Light fireproof heat-insulation decorative composite plate and method for preparing same

A technology for fire-proof thermal insulation and composite panels, which is applied in chemical instruments and methods, hydraulic material layered products, floors, etc. problems such as low safety factor, to achieve the effect of light weight per unit area, lower quality per unit area, and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

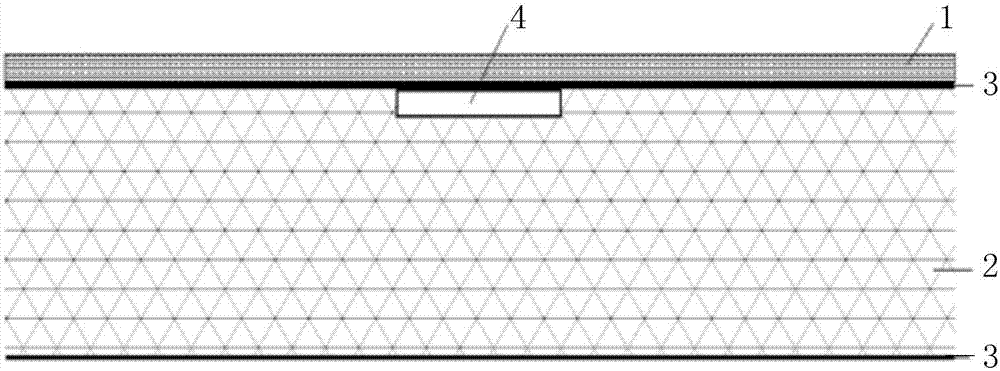

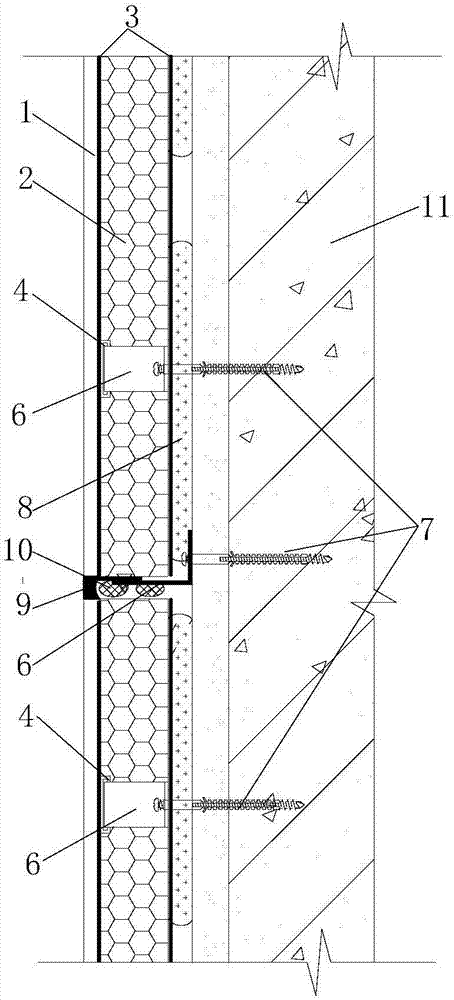

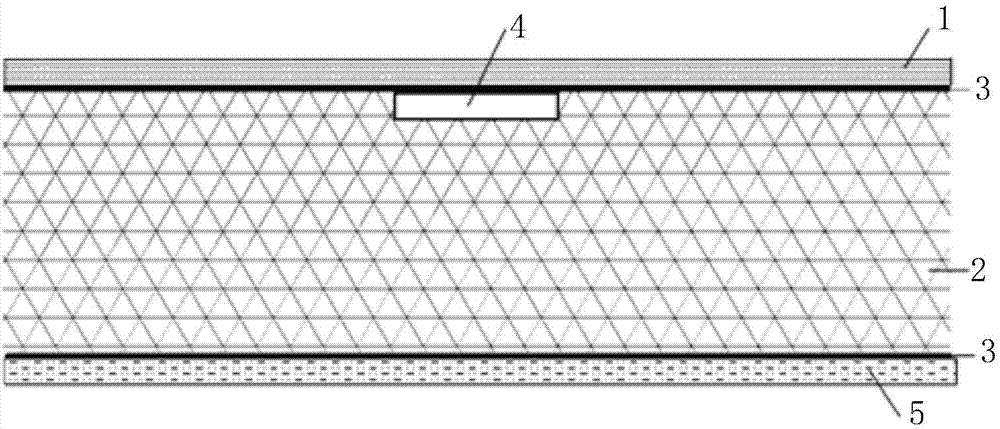

[0053] Another aspect of this application, such as Figure 6 As shown, the preparation method of the above-mentioned preferred lightweight fireproof heat preservation decorative composite board is provided, and the heat preservation board is a rock wool tape composite board, comprising the following steps:

[0054] Step 101, assembling the rock wool tape to form a rock wool tape combination board;

[0055] Step 102, scrape the mortar or putty leveling layer on the bottom surface of the rock wool tape composite board for leveling, and press the glass fiber cloth into the leveling layer to enhance the strength of the leveling layer;

[0056] Step 103, groove the front side of the rock wool tape composite board, bury the anchorage installation through groove, and then scrape the mortar or putty leveling layer for leveling, and press the glass fiber cloth into the leveling layer to strengthen the leveling layer. Describe the strength of the screed;

[0057] Step 104 , on the mor...

Embodiment example 1

[0062] For thickness 20mm, density 130kg / m 3 The rock wool belt is assembled to form a rock wool belt composite board;

[0063] Scrape and level with 1mm mortar on the bottom surface of the rock wool belt composite board, and press 80g / m 2 Fiberglass cloth to enhance its strength;

[0064] Make a groove on the front of the rock wool belt composite board, pre-embed the aluminum alloy anchoring groove, then scrape the mortar or putty to level it, and press it into the glass fiber cloth to enhance its strength;

[0065] On the batch scraping mortar or putty leveling layer on the front of the rock wool belt composite board, the lightweight flexible sheet is composited with an epoxy adhesive;

[0066] On the batch scraping mortar or putty leveling layer on the bottom surface of the rock wool tape composite board, the inorganic board with holes is composited with an epoxy adhesive, and used as a bottom board for support, so as to make the lightweight fireproof, heat preservation a...

Embodiment example 2

[0068] For thickness 40mm, density 100kg / m 3 The rock wool belt is assembled to form a rock wool belt composite board;

[0069] Scrape 2mm putty on the bottom surface of the rock wool belt composite board for leveling, and press 100g / m 2 Fiberglass cloth to enhance its strength;

[0070] Make a groove on the front of the rock wool belt composite board, pre-embed the plastic anchoring groove, then scrape the mortar or putty to level it, and press it into the glass fiber cloth to enhance its strength;

[0071] Lightweight flexible sheets are compounded with a polyurethane adhesive on the batch-scraped mortar or putty leveling layer on the front of the rock wool composite board to make the lightweight fireproof, thermal insulation and decorative composite board.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com