Auto-rolling shielding sleeve

A casing and self-rolling technology, which is applied in the fields of magnetic/electric field shielding, pipeline protection, pipe/pipe joints/fittings, etc., can solve the problems of complex process and many parts, and achieve the advantages of shaping, long service life, and anti-corrosion The effect of high vertical strike force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

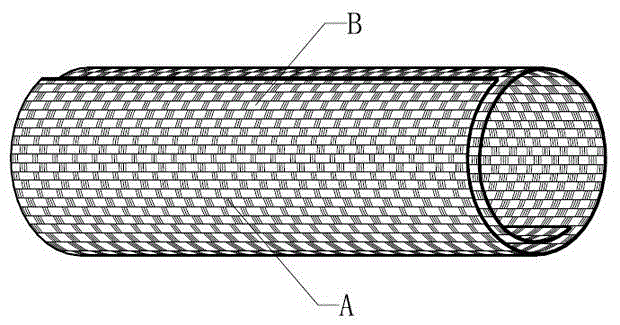

[0023] refer to figure 1 , in some embodiments of the self-rolling shielding sleeve, the axial direction of the sleeve is the warp direction, and the circumferential direction of the sleeve is the weft direction, and the sleeve includes a first strand B along the warp direction and A sheet composed of warp and weft weaving of the second strand A along the weft direction, wherein the first strand B is a strand synthesized from metal monofilament and / or plastic fiber, and the second strand A is synthesized from metal monofilament and / or plastic monofilament A strand of the sheet, the sheet is processed and shaped into a hollow roll that is self-curling around the axial direction, and the two opposite free edg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com