Light powder geosynthetic clay liner

A technology of bentonite waterproof blanket and bentonite, which is applied in the field of building waterproof materials, can solve the problems of large area and quality, inconvenient construction, etc., and achieve the effects of excellent waterproof performance, convenient construction, and saving transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

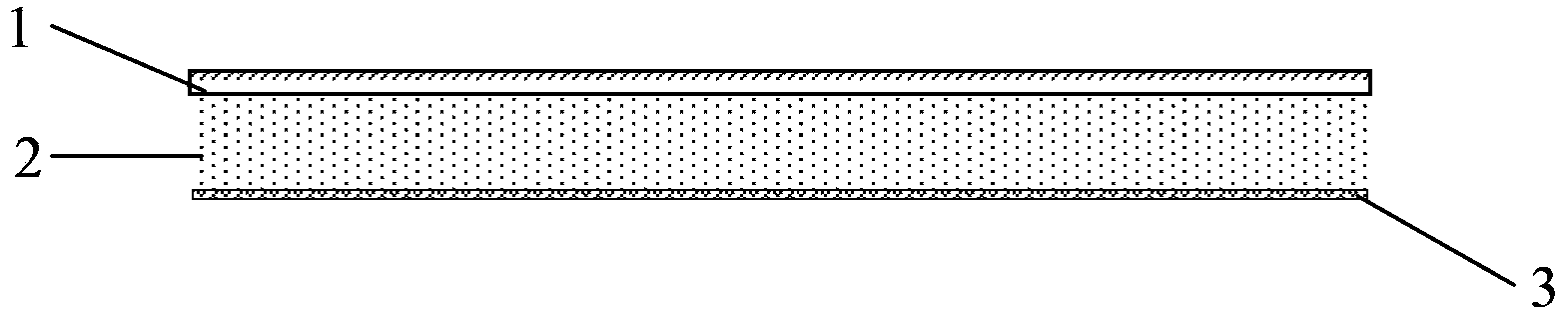

[0029] Such as figure 1 As shown, a light-weight powdery bentonite waterproof blanket includes a face cloth 1 and a base cloth 3, and between the face cloth 1 and the base cloth 2 is fixed a bentonite composite superabsorbent material powder through a needle punching process. The face cloth 1 used is a non-woven fabric, and the base cloth 3 used is a woven cloth.

[0030] The preparation method of the bentonite composite superabsorbent material powder comprises the following steps:

[0031] (1) Take 10 parts by weight of 200 mesh sodium bentonite powder, add distilled water according to the weight ratio of 1:2, and stir thoroughly;

[0032] (2) Add 10 parts by weight of 40% acrylamide aqueous solution, stir and mix thoroughly, then add 0.002 parts by weight of N,N-methylenebisacrylamide, 0.05 parts by weight of ammonium persulfate, and 0.5 parts by weight of Sodium hydroxide, the sodium thiosulfate of 0.15 parts by weight are fully stirred and mixed;

[0033] (3) Polymerize...

Embodiment 2

[0038] Such as figure 1 As shown, a light-weight powdery bentonite waterproof blanket includes a face cloth 1 and a base cloth 3, and between the face cloth 1 and the base cloth 2, there is bentonite composite superabsorbent material powder fixed through a needle punching process. The face cloth 1 used is a non-woven fabric, and the base cloth 3 used is a woven cloth.

[0039] The preparation method of the bentonite composite superabsorbent material powder comprises the following steps:

[0040] (1) Take 8 parts by weight of 200-mesh high-purity natural sodium-based bentonite, add distilled water according to the weight ratio of 1:2, and stir thoroughly. After drying and crushing, pass through a 50-100 mesh sieve and then purify to make the montmorillonite content higher than 80%, and then dry and crush until 90% pass through a 200 mesh standard sieve;

[0041] (2) Add 8 parts by weight of 40% acrylamide aqueous solution, stir and mix thoroughly, then add 0.001 parts by weig...

Embodiment 3

[0047] Such as figure 1 As shown, a light-weight powdery bentonite waterproof blanket includes a face cloth 1 and a base cloth 3, and between the face cloth 1 and the base cloth 2 is fixed a bentonite composite superabsorbent material powder through a needle punching process. The face cloth 1 used is a non-woven fabric, and the base cloth 3 used is a woven cloth.

[0048] The preparation method of the bentonite composite superabsorbent material powder comprises the following steps:

[0049] (1) Take 12 parts by weight of 200-mesh high-purity natural sodium-based bentonite, add distilled water according to the weight ratio of 1:2, and after fully stirring, the preparation method of the high-purity natural sodium-based bentonite: prepare natural sodium-based bentonite ore After drying and crushing, pass through a 50-100 mesh sieve and then purify to make the montmorillonite content higher than 80%, and then dry and crush until 90% pass through a 200 mesh standard sieve;

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| swell index | aaaaa | aaaaa |

| filtration | aaaaa | aaaaa |

| osmotic coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com