Process of producing fireproof sofa artificial leather

A manufacturing method, sofa leather technology, applied in textiles and papermaking, etc., to achieve the effects of reduced solvent content, enhanced flame retardancy, and good fireproof function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

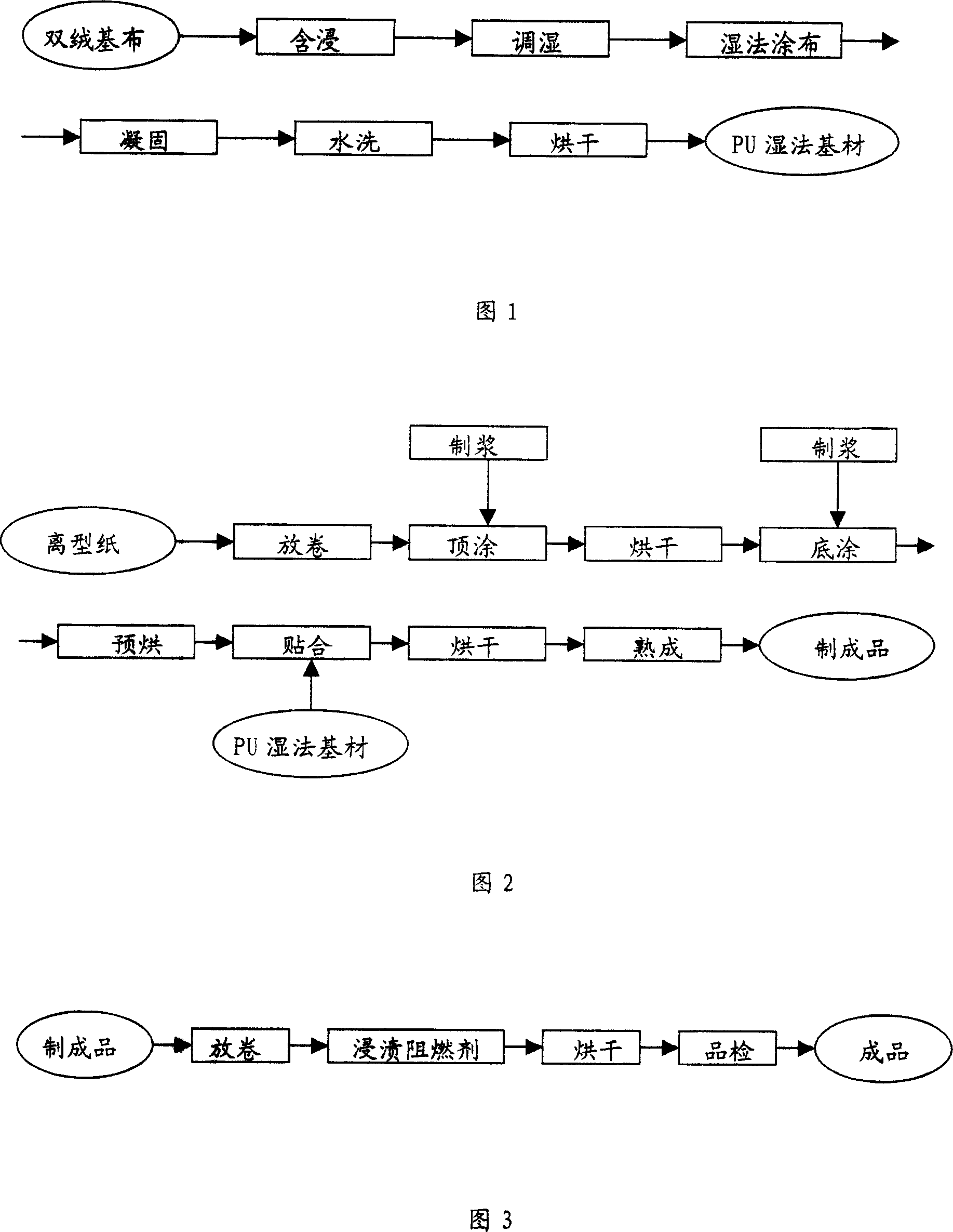

Method used

Image

Examples

Embodiment 1

[0045] A. Wet slurry formula:

[0046] Polyether, polycarbonate polyurethane resin (model HX-3025A) 100 parts,

[0047] DMF 50 parts,

[0048] 1 part of solvent-based colorant,

[0049] Wood flour (model FD600 / 30) 5 parts,

[0050] Anti-mildew and antibacterial agent (model KF-100) 0.2 parts,

[0051] Phosphorous flame retardant (model VB-02) 2 parts.

[0052] B. Dry slurry process formula:

[0053] Top coat:

[0054] Aliphatic polycarbonate polyurethane resin (HX-6075) 100 parts,

[0055] 10 parts of solvent,

[0056] 15 parts of coloring material,

[0057] Leveling agent 1 part,

[0058] 1 part peeling aid,

[0059] Phosphorus flame retardant (model VB-01) 3 parts;

[0060] Primer:

[0061] Aromatic polycarbonate polyurethane resin (HX-6040) 100 parts,

[0062] 10 parts of solvent,

[0063] 10 parts of coloring material,

[0064] Leveling agent 1 part

[0065] Phosphorous flame retardant (model VB-01) 2 parts.

[0066]C. The formula of water-based environmen...

Embodiment 2

[0070] A. Wet slurry formula:

[0071] Polyether, polycarbon type polyurethane resin HX-3025A 100 parts,

[0072] DMF 60 parts,

[0073] 3 parts of solvent-based colorant,

[0074] Wood flour (FD600 / 30) 10 parts,

[0075] Phosphorous flame retardant (model VB-02) 2.5 parts.

[0076] B. Dry slurry process formula:

[0077] top coat

[0078] Aliphatic polycarbonate polyurethane resin (HX-6075) 100 parts,

[0079] 30 parts of solvent,

[0080] 15 parts of coloring material,

[0081] Leveling agent 0.5 parts,

[0082] 0.5 part of peeling aid,

[0083] Phosphorus flame retardant (model VB-01) 2 parts;

[0084] Primer

[0085] Aromatic polycarbonate polyurethane resin (HX-6040) 100 parts,

[0086] 20 parts of solvent,

[0087] 10 parts of coloring material,

[0088] Leveling agent 0.5 parts,

[0089] Phosphorous flame retardant (model VB-01) 1.5 parts.

[0090] C. The formula of water-based environment-friendly flame retardant solution is by weight:

[0091] 30 part...

Embodiment 3

[0094] A. Wet slurry formula:

[0095] Polyether, polycarbon type polyurethane resin HX-3025A 100 parts,

[0096] DMF 80 parts,

[0097] 5 parts of solvent-based colorant,

[0098] Wood flour (FD600 / 30) 15 parts,

[0099] Phosphorus flame retardant (model VB-02) 3 parts.

[0100] B dry slurry process formula:

[0101] top coat

[0102] Aliphatic polycarbonate polyurethane resin (HX-6075) 100 parts,

[0103] 40 parts of solvent,

[0104] 25 parts of coloring material,

[0105] Leveling agent 1 part,

[0106] 1 part peeling agent,

[0107] Phosphorous flame retardant (model VB-01) 2 parts.

[0108] Primer:

[0109] Aromatic polycarbonate polyurethane resin (HX-6040) 100 parts,

[0110] 30 parts of solvent,

[0111] 15 parts of coloring material,

[0112] Leveling agent 1 part,

[0113] Phosphorus flame retardant (VB-01) 1.5 parts.

[0114] C. The formula of water-based environment-friendly flame retardant solution is by weight:

[0115] 70 parts of water,

[01...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com