High speed dish type circular valve highly effective slag draining and separating machine

A slag separation and separation mechanism technology, applied in centrifuges with rotating drums, centrifuges, etc., can solve the problems of insufficient material strength, waste of human resources, long production cycle, etc., and achieve strong economic competitiveness and technology. Advantages, simple structure and production process, and the effect of a small number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

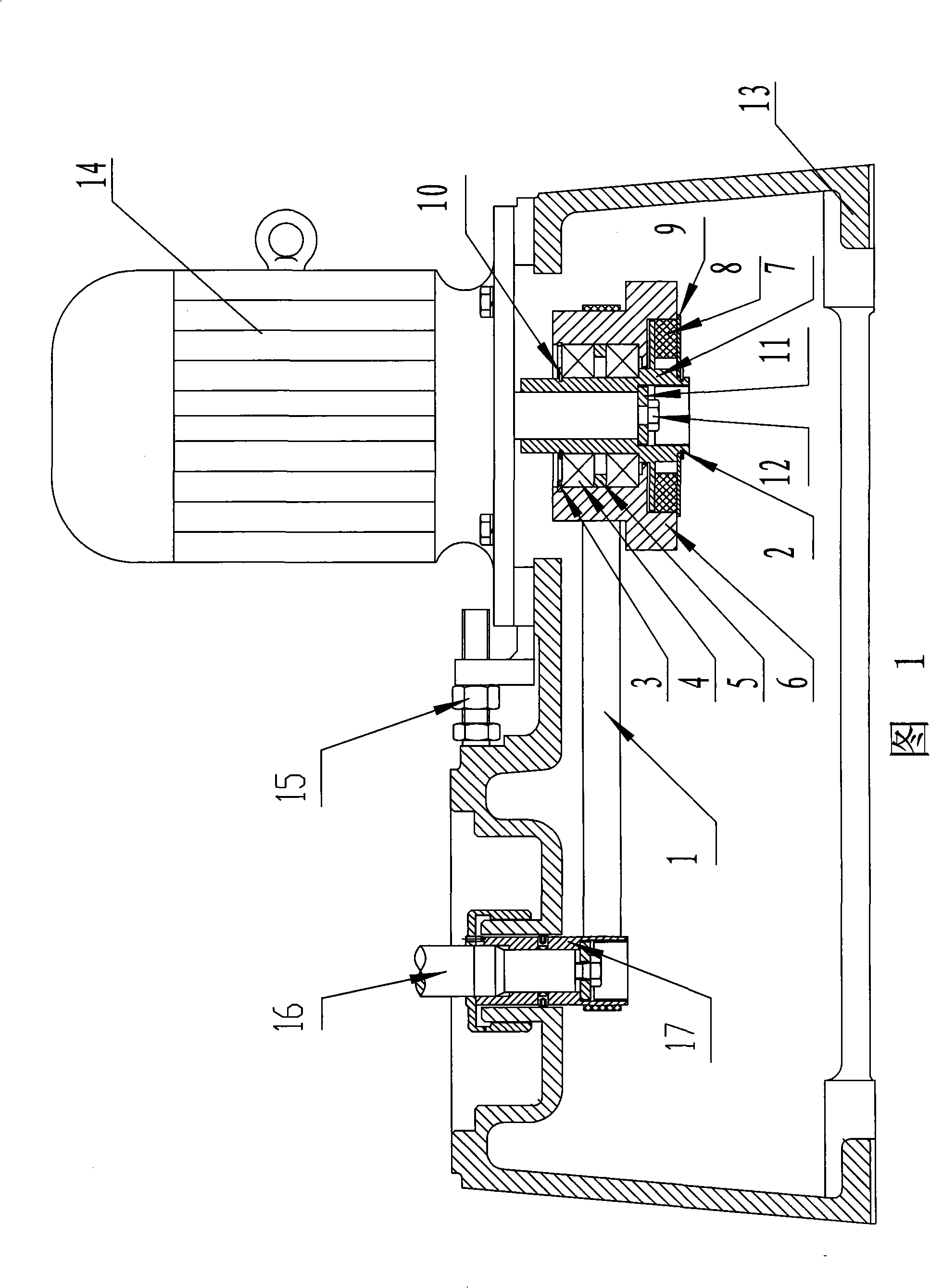

