Special-shaped modular type hollow space solar energy high-temperature receiver

A modular, solar energy technology, applied in the field of solar thermal utilization, can solve the problems of complex manufacturing process, high cost, inconvenient engineering promotion and application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

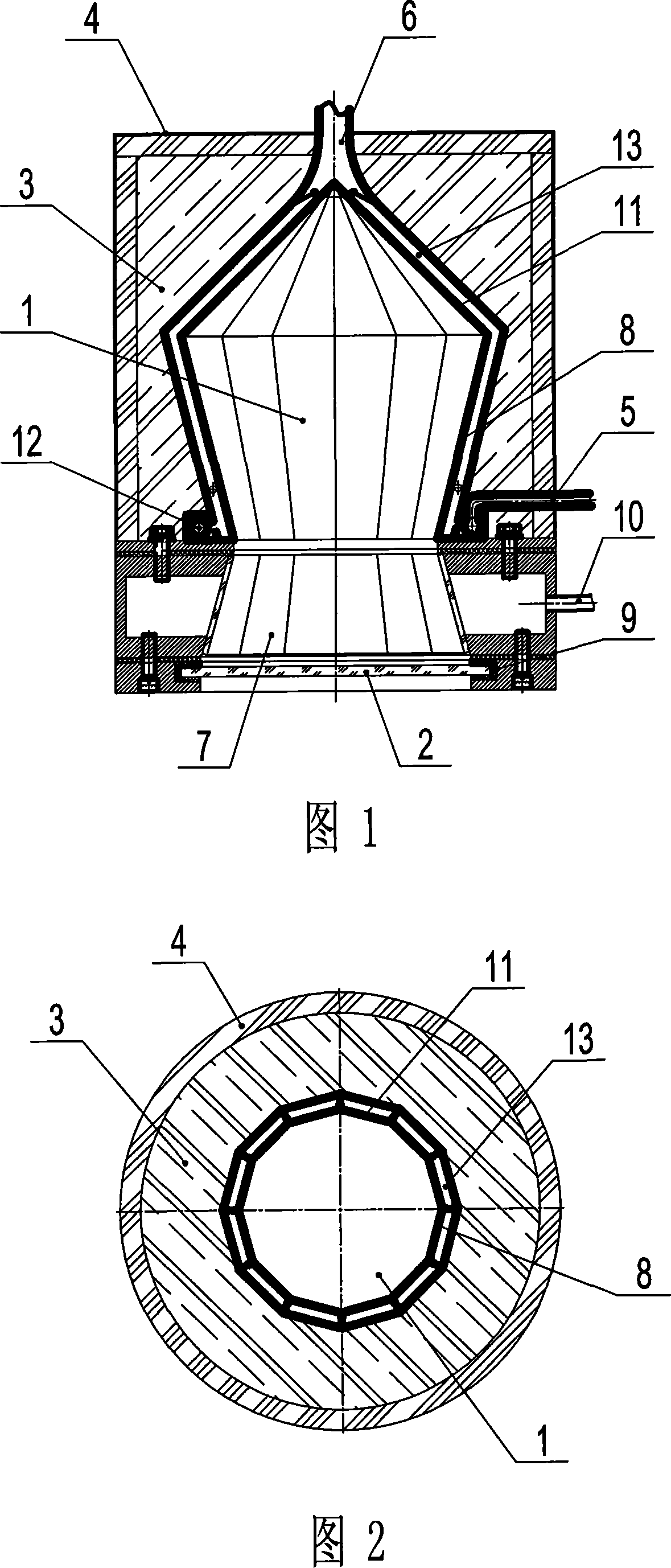

[0019] The special-shaped modular cavity solar high temperature receiver of this embodiment is shown in Fig. 1, Fig. 2 and Fig. 3. The glass window 2, the insulation layer 3 covering the outer wall of the heat absorption cavity, the shell 4 covering the insulation layer, and the working fluid inlet 5 and the working fluid outlet 6 connected to the heat absorption cavity.

[0020] The heat-absorbing cavity 1 is composed of a group of 12 interlayer wall panels extending from the mouth of the cup to the center of the cup bottom. The bottom of the cup is in the shape of a cone. , forming a working fluid channel 13 inside. The outside of the cup-shaped heat-absorbing chamber 1 is covered by an insulating layer 3 and its shell 4. The insulating layer 3 reduces the heat exchange between the heat-absorbing chamber and the outside air, further reducing the heat loss of the solar receiver, and the outer shell of the insulating layer 4 has played the effect of fixing and strengthening t...

