Carbon fiber-reinforced plastic steel reinforced-steel tube concrete combination column

A technology of steel pipe concrete and reinforced plastics, which is applied in the direction of columns, pier columns, pillars, etc., can solve the problems that cannot be destroyed at the same time, the hoop ratio of the boundary volume is large, and it is difficult to realize, so as to achieve the effect of improving bearing capacity and ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below with reference to the drawings.

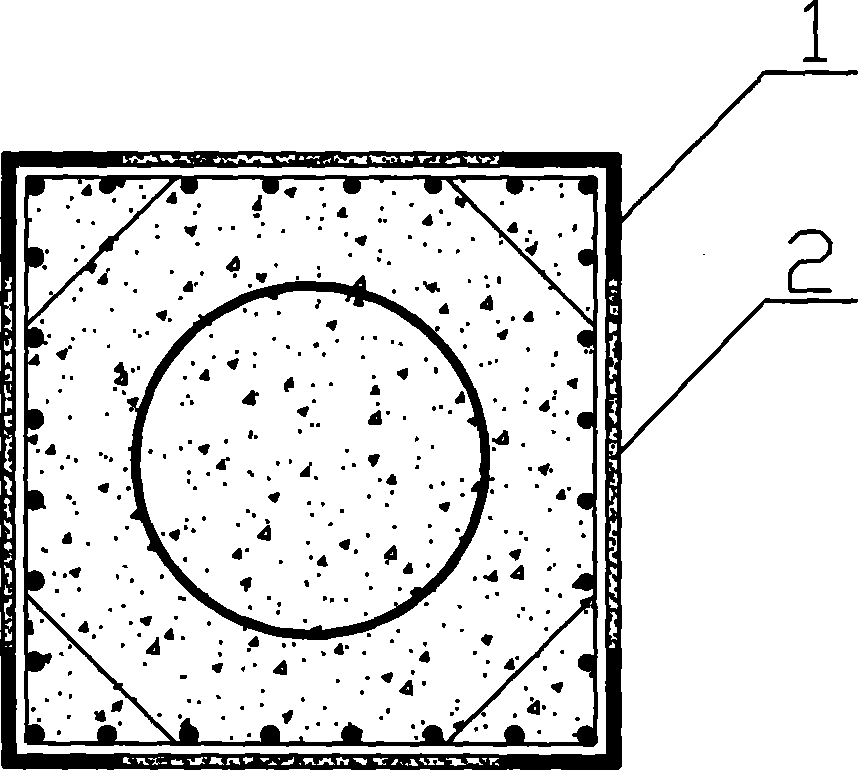

[0017] As shown in the figure, the carbon fiber reinforced plastic steel-concrete steel tube composite column of the present invention includes three parts: carbon fiber reinforced plastic fiber fabric 2, steel frame 1, and steel tube concrete core column. Among them, the concrete-filled steel tube core column includes a round steel tube and its inner and outer concrete. The steel frame 1 is located at the four corners of the steel tube concrete core column, the carbon fiber reinforced plastic fiber fabric 2 is located on the outside of the steel frame, and the carbon fiber reinforced plastic is integrated with the steel frame and the steel tube concrete core column by pasting. The steel frame can be an angle steel or welded by steel plates; the fiber fabric used in the carbon fiber reinforced plastic fiber fabric 2 can be unidirectional or bidirectional, and the angle between the fibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com