High-hardenability Mn-Cr series carburizing steel

A technology of high hardenability and carburized steel, applied in the field of alloy structural steel, can solve the problem that Mn-Cr series carburized steel cannot be applied to heavy-duty gearboxes and drive axle gears of commercial vehicles, etc. The effect of reducing intergranular oxidation and improving surface corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

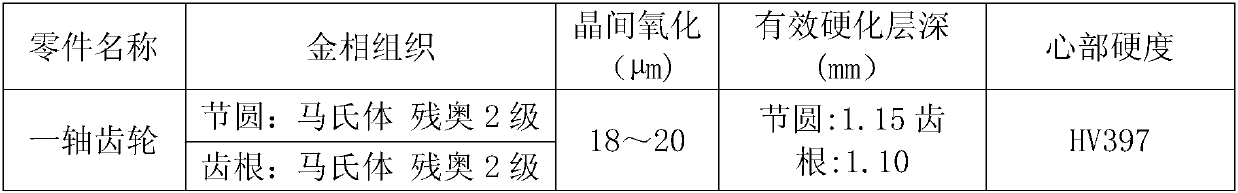

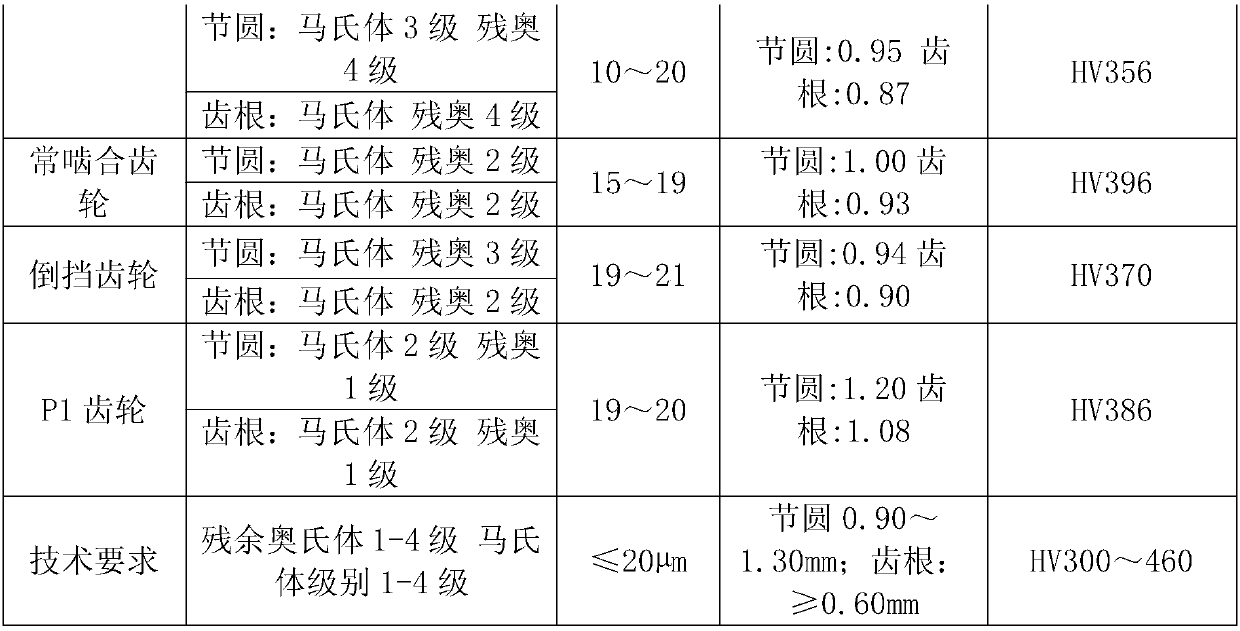

Image

Examples

Embodiment 1

[0030] A high hardenability Mn-Cr series carburizing steel, its composition and mass percentage content are: C 0.18, Si 0.20, Mn 1.40, P 0.035, S 0.028, Cr 1.35, Mo 0.10, Al 0.017, N 0.010, Ni 0.10, Cu 0.11, B0.0001, the rest are Fe and unavoidable impurities.

Embodiment 2

[0032]A high hardenability Mn-Cr series carburizing steel, its composition and mass percentage content are: C 0.20, Si 0.19, Mn 1.38, P 0.013, S 0.021, Cr 1.39, Mo 0.022, Al 0.022, N 0.013, Ni 0.14, Cu 0.10, B0.00025, the rest are Fe and unavoidable impurities.

Embodiment 3

[0034] A high hardenability Mn-Cr series carburizing steel, its composition and mass percentage content are: C 0.21, Si 0.18, Mn 1.33, P 0.012, S 0.019, Cr 1.40, Mo 0.021, Al 0.029, N 0.018, Ni 0.14, Cu 0.13, B0.0003, the rest are Fe and unavoidable impurities.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com