Combined treatment technology for biochemical odors

A technology for treating odors, applied in air quality improvement, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of low purification efficiency of odorous exhaust gas and changes in ambient temperature, and achieve low operating costs, simple and convenient maintenance and management. , powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

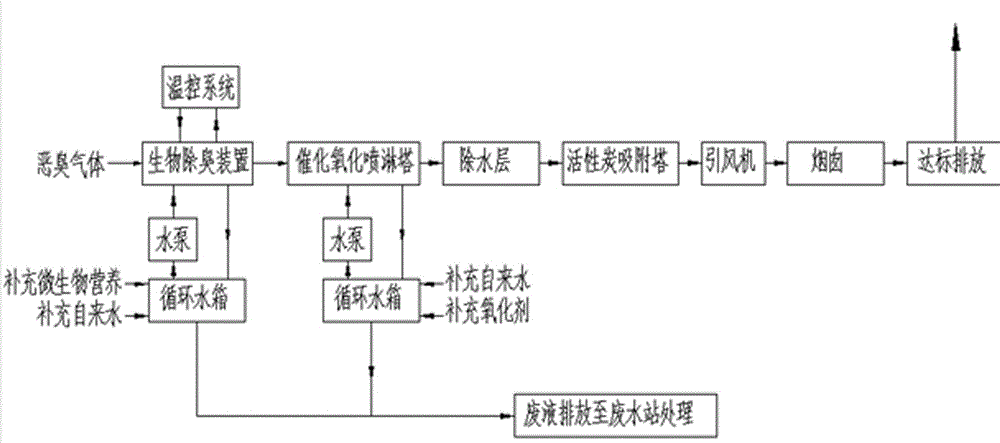

[0047] see Figure 1-Figure 4 , a biochemical odor combined treatment process, comprising the steps of:

[0048] (1) Biological deodorization;

