Composite pipe for nuclear fuel component and manufacturing method of composite pipe

A nuclear fuel assembly and manufacturing method technology, applied in the direction of reactor fuel elements, manufacturing reactors, nuclear engineering, etc., to achieve the effects of simplifying the safety system, increasing the temperature of the coolant, and increasing the output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

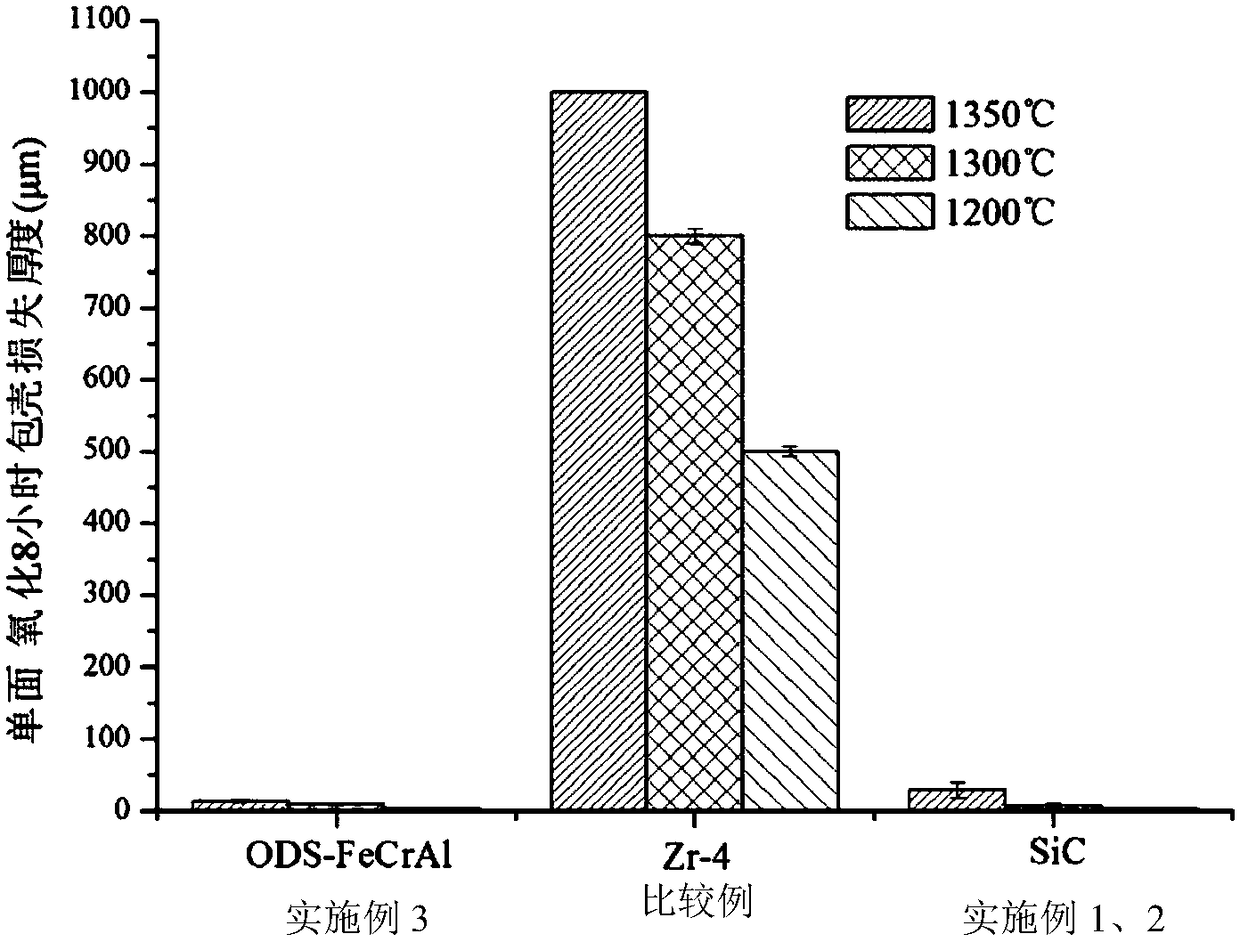

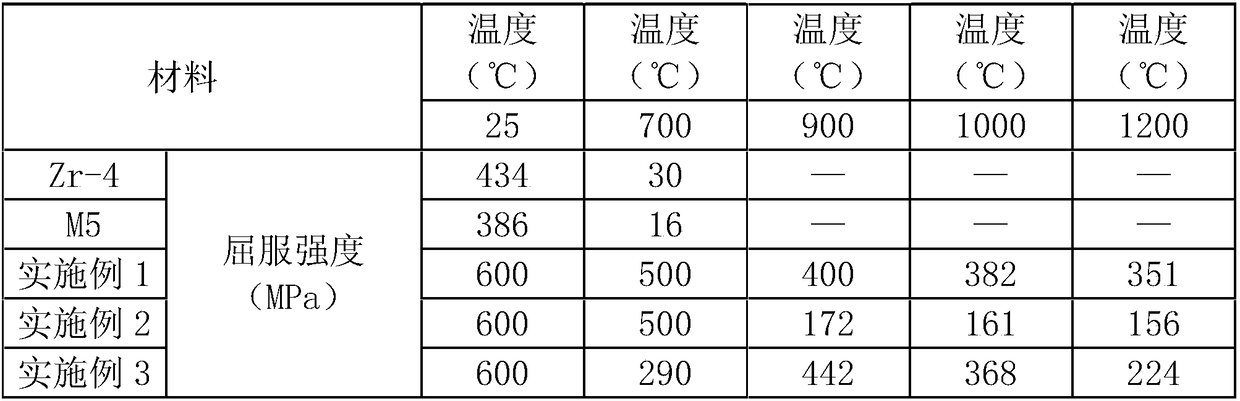

Embodiment 1

[0047] Inner tube: The third-generation SiC fiber with a high stoichiometric ratio is woven into an elastic inner tube skeleton with a wall thickness of 0.2mm, an outer diameter of 9.4mm, and a length of 800mm. Using the precursor impregnation pyrolysis process (PIP), the low-melting polycarbosilane is used as a precursor to infiltrate the inner tube skeleton of the fiber braid, and it is cracked at a low temperature under normal pressure, so that the precursor and the fiber undergo a cross-linking reaction to form a dense elastic inner tube (Ceramic tube).

[0048]Outer tube: High-purity SiC powder is used to prepare thin-walled tube blanks, which are pressed into green bodies with high strength and density by cold isostatic pressing, and sintered at high temperature under normal pressure to obtain a density of 3.1g / cm 3 A dense SiC ceramic tube with an outer diameter of 10mm, a wall thickness of 0.7mm, and a length of 800mm.

[0049] The inner tube is compressed so that it ...

Embodiment 2

[0051] Inner tube: Use metal tantalum with good formability and elasticity to make an elastic inner tube (tantalum tube) with a wall thickness of 0.2mm, an outer diameter of 9.4mm, and a length of 800mm by multiple cold rolling-heat treatment methods. Surface induction heating is carried out on the tantalum tube, and pre-oxidation treatment is carried out.

