Low-energy-consumption energy-saving building system

A low energy consumption and architectural technology, applied in the direction of buildings, building components, building structures, etc., can solve problems such as long-term durability instability, foundation subsidence, fire hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

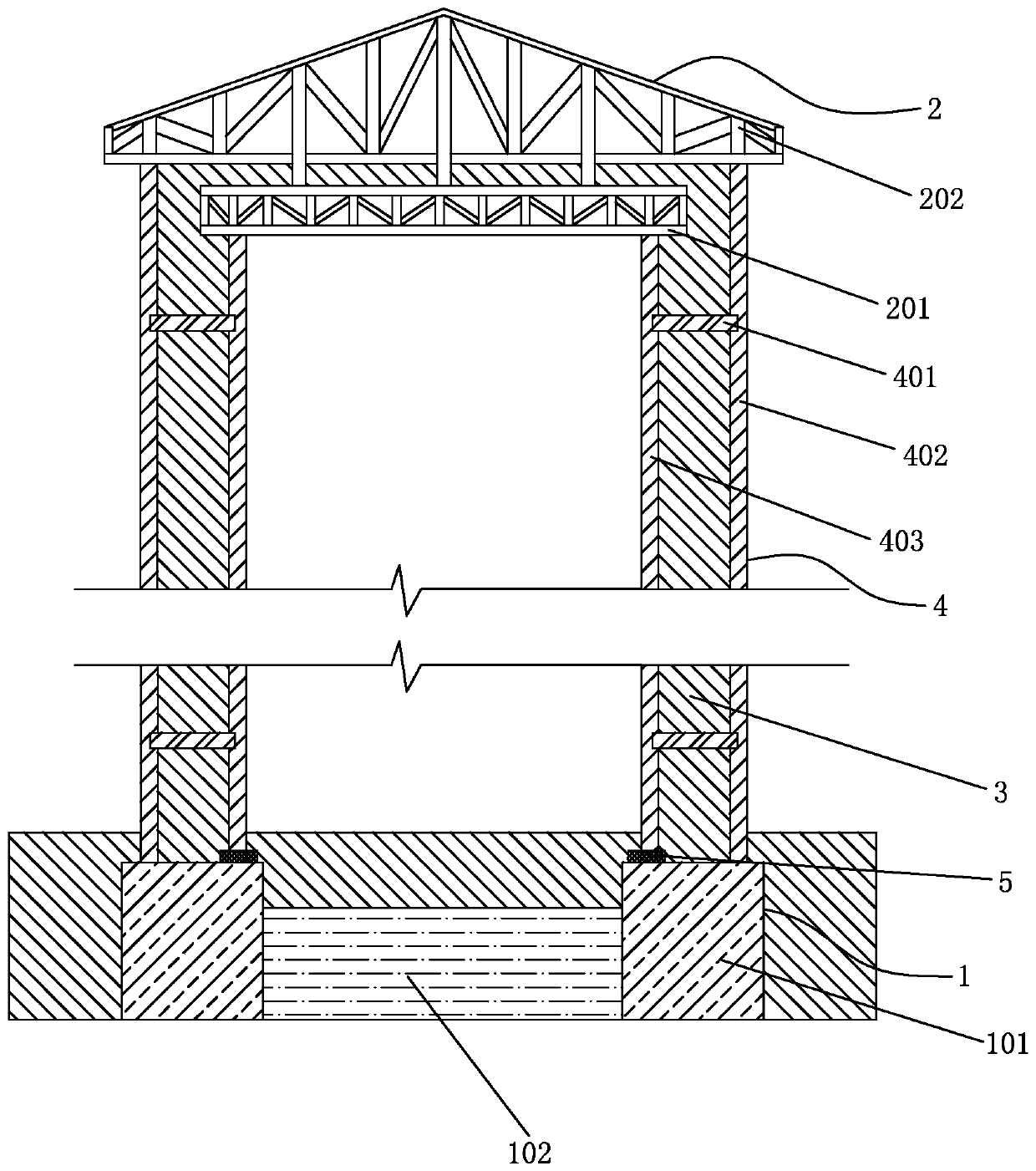

[0033] Embodiment 1 of the present invention provides a low-energy and energy-saving building system, such as figure 1 As shown, it includes a foundation 1, a maintenance wall and a roof system 2. The foundation 1 includes a geosphere beam 101, the inner end surface of the geosphere beam 101 is provided with a backfill soil layer 102, and the outer end surface of the geosphere beam 101 is And the top of the backfill soil layer 102 is poured with porous silicate thermal insulation material 3;

[0034] The maintenance wall includes an outer wall 4 arranged on the geosphere beam 101, the outer wall 4 includes an outer support body 402 and an inner support body 403 connected by a heat insulating connector 401, the outer support body 402 and the inner support body 403 Porous silicate thermal insulation material 3 is poured between the inner supports 403, the lower ends of the outer supports and the lower ends of the inner supports 403 are both arranged on the geosphere beam 101, an...

