Heat insulation fireproofing honeycomb cement board and preparation method thereof

A technology of cement board and honeycomb, which is applied in the field of thermal insulation and fireproof honeycomb cement board and its preparation, which can solve the problems of high thermal conductivity, poor durability, and easy breakage, and achieve high flexural and compressive strength, simple manufacturing process, and strong strength. Shrink effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical scheme of the present invention is described below with specific examples, but protection scope of the present invention is not limited thereto:

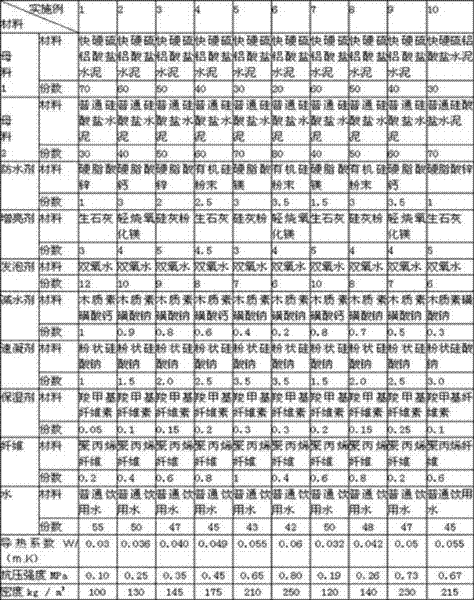

[0040] The masterbatch of embodiment 1-10 and the weight composition ratio of auxiliary material are shown in the table below:

[0041]

[0042] The obtained fireproof and temperature-resistant honeycomb cement board has a honeycomb cell diameter of 1-8mm.

[0043] The concentration that adopts hydrogen peroxide in the embodiment is 27.5%.

[0044] The length of cellulose is 3-8mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com