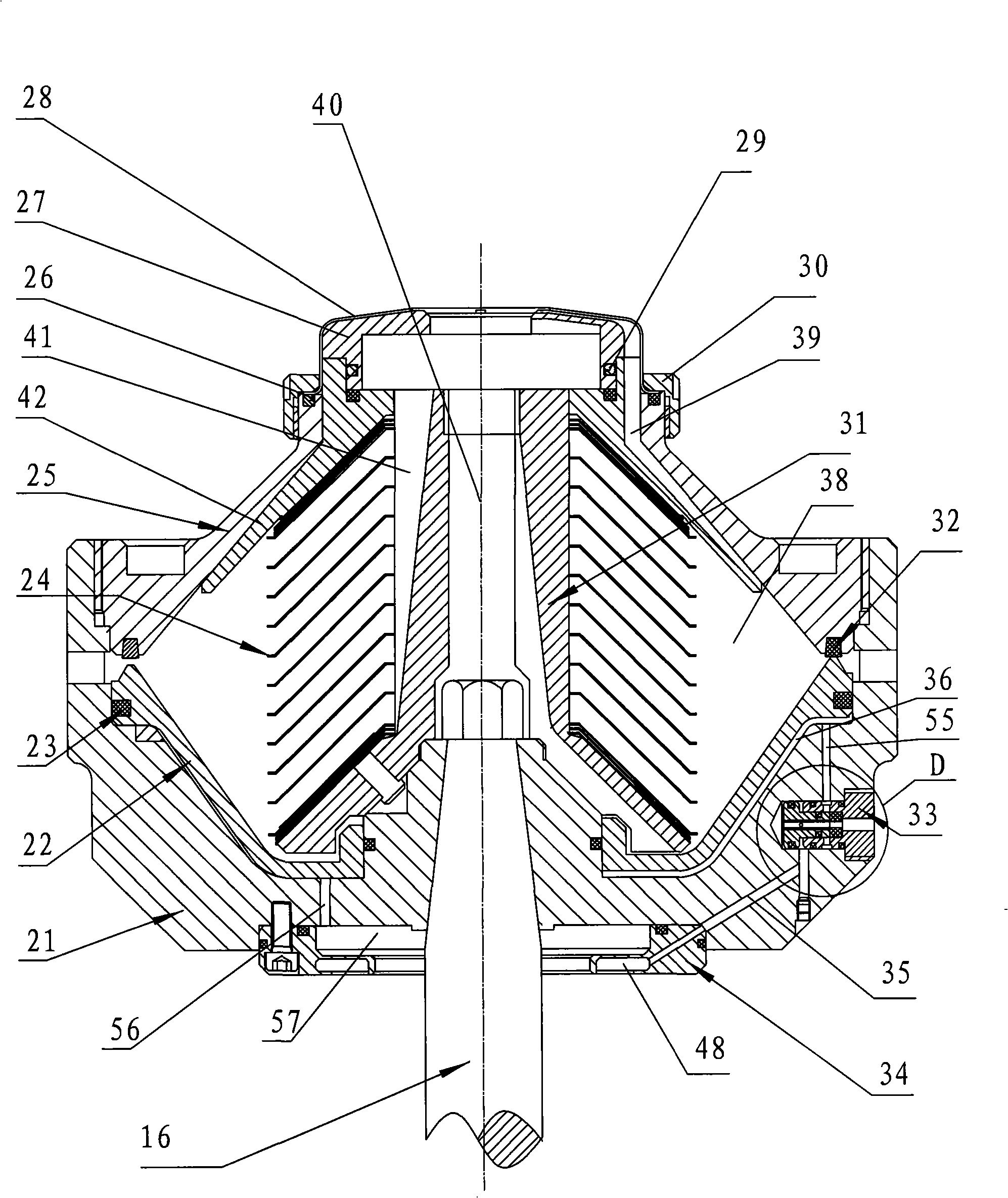

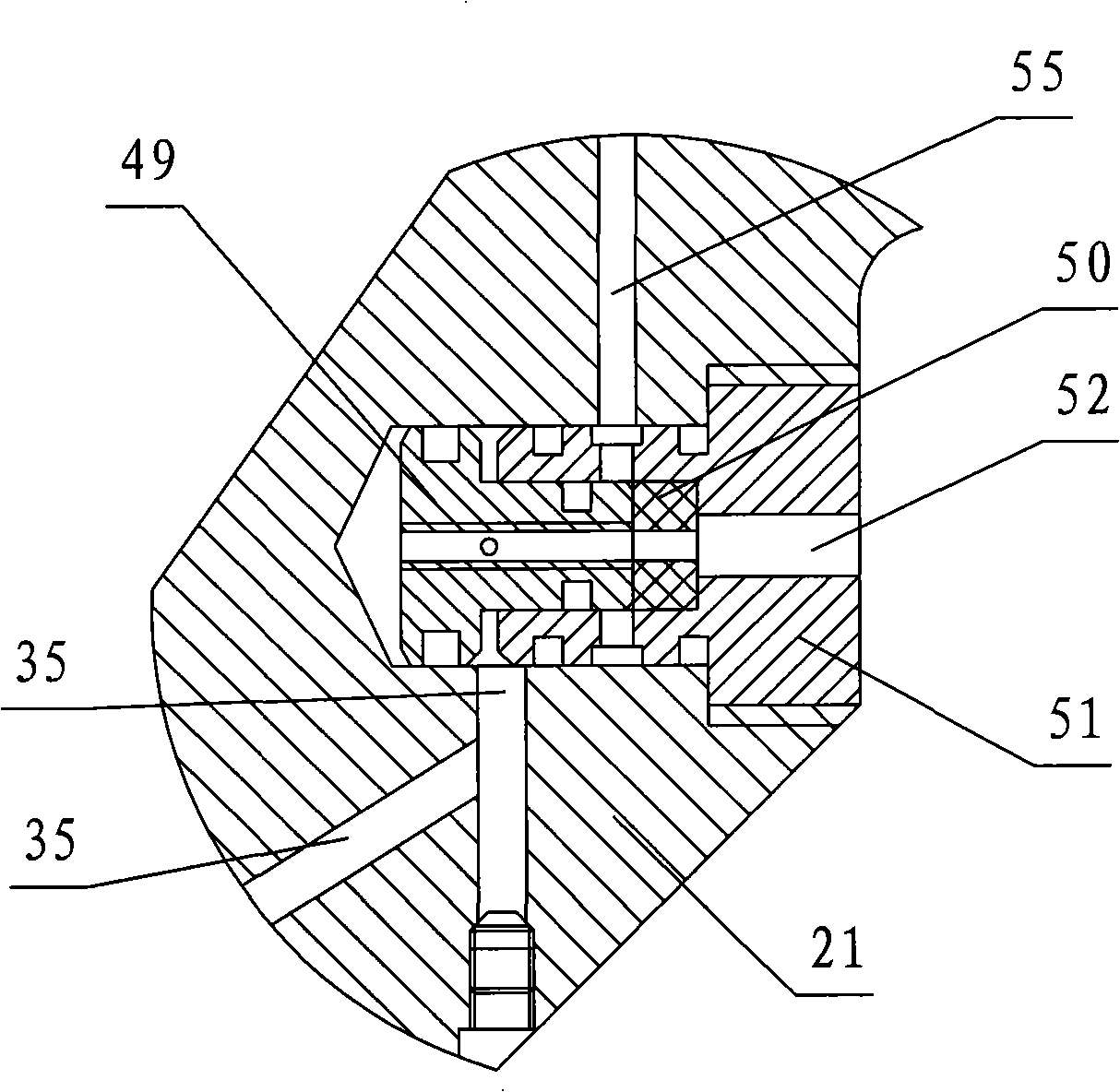

[0021] As shown in Figures 1 and 2: a separation mechanism and a transmission mechanism thereof are installed on the base 13; 21 and the cylinder cover 25 form a separation cavity 38, and a disc frame 31 with a sewage inlet channel 40 is arranged in the center of the separation cavity 38, and a number of inverted discs 24 are arranged on the outer wall of the disc frame 31. A piston 22 that can slide up and down relative to the separation cylinder 21 is arranged on the top, a slag discharge port 37 is provided on the separation cylinder 21 or the cylinder cover 25, and a control channel 35 is arranged in the separation cylinder 21, and the control channel 35 is formed in the piston 22 and the separation cylinder. The gap 36 between 21 communicates, and the control valve 33 for closing or opening the control channel 35 is set on the control channel 35. When the control valve 33 is opened, the high-pressure fluid at the bottom of the piston 22 enters the control valve 33 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com