Multi-channel cocurrent flow microfluidic chip and controllable spinning method for linear multi-phase heterostructure fiber based on same

A technology of microfluidic chips and heterostructures, applied in the fields of fluid controller, fiber processing, fiber chemical characteristics, etc., can solve the problems of fragility and limitation of chips, achieve low cost, simple manufacturing process, and overcome high manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

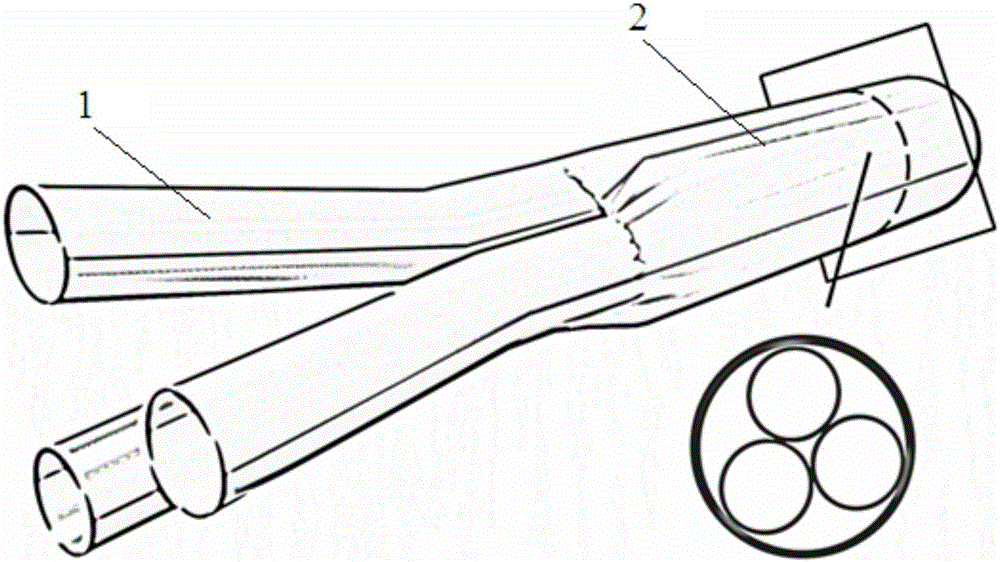

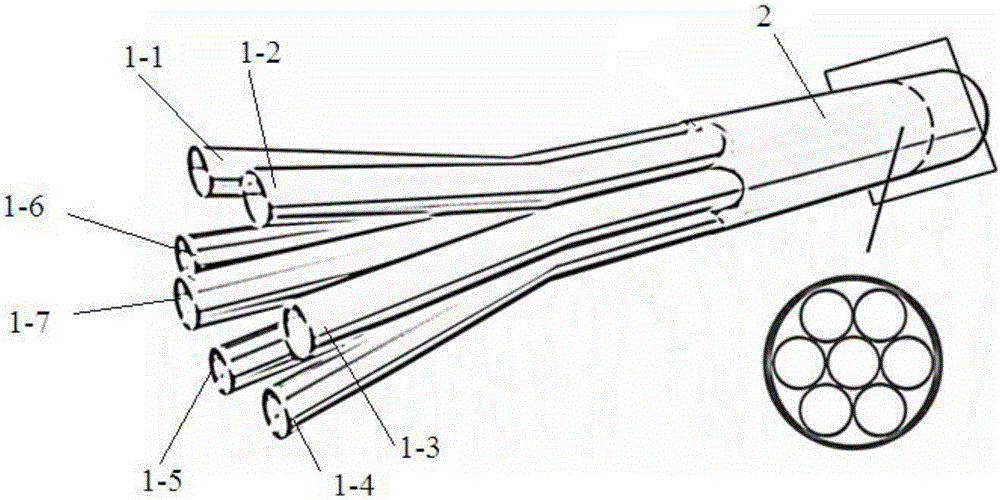

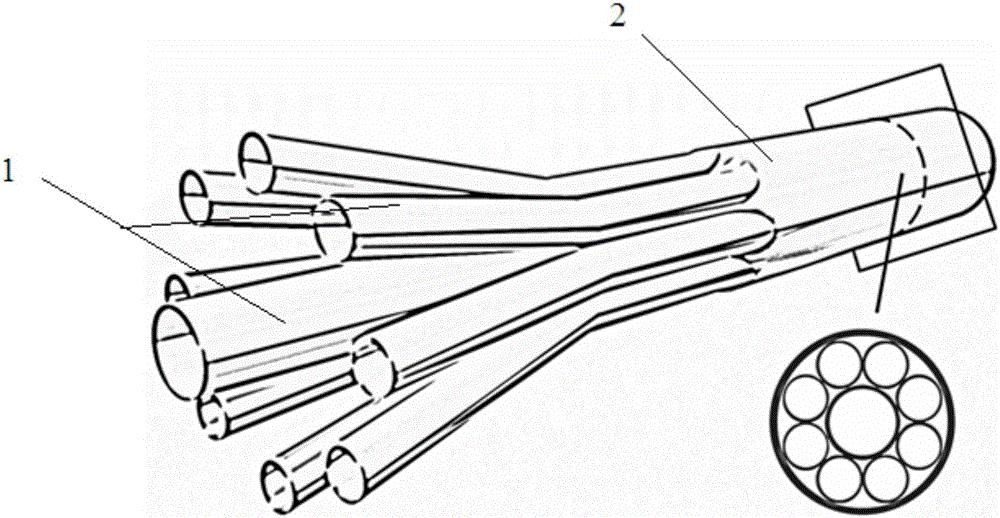

[0032] The structure of the seven-channel parallel flow microfluidic chip:

[0033] structured as figure 2 As shown, there are 7 stainless steel shunt capillaries 1-1, 1-2, 1-3, 1-4, 1-5, 1-6 with an inner diameter of 80 μm, an outer diameter of 200 μm, and a length of 25 mm for each spinning solution to circulate separately. , 1-7, and a stainless steel confluence capillary 2 with an inner diameter of 600 μm, an outer diameter of 900 um, and a length of 25 mm that converges the spinning solutions flowing out of each split capillary. The inside of the confluence capillary is bonded and fixed to the port of the confluence capillary by normal temperature hardening glue, and the normal temperature hardening glue seals the socket port of the confluence capillary. The depth of inserting the shunt capillary into the sink capillary is 10mm. The way that the split capillaries are arranged side by side is to make the cross-section of the capillary bundle formed after the side-by-side ...

