Integrated type modularization comprehensive deodorization device

A modular and integrated technology, applied in the fields of deodorization, gasification substances, chemical instruments and methods, etc., can solve the problems of very different physical and chemical properties, single processing technology, poor deodorization effect of odorous gas, etc. High deodorization efficiency, lower investment and operating costs, easy maintenance and rapid results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

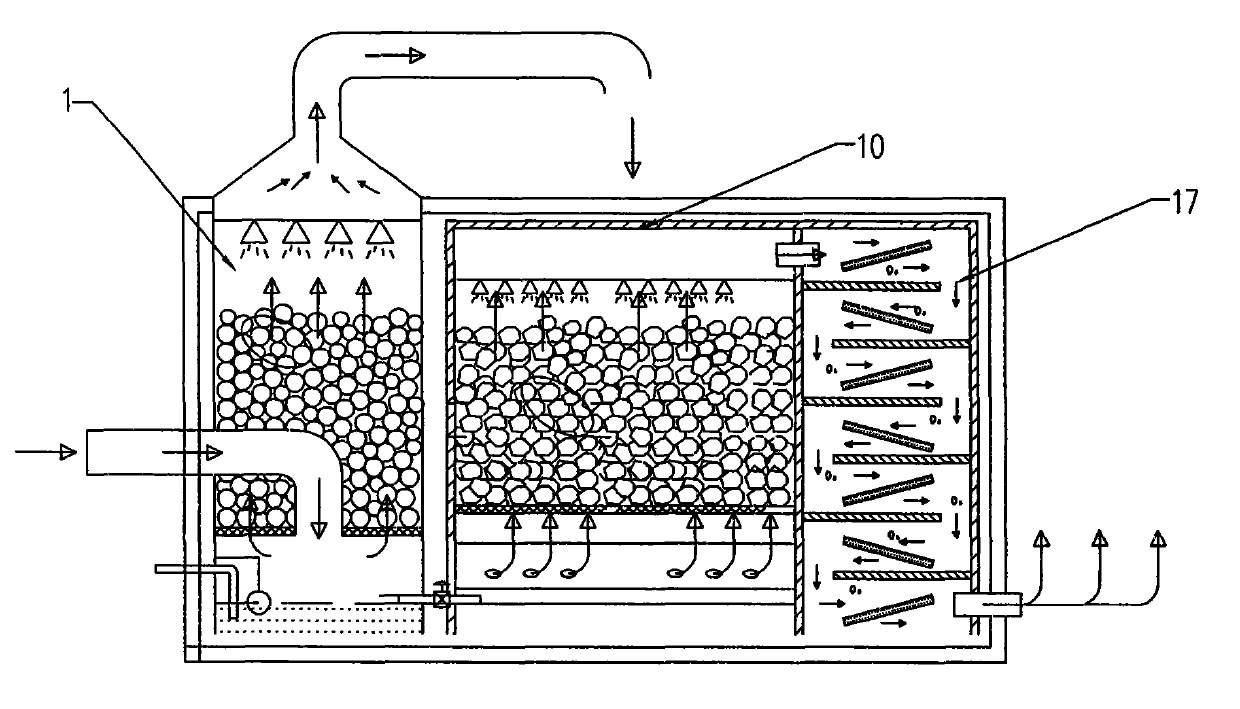

[0031] The integrated combination of this embodiment is as figure 2As shown, this embodiment is composed of water film filtration and absorption treatment chamber 1+2x biofilm degradation treatment chamber 10+ozone oxidation treatment chamber 17. The three processing chambers are integrated and combined in one frame. This embodiment rack size and figure 1 Identical, the size of the water membrane filtration absorption treatment chamber 1 and the ozone oxidation treatment chamber 17 is also the same as figure 1 Same, all adopt the standard size, but the length of the biofilm degradation treatment chamber 10 is expanded to twice the original size, so the processing capacity of the biofilm degradation treatment chamber 10 is also multiplied.

