Opening closing mould of pressure equalizing barrel

A technology for pressing cylinders and moulds, which is applied to the field of inner flanging and closing moulds in the cylinder mouth, can solve the problems of rough appearance, high cost and low efficiency of spinning moulds, and achieve the effects of smooth appearance, low cost and accurate size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

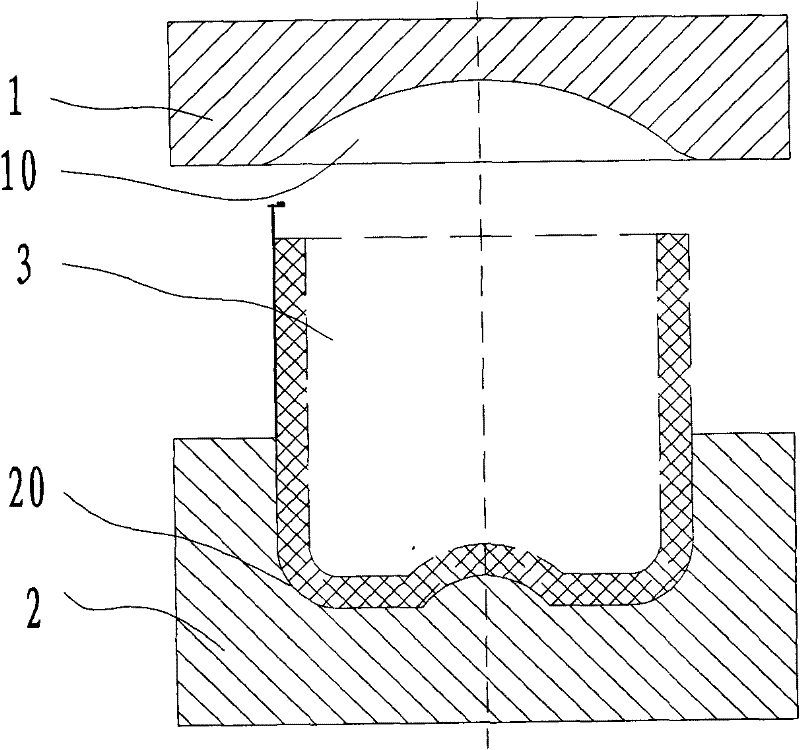

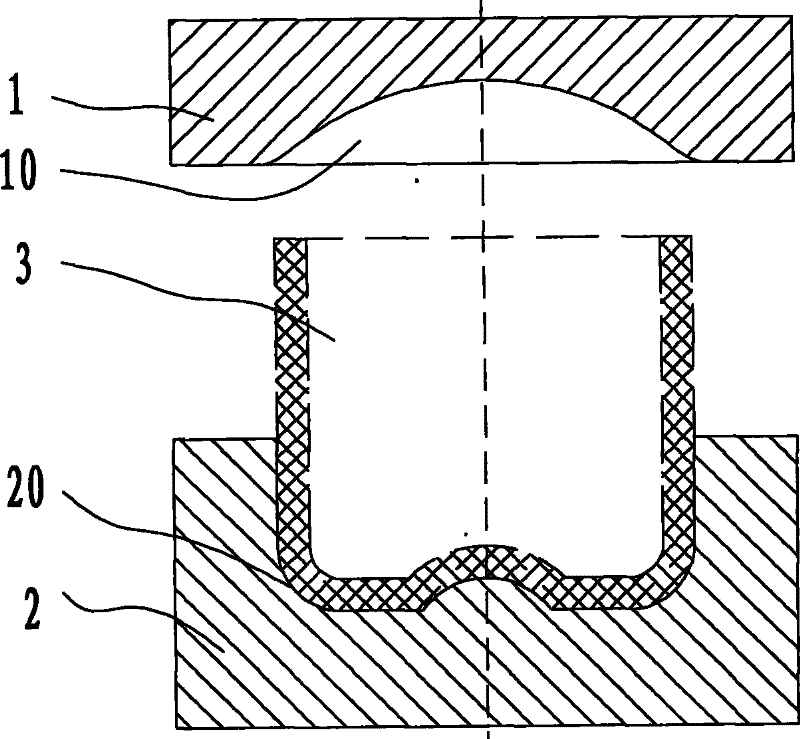

[0011] The present invention as figure 1 As shown, it includes an upper mold 1 and a lower mold 2, the lower mold 2 has a mold cavity 20 consistent with the surface contour of the lower part of the pressure equalizing cylinder 3, and the bottom surface of the upper mold 1 is provided with a spherical crown groove 10 , and the maximum diameter of the notch of the spherical crown groove 10 is greater than the diameter of the mouth of the pressure equalizing cylinder 3 .

[0012] The ratio of the radius of the pressure equalizing cylinder 3 to the radius of the spherical crown of the spherical groove 10 is 1:1.3-1.5.

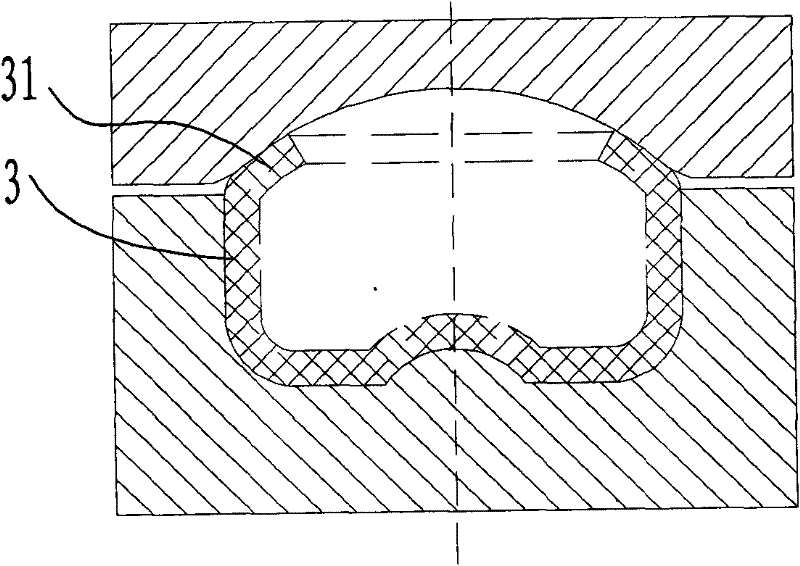

[0013] The use state of the present invention is as figure 2 As shown, the feeding port of the upper mold 1 uses the curved surface of the spherical crown-shaped groove 10 to shrink the mouth of the pressure equalizing cylinder 3 to form a closing structure 31 finally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com