Plastic supports with shear walls and steel bar positioning

A technology for plastic brackets and shear walls, applied in the direction of walls, structural elements, building components, etc., can solve the problem that the thickness of the protective layer of steel bars in shear walls is difficult to ensure, cannot accommodate steel bars of various diameters, and sand paddle blocks are easily broken and falling off, to achieve the effect of fixing without exposure, good elasticity, and improving installation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

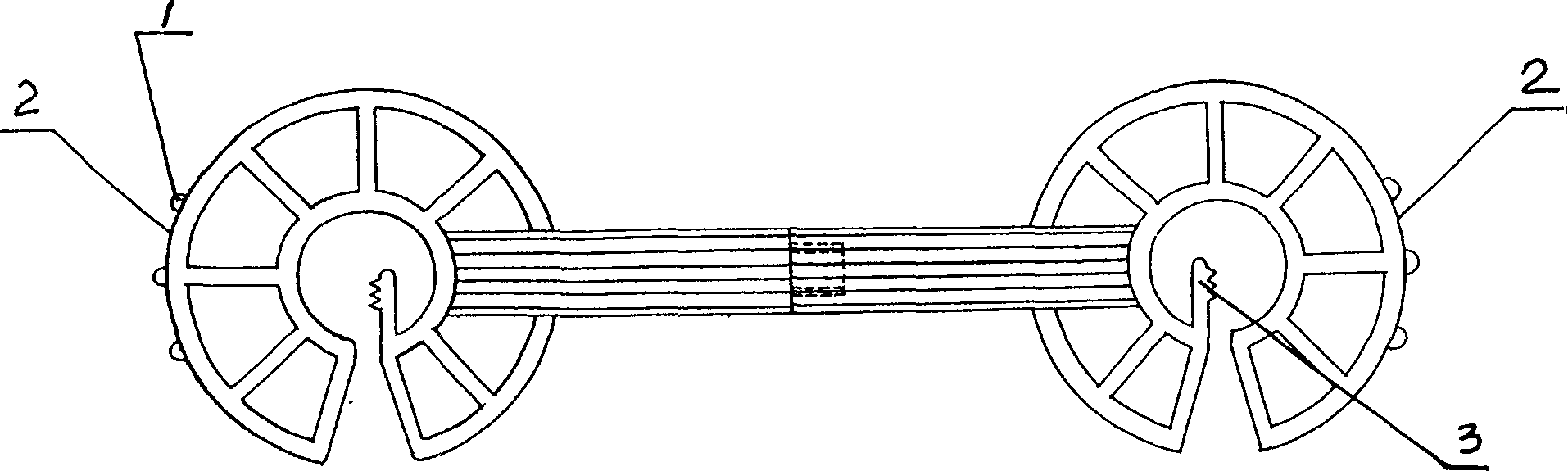

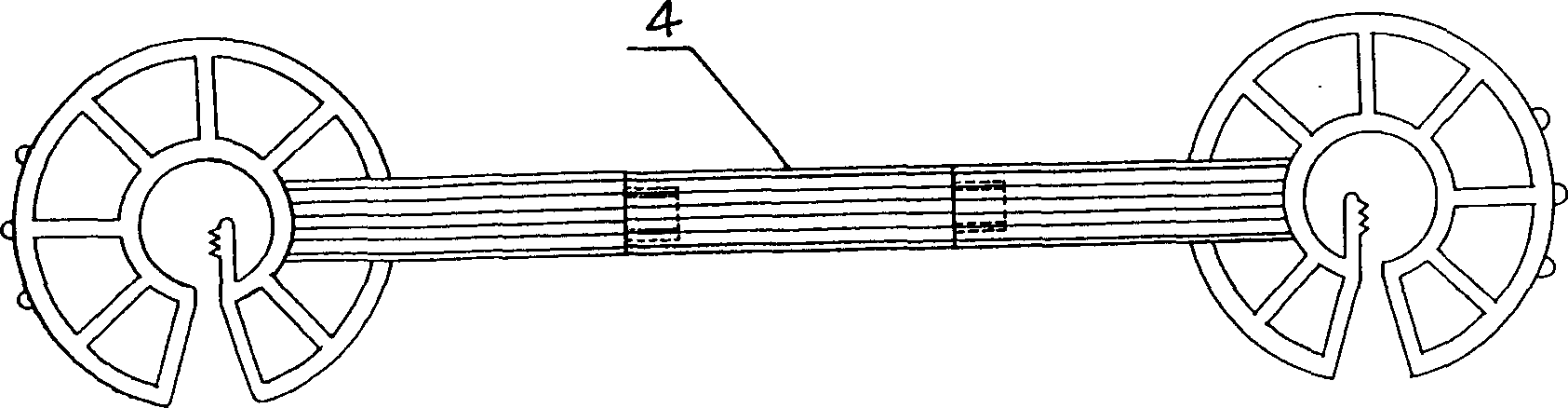

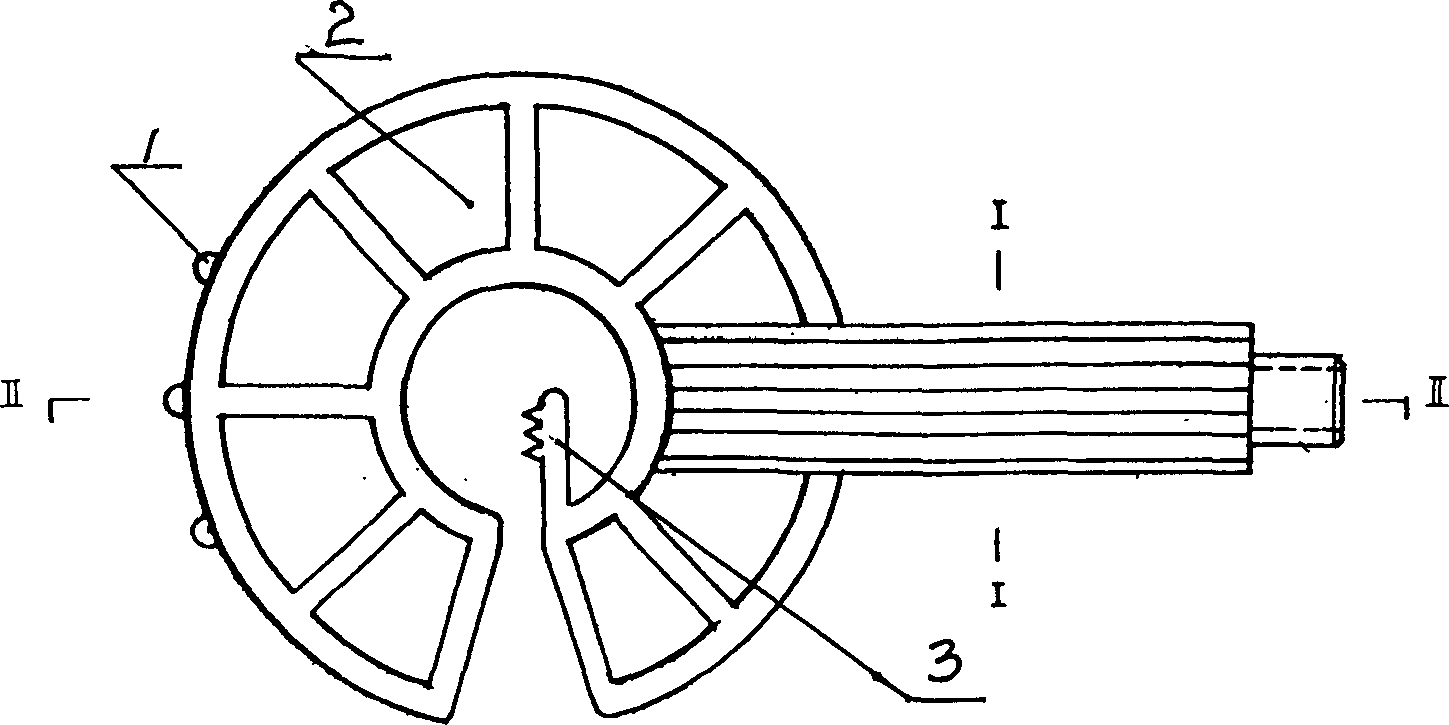

[0017] According to the accompanying drawings, the embodiment is further described. The plastic bracket for positioning the steel bars in the shear wall is made of engineering plastics. The left and right two groups of steel bar positioning members 2 are threaded connections, and the extension rods 4 can be made into different lengths of 50mm and 100mm. The length of the bracket is determined according to the thickness of the shear wall. The wheeled structure of the reinforcing bar positioning member 2 is provided with an elastic bayonet, and an elastic card 3 is arranged in the bayonet, and a groove is provided on the outer surface of the straight rod part. The outer side of the wheel rim of the wheel structure of the steel bar positioning member 2 is provided with three convex points 1 . When in use, after the double rows of steel bars in the shear wall are bound, choose a plastic frame of appropriate length, perpendicular to the double rows of steel bars, and just clamp the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com