Touch sensor, preparation method thereof and display device provided with touch sensor

A touch sensor and emission layer technology, applied in the input/output process of instruments, computer parts, and data processing, etc., can solve problems such as unsatisfactory user experience, no feedback on touch force, and complex overall device manufacturing process. Achieve the effect of low cost and simple structure and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

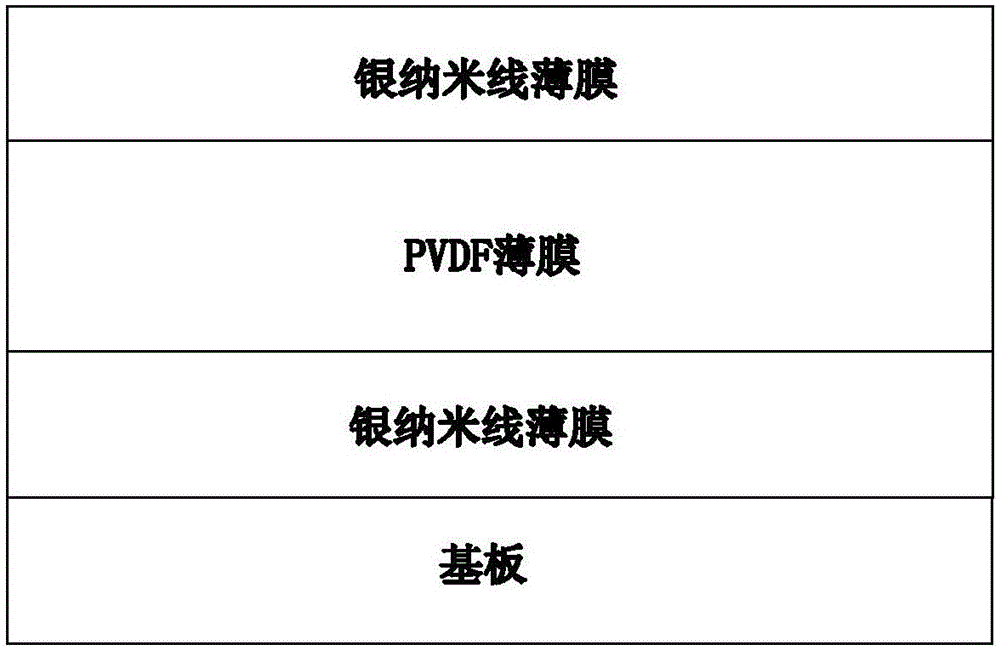

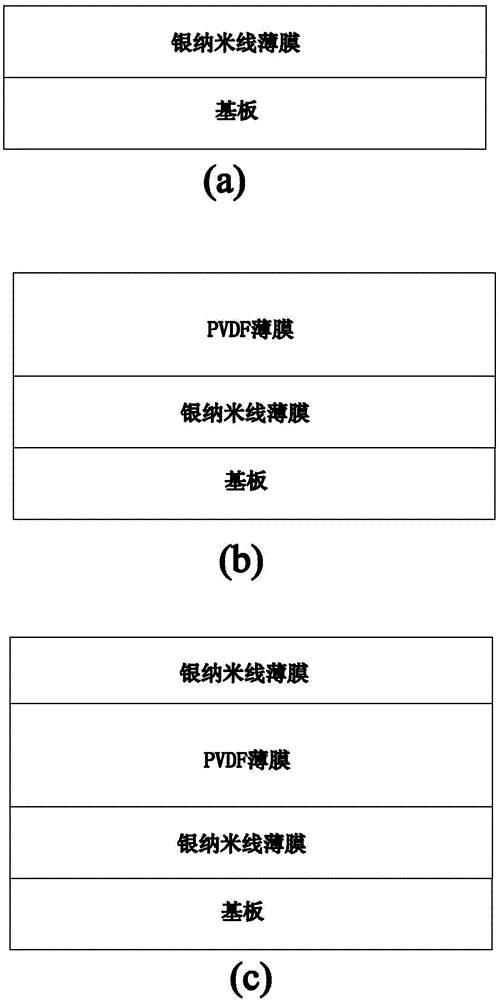

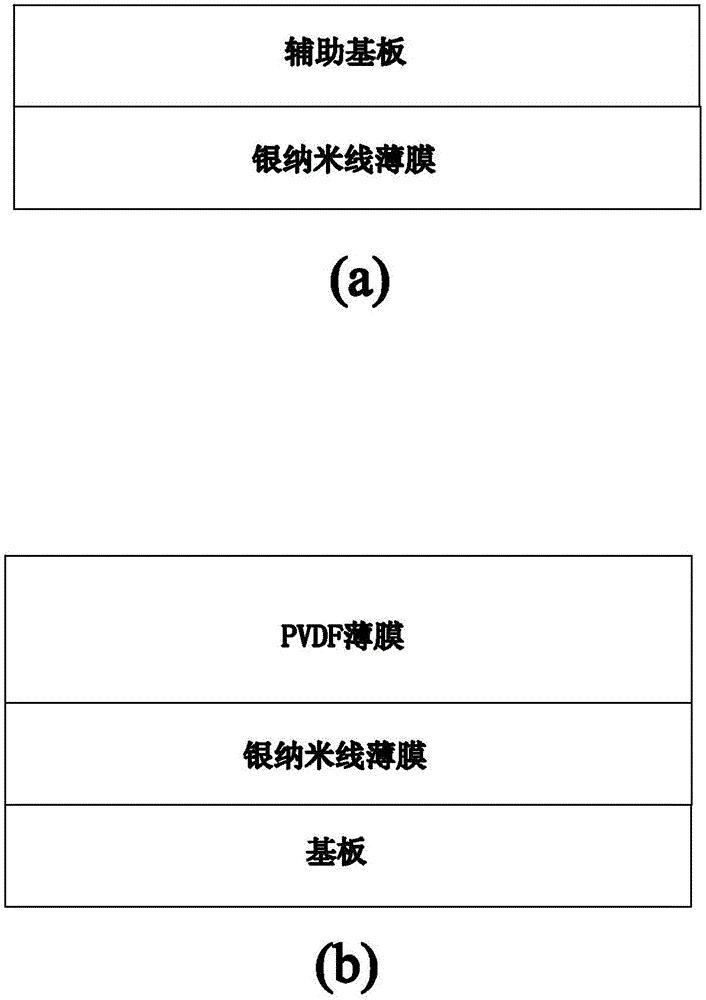

[0022] see Figure 1~Figure 4 As shown, the present invention provides a touch sensor, including a substrate and a conductive film on the substrate. The conductive thin film includes an emitting layer, an accepting layer, and a piezoelectric layer sandwiched between the emitting layer and the accepting layer; wherein there is no gap in the conducting thin film.

[0023] The touch sensor has a window area for user interaction and a peripheral area surrounding the window area, the conductive film located in the window area has a conductive pattern area and a conductive channel area, and the peripheral area is provided with the The receiving layer and the emitting layer are connected to transmit the conductive line of the electric signal, and the IC chi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com