Water mist nozzle with combination of direct-spray atomizing nozzle and cyclone atomizing nozzles

A technology of swirling atomizing nozzles and fine water mist, which is applied in fire rescue and other directions, and can solve the problems of large atomization distance and unsuitable application places where the distance between the protective object and the nozzle is relatively close

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

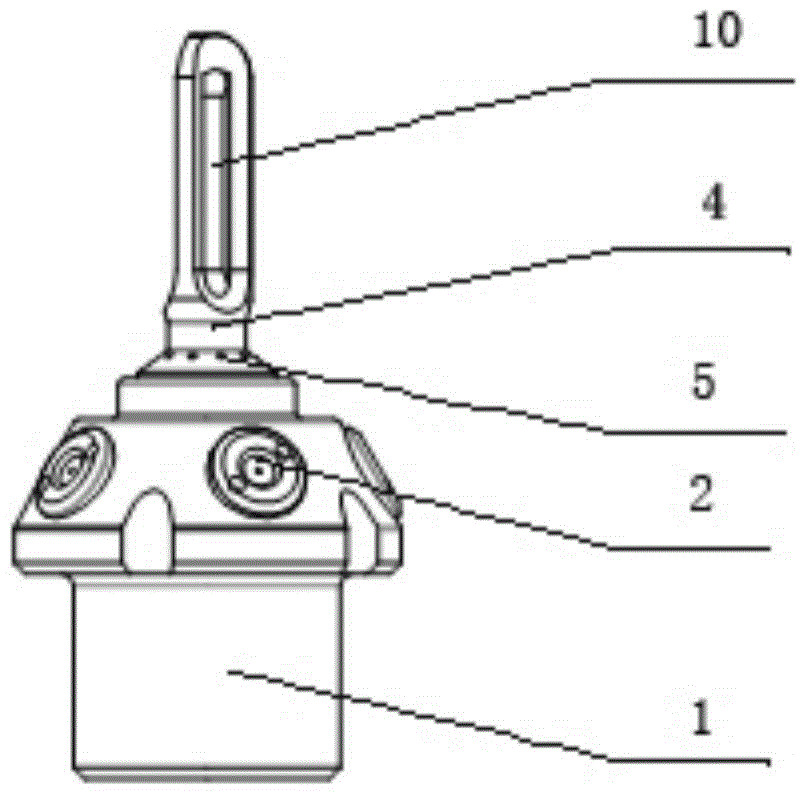

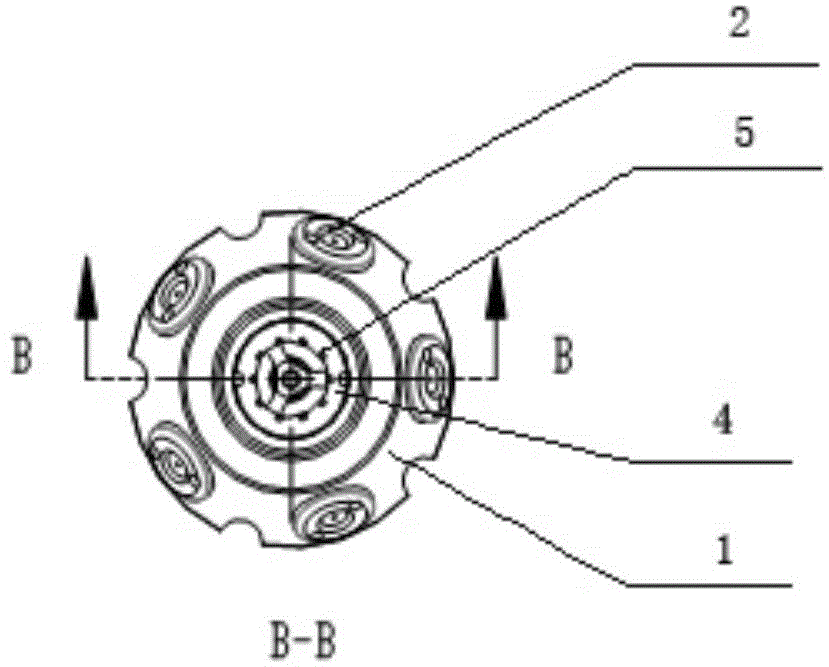

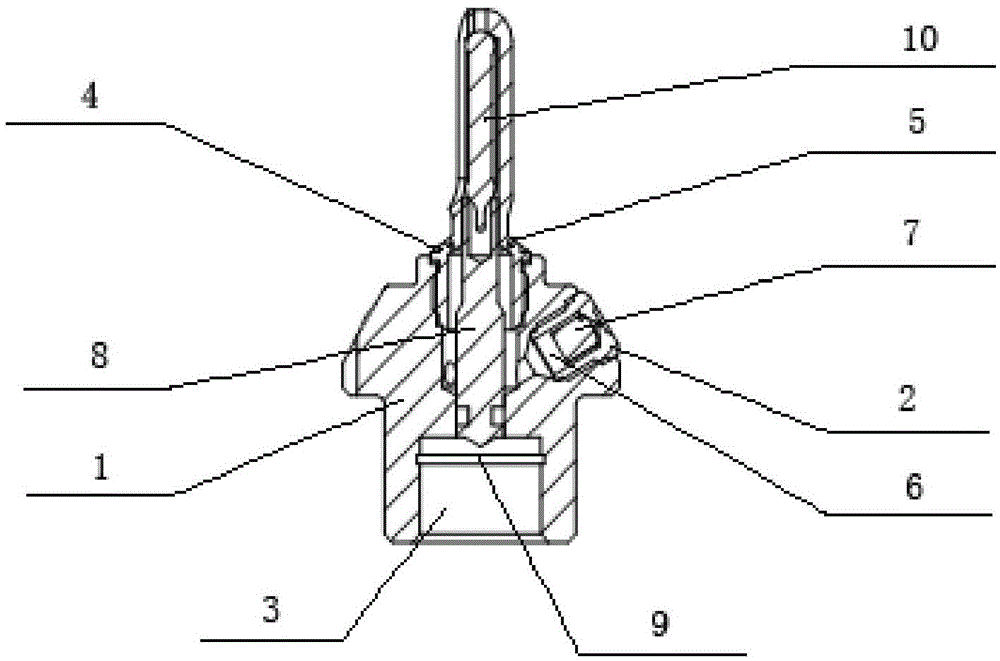

[0022] Such as Figure 1 to Figure 4 As shown, the fine water mist spray head of the combination of the straight spray nozzle and the swirl atomization nozzle includes a spray head body 1 and 5 swirl atomization nozzles 2 installed on the spray head body 1 by thread sealing, the spray head body 1 has a water flow channel 3 inside, and a straight spray nozzle 4 is installed on the spray head body 1 through thread sealing, and the swirl spray nozzle 2 is evenly arranged around the straight spray nozzle 4. The swirl atomizing nozzle 2 includes a cavity 6 and an atomizing core 7 arranged in the cavity 6, the cavity 6 includes a water inlet and a water outlet hole, the water inlet of the swirl atomizing nozzle 2 It communicates with the flow channel 3 . The atomizing core 7 is a cylindrical helix with three spiral grooves evenly arranged on the outside, the inner diameter of the spiral grooves gradually decreases from the entrance to the exit, and the atomizing core 7 can make the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com