Five-station automatic rotary machine tool and part machining method applying same

An automatic rotation, five-station technology, used in metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of insufficient connection time before and after the four processing procedures, delayed processing time, and difficult product size deviation. , to achieve the effect of saving labor costs, high product processing efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The specific implementation of the five-station automatic rotary machine tool and the part processing method using the five-station automatic rotary machine tool of the present invention will be described in detail below in conjunction with the accompanying drawings.

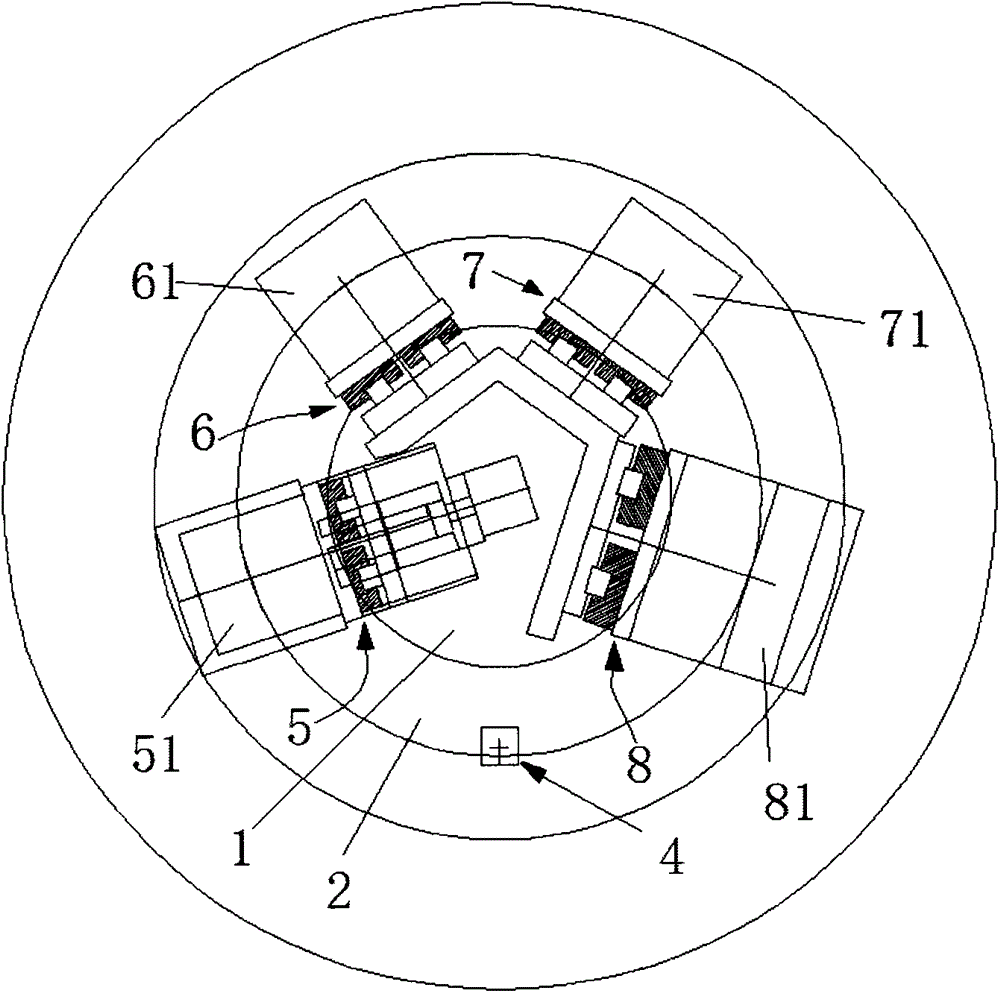

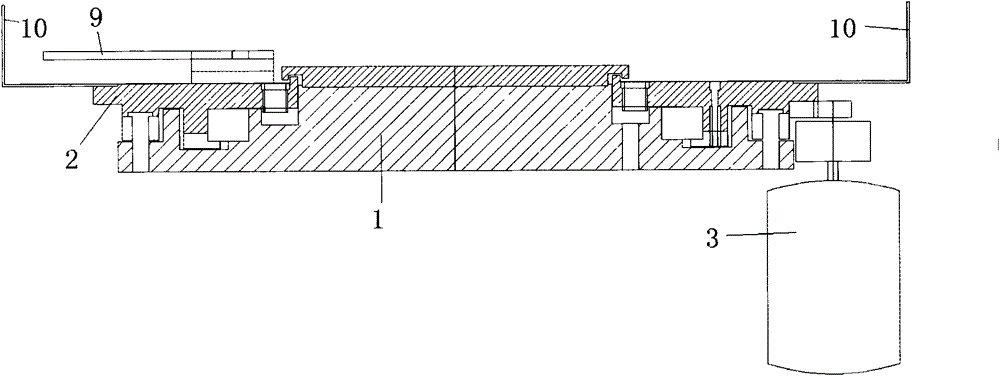

