Manufacturing method of high-mechanical-strength sintered neodymium iron boron permanent magnets

A technology of mechanical strength and manufacturing method, which is applied in the direction of inductance/transformer/magnet manufacturing, magnetic objects, magnetic materials, etc., can solve problems such as poor strength and toughness, peeling, falling edges and corners, etc., to improve fracture toughness and bending resistance Strength, improve bending strength, increase the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

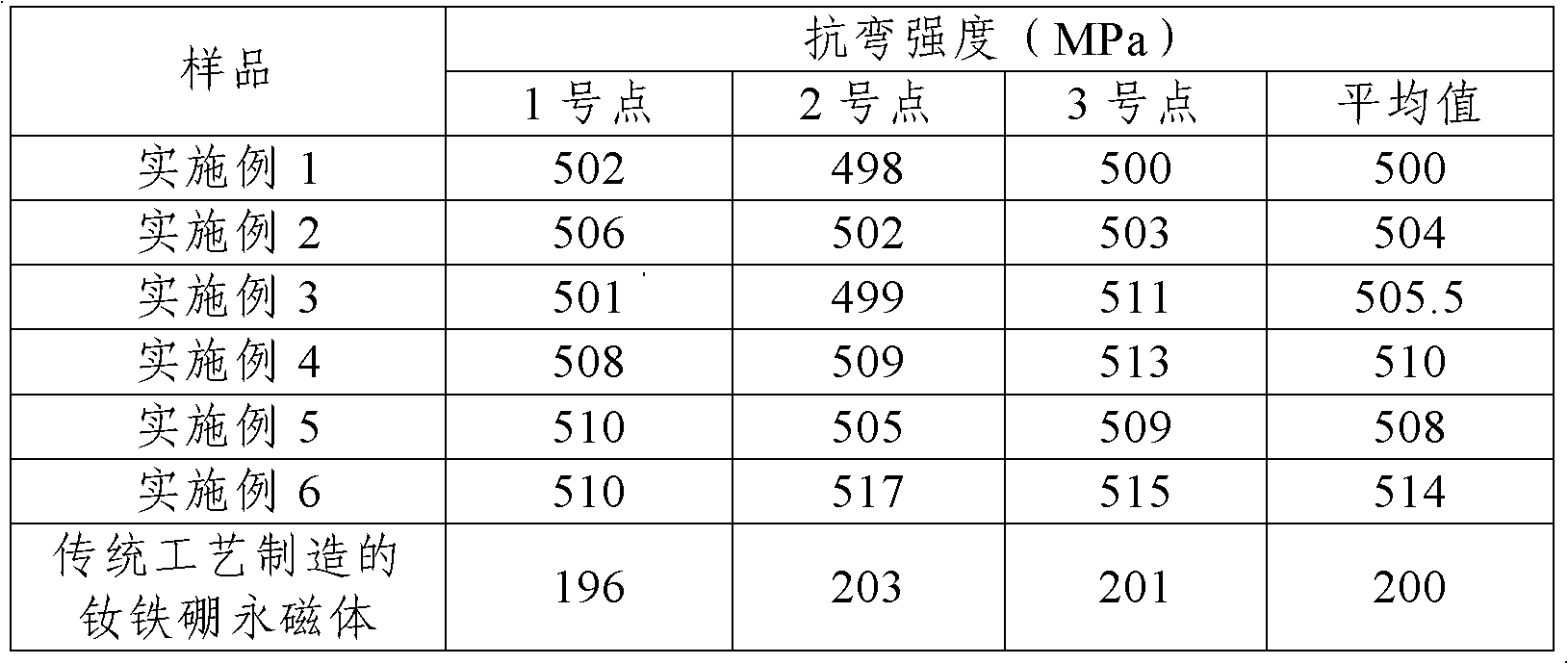

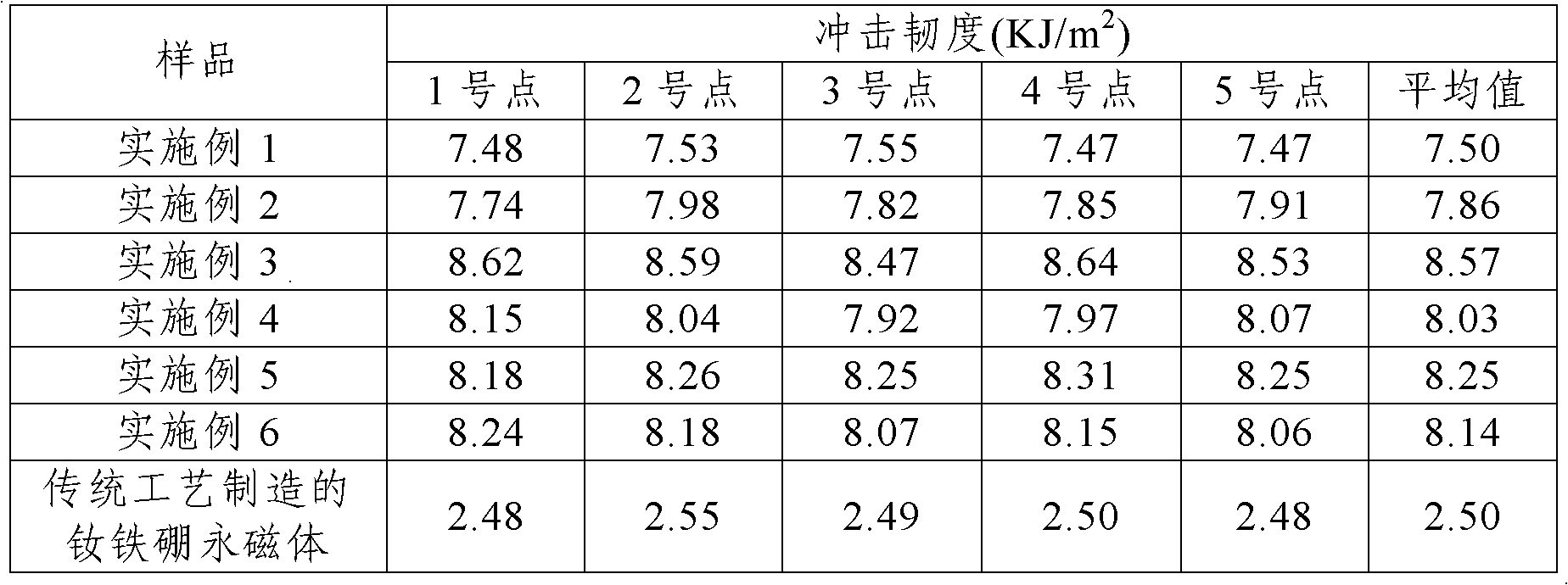

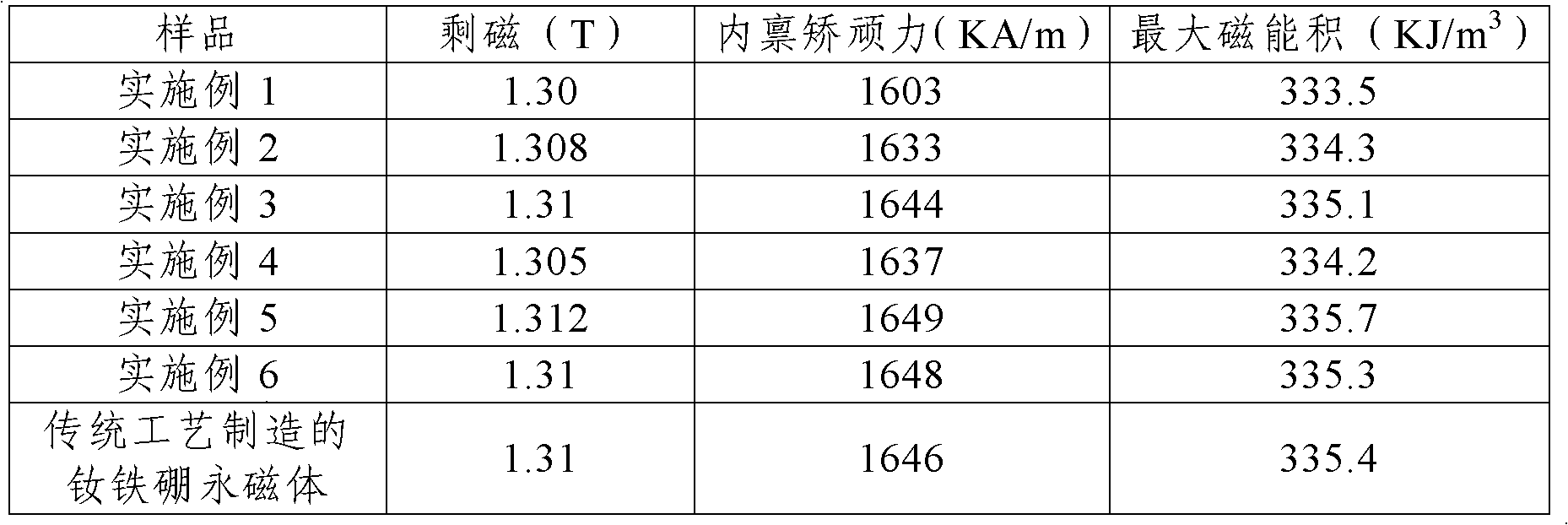

Examples

Embodiment 1

[0027] Step 1, take by weighing 25kg of neodymium, 0.49kg of titanium, 0.62kg of cobalt, 6.63kg of iron-boron alloy, and 67.26kg of iron, wherein the mass purity of neodymium, iron, titanium, cobalt and iron-boron alloy is not less than 99.5%, and the boron in the iron-boron alloy The mass percentage content is 19.3%;

[0028] Step 2. Mix the raw materials weighed in step 1 and place them in a strip furnace, and use a conventional quick-setting process to prepare a 0.45mm thickness under the condition that the vacuum degree is 10Pa and the surface speed of the roller is 0.8m / s. quick-setting tablets;