Embodiment 2

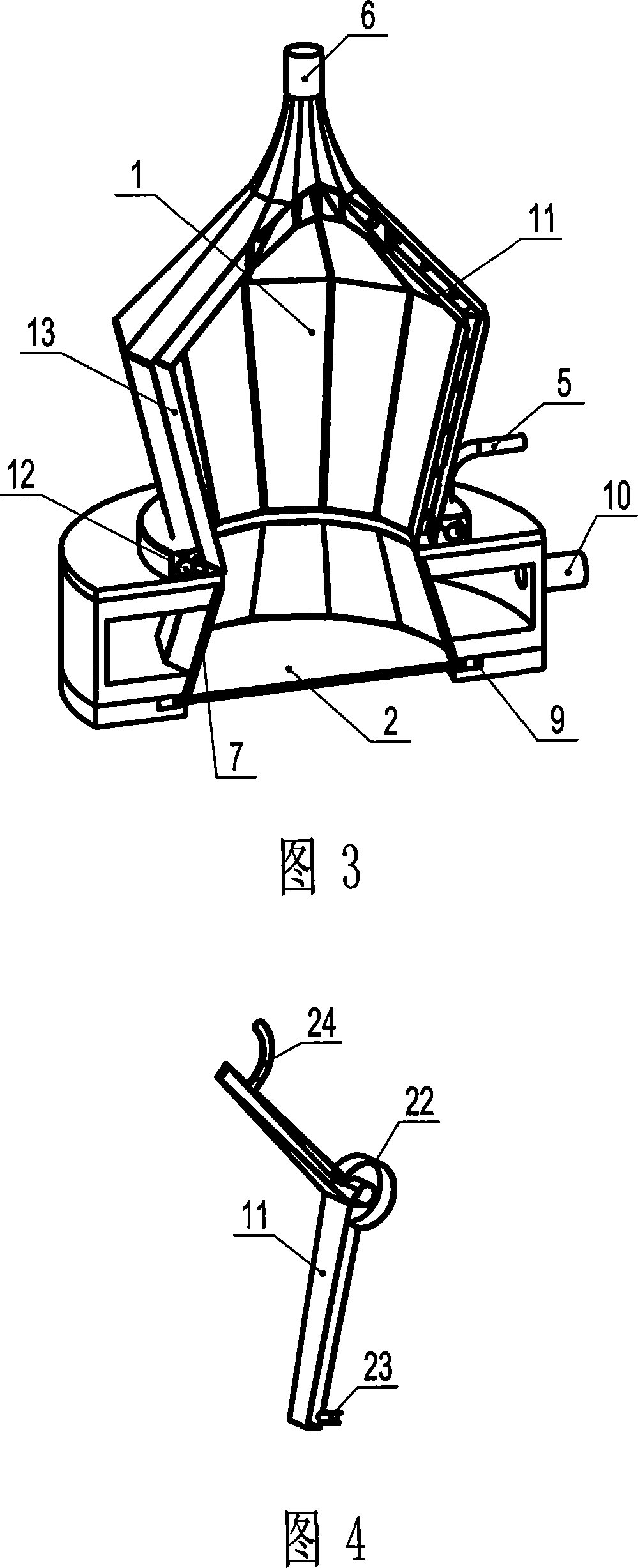

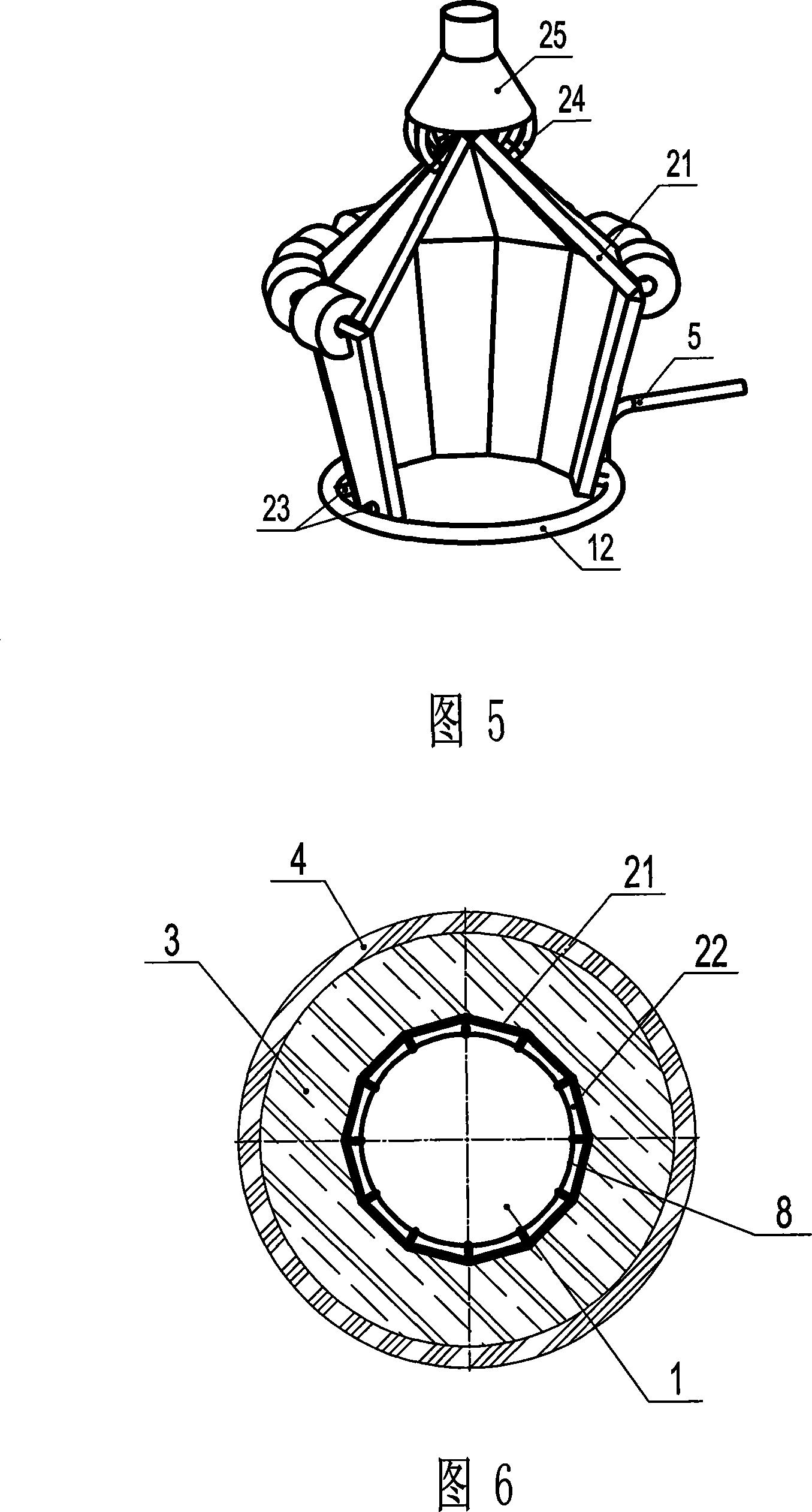

[0026] The special-shaped modular cavity solar high temperature receiver of this embodiment is shown in Figure 4, Figure 5 and Figure 6, and the basic structure of Embodiment 1 is generally the same, and its main difference is that the interlayer wall plate of the heat absorption chamber 1 is made of independent The heat-absorbing box body 21 (ie module) is formed. As shown in FIG. 4 , each heat-absorbing box 21 is composed of an upper and a lower sandwich plate, and a working fluid circulation channel is formed inside the sandwich plate, and the inner surface is composed of a curved metal module 11 with a slightly arc-shaped cross section. The upper sandwich plate is isosceles triangle, the lower sandwich plate is trapezoidal, one side of the upper and lower sandwich plates is butted, the inner side forms an obtuse angle, and the outer side forms a guide ring 22 connecting the upper and lower sandwich plates. An outlet 24 and an inlet 23 are respectively provided at the ends ...

Embodiment 3

[0030] The special-shaped modular cavity solar high-temperature receiver of this embodiment is shown in Fig. 7 and Fig. 8, and its basic structure is basically the same as that of Embodiment 2, the main difference being that a heat-conducting column 31 is provided on the inner surface 11 of the heat-absorbing box.

[0031] The outer end of the heat-conducting column 31 is located in the heat-absorbing chamber, and the inner end extends into the interlayer wall of the heat-absorbing box and is immersed in the working fluid. When working, the heat-conducting column with good thermal conductivity can quickly and fully transfer the heat in the heat-absorbing cavity to the working fluid in the heat-absorbing box, thereby further improving the heat transfer efficiency of the solar high-temperature receiver.

[0032] The heat-conducting column structure adopted on the heat-absorbing box in this embodiment not only increases the heat-absorbing area of the heat-absorbing box, improves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com