Bi-component polysulfide fireproofing flame retardant sealant and preparation method thereof

A fire retardant, sealant technology, applied in chemical instruments and methods, adhesives, other chemical processes, etc., can solve problems such as unsatisfactory flame retardant performance and comprehensive performance, achieve significant economic and social benefits, good adhesion The effect of knot strength and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

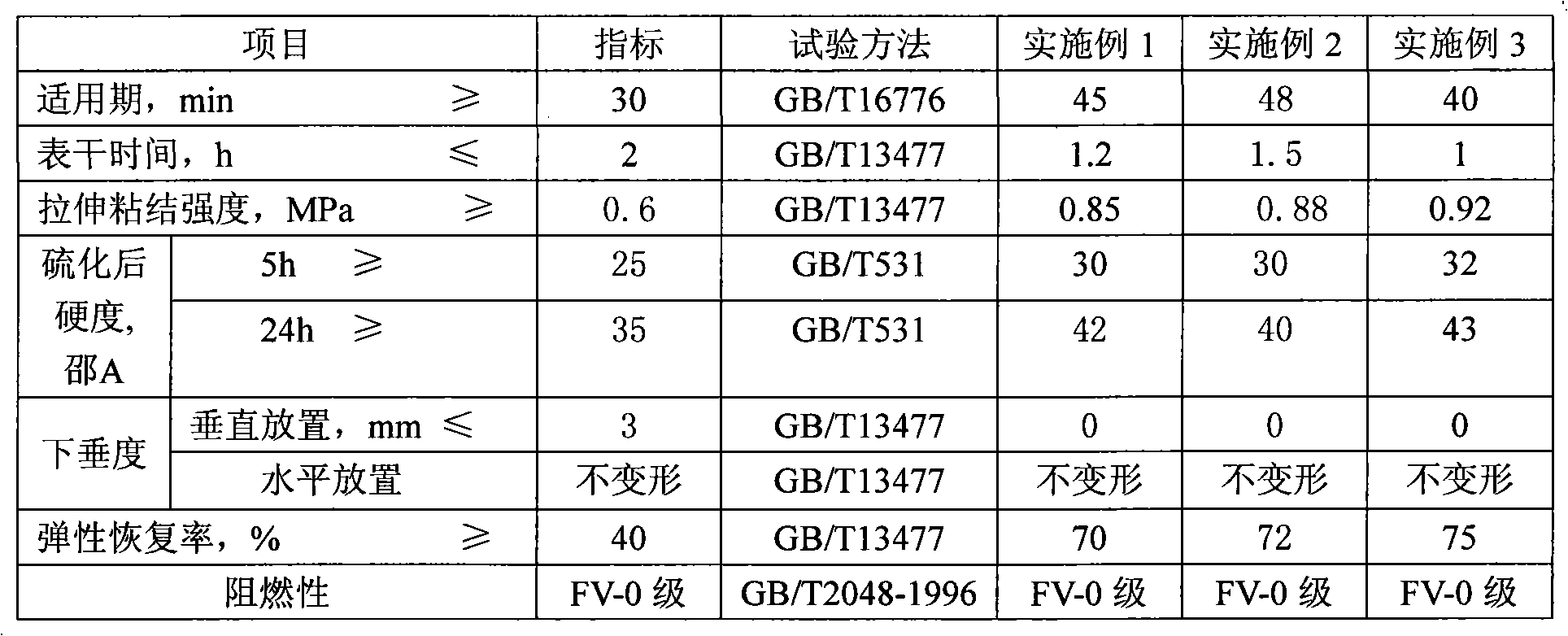

Examples

Embodiment 1

[0028] The two-component polysulfide fireproof and flame retardant sealant of the present invention is prepared from the following components in parts by weight:

[0029] A component:

[0030] 100 parts of liquid polysulfide rubber

[0031] Chlorinated paraffin 60 parts

[0032] Aluminum hydroxide 80 parts

[0033] Active ground calcium carbonate 120 parts

[0034] Sulfur 0.5 parts

[0035] KH-550 1.5 parts

[0036] The preparation method of component A is as follows: at room temperature, the liquid polysulfide rubber and chlorinated paraffin of the above-mentioned parts by weight are added in a vacuum mixer, and the stirring is stopped after mixing at a vacuum degree of 0.06Mpa for 10 minutes; then adding aluminum hydroxide, Active ground calcium carbonate, KH-550 and sulfur are stirred for 40 minutes under a vacuum of 0.06Mpa to prepare component A. During production, the temperature should be measured. If the temperature of the glue exceeds 80°C, it should be cooled wi...

Embodiment 2

[0046] The two-component polysulfide fireproof and flame retardant sealant of the present invention is prepared from the following components in parts by weight:

[0047] A component:

[0048] 100 parts of liquid polysulfide rubber

[0049] Cresyl diphenyl phosphate 50 parts

[0050] Magnesium hydroxide 100 parts

[0051] Active ground calcium carbonate 80 parts

[0052] Active light calcium carbonate 50 parts

[0053] Sulfur 0.5 parts

[0054] KH-560 1.5 parts;

[0055] The preparation method of component A is as follows: at room temperature, add the above-mentioned liquid polysulfide rubber and toluene diphenyl phosphate into a vacuum mixer, mix at a vacuum of 0.075Mpa for 15 minutes and stop stirring; then add hydrogen Magnesium, active heavy calcium carbonate, active light calcium carbonate, KH-560 and sulfur, and stir for 30 minutes under a vacuum of 0.075Mpa to obtain component A. Measure the temperature during production, if the glue temperature exceeds 80°C , us...

Embodiment 3

[0065] The two-component polysulfide fireproof and flame retardant sealant of the present invention is prepared from the following components in parts by weight:

[0066] A component:

[0067] 100 parts of liquid polysulfide rubber

[0068] Triaryl phosphate 70 parts

[0069] Decabromodiphenyl ether 80 parts

[0070] Active ground calcium carbonate 90 parts

[0071] Active light calcium carbonate 40 parts

[0072] Sulfur 0.5 parts

[0073] KH-560 2 copies

[0074] The preparation method of component A is as follows: at room temperature, add the liquid polysulfide rubber and triaryl phosphate ester in the above parts by weight into a vacuum mixer, mix for 9 minutes at a vacuum degree of 0.095Mpa and stop stirring; then add decabromobi Phenyl ether, active heavy calcium carbonate, active light calcium carbonate, KH-560 and sulfur, and stir for 25 minutes under a vacuum of 0.095Mpa to obtain component A. Measure the temperature during production. If the glue temperature exc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com