Organic electroluminescence component and manufacturing method thereof

An electroluminescent device and luminescence technology, which is applied in the manufacture of semiconductor/solid-state devices, electric solid-state devices, electrical components, etc., can solve the problems of low aperture ratio of high-resolution display screens, and achieve improved luminous utilization and increased aperture The effect of high efficiency and good display effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

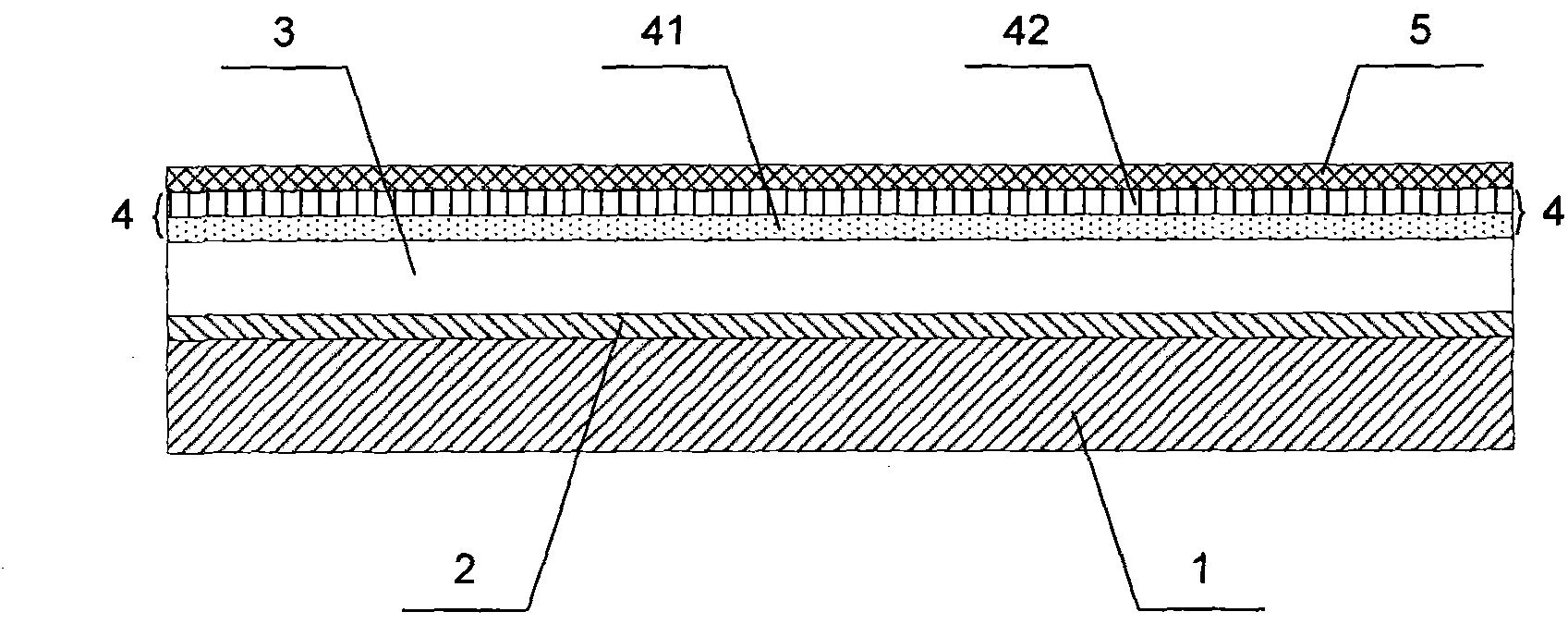

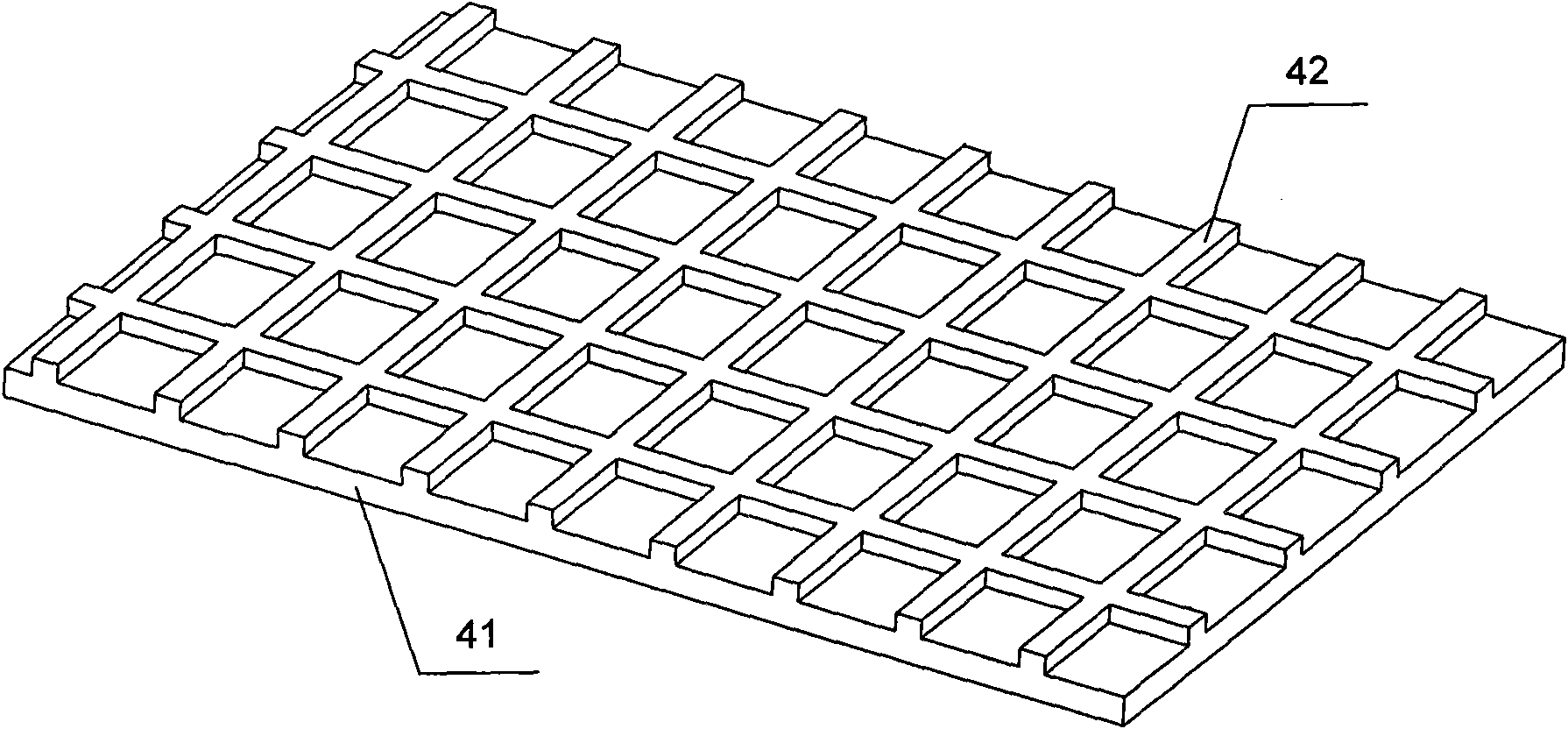

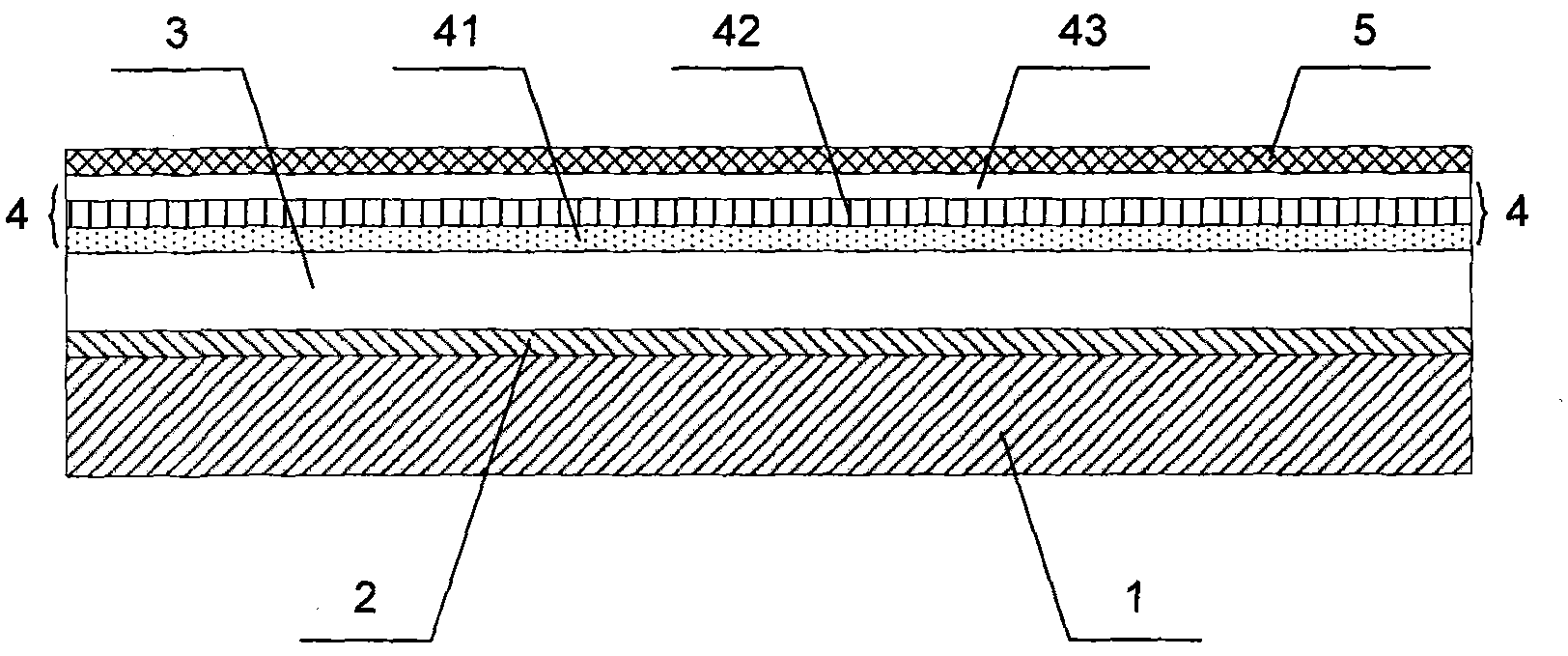

[0031] figure 1 It is a schematic structural diagram of the first embodiment of the organic electroluminescent device of the present invention. Such as figure 1 As shown, the main structure of the organic electroluminescent device in this embodiment includes a first electrode 2, an organic material layer 3, a second electrode 4 and a sealing layer 5 sequentially formed on a substrate 1, wherein the first electrode 2 serves as an anode, The second electrode 4 is used as the cathode, and is a composite transparent structure, the organic material layer 3 is arranged between the first electrode 2 as the anode and the second electrode 4 as the cathode, and the sealing layer 5 is arranged outside the second electrode 4 for delaying The decay of the second electrode 4 and the organic material layer 3 is caused by the influe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com