[0029] Step 3: Saturate the quick-setting tablet described in step 2 with hydrogen absorption at room temperature for 6 hours, then dehydrogenate the saturated quick-setting tablet at a temperature of 570°C to make hydrogen explosion powder, and then hydrogen explosion The powder adopts the conventional jet milling process, and the magnetic powder with an average particle size ...

Embodiment 2

[0035]Step 1. Weigh 35kg of neodymium, 0.51kg of titanium, 0.58kg of cobalt, 3.91kg of iron-boron alloy, and 60kg of iron, wherein the mass purity of neodymium, iron, titanium, cobalt and iron-boron alloy is not less than 99.5%, and the mass of boron in the iron-boron alloy The percentage content is 19.7%;

[0036] Step 2. Mix the raw materials weighed in step 1 and place them in a strip furnace, and use a conventional quick-setting process to prepare a 0.4mm-thick film under the conditions of a vacuum of 5Pa and a surface speed of the roller of 0.85m / s. quick-setting tablets;

[0037] Step 3. Saturate the quick-setting tablet described in step 2 with hydrogen absorption at room temperature for 4 hours, then dehydrogenate the saturated quick-setting tablet at a temperature of 550°C to make hydrogen explosion powder, and then hydrogen explosion The powder adopts the conventional jet milling process, and the magnetic powder with an average particle size of 3.4 μm is made under ...

Embodiment 3

[0042] Step 1, take by weighing 30kg of neodymium, 0.50kg of titanium, 0.60kg of cobalt, 5.23kg of iron-boron alloy, and 63.67kg of iron, wherein the mass purity of neodymium, iron, titanium, cobalt and iron-boron alloy is not less than 99.5%, and the boron in the iron-boron alloy The mass percentage content is 19.5%;

[0043] Step 2. Mix the raw materials weighed in step 1 and place them in a strip furnace. Use a conventional quick-setting process to prepare a 0.43mm thick film under the condition that the vacuum degree is 1Pa and the surface speed of the roller is 0.83m / s. quick-setting tablets;

[0044] Step 3. Saturate the quick-setting tablet described in step 2 with hydrogen absorption at room temperature for 5 hours, then dehydrogenate the saturated quick-setting tablet at a temperature of 560°C to make hydrogen explosion powder, and then hydrogen explosion The powder adopts conventional jet milling process, and the magnetic powder with an average particle size of 3.5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com