Universal rechargeable battery formed by adopting lithium-ion battery and control method thereof

A technology of lithium-ion batteries and rechargeable batteries, which is applied in the direction of secondary battery charging/discharging, battery overcharge protection, battery circuit devices, etc., which can solve unfavorable automatic mass production assembly, reduced efficiency and reliability, reduced cycle life and safety In order to achieve the effects of automatic mass production assembly, simple structure and assembly process, and prevention of circuit failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

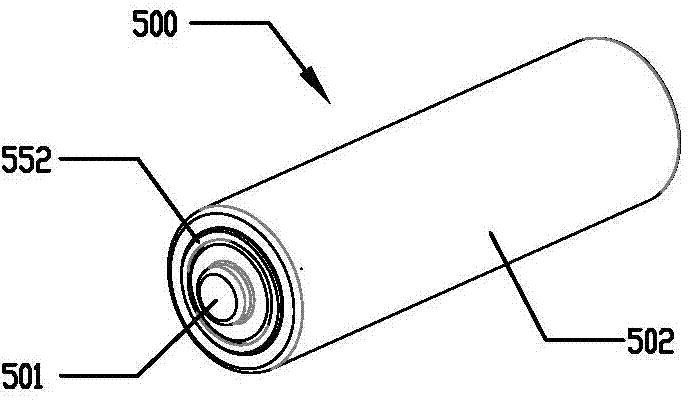

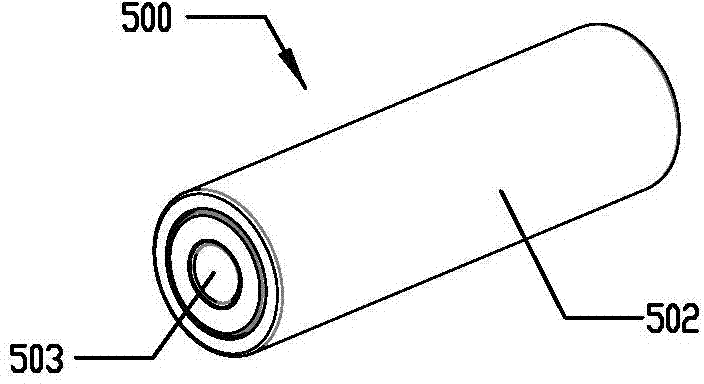

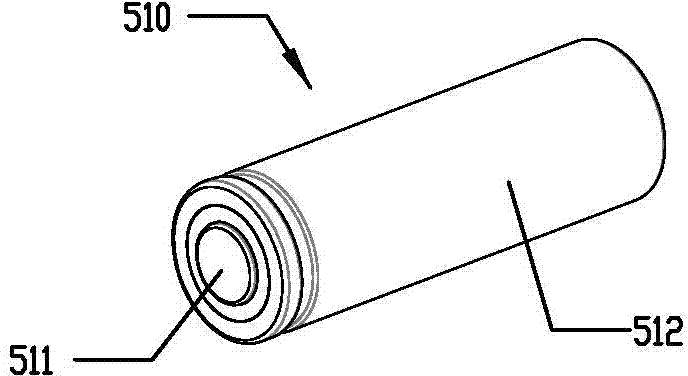

[0090] The invention provides a general-purpose rechargeable battery composed of a lithium-ion battery, comprising: an outer package casing, and a charge-discharge controller, a positive electrode crimping piece, a lithium-ion battery, and a negative electrode that are sequentially pressed and assembled in the outer package casing. terminal cover; one end of the charge-discharge controller is provided with a positive terminal cover with a positive contact point exposed to the outer packaging shell, the positive contact point is used as the positive electrode of a general-purpose rechargeable battery, and one end of the negative terminal cover is provided with a positive terminal cover exposed to the The negative electrode contact point of the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com