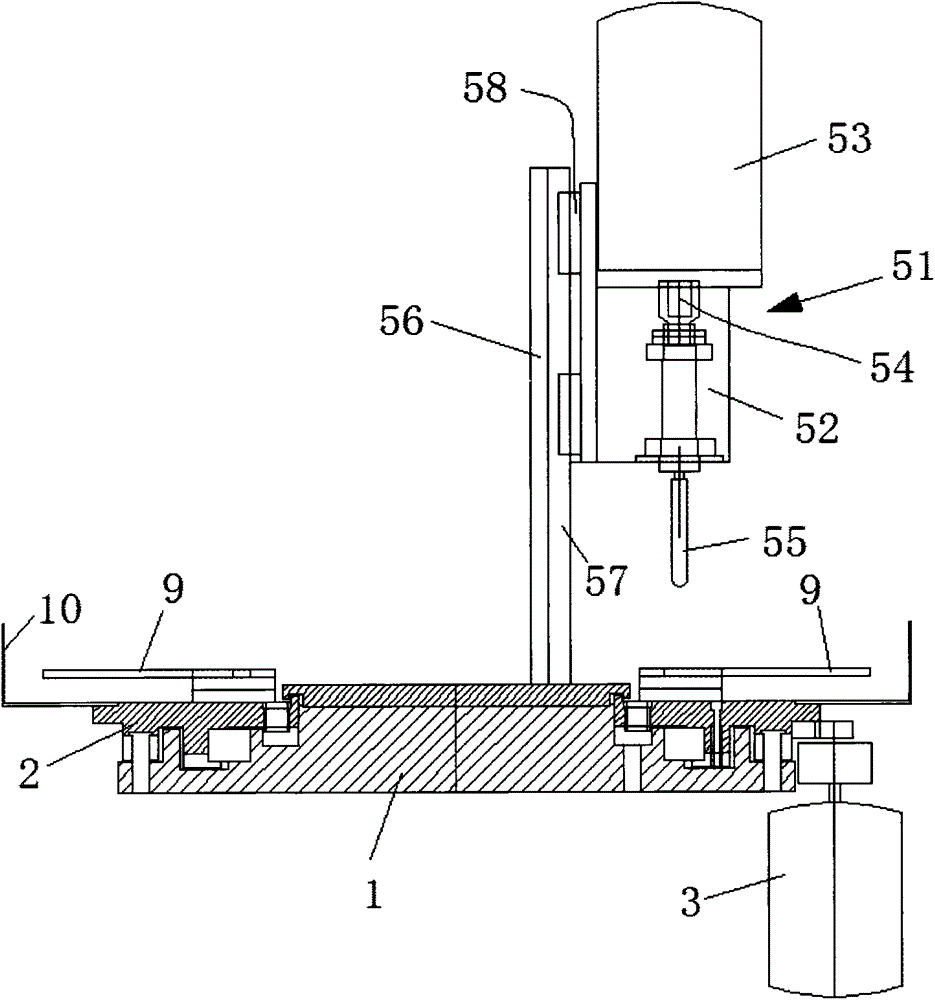

[0058] See attached figure 1 , 2, the table 1 of the five-station automatic rotary machine tool is circular, and five toolings are installed on the rotary table 1, the rotary table 2 is rotatably arranged on the table 1 through the bearing, and the rotary table 2 is driven by the motor 3, Five part positioning positions are set on the rotary table 2, and five work station positions are arranged on the outside of the rotary work table 2, and the five part positioning positions correspond to the five work station positions respectively. The five stations are clamping station 4, punching station 5, rough boring station 6, fine boring station 7 and moon groove station 8, and tooling station 4 is used to clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com