Embodiment 2

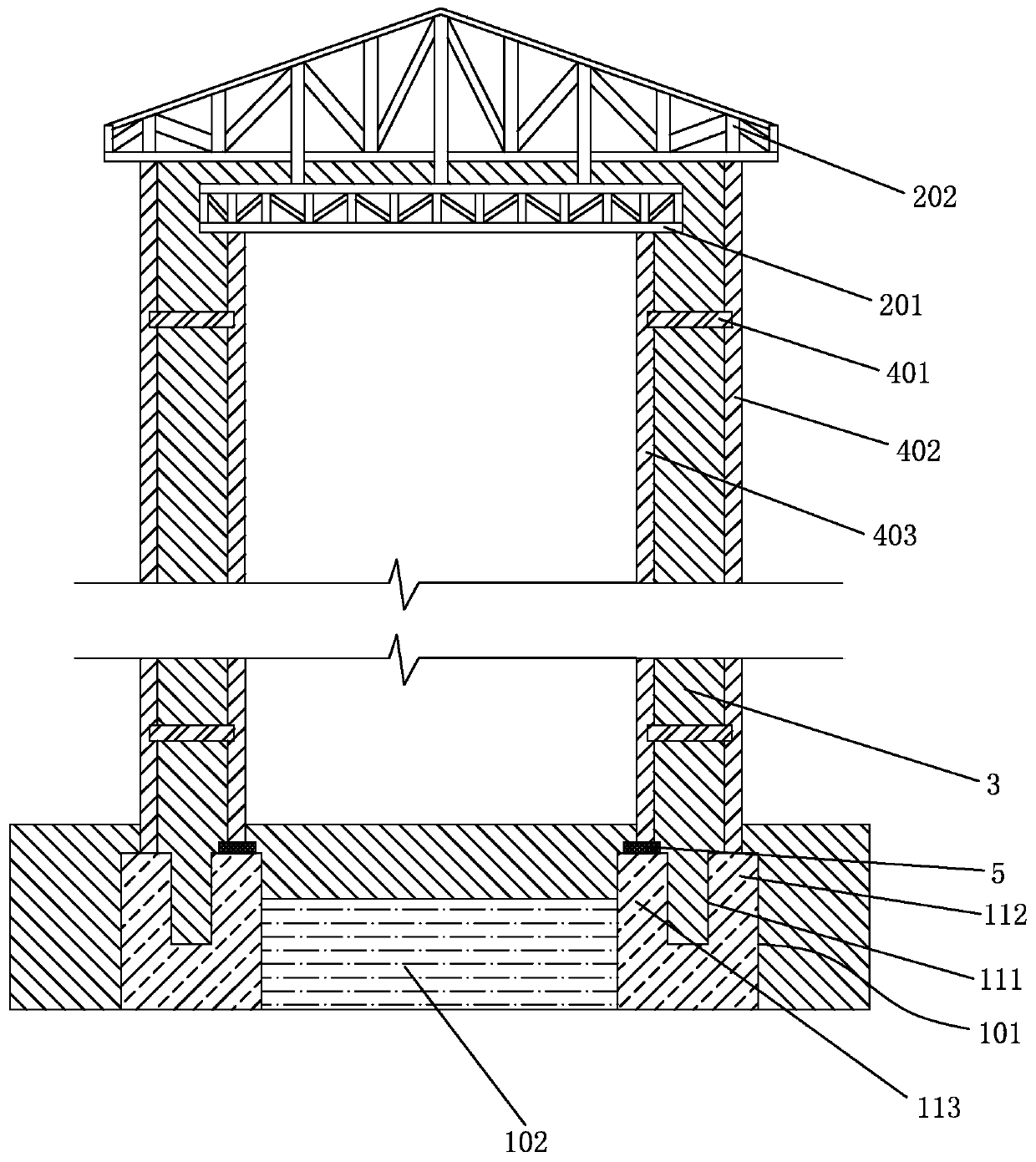

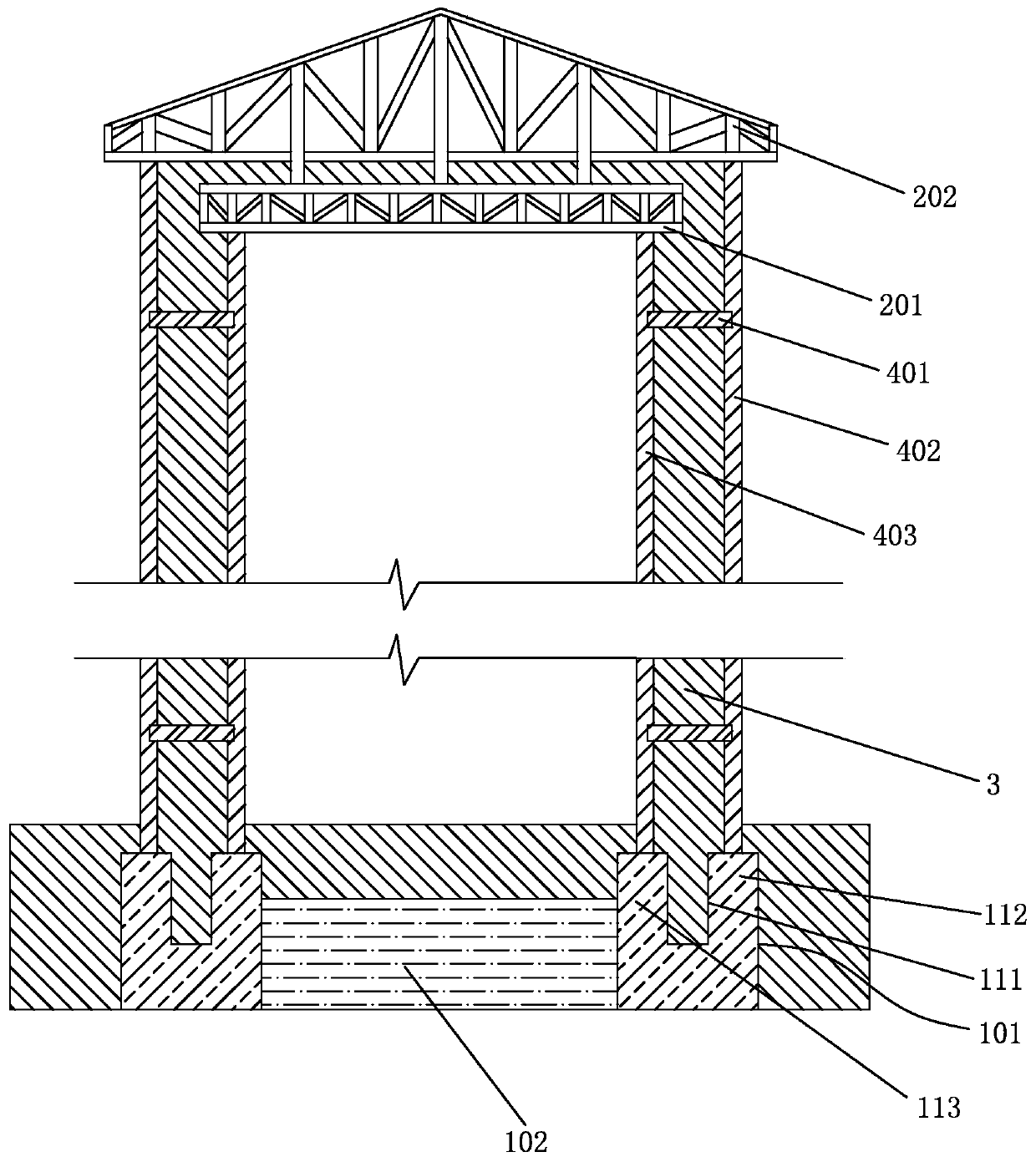

[0045] The low-energy and energy-saving building system provided by Embodiment 2 of the present invention is basically the same as Embodiment 1, the difference is that, as shown in figure 2 , 3 As shown, the upper part of the geosphere beam 101 is divided into an outer support ring beam 112 and an inner support ring beam 113 by a groove 111, and a porous silicate heat insulating material 3 is poured in the groove 111, and the The lower end of the outer supporting body is arranged on the outer supporting ring beam 112 , and the lower end of the inner supporting body 403 is arranged on the inner supporting ring beam 113 .

[0046] The building foundation ring beam can be divided into inner and outer independent rings. The inner support ring beam and the outer support ring beam support the inner support body of the outer wall and the outer support body of the outer wall respectively, and the same porous silicate insulation material can be filled in the middle , the depth is abo...

Embodiment 3

[0048] The low energy consumption and energy-saving building system provided by Embodiment 3 of the present invention is basically the same as Embodiment 1, the difference is that, as Figure 4 As shown, the two ends of the roof truss 201 respectively extend to both sides and are arranged between the outer support body 402 and the inner support body 403 .

[0049] In this embodiment, the part of the roof truss 201 disposed between the outer support body and the inner support body 403 is provided with pouring baffles 6 all around. If the space surrounded by the thickness of the floor slab or roof slab formed by multiple trusses does not need to be filled with surrounding materials and is a cavity structure, it is necessary to install a The baffle shall be poured with ring insulation material to prevent the slurry from entering the cavity of the truss when the exterior wall is poured.

[0050] In the present invention, the roof truss only extends to the position between the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com