Method for continuously preparing phase step type plastics optical fibre by multi-layer co-extruded method

A plastic optical fiber and step-type technology, which is applied in the field of the preparation of step-type plastic optical fibers, can solve the problems affecting the optical properties of plastic optical fibers, differences in material compatibility, joint defects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

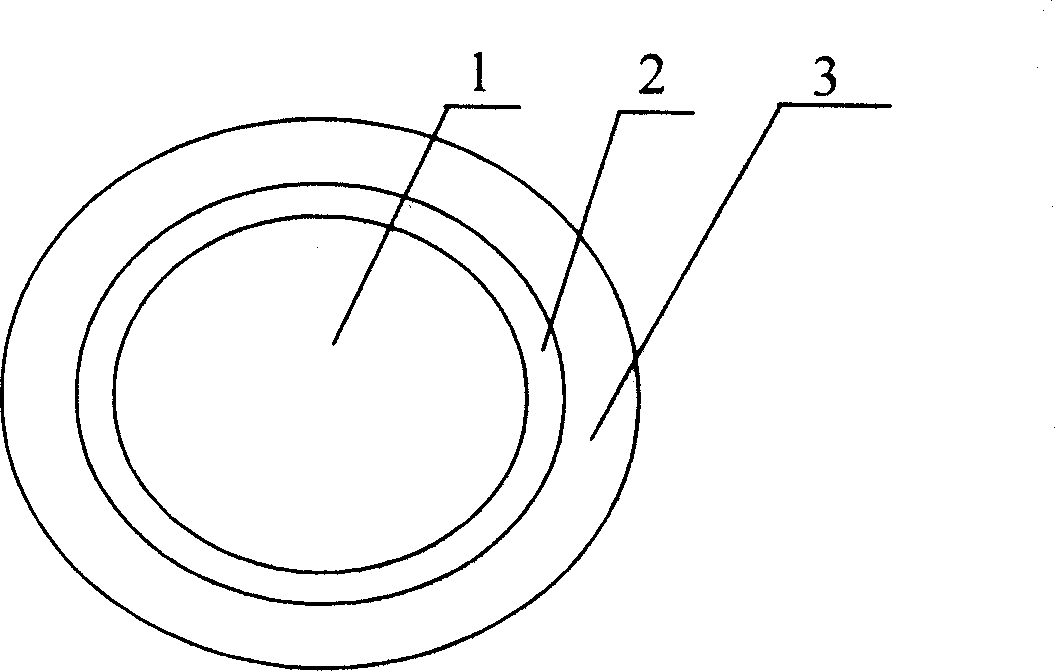

[0027] First, the three kinds of high polymer masterbatches were placed in three single-screw extruders, among which polymethyl methacrylate was used as the core layer material, poly(pentafluoropropyl methacrylate) was used as the reflective layer material, and polyvinylidene fluoride was used as the material for the reflective layer. It is a flexible layer material.

[0028] Connect the discharge port of the above-mentioned single-screw extruder to a circular tube connected to a central circular hole and a 4-layer co-extruded circular tube mold with 4 concentric rings, and then combine the core layer material, the light-reflecting layer material and After the polymer masterbatches of the flexible layer material are heated and melted in their respective extruders (both at 230°C), they pass through the respective extruders through the respective exits of the respective layers of the concentric ring-shaped co-extrusion die to form the core layer Material extruder: reflective lay...

Embodiment 2

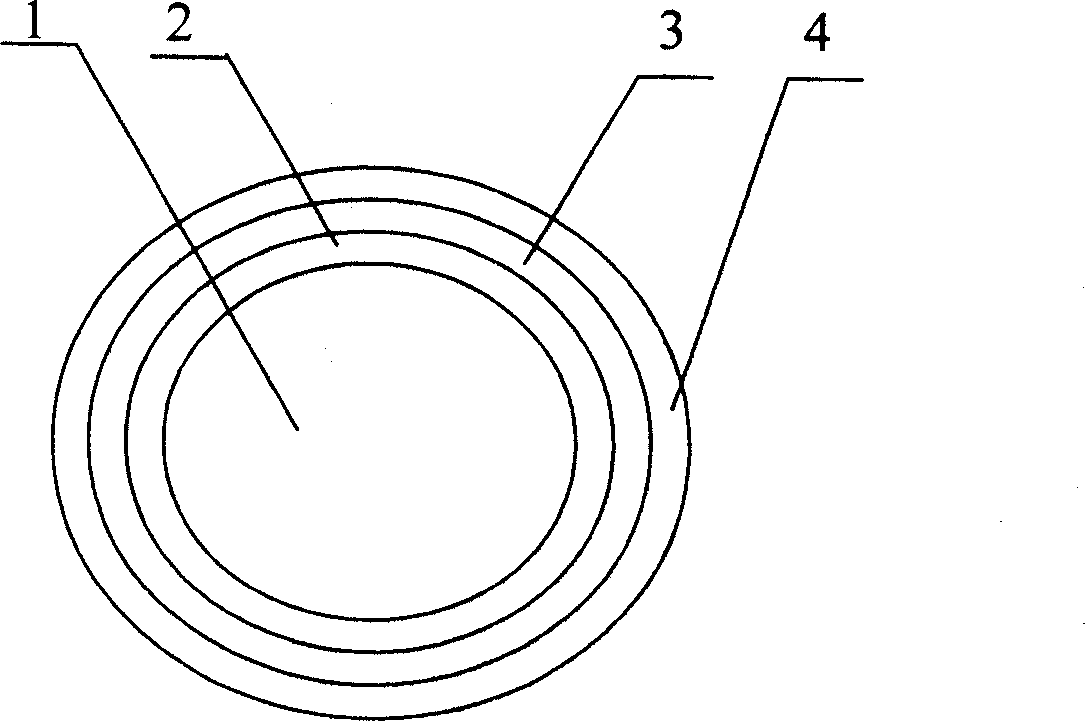

[0030] First, the four kinds of high polymer masterbatches were placed in four single-screw extruders, among which polymethyl methacrylate was used as the core layer material, poly(pentafluoropropyl methacrylate) was used as the reflective layer material, and polyvinylidene fluoride was used as the material for the reflective layer. It is a flexible layer material, and polyvinyl chloride is an outer protective layer material.

[0031]Connect the discharge port of the above-mentioned single-screw extruder to a circular tube connected to a central circular hole and a 4-layer co-extruded circular tube mold with 4 concentric rings, and then core material, reflective layer material, After the polymer masterbatches of the flexible layer material and the protective layer material are heated and melted in their respective extruders, they are extruded with the core layer material through the respective extruders through the respective exits of the respective layers of the concentric rin...

Embodiment 3

[0033] First, the four kinds of high polymer masterbatches were placed in four single-screw extruders, in which polystyrene was used as the core layer material, polymethyl methacrylate was used as the reflective layer material, and polyvinylidene fluoride was used as the flexible layer material. PVC is the outer protective layer.

[0034] Connect the discharge port of the above-mentioned single-screw extruder to a circular tube connected to a central circular hole and a 4-layer co-extruded circular tube mold with 4 concentric rings, and then core material, reflective layer material, After the polymer masterbatches of the flexible layer material and the protective layer material are heated and melted in their respective extruders, they are extruded with the core layer material through the respective extruders through the respective exits of the respective layers of the concentric ring-shaped co-extrusion die. Extruder: reflective layer material extruder: flexible layer material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com