Inner wall board joint treatment technology

A technology for seam treatment and interior wall panels, which is applied to walls, building components, building insulation materials, etc., can solve the problems of thermal insulation of wall panel joints, unsatisfactory fire protection functions, etc., and achieve good adhesion, wide application range, The effect of good fire performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

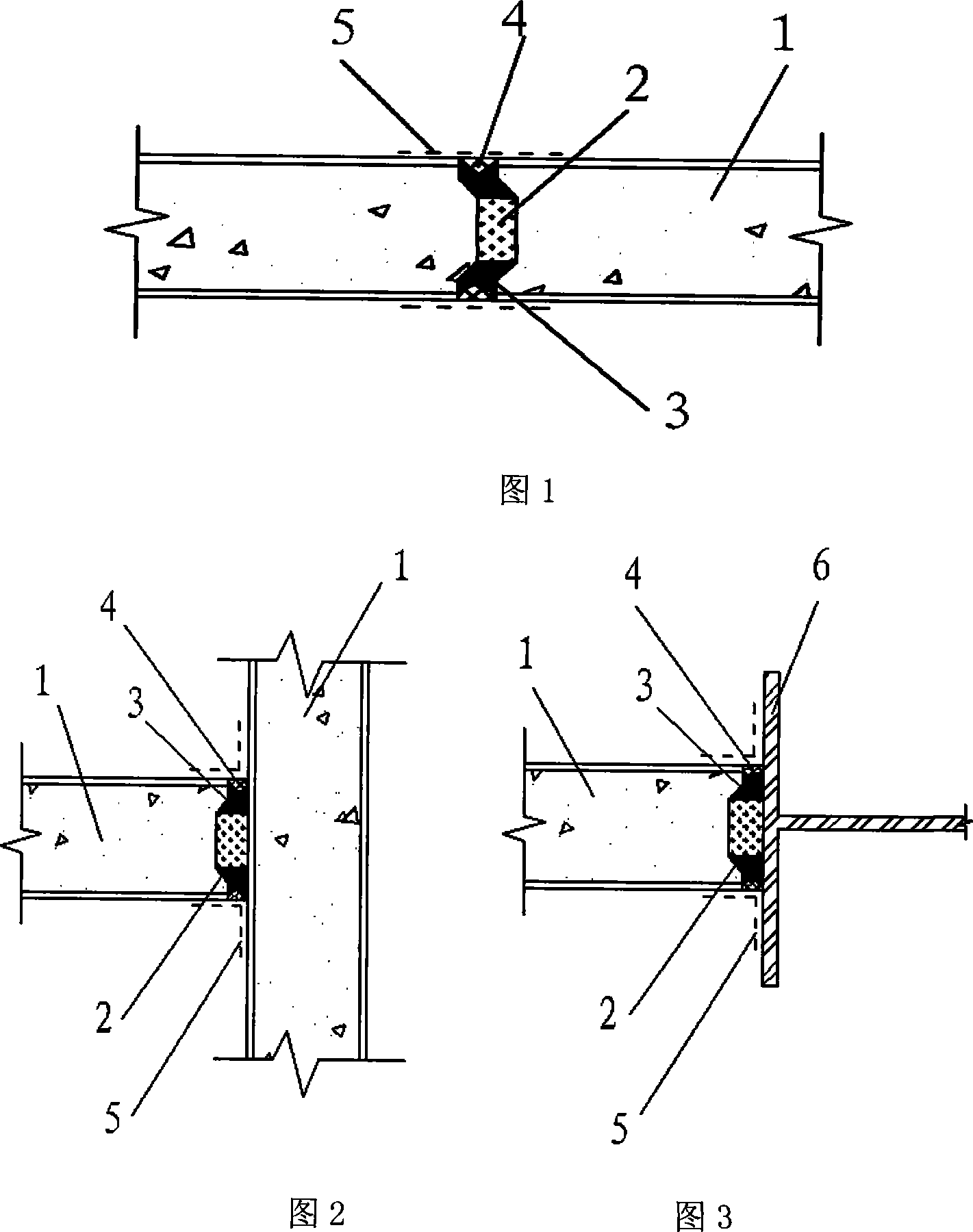

Embodiment 1

[0022] An interior wall panel seam treatment technology, the specific treatment method is:

[0023] 1) Paste a rubber sponge layer in the groove on one side of the wallboard;

[0024] 2) Apply polymer mortar on both sides of the rubber sponge, then dock with the tenon of another wallboard and squeeze tightly;

[0025] 3) Fill a layer of elastic putty on both sides of the joint between the wallboard and the tenon of another wallboard;

[0026] 4) Paste a layer of anti-crack grid tape outside the putty layer on both sides of the joint.

Embodiment 2

[0028] An interior wall panel seam treatment technology, the specific treatment method is:

[0029] 1) Paste a rubber sponge layer in the groove on one side of the wallboard;

[0030] 2) Apply polymer mortar on both sides of the rubber sponge, and then connect and squeeze the side of the other wallboard;

[0031] 3) Fill a layer of elastic putty on both sides of the joint between the wall panel and the side of the wall panel of another wall panel;

[0032] 4) Paste a layer of anti-crack grid tape outside the putty layer on both sides of the joint.

Embodiment 3

[0034] An interior wall panel seam treatment technology, the specific treatment method is:

[0035] 1) Paste a rubber sponge layer in the groove on one side of the wallboard;

[0036] 2) Apply polymer mortar on both sides of the rubber sponge, then dock with the column and squeeze tightly;

[0037] 3) A layer of elastic putty is filled on both sides of the joint between the wall panel and the column;

[0038] 4) Paste a layer of anti-crack grid tape outside the putty layer on both sides of the joint.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com