[0052] Outer tube: High-purity SiC powder is used to prepare thin-walled tube blanks, which are pressed into green bodies with high strength and density by cold isostatic pressing, and sintered at high temperature under normal pressure to obtain a density of 3.1g / cm 3 Above, a dense SiC ceramic tube with an outer diameter of 10mm, a wall thickness of 0.7mm, and a length of 800mm.

[0053] The inner tube is compressed to fit into the outer tube, and the tantalum tube is expanded by water pressure or air pressure, and is tightly combined with the inner wall of the outer SiC ceramic tube to obtain a composite tube.

Embodiment 3

[0055] Inner tube blank: using NS-Mo powder in a cold isostatic press with a pressure of 120MPa to obtain a relatively high-density tube blank with an outer diameter of 59.5mm and a suitable inner diameter.

[0056] Outer tube blank: ODS-FeCrAl powder is used to obtain a relatively dense tube blank with an outer diameter of 66mm and an inner diameter of 60mm in a cold isostatic press at a pressure of 120MPa.

[0057] Double-layer composite pipe: put the inner pipe blank into the outer pipe blank, and then perform hot isostatic pressing at 1000°C with a pressure of 200MPa, and finally obtain a high-density double-layer composite metal pipe blank. Through multiple hot rolling, cold rolling and intermediate heat treatment, a reasonable amount of wall reduction and diameter reduction is adjusted, and finally a long tube (composite tube) with an outer diameter of 9.5mm, a wall thickness of 0.4mm, and a length of 4m is obtained. Among them, the ODS-FeCrAl outer tube wall thickness i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com