix is distributed with eutectic carbides and fine secondary carbides precipitated by tempering.

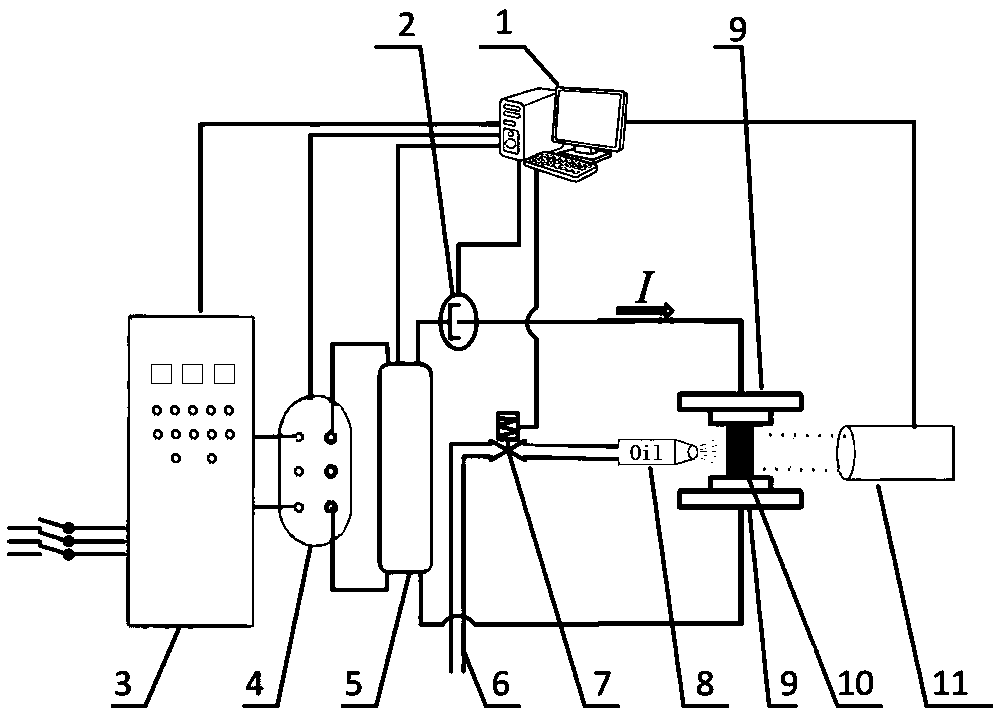

[0037] Turn on the power supply 3 of the electric pulse device, and connect to the grid. Turn on the charging power supply 3, the transformer 4 and the energy storage 5 through the control system 1 to complete the energy storage charging process.

[0038] The high-speed steel workpiece 10 after preliminary heat treatment is polished smooth, and the two ends are clamp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com