Embodiment 2

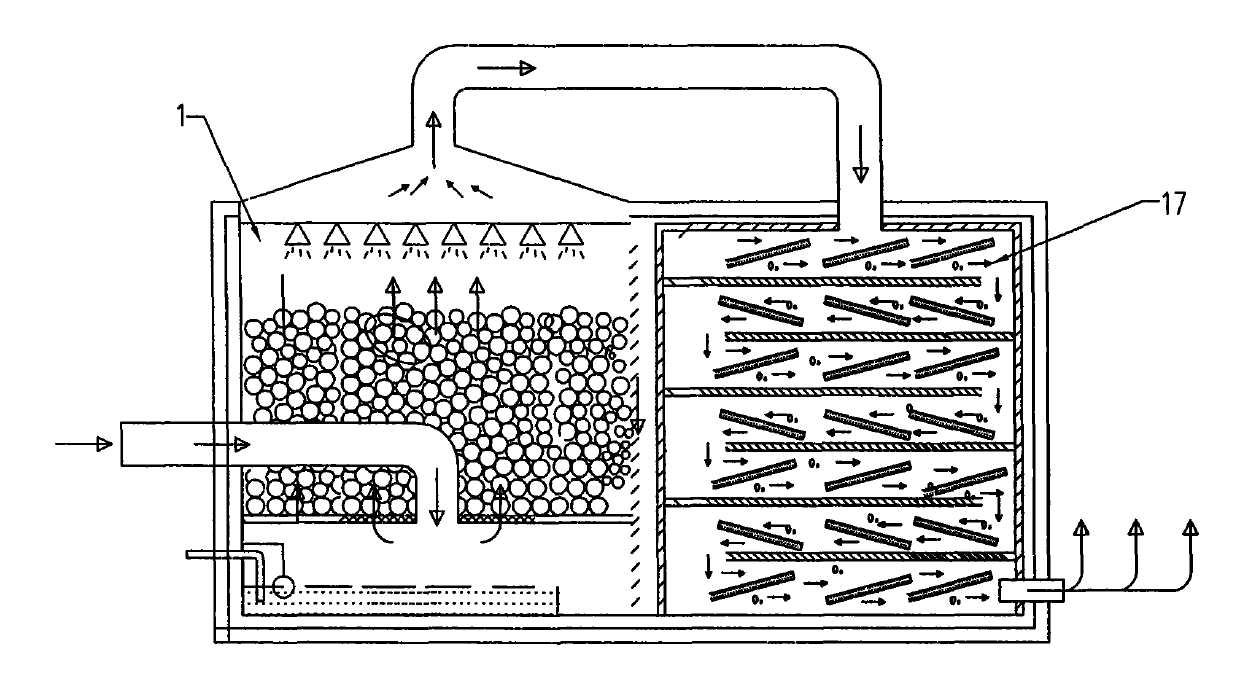

[0033] The integrated combination of this embodiment is as image 3 As shown, this embodiment is composed of 2x water film filtration absorption treatment chamber 1 and 2x ozone oxidation treatment chamber 17. The two treatment chambers are integrated and combined in one frame. The frame size of this embodiment is the same as figure 1 Similarly, the lengths of the water membrane filtration and absorption treatment chamber 1 and the ozone oxidation treatment chamber 17 are doubled, so the processing capacities of the water membrane filtration and absorption treatment chamber 1 and the ozone oxidation treatment chamber 17 are also multiplied.