Embodiment 2

[0037] The seven-channel co-current microfluidic chip in Example 1 was used as the spinning spinneret, and the spinning device was connected according to the method in Example 1, and then the following hydrogel wet spinning was performed.

[0038] Hollow tubular structure microfiber spinning:

[0039] Use a multi-channel micro-injection pump to pass 2wt% sodium alginate solution at a speed of 10mL / h into the split capillary tubes marked 1-1 to 1-6, and put a 5wt% hyaluronic acid solution at a speed of 10mL / h Into the split capillary labeled 1-7; the outlet of the confluence capillary (i.e. the outlet of the seven-channel parallel flow microfluidic chip) is immersed in 100mmol / L of CaCl 2 solution (colloidal solution). Spinning solution into CaCl 2 solution, the sodium alginate component and Ca 2+ The ion chelation reaction occurs to gel, the hyaluronic acid solution does not gel, and the CaCl diffuses outside the fiber 2 solution, thereby forming hollow sodium alginate hyd...

Embodiment 3

[0041] Using the seven-channel co-current microfluidic chip in Example 1 as the spinning spinneret, the perfusion velocity of the sodium alginate solution was regulated within the range of 5 to 30 mL / h. The remaining steps and conditions were the same as in Example 2, and the obtained diameter was 600-1000 μm hollow sodium alginate hydrogel microfibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com