Technical cubic foam block cutting machine

A foam block and cutting machine technology, which is applied in metal processing and other directions, can solve the problems of inability to carry out mass production, irregular cubic foam blocks, and large manual operation errors, so as to achieve fewer opportunities for manual contact with machinery, neat cuts, and improved production. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

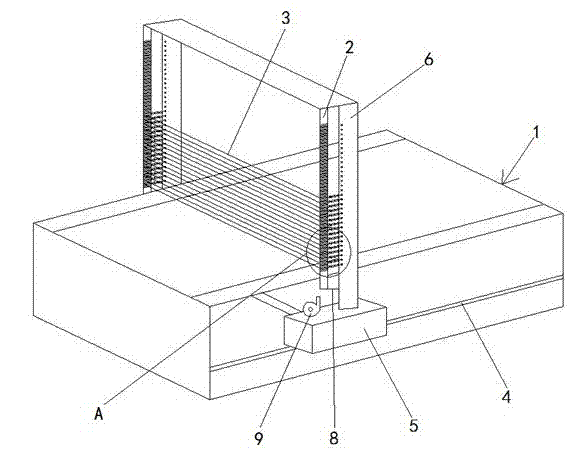

[0019] Such as figure 1 As shown, the present invention includes a frame 1, a heating rod 2 and a heating wire 3. The heating rod 2 is vertically arranged on both sides of the frame 1, and the heating wire 3 is fastened between the heating rods 2. The two sides of the frame 1 are provided with There is a guide rail 4, and the guide rail 4 is equipped with a sliding seat 5 moving along the direction of the guide rail 4, and the electric heating rod 2 is vertically fixed on the sliding seat 5.

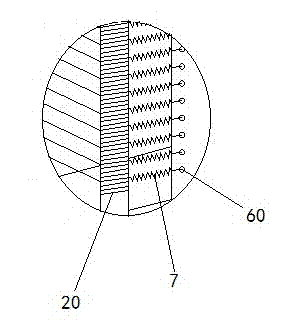

[0020] Equidistant limiting grooves 20 are provided on the heating rod 2 , and both ends of the heating wire 3 are located in the limiting grooves 20 .

[0021] The limit slot 20 can be used to identify and measure the distance between the heating wires 3 , and can also be used to prevent the heating wire 3 from sliding on the heating rod 2 .

[0022] Next to the electric heating rod 2, tightening screw rods 6 are arranged side by side, and connecting holes 60 are equally arranged on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com