Embodiment 3

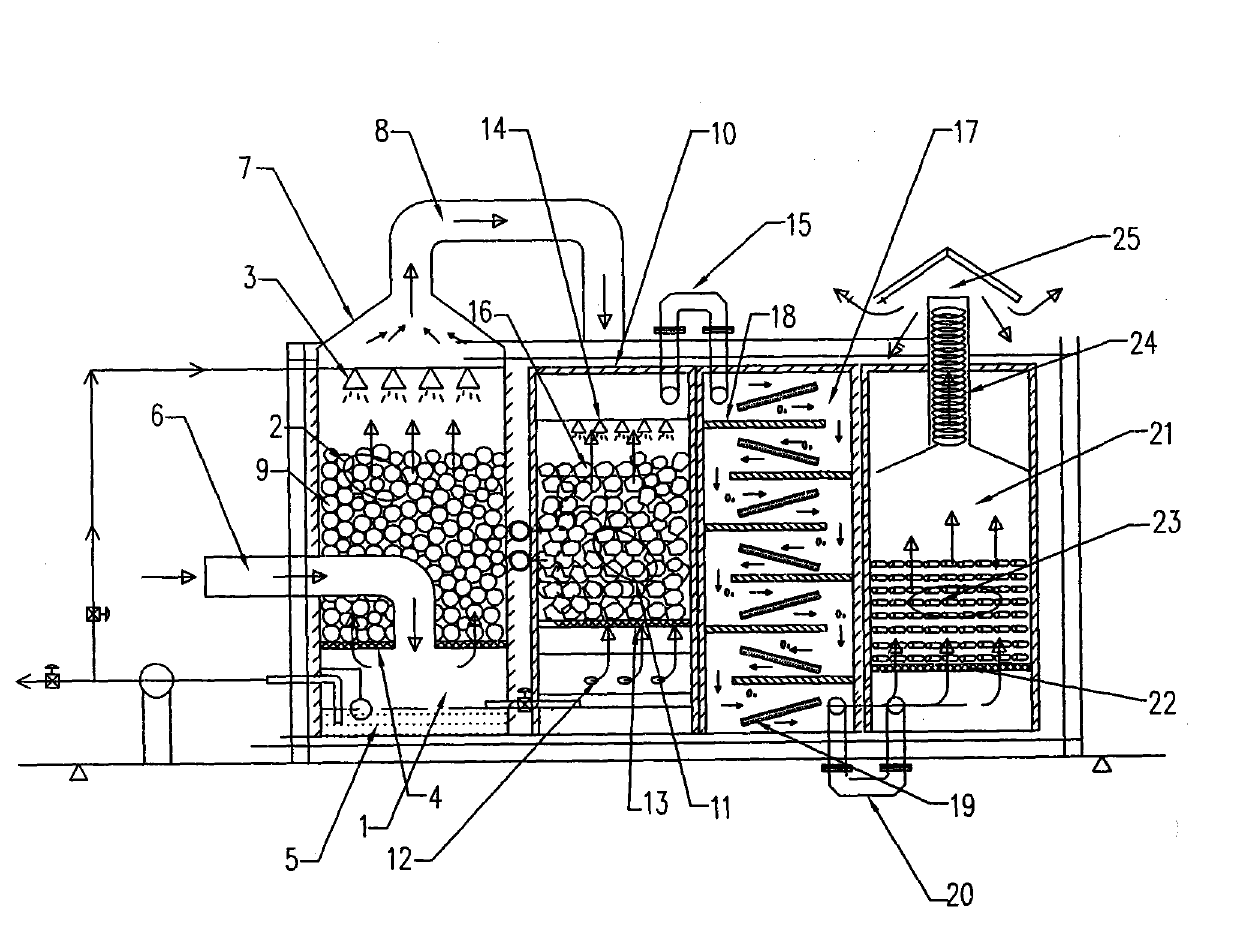

[0035] The integrated combination of this embodiment is as Figure 4 As shown, it is a vertically integrated integrated modularized comprehensive deodorization device, which is composed of a water film filtration absorption treatment cabin 1, a biofilm degradation treatment cabin 10, an ozone oxidation treatment cabin 17 and a natural material adsorption filtration treatment cabin 21 , the water film filtration and absorption processing chamber 1, the biofilm degradation processing chamber 10, the ozone oxidation processing chamber 17 and the natural material adsorption and filtration processing chamber 21 are all separately installed in a standard-sized frame, and are arranged in a vertical structure. The type occupies a small area and has a high space height.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com