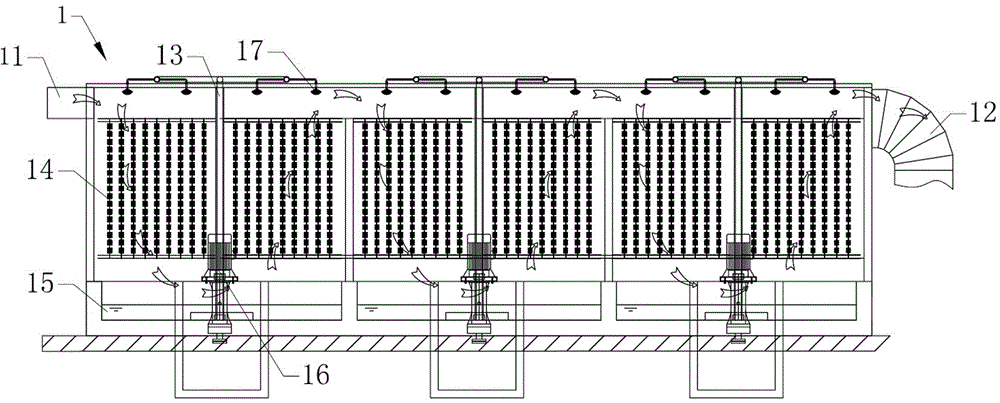

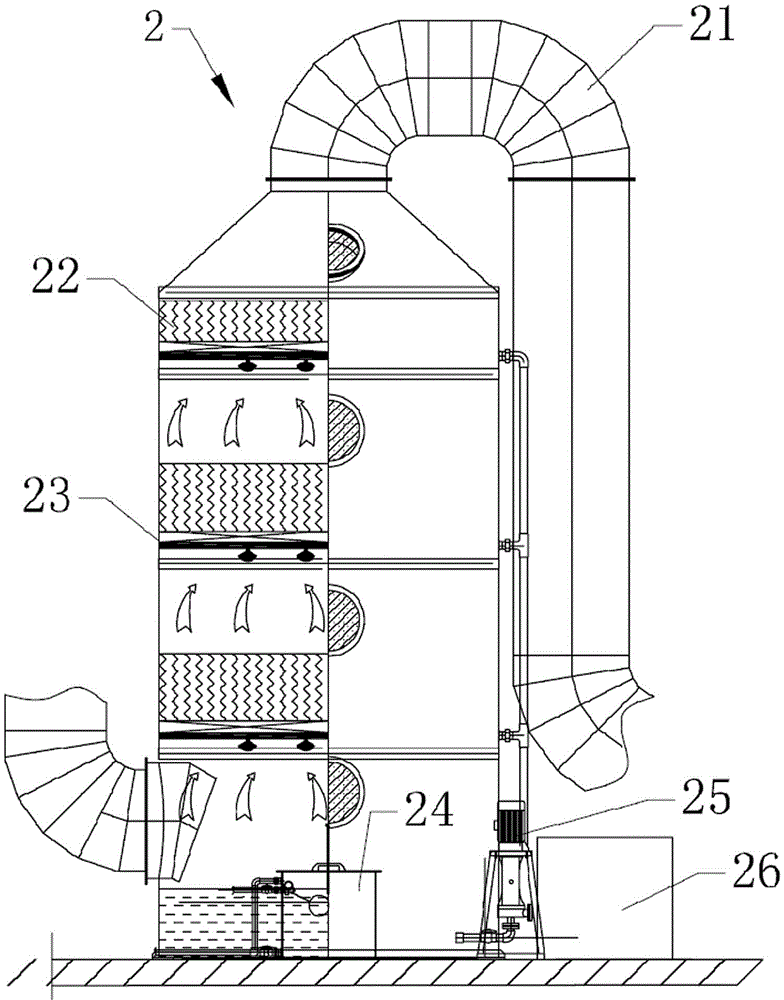

[0049] Pass the malodorous gas through the biological deodorization equipment (control the air intake to 6m 3 / h, and the residence time in the biological deodorization equipment is controlled at 15s), the biological deodorization equipment is equipped with a combined filler, and microorganisms are attached to the inert filler, and the temperature is kept at 16°C for biological decomposition; the biological deodorization The front end of the equipment is equipped with an air inlet, and the rear end is equipped with an air outlet, and the interior of the biological deodorization equipment is equipped with baffles arranged in a staggered manner up and down, and the baffles form a circuitous airflow inside the biological deodorization equipment. channel, the airflow channel is filled with combined packing, the lower part of the biologi...

Embodiment 2

[0057] A biochemical odor combined treatment process, comprising the steps of:

[0058] (1) Biological deodorization;

[0059] Pass the malodorous gas through the biological deodorization equipment (control the air intake to 10m 3 / h, the residence time in the biological deodorization equipment is controlled at 25s), the biological deodorization equipment is equipped with combined packing, and microorganisms are attached to the inert packing, and the temperature is kept at 30°C for biological decomposition;

[0060] (2) catalytic oxidation;

[0061] Pass the gas in step (1) into the catalytic oxidation spray tower, and continuously replenish the strong oxidant into the spray water;

[0062] (3) Adsorption;

[0063] The wastewater after catalytic oxidation passes through the corrugated plate water removal layer, and then enters the activated carbon adsorption tower for adsorption;

[0064] (4) emissions;

[0065] The exhaust gas after adsorption enters the exhaust chimney fo...

Embodiment 3

[0067] A biochemical odor combined treatment process, comprising the steps of:

[0068] (1) Biological deodorization;

[0069] Pass the malodorous gas through the biological deodorization equipment (control the air intake to 8m 3 / h, the residence time in the biological deodorization equipment is controlled at 20s), the biological deodorization equipment is equipped with a combined filler, and microorganisms are attached to the inert filler, and the temperature is kept at 25°C for biological decomposition;

[0070] (2) catalytic oxidation;

[0071] Pass the gas in step (1) into the catalytic oxidation spray tower, and continuously replenish the strong oxidant into the spray water;

[0072] (3) Adsorption;

[0073] The wastewater after catalytic oxidation passes through the corrugated plate water removal layer, and then enters the activated carbon adsorption tower for adsorption;

[0074] (4) emissions;

[0075] The exhaust gas after adsorption enters the exhaust chimney f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com