Sintered decorative brick of dry wall and manufacturing method thereof

A manufacturing method and technology of decorative bricks, applied in the direction of manufacturing tools, cement mixing devices, chemical instruments and methods, etc., can solve the problems of no surface decoration function, low density of decorative bricks, and imprecise raw material processing, etc., to achieve elegant appearance Beautiful, good economic and social benefits, high compactness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] This embodiment is made of the following raw materials in mass percentage: 60% of shale, 30% of fly ash, 10% of metallurgical tailings or reservoir sludge; One of tailings and bauxite tailings; the additive is one of chromium powder, manganese powder, cobalt powder and iron powder.

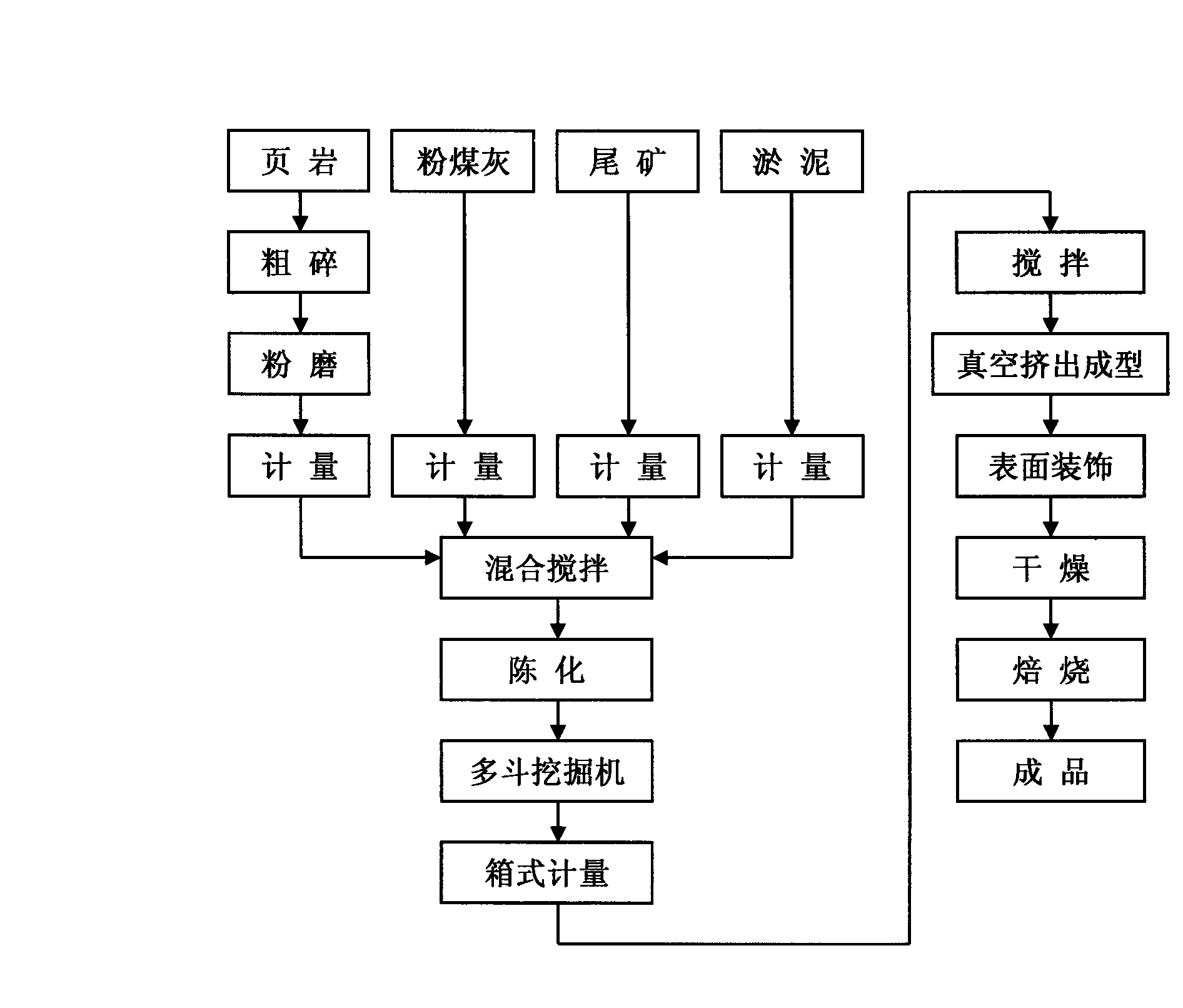

[0022] Such as figure 1 Shown, the manufacturing method of the present embodiment is:

[0023] (1) After the massive shale is roughly crushed, it is sent to the pulverizer by the belt conveyor for grinding, and the fineness after grinding is ≤1mm;

[0024] (2) Add fly ash, metallurgical tailings or reservoir sludge and admixtures to the shale with a grinding fineness of ≤1 mm according to the mass percentage, and then send it to a twin-shaft mixer and add water to stir. The mass of the pre-added mixture is 18% to 20%. The water is then sent to the aging warehouse through the belt conveyor for aging;

[0025] (3) After aging for 72 hours, it is sent into a high vacuum extruder through a m...

Embodiment 2

[0028] This embodiment is made of the following raw materials in mass percentage: shale 80%, fly ash 8%, metallurgical tailings or reservoir sludge 10%, admixture 2%; the metallurgical tailings are ore gold tailings, lead One of zinc tailings, iron tailings and bauxite tailings; the additive is one of chromium powder, manganese powder, cobalt powder and iron powder.

[0029] The manufacturing method of this embodiment is the same as that of Embodiment 1.

Embodiment 3

[0031] This embodiment is made of the following raw materials in mass percentage: 25% of shale, 11% of fly ash, 60% of metallurgical tailings or reservoir sludge, and 4% of admixture; the metallurgical tailings are mine gold tailings, lead One of zinc tailings, iron tailings and bauxite tailings; the additive is one of chromium powder, manganese powder, cobalt powder and iron powder.

[0032] The manufacturing method of this embodiment is